Full-box crawler-type large-scale mine truck

A technology of crawler and mining vehicles, which is applied in the direction of motor vehicles, loading and unloading vehicle arrangements, vehicles used for freight, etc., and can solve problems such as rollover, difficult operation, and tire wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

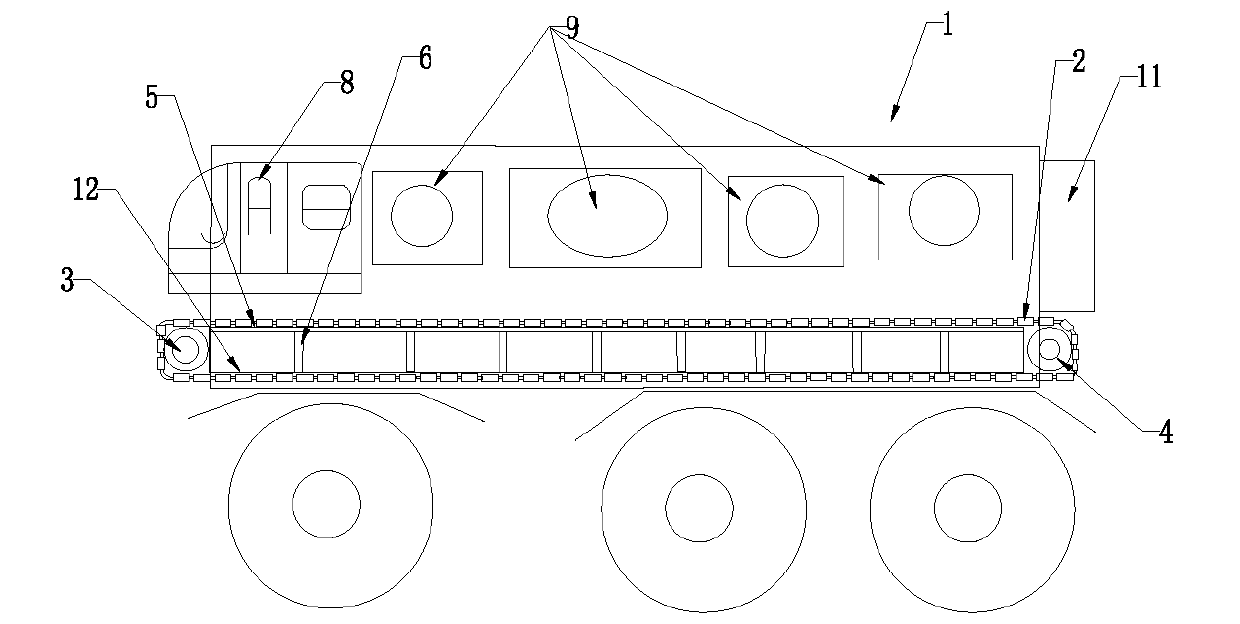

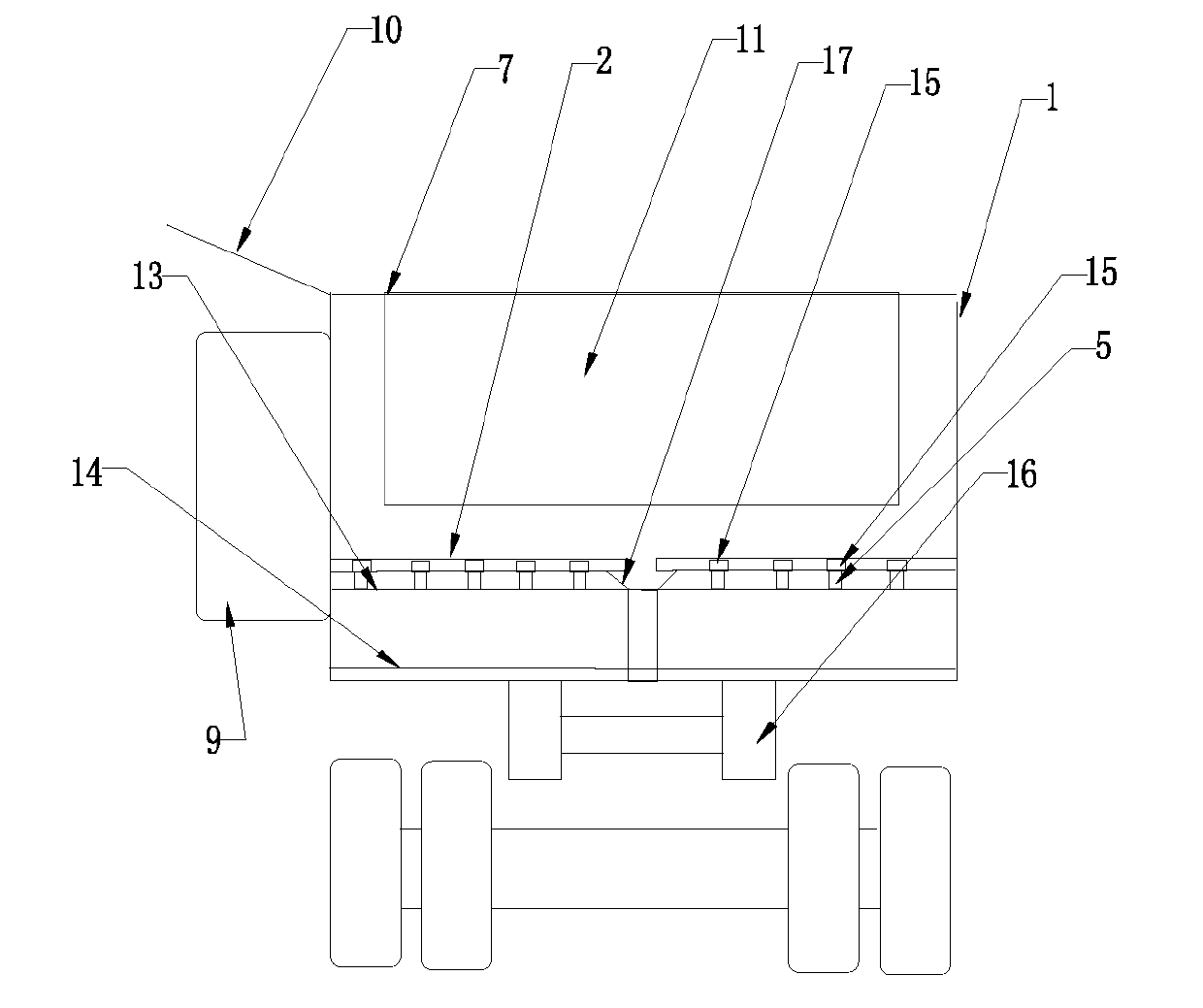

[0027] Such as Figure 1 to Figure 3 As shown, the full-box crawler-type large-scale mining vehicle includes a car box assembly, a front axle steering assembly, and a rear axle power assembly, and the car box assembly is arranged above the front axle steering assembly and the rear axle power assembly. The lower part of the car box 1 of the car box assembly is provided with a crawler device for unloading, and the four sides of the car box assembly are provided with a cockpit 8 and power system equipment 9 . The four sides include the front side, the rear side and both sides of the carriage 1, all referring to the outside of the carriage 1. The car box assembly includes the car box 1 for loading ore and the crawler device for unloading that is arranged at the inner bottom of the car box 1. The front axle steering assembly includes front tires and related transmission mechanisms, and the rear axle power assembly includes rear tires and related gears. The transmission mechanism a...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the crawler belt device includes a rear unloading driven wheel installed in front of the lower part of the carriage and a rear unloading driving wheel behind the lower part of the carriage, and the crawler belt chain is wound around the rear unloading driving wheel and the rear unloading driving wheel. Remove it from the driven wheel.

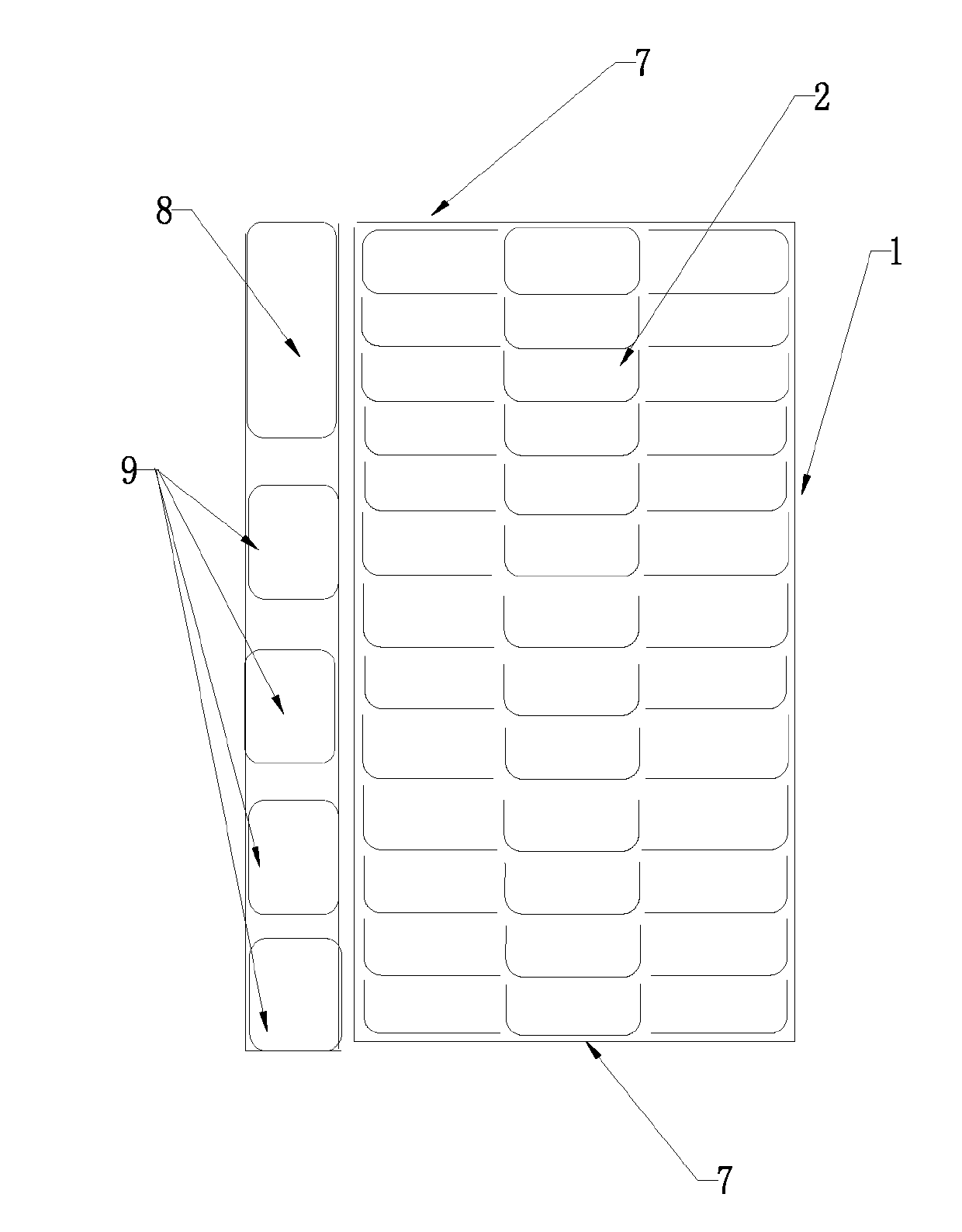

[0041] A baffle plate 7 is provided on the rear side of the vehicle box 1 assembly. When unloading the ore, open the baffle plate 7 on the rear side, and the crawler device moves backward to unload the ore from behind. The engine 11 of this embodiment can be selectively hung on the front side or both sides of the carriage 1 . Correspondingly, the rear unloading driving wheel stretches out the distance of at least half the wheel diameter of the carriage 1, ensuring that the unloaded ore will not affect the operation of the mine car.

[0042] Other technical features of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com