Container turnover platform capable of achieving door holding and door opening

A technology for flipping platforms and containers, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve the problems of difficult operation for unloading personnel when opening the door, inability to take dust removal measures, and high labor intensity for personnel, so as to achieve controllable dust, Prevent material erosion damage, the effect of small work site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

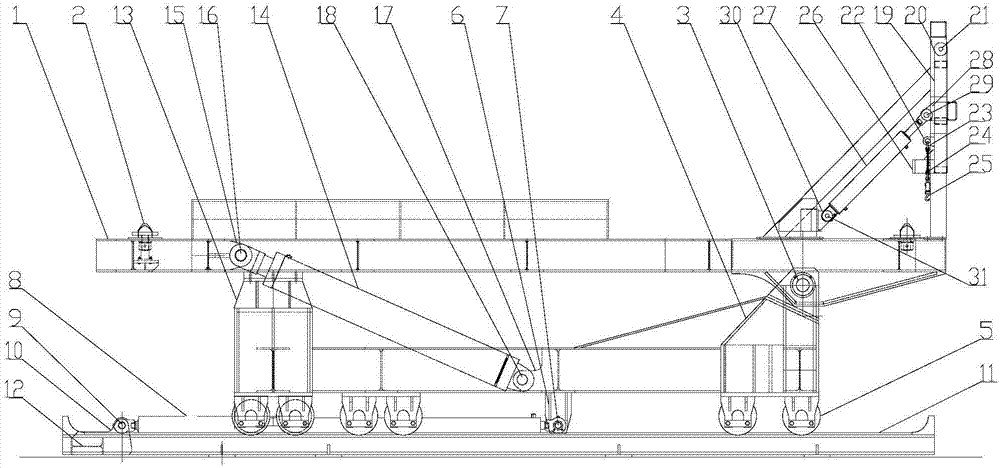

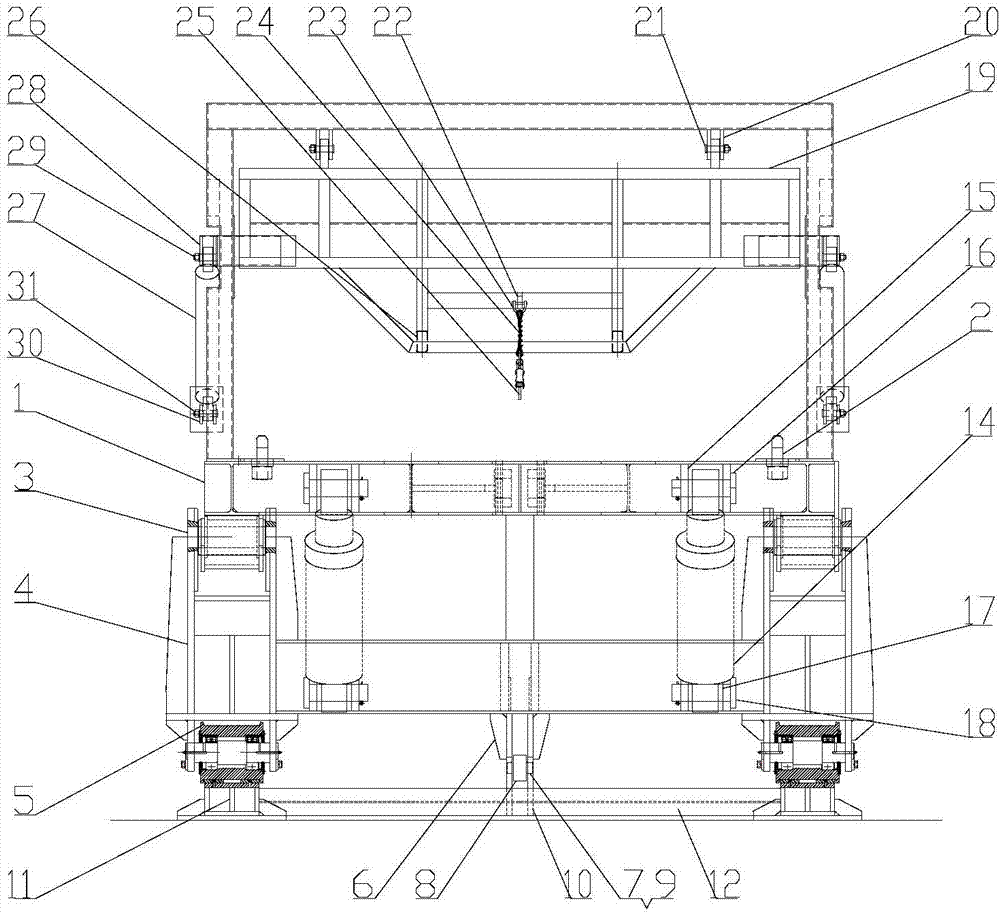

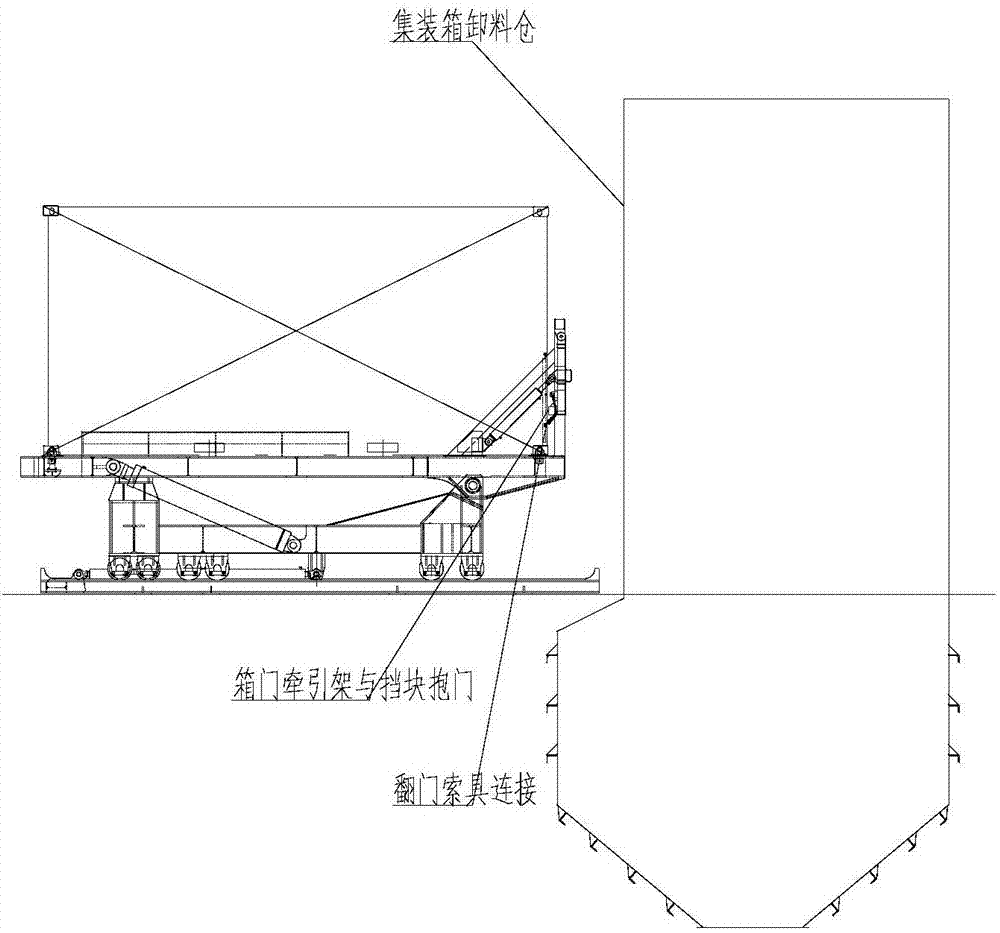

[0032] From figure 1 , figure 2 It can be seen that the patented turning platform of the present invention is mainly composed of a container bracket 1, a mobile trolley 4, a hydraulic jacking and pushing system, and the like. The front part of the bracket 1 is hinged with the head of the mobile trolley 4 through the pin shaft 3 to realize relative rotation with the mobile trolley 4. The support frame 13 is located at the tail of the mobile trolley 4 to support the bracket 1 and limit the counterclockwise rotation of the rear of the bracket 1 . The left and right sides of the upper surface of the bracket are provided with bar-shaped stoppers, and the inward side of the bar-shaped stopper is adapted to the shape of the two bottom edges of the container along the length direction; the limit wedge 2 The four corners on the upper surface of the bracket 1 are used to lock the container above the bracket 1 . The mobile trolley 4 walks on the track 11 through the wheels 5, and ste...

Embodiment 2

[0039] The difference between this implementation and Embodiment 1 is that the vehicle frame in this embodiment is fixed, and there is no need to set rollers, rails and other components for ensuring the movement of the vehicle frame. The vehicle frame in the embodiment 1 is arranged in a mobile form in order to ensure that there is enough space when the door of the container is unlocked. When there is enough unlocking space between the vehicle frame and the unloading bin, the vehicle frame does not need to be moved move.

Embodiment 3

[0041] The difference between this embodiment and the above two embodiments is that the locking method of the container in this embodiment is as follows: four limit wedge groups are arranged on the bracket corresponding to the four bottom corners of the container; The set of limiting wedges includes two wedges arranged perpendicular to each other, and the slopes of the two wedges face the position where the container is placed. In this embodiment, each bottom corner of the container is limited in two directions, so that the position of the container can be fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com