Novel logistics unloading device

A technology of unloading device and logistics, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of endangering personal safety, affecting the safety of goods, prone to accidents, etc., and achieving the effect of ensuring personal safety and safe unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

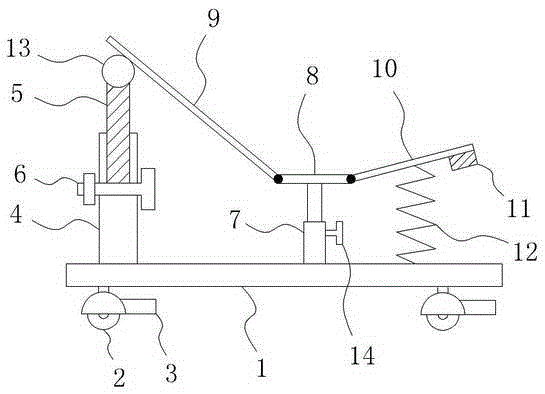

[0013] like figure 1 As shown, a new type of logistics unloading device includes a base plate 1 and a wheel 2 located at the bottom of the base plate 1, a wheel brake 3 is also provided at the wheel 2, and a casing 4 extending vertically is provided at the left end of the base plate 1 , there are many pairs of through holes (not shown in the figure) evenly distributed from top to bottom on the left and right sides of the sleeve 4, the first strut 5 is also embedded in the sleeve 4, and when the sleeve 4 When positioning bolts 6 are installed in one of the pair of through holes, the bottom end of the first pole 5 is against the positioning bolts 6;

[0014] On the bottom plate 1 on the right side of the casing 4, a second support rod 7 is vertically arranged, and a buffer plate 8 is also arranged on the second support rod 7. The unloading device also includes a first slide plate 9 and a second slide plate 10, wherein the right end of the first slide plate 9 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com