Garment transfer trolley facilitating unloading

A transfer vehicle and clothing technology, which is applied in the field of clothing production, can solve the problems of laborious unloading and inapplicability of full-box transshipment, and achieve the effects of avoiding secondary turnover, preventing the car body from moving backwards, and unloading safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

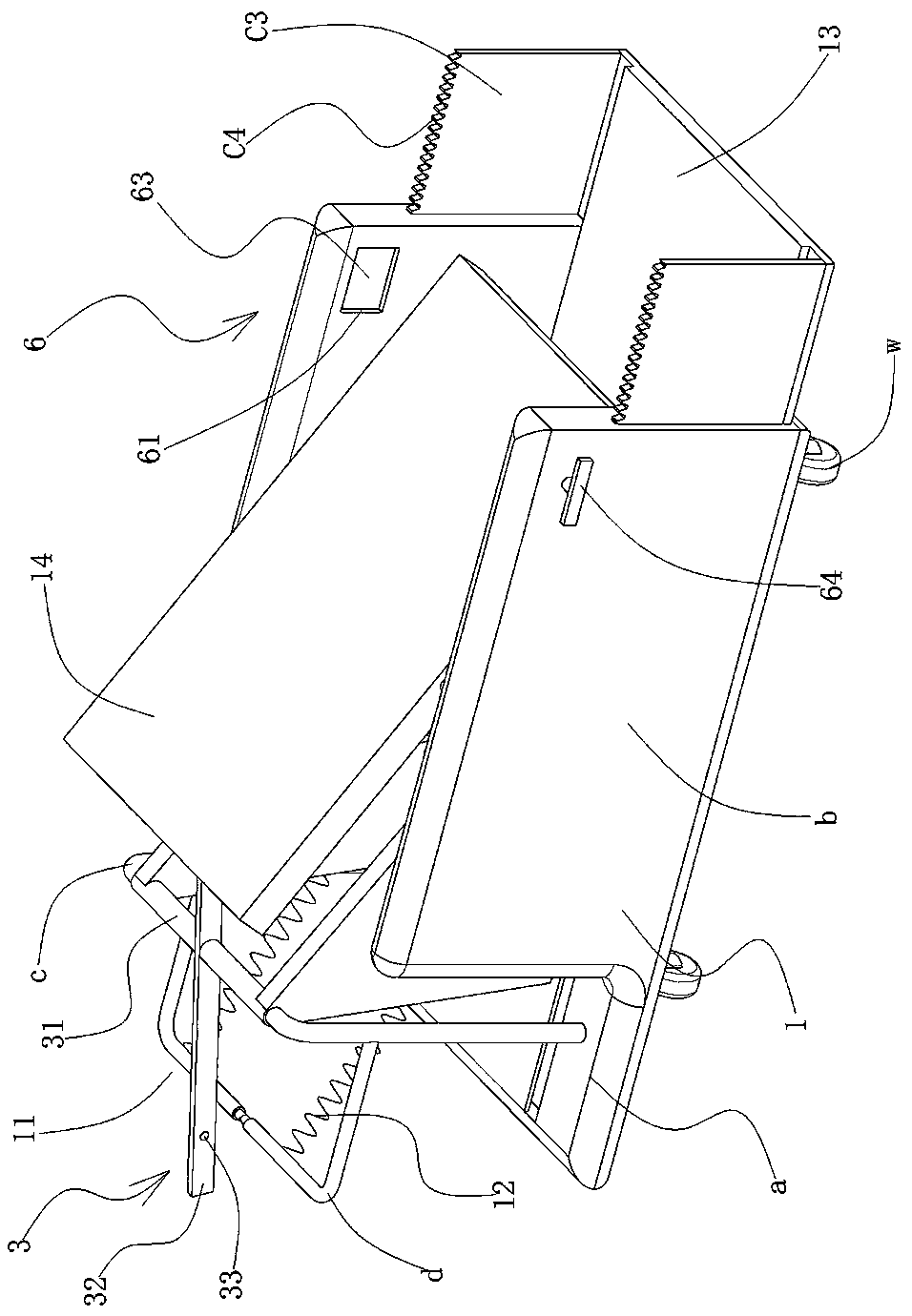

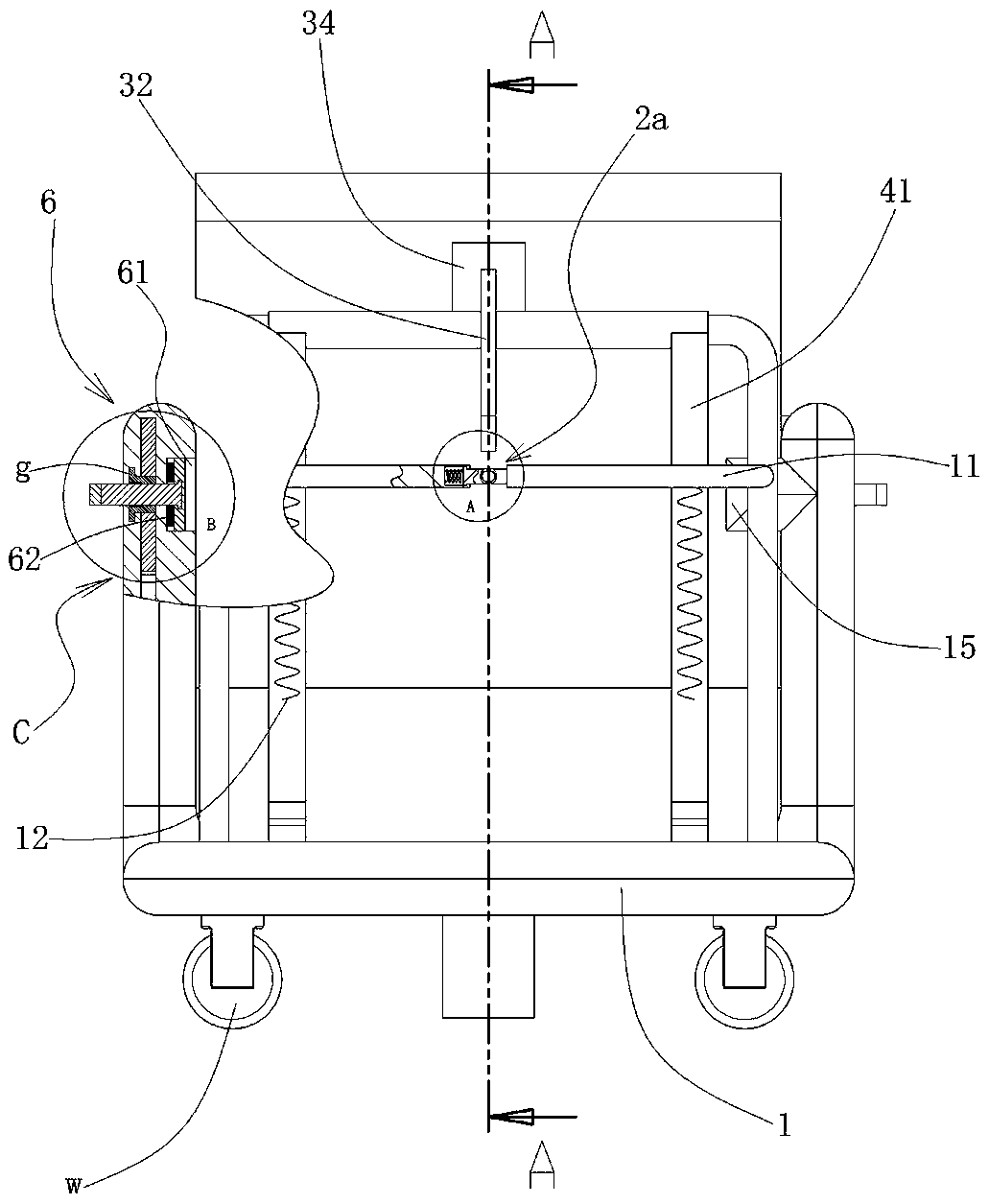

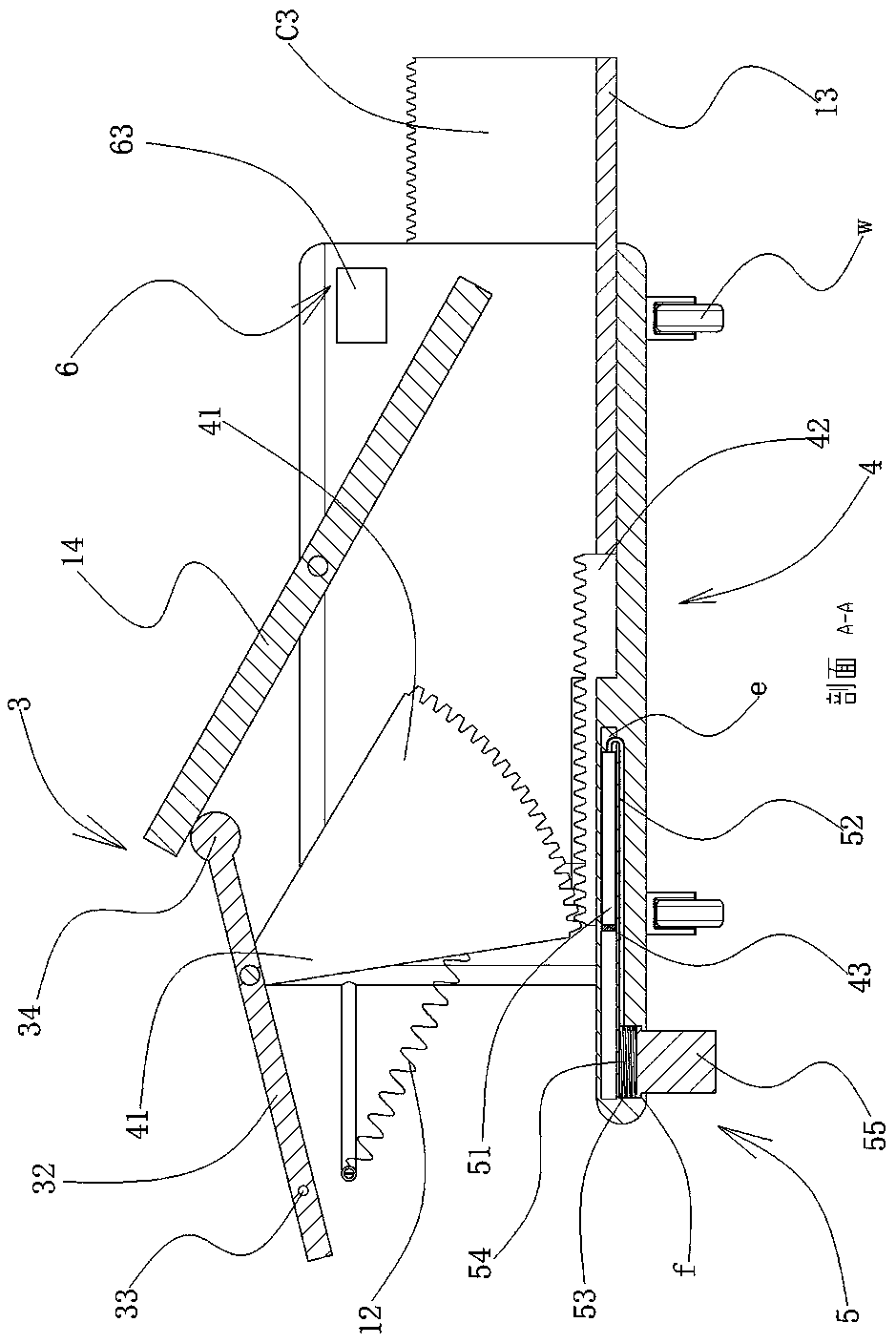

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a clothing transfer vehicle that is convenient for unloading includes a vehicle body 1 equipped with several universal wheels w. The end of the vehicle body 1 is provided with two symmetrically distributed push rods 11 with locking devices 2. Each push rod 11 is hinged with a lever device 3, the two ends of the lever device 3 are provided with a driving device 4 connected to the lower supporting plate 13, and one end of the driving device 4 is connected with the push rod 11 through a spring 12, and one side of the driving device 4 is provided with an anti-backward Device 5; the upper end of the car body 1 is hinged with an upper supporting plate 14, a first fixing block 15 is provided under the end of the upper supporting plate 14, and a retractable fixing device 6 is provided under the front end of the upper supporting plate 14, and the fixing device 6 The lower end links to each other with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com