Gas tank unloading device

A technology of unloading device and gas tank, which is applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of high risk factor and difficult control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

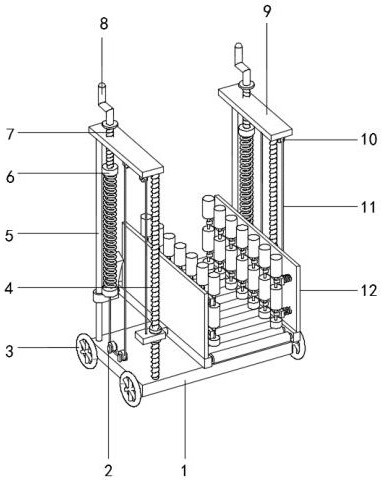

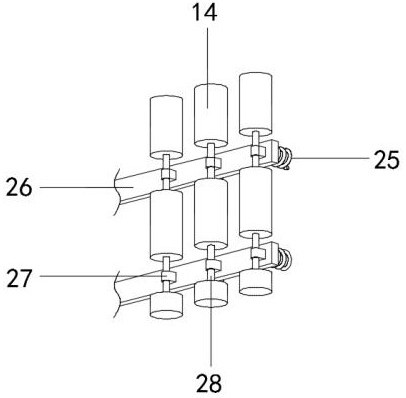

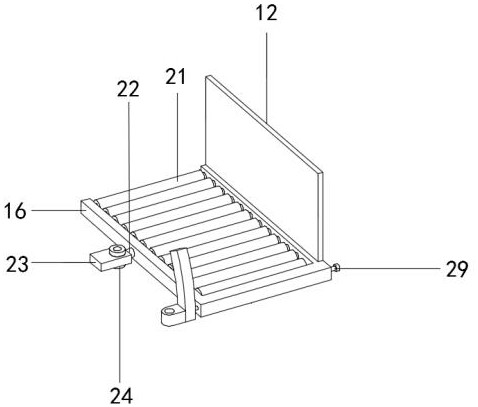

[0030] refer to Figure 1-5 , a gas tank unloading device, comprising a base plate 1 and a top plate 9, the top outer wall of the base plate 1 and the bottom outer wall of the top plate 9 are fixedly connected with a slide bar 5 and a first threaded rod 4 by bolts, and the outer wall of the first threaded rod 4 is threaded. Cover block 24, the outer wall of cover block 24 is connected with base block 23 through bearing, one side outer wall of base block 23 is welded with connecting shaft 22, one end of connecting shaft 22 is connected with unloading plate 16 through bearing, the inner wall of unloading plate 16 A groove is opened, the inner wall of the groove is connected with a roller shaft 21 through a bearing, the top outer wall of the unloading plate 16 is fixed with a side plate 12 by bolts, one side outer wall of the side plate 12 is provided with a guide mechanism, and the outer wall of the slide bar 5 is sleeved with a Slider 15, one side of the outer wall of the slide...

Embodiment 2

[0039] refer to Image 6 , The gas tank unloading device, compared with Embodiment 1, this embodiment also includes a magnetic ball 18 bonded to the top of the strut 17 .

[0040] In the present invention, the top outer wall side of the discharge plate 16 is fixed with a magnetic block 19 by screws, and the magnetic block 19 and the magnetic ball 18 are arranged as opposite magnets.

[0041] During use, after completing the unloading of a gas tank, the release elastic potential energy of the contraction spring 6 will pull the unloading plate 16 upwards under the action of the steel wire 11, the top pulley 10 and the bottom pulley 2. At this time, the magnetic ball 18 and the magnetic block 19 under the action of the opposite magnetic force, first slide the slider 29 to the bottom inner wall of the slide rail 29 again, and the center of gravity of the unloading plate 16 is located at the connection between the steel wire 11 and the base block 23, so that the unloading The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com