Novel discharging equipment of microcrystalline glass melting furnace

A technology of glass-ceramic and melting pool, applied in the direction of inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve the problems of high labor intensity for salvage and cleaning, large occupied area, high investment cost, etc., to save energy and raw materials, The effect of safe discharge and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

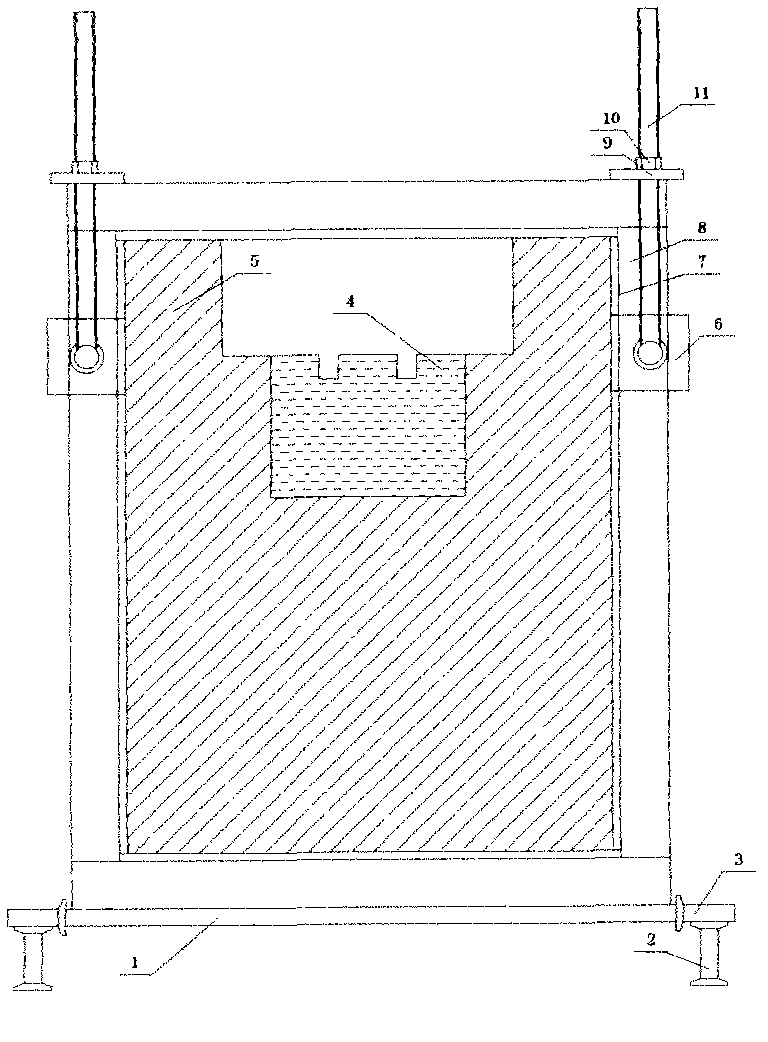

[0009] The present invention is a new type of glass-ceramic melting tank kiln discharge equipment, which consists of a moving wheel shaft (1), a light rail (2), a moving wheel (3), a zirconium corundum flow chute (4), a refractory insulation brick (5), a lifting Ear handle (6), inner layer heat-resistant steel plate (7), outer layer heat-resistant steel plate (8), heat-resistant steel plate gasket (9), nut (10), lifting screw rod (11) and other components.

[0010] figure 1 The mobile lifting trough is equipped with two flow troughs on the upper part of the zirconium corundum flow chute (4), so that two glass-ceramic liquid columns can come out at the same time during production, increasing the output of the glass-ceramic liquid and strengthening the micro-glass The water quenching effect of crystal glass liquid column is built with refractor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com