Sintered coal gangue brick composite heat preservation brick and transfer device thereof

A technology of composite thermal insulation and transfer device, which is applied in the direction of transportation and packaging, trolleys, building components, etc., can solve problems such as shedding, missing structures, and damage to composite thermal insulation bricks, fireproof and thermal insulation structures, etc., to avoid damage, ensure integrity, and carry Lego effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

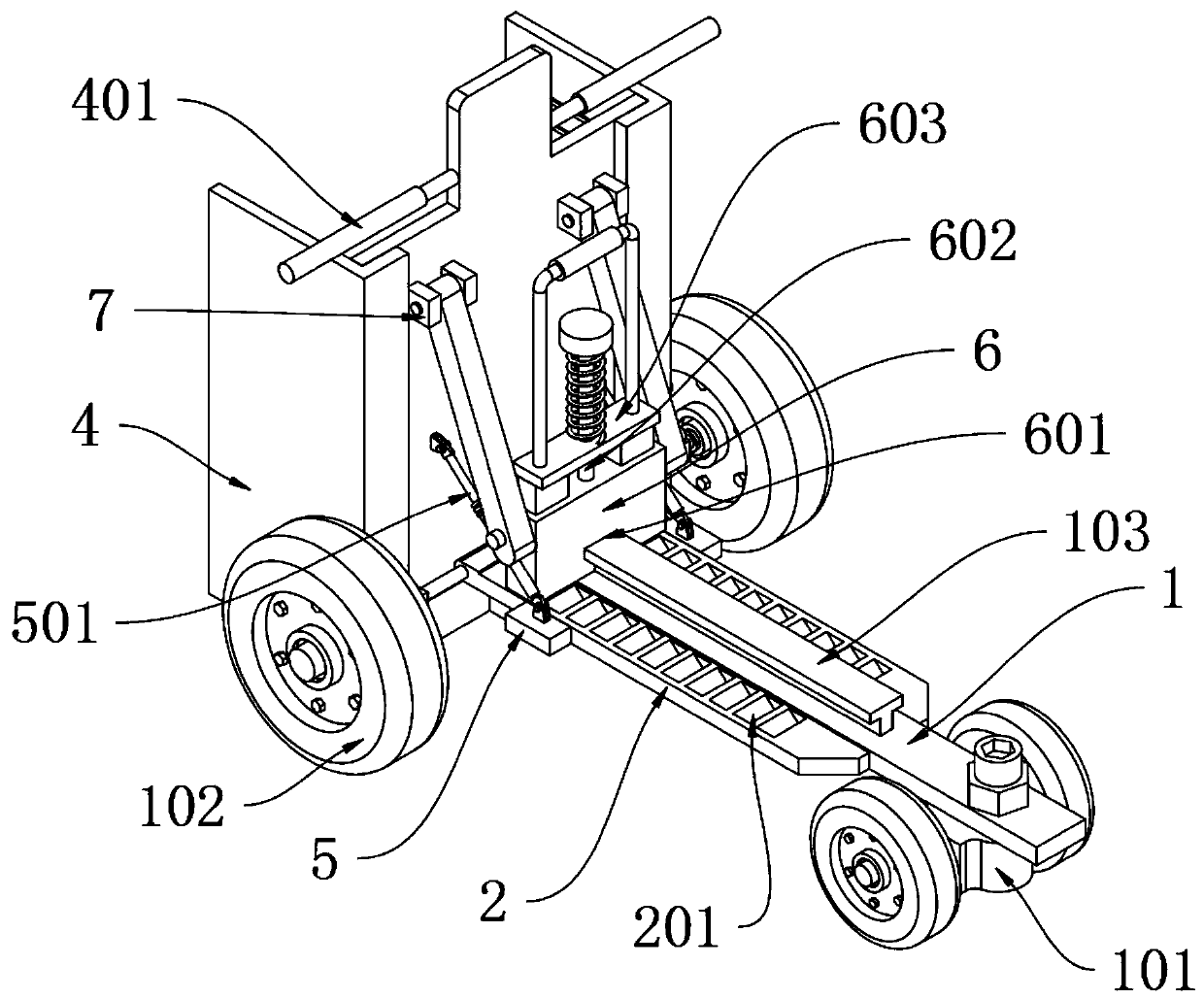

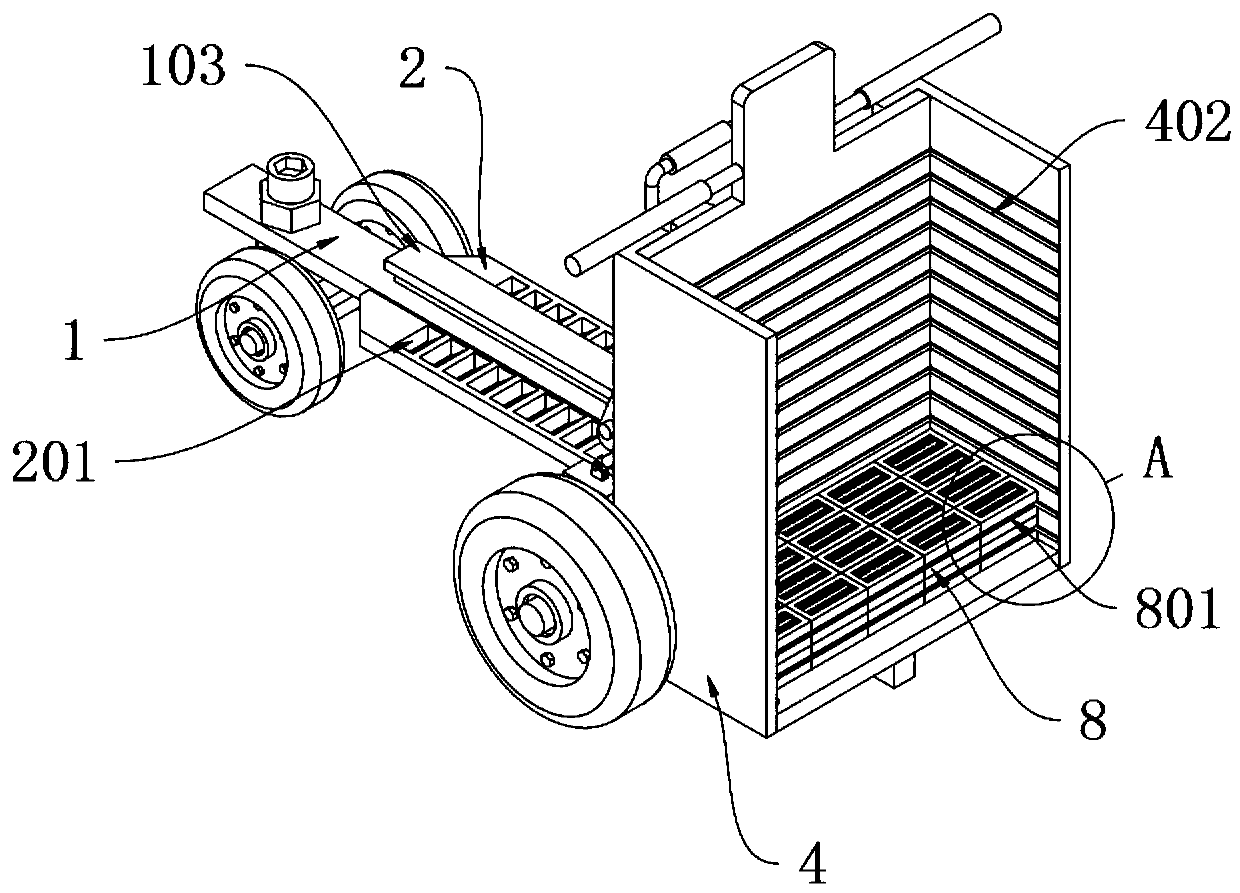

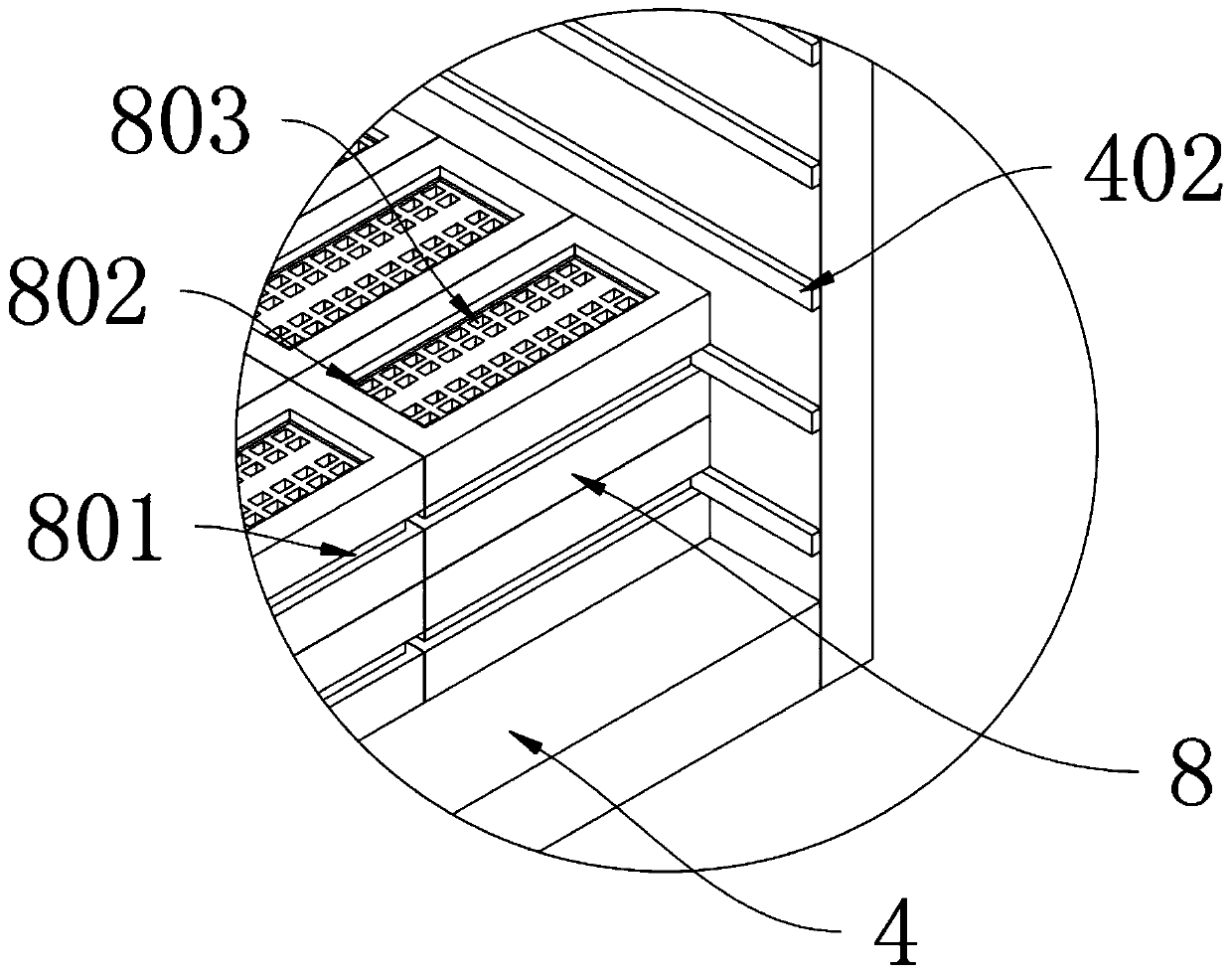

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a sintered coal gangue brick composite thermal insulation bricklaying device and its transfer device, which includes a vehicle frame body 1; a limit plate 2 and a limit plate 2 are respectively symmetrically installed on the left end edge and the right end edge of the frame body 1 Including the limit groove 201, the top plane of the limit plate 2 is evenly spaced in the longitudinal direction to set the limit groove 201, and the limit groove 201 is a structure in which the rear end side wall is inclined forward; the rear end of the frame body 1 is rotated and installed with a box body 4. The box body 4 is a drawer-like structure as a whole; bricks 8 are placed in the box body 4;

[0037] The middle part of frame body 1 top plane longitudinally slides and installs limit mechanism 6; The upper end of the left end of limit mechanism 6 and the upper end of right end side wall are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com