Thickening seal head and design method thereof

A design method and head technology, applied in ship design, ship parts, ships, etc., can solve problems such as the decline of compressive capacity, achieve the effect of reducing stress concentration and increasing ultimate load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

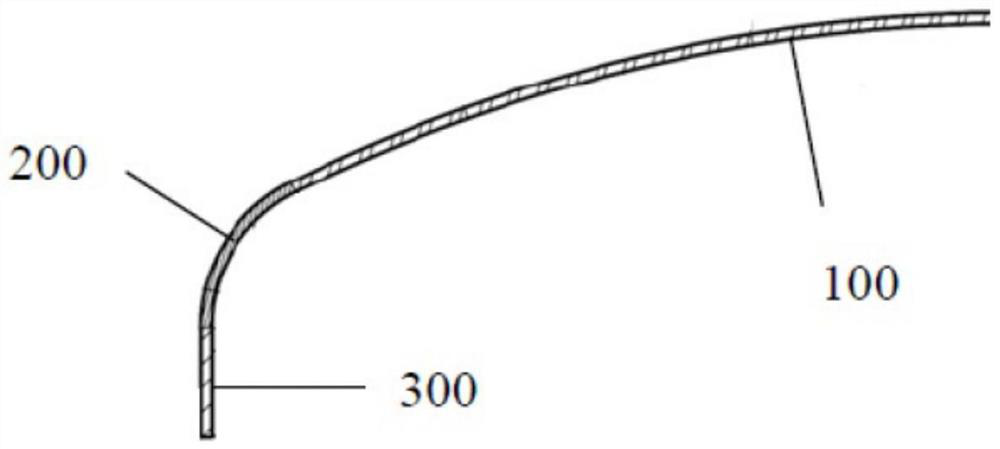

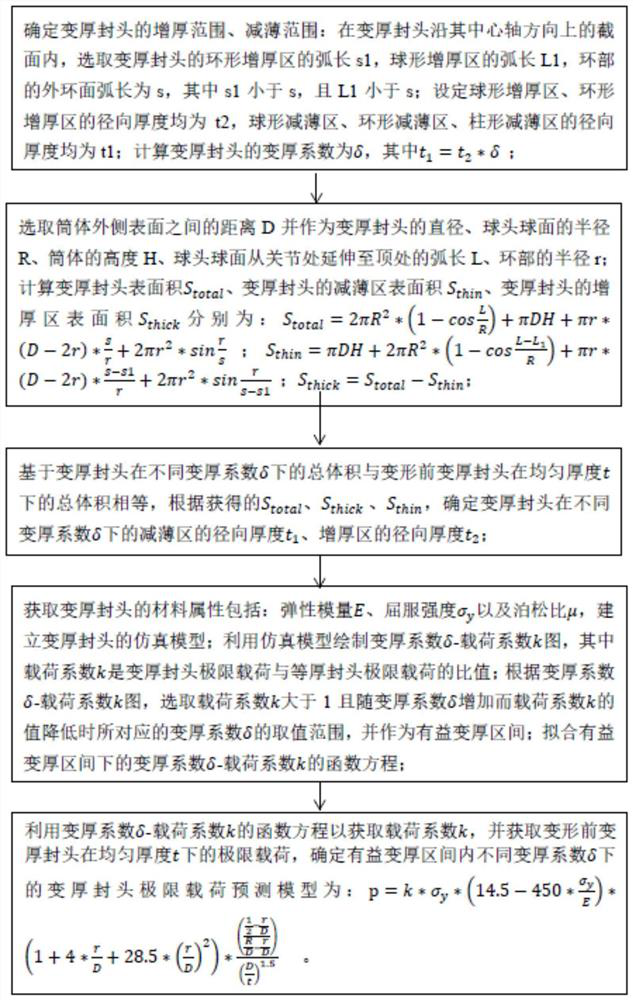

[0077] A method for designing a thickened head is provided, which specifically includes the following steps:

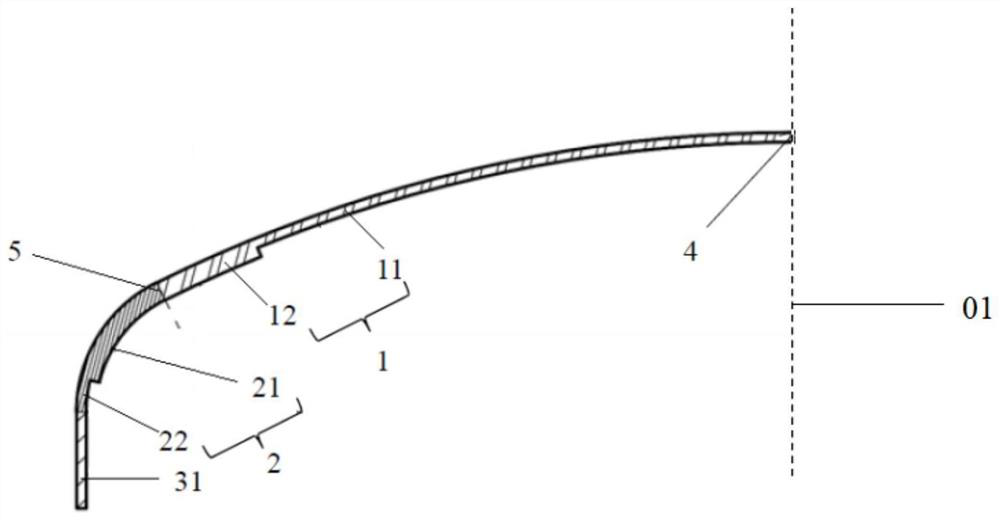

[0078] (101), select an existing butterfly head as the head before deformation, determine the thickening range and thinning range of the thickening head relative to the thickening head before deformation: in the thickening head along its central axis In the half section or the whole section in the direction of 01, the arc length L1 of the first thickening zone 12 of the thickening head, the arc length s1 of the second thickening zone 21, and the arc length of the outer ring surface of the ring part 2 are selected. The length is s, wherein s1 is less than or equal to s, and L1 is less than or equal to s; the radial thicknesses of the first thickened region 12 and the second thickened region 21 are set to be equal and both are t 2 , the radial thicknesses of the first thinned region 11, the second thinned region 22, and the third thinned region 31 are equal and all are ...

no. 2 example

[0128] A method for designing a thickened head is provided, which specifically includes the following steps:

[0129] (201) Select an existing butterfly head as the head before deformation, and determine the thickening range and thinning range of the thickened head relative to the thickened head before deformation: in the thickened head along its central axis 01 In the cross-section in the direction, select the arc length L1 of the first thickening zone 12 of the thickening head, the arc length s1 of the second thickening zone 21, and the arc length of the outer ring surface of the ring part 2 is s, wherein s1 is less than or equal to s, and L1 is less than or equal to s; the radial thickness of each first thickened region 12 and second thickened region 21 is set to be t 2 , the radial thicknesses of the first thinned region 11, the second thinned region 22, and the third thinned region 31 are all t 1 ; Calculate the thickness coefficient δ of the thickening head as: t 1 = t...

no. 3 example ;

[0159] A method for designing a thickened head is provided, which specifically includes the following steps:

[0160] (301), select an existing butterfly head as the head before deformation, determine the thickening and thinning range of the thickening head relative to the thickening of the head before deformation;

[0161] The difference from the parameters of the first embodiment and the second embodiment is that the thickened part of the thickened head includes: an area with an arc length s1=s extending from the joint part 5 to the junction of the ring part 2 and the column 3 , and the arc length extending from the joint 5 to the top 4 Area;

[0162] Set the radial thickness of the thickening zone as t 2 , the radial thickness of the thinned zone is t 1 , using the formula (1) to calculate the thickness coefficient δ, which satisfies the formula: t 1 = t 2 *δ(5);

[0163] In this step (301), select as figure 1 The existing butterfly head as shown, and the uniform th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com