Spiral type rope locking device

A rope lock, screw technology, applied in the direction of transmission element or pulley rope or cable, textile cable, belt/chain/gear, etc. To achieve the effect of simple structure, simplified operation steps, and improved force form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

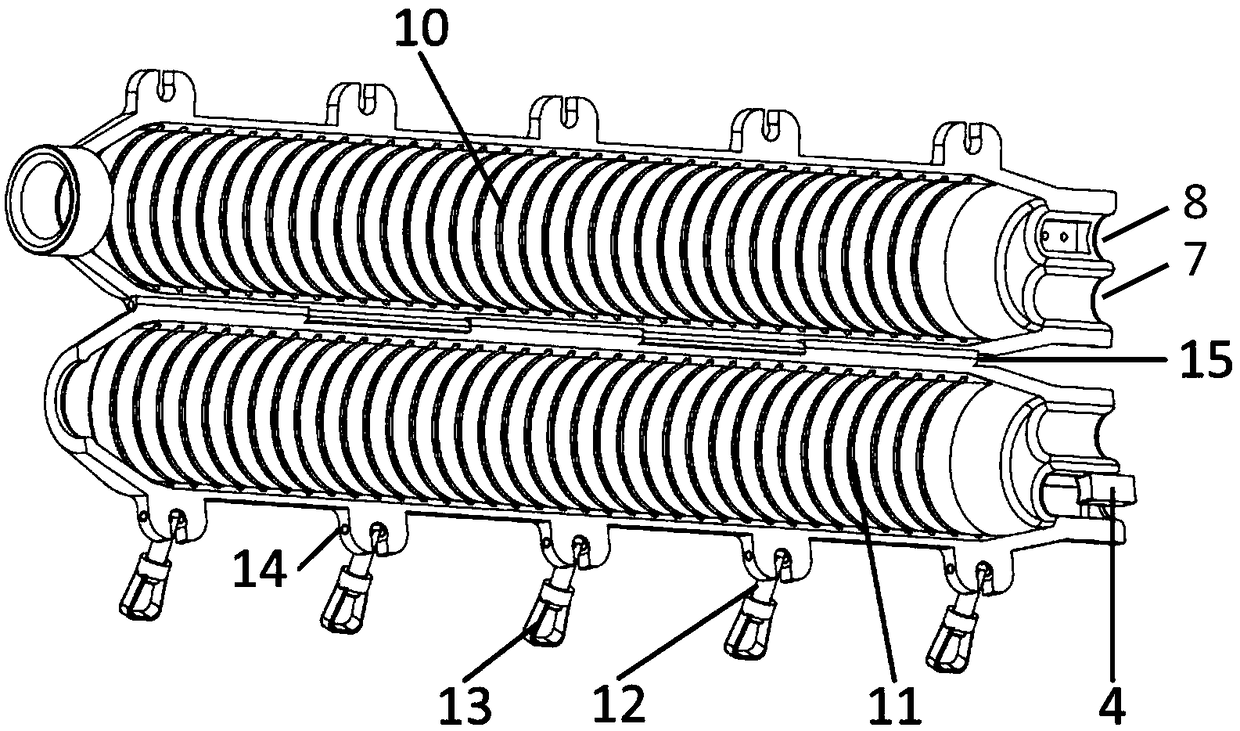

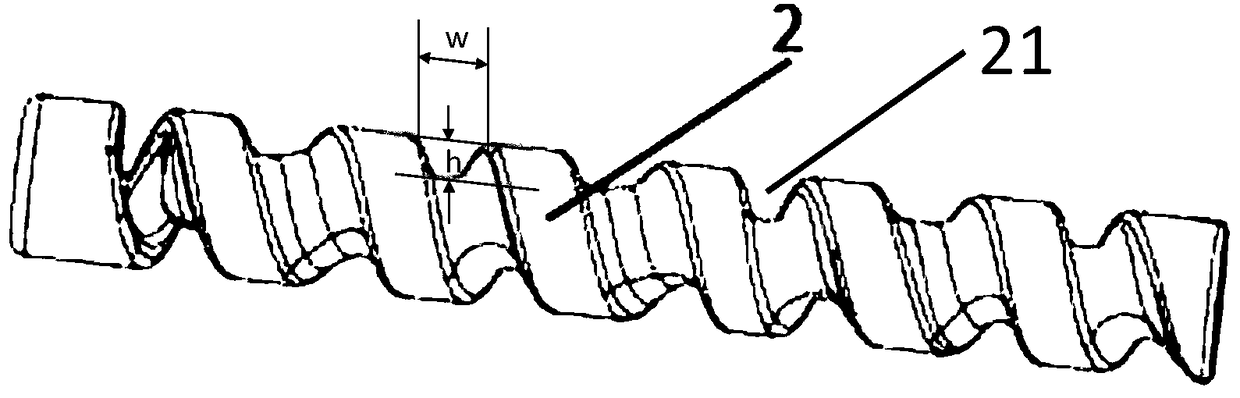

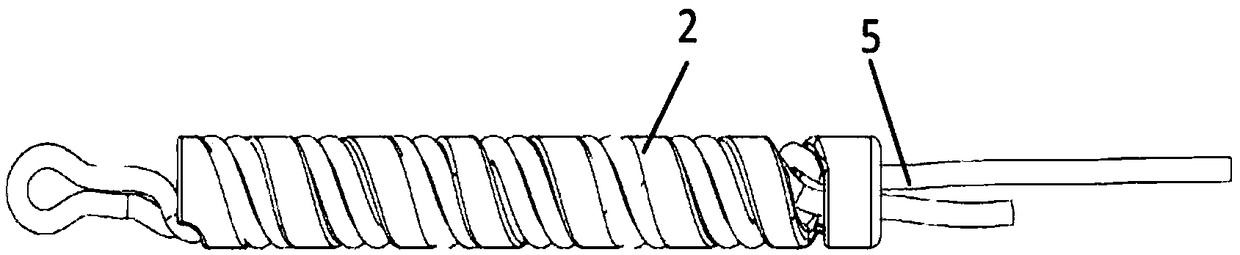

[0034] Such as Figure 1-Figure 5 As shown, Embodiment 1 of the present invention provides a screw-type rope lock, which includes a hinged hoop 1 , a screw column 2 , a support ring 3 , a rope inlet chamber 7 , a rope outlet chamber 8 and a pressing block 4 .

[0035] Such as figure 1 As shown, the upper cover 10 and the lower cover 11 of the hinged hoop 1 are cavity structures, which are connected and rotatable through the hinge shaft 15 , and form an internal cavity when closed to accommodate the screw column 2 . The cavity is narrowed at both ends of the hoop 1 , thereby forming two circular frustums at both ends of the hoop 1 for constraining the axial movement of the screw column 2 .

[0036] Inside the cavity, that is, on the inner surface of the hoop 1, annular grooves parallel to each other are processed to form anti-skid bosses at equal intervals.

[0037] One end of loam cake 10 (such as Figure 4 The right end) is provided with a support ring 3, the rope enters a...

Embodiment 2

[0047]In another simpler embodiment, the support ring 3, the rope access cavity, and the pressure block 4 can all be omitted. The cavity of the hoop 1 is narrowed at both ends of the hoop 1 , thereby accommodating the screw column 2 in the cavity, and cannot pass through the cavity freely. This embodiment is suitable for application environments with relatively small loads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com