Mold pressing forming device used for producing base of power distribution cabinet and using method thereof

A power distribution cabinet base, molding technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of manual unloading of workers, irritating smell and high temperature, etc., to achieve high safety, improve safety, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

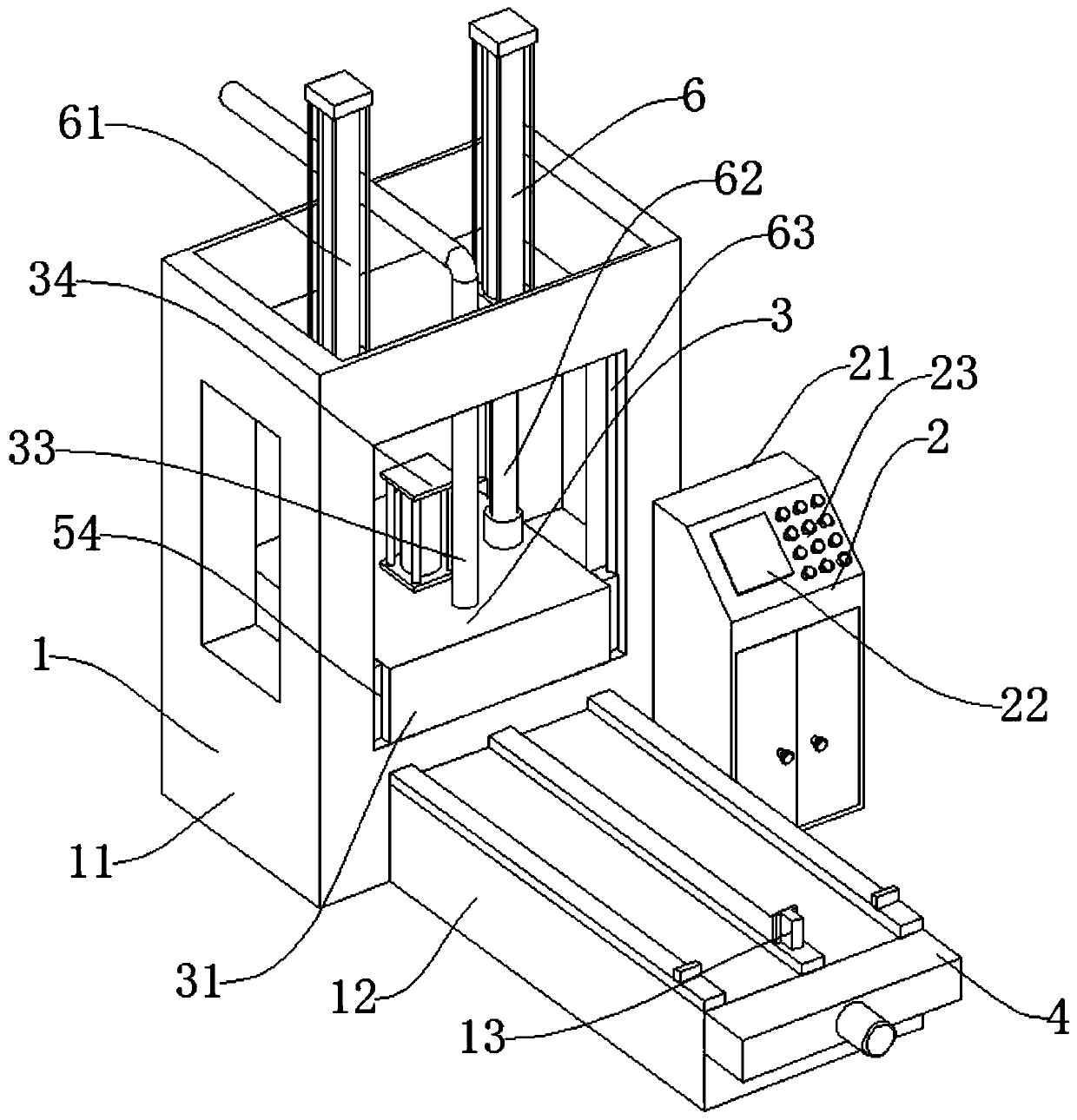

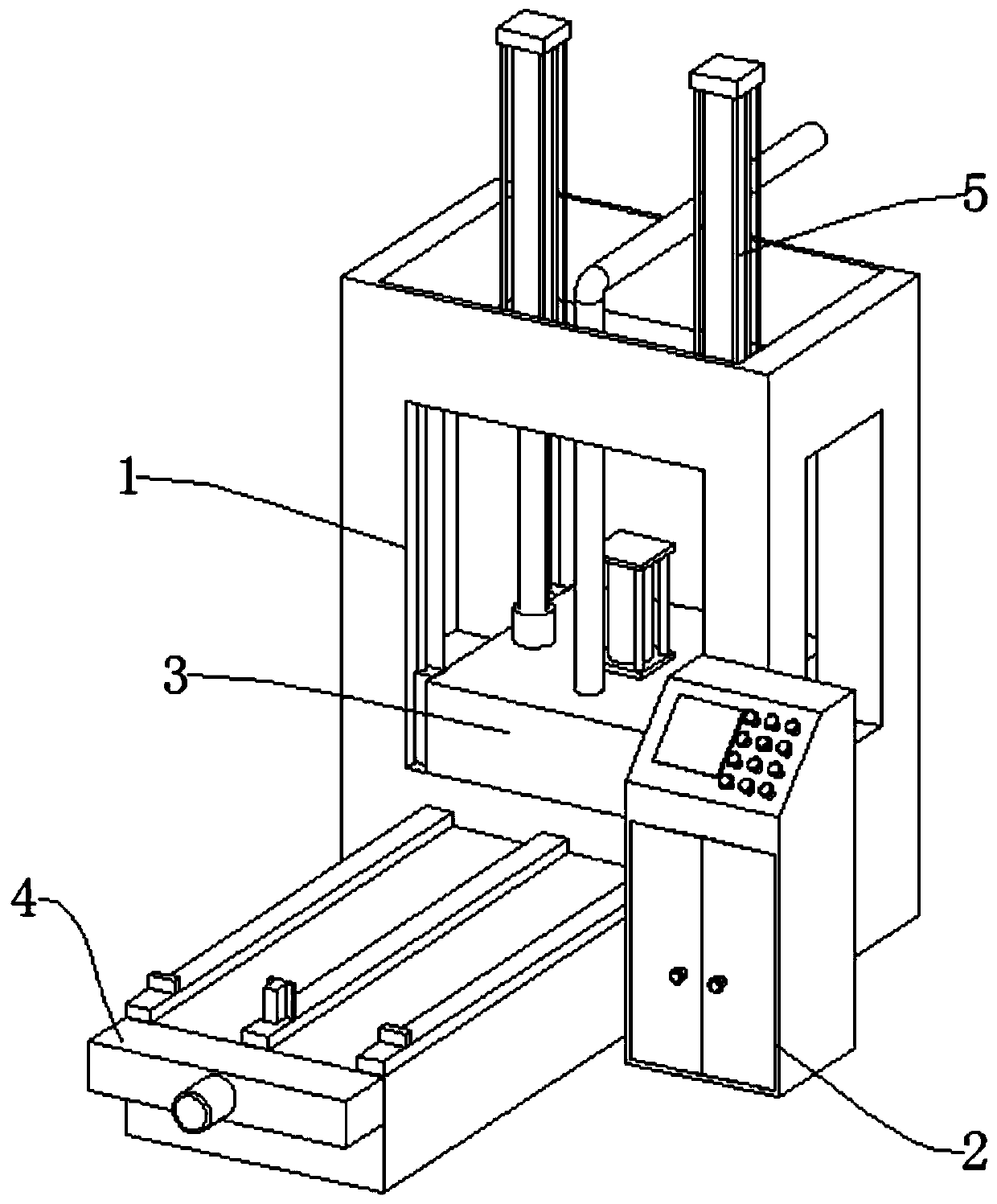

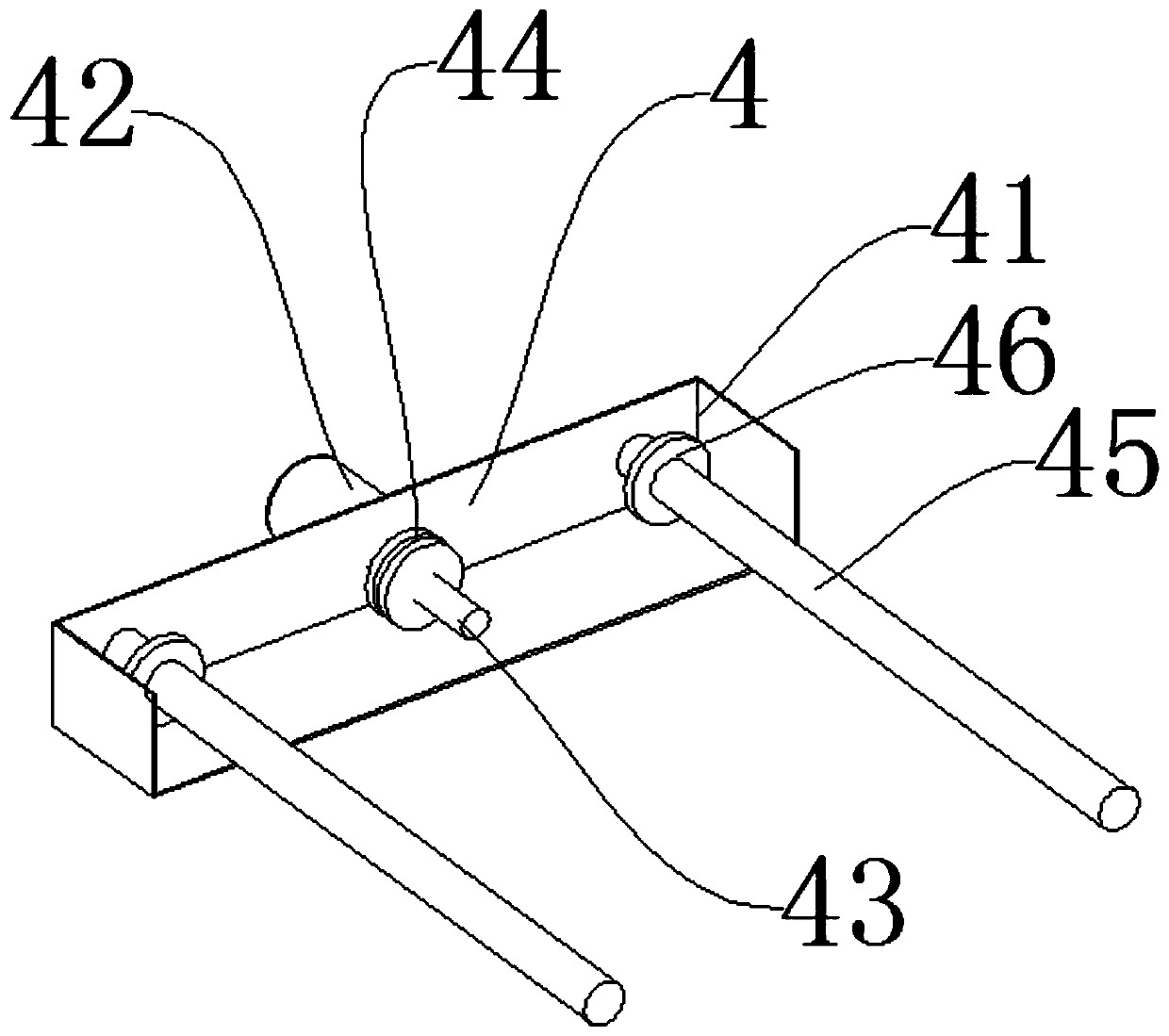

[0045] like figure 1 , figure 2 , image 3 , Figure 4As shown, the pushing mechanism 5 includes an L-shaped push plate 51, a first slider 52, and a limit groove 53. The first slider 52 is connected to the screw 45 of the power mechanism 4, and the upper end of the first slider 52 is connected to the L-shaped push plate 51. , the first slider 52 and the support frame 11 of the support mechanism 1 are provided with a limit groove 53, the L-shaped push plate 51 acts as a pusher, and the first slider 52 acts as a linkage; the power mechanism 4 includes a fixed box 41, a motor 42, the central shaft 43, the driving sprocket 44, the support frame 11 or the receiving frame 12 that the fixed box 41 is connected to the support mechanism 1, the fixed box 41 is provided with a motor 42, the motor 42 is connected with the central shaft 43, and the central shaft 43 is provided with Two driving sprockets 44, both sides of the central shaft 43 are provided with screw rods 45, the screw r...

Embodiment 2

[0047] like figure 1 , figure 2 , image 3 , Figure 5 , Image 6 As shown, the difference between this embodiment and Embodiment 1 is: preferably: the pushing mechanism 5 includes a second slider 511, a column 512, a horizontal plate 513, a connecting pin 514, and the second slider 511 is connected to the screw rod of the power mechanism 4 45. The upper end of the second slider 511 is connected to the column 512, the rear end of the column 512 is connected to the horizontal plate 513, the inner side of the horizontal plate 513 is provided with a connecting pin 514, and the lower end of the connecting pin 514 is provided with a hook bar 515, between the hook bar 515 and the horizontal plate 513 A storage slot 516 is provided, the second slider 511 acts as a linkage, and the hook bar 515 acts as a hook.

[0048] A method for using a molding device for producing a base of a power distribution cabinet includes the following steps:

[0049] a. When processing is required, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com