Meat cleaning device for production of canned food

A cleaning device and meat technology, which is applied in meat processing equipment, processed meat, slaughtering, etc., can solve the problems of unfavorable meat processing and preservation, high labor efficiency, and affecting meat quality, so as to achieve a gentle cleaning method and ensure quality , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

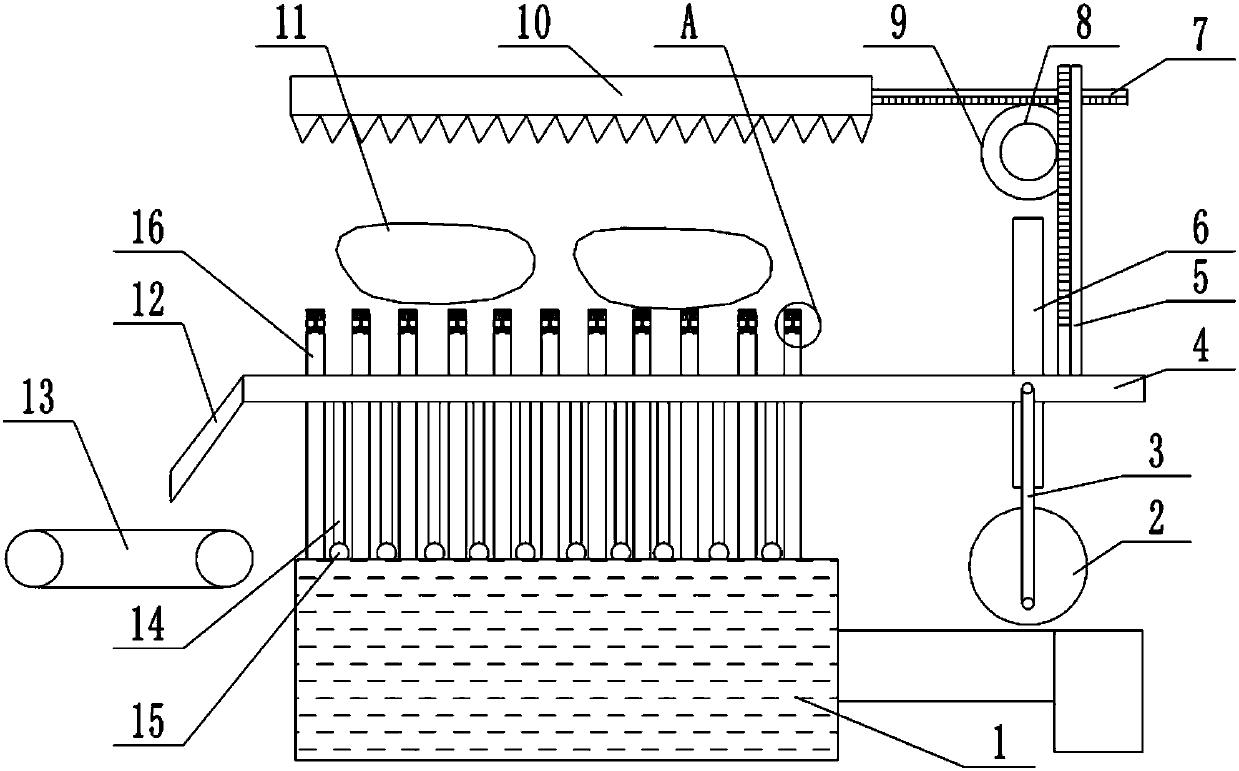

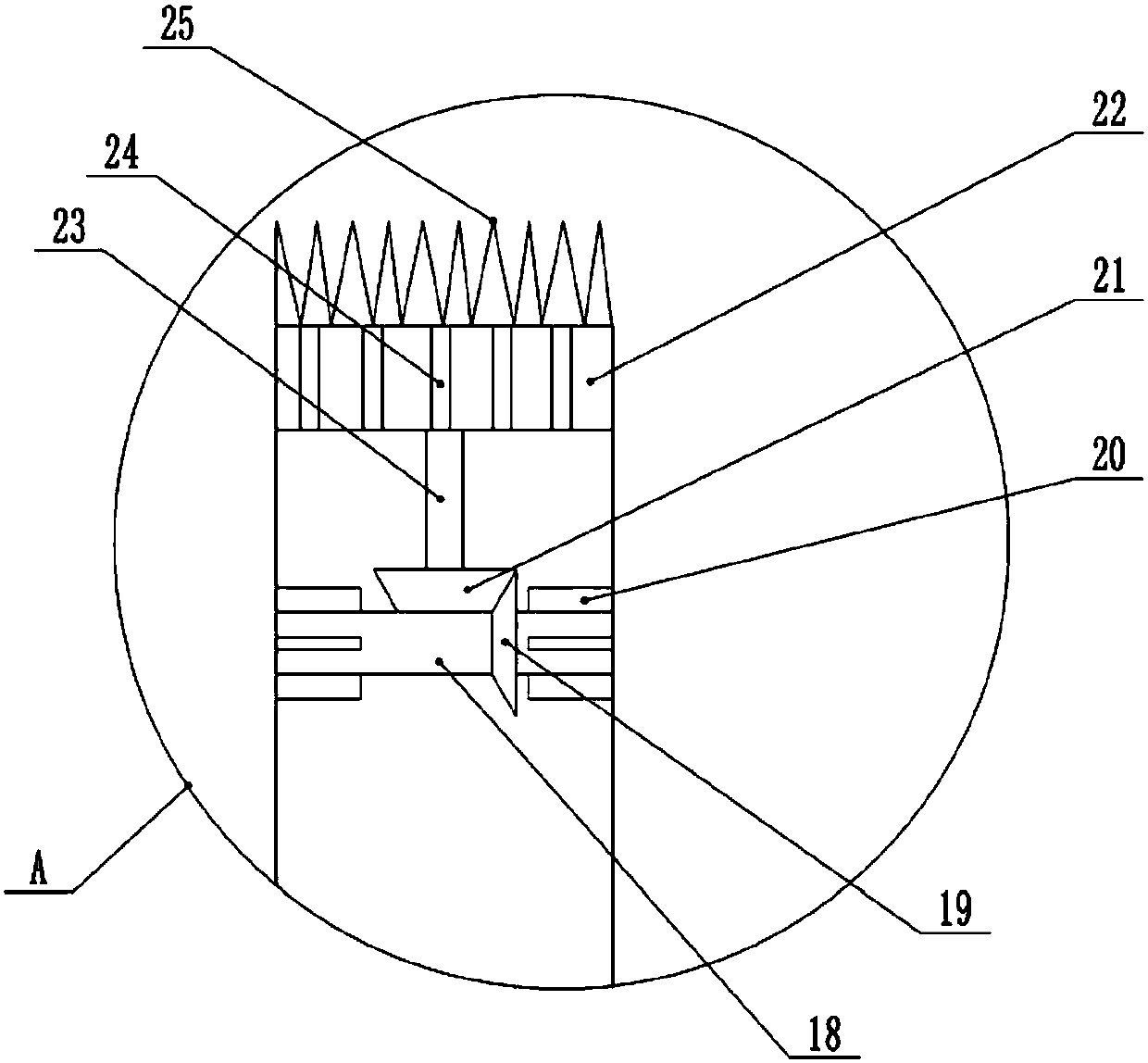

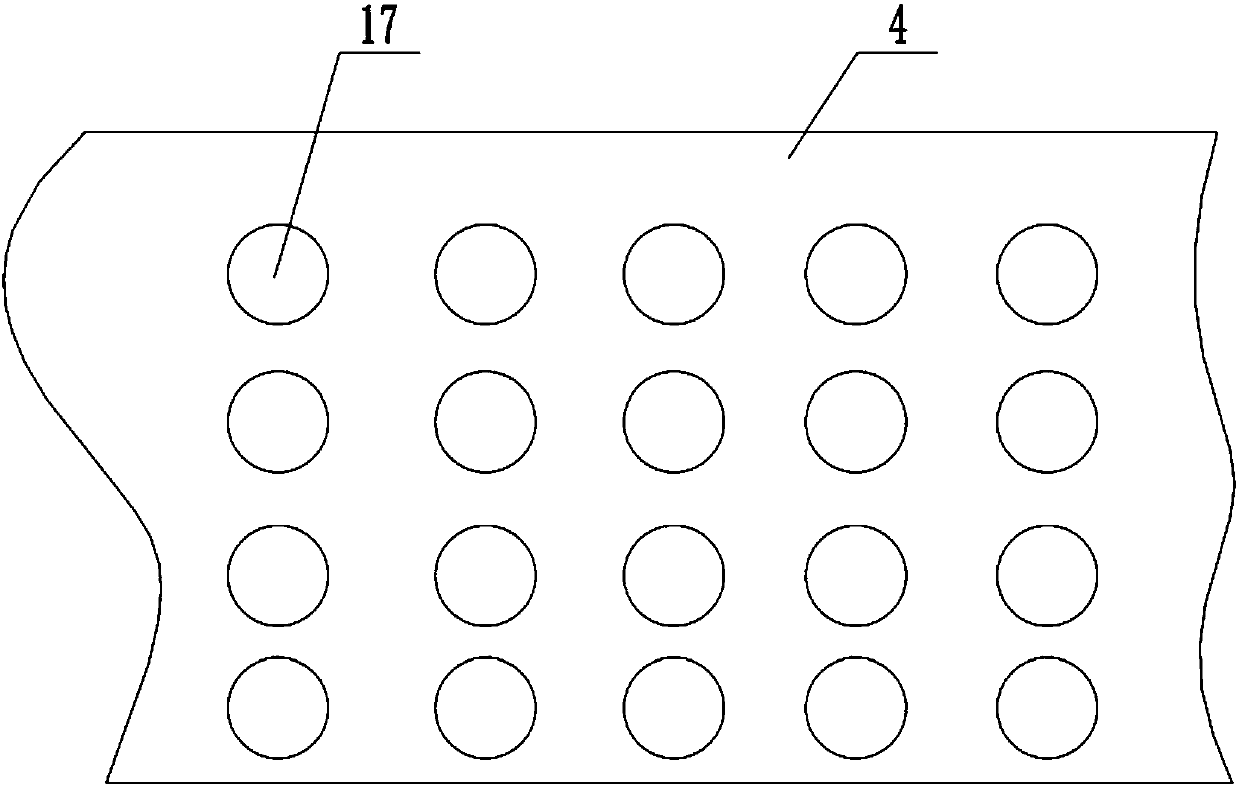

[0016] The reference signs in the accompanying drawings include: water bag 1, turntable 2, connecting rod 3, slide plate 4, second rack 5, guide rail 6, first rack 7, second spur gear 8, first spur gear 9 , moving plate 10, meat piece 11, guide plate 12, conveyer belt 13, pressure rod 14, pressure ball 15, cleaning pipe 16, through hole 17, rotating rod 18, first bevel gear 19, blade 20, second bevel gear 21, Cleaning tray 22, vertical bar 23, water hole 24, hairbrush 25.

[0017] The embodiment is basically as attached Figure 1-Figure 3 Shown: a meat cleaning device for producing canned food, including a rubber water bag 1, a slide plate 4 and a moving plate 10, a water pump is connected to the right side of the water bag 1, and several vertical washing machines are connected to the top of the water bag 1 The tops of the pipe 16 and the cleaning pipe 16 are rotatably connected with a cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com