Swing Shrimp Cleaning Device

A cleaning device and a swinging technology, applied in the field of swinging shrimp cleaning devices, can solve the problems of unguaranteed cleaning degree of lobsters, high labor intensity, low efficiency, etc., to save manpower, avoid washing dead ends, and facilitate secondary utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

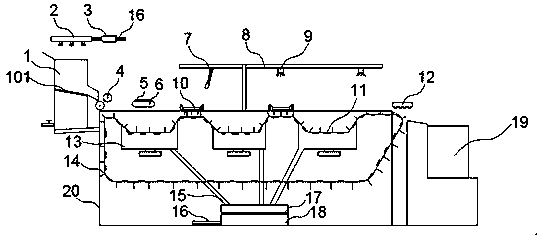

[0022] Such as figure 1 Shown, swing type shrimp cleaning device comprises frame 20, is installed on the net conveyor belt 14 on the frame and cleaning pool 13, and net conveyor belt 14 passes through cleaning pool 13 tops, and net conveyor belt 14 between cleaning pools 13 A rocker 10 is arranged above, and a feeding box 1 is connected to one side above the frame 20, and two adjacent brush rollers 4 are arranged below the outlet of the feeding box 1, and the brush rollers 4 are arranged above the mesh conveyor belt 14, The side of the brush roller 4 is provided with a conveyor belt 6 arranged vertically, the other side above the frame 20 is provided with a collector 19, and the bottom of the frame 19 is provided with a liquid collection tank 18, and the cleaning pool 13 is connected to the liquid collection tank through the liquid collection pipe 15. 18 connections, the bottom of the liquid collection tank 18 is connected with a drain pipe 16, and the cleaning tank 13 selecte...

Embodiment 2

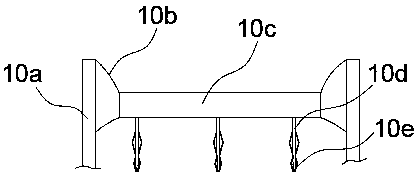

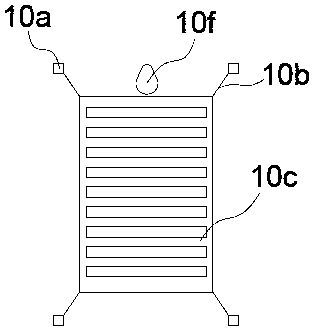

[0029] Such as Figure 2-4 As shown, this embodiment is optimized on the basis of Embodiment 1: the conveyor belt 6 is used to transmit the cover platen 5, the conveyor belt 6 and the net conveyor belt 14 are in a vertical state on the horizontal plane, and the conveyor belt 6 is positioned higher than the net conveyor belt 14, The cover plate 5 is transported by the conveyor belt 6 and finally falls to the top of the shrimp body transported by the net conveyor belt 14. The surface of the cover plate 5 is provided with honeycomb holes. The cover plate 5 is composed of an iron layer 5a and a sponge layer 5b, and the sponge layer 5b is located on the iron plate. Below the layer 5a, since the back side of the net conveyor belt 14 is provided with a flexible magnet 11, the iron plate layer 5a on the cover plate 5 is adsorbed, so that the shrimp body is initially fixed on the net conveyor belt 14, preventing the shrimp from scurrying on the net conveyor belt. The cleaning effect ca...

Embodiment 3

[0033] The preparation method of the shrimp cleaning solution used in the present invention is as follows: in parts by weight, place mussel shells at 1500° C. for calcination for 1 hour, take 30 parts of mussel shells and crush them through a 100-mesh sieve to obtain shell powder for later use, and mix 12 parts of sodium chloride Crush 22 parts of sucrose to 140 mesh, add 30 parts of distilled water to the reactor and heat to 70°C, add shell powder, sodium chloride and sucrose in turn, stir for 10 minutes, add 0.02 parts of L-cysteine hydrochloride and D- 0.03 part of cysteine hydrochloride, heat to 94°C for 5 minutes, add 3 parts of plant fiber, 0.2 part of peanut coat, 20 parts of vegetable protein, 7 parts of soybean lecithin, naturally cool down to 30°C and stir for 50 minutes. 0.5 parts of sodium chloride and 0.2 parts of starch were added to the reactor, and 3 diamonds with a diameter of 0.1 cm were placed in the reactor, and nitrogen gas was continuously injected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com