A tank car condensed heavy oil heating crane tube pendant arm mechanism

A tank car and heavy oil technology, which is applied in the field of tank car condensed heavy oil heating crane pipe pendant arm mechanism, can solve the problems that cannot be used immediately, and achieve the effects of reducing waste, simple operation, and automatic cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments.

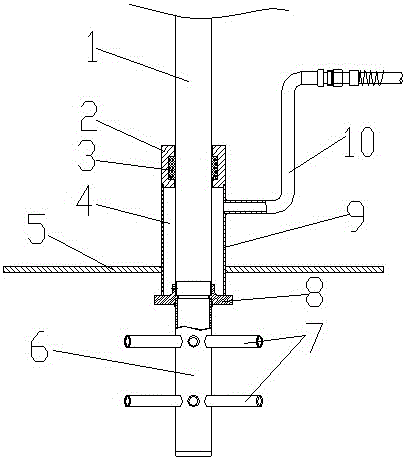

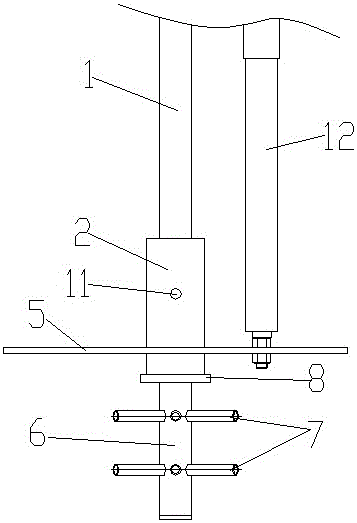

[0020] like figure 1 and figure 2 As shown, a tank car condensed heavy oil heating crane pipe pendant arm mechanism, including telescopic vertical pipe 1, sealing cover 5, oil pan fixing ring 2, oil scraping ring 3, cylinder 9, steam injection device and hydraulic cylinder 12, The upper end of the telescopic vertical pipe 1 is connected with the pneumatic hoisting mechanism, and there is steam in it, and the lower end of the telescopic vertical pipe 1 is provided with a steam injection device, and the steam injection device includes a steam injection head 6, a steam injection pipe 7 and Fixed bracket 8, the steam spray head 6 is cylindrical, and it matches the size and shape of the bottom of the telescopic vertical pipe 1 and communicates and is fixedly connected to each other. The junction of the steam spray head 6 and the telescopic vertical pipe 1 The periphery is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com