Tank car condensate oil heating crane pipe

一种油加热、槽罐车的技术,应用在管子/管接头/管件、包装、可调连接等方向,能够解决不能立即采用等问题,达到减少使用量、降低成本、降低使用和生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments.

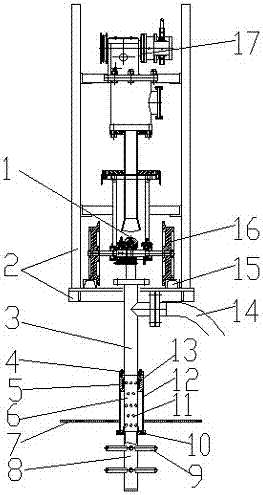

[0023] Such as figure 1 As shown, a tank truck condensate oil heating crane tube includes a truss 2, a pneumatic hoist 17, an air motor 1, a sealing cover 7, a double-layer pipe, a heating and purging steam injection device and a trolley, and the trolley includes two parallel arrangements. And along the four coaxial wheels 16 perpendicular to the length direction of the truss 2, a pneumatic winch 17 is fixed on the trolley, and the lower end of the pneumatic hoist 17 is provided with a double-layer pipe passing through the lower end of the middle part of the trolley. The double-layer pipe includes a vertical pipe 3 and a telescopic pipe 6, and a chain connected to the pneumatic winch 17 is passed through the telescopic pipe 6, and the telescopic pipe 6 is sleeved in the inner cavity of the vertical pipe 3, and the The truss 2 is also provided with a track 15 with a width e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com