Fast food rinsing and pickling processing mechanism and method for producing braised pig's trotters

A processing mechanism and instant food technology, applied in the field of instant food processing, can solve the problems of affecting work efficiency, poor equipment integration effect, difficult processing and production, etc., and achieve the effect of preventing damage, improving effect, and gentle cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

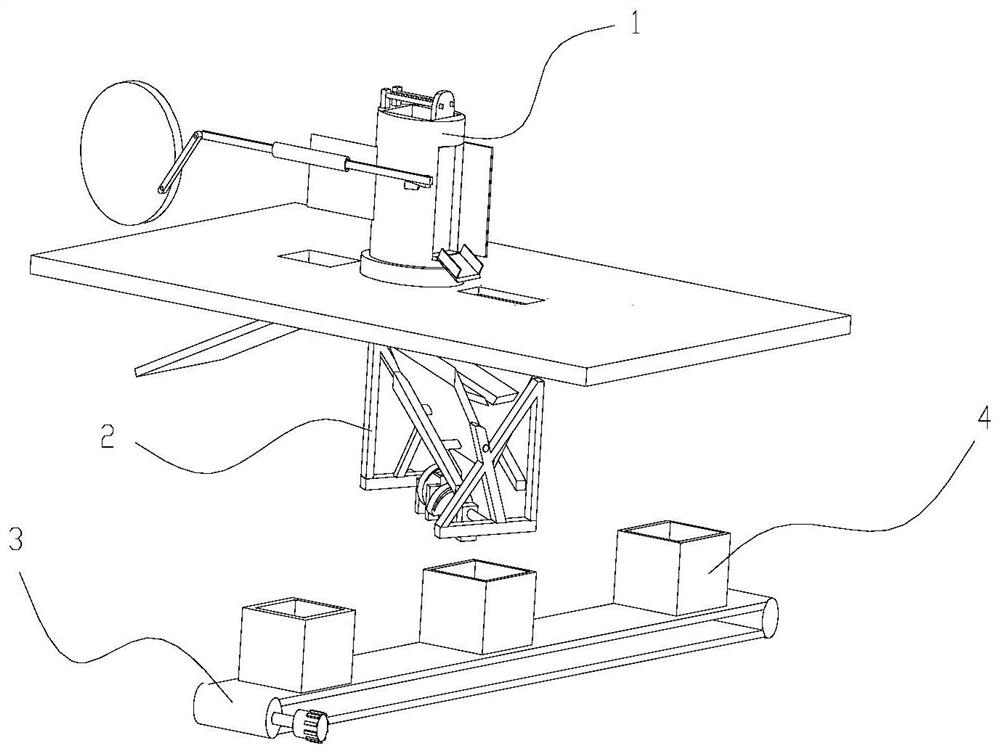

[0058] like figure 1 As shown, this embodiment discloses a pig trotter rinsing and pickling processing mechanism, which includes a rotary type rinsing device 1 , a batch unloading device 2 , a conveyor belt 3 , and a pickling tank 4 . The rotary type rinsing device 1 performs cyclic forward and reverse angular motion to clean the pig's trotter, and the batch feeding device 2 is used to transport the cleaned pig's trotter to the corresponding pickling tank 4 in batches, and batch feeding The feeding opening of the device 2 is opened many times, and the same batch of pig trotters as the opening times are dropped. A plurality of pickling tanks 4 are arranged on the conveyor belt 3 at intervals to ensure that pig trotters of the same batch fall into the same pickling tank 4 , and pig trotters of different batches fall into different pickling tanks 4 .

[0059] In the present invention, after dehairing and half-cutting pig trotters, clear water is added to the rotary type rinsing ...

Embodiment 2

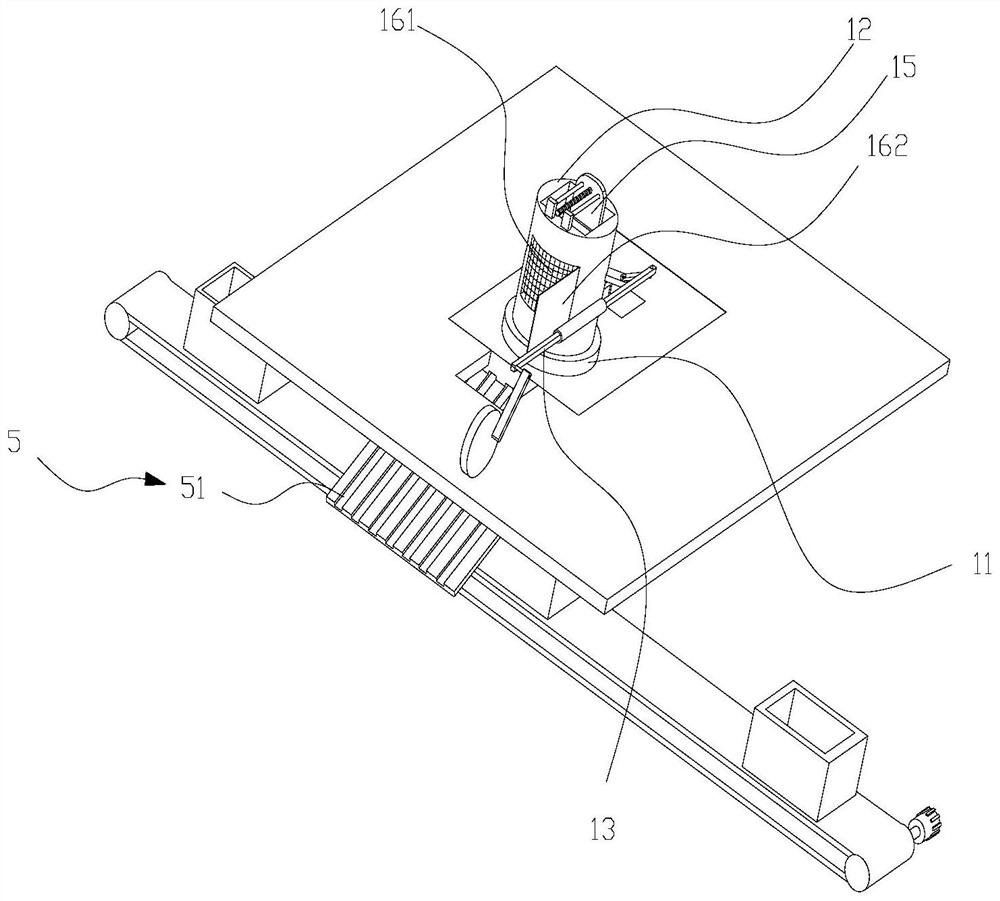

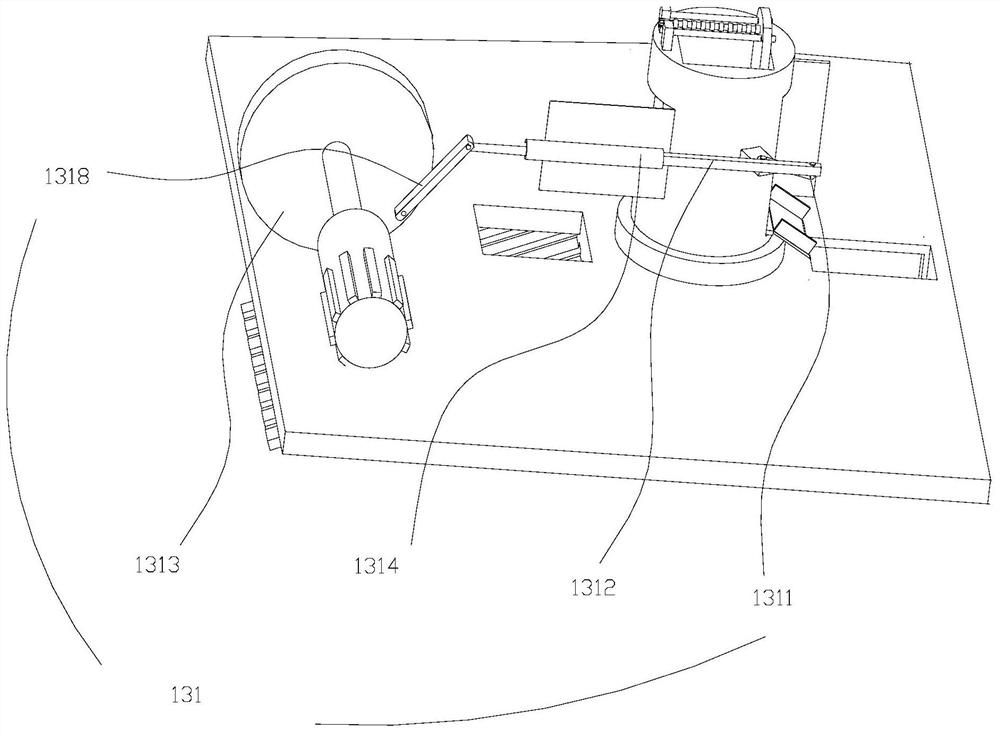

[0082] like figure 2 As shown, the difference between this embodiment and the above embodiments is that one end of the shutter 14 is hinged with the outer side of the rinsing tub 12 , and the other end of the shutter 14 can be snapped or inserted with the outer side of the rinsing tub 12 . It also includes a drain gate 16 , a drain port is opened on the outer side of the rinsing bucket 12 , and the drain gate 16 is installed at the drain port; the drain gate 16 includes an inner gate 161 and an outer gate 162 . The sector of the inner gate 162 includes a network structure formed by a plurality of steel wires crisscrossing each other. Sealing strips are installed on the outer periphery of the gate 14 and the outer gate 161 .

[0083] When draining, by opening the outer gate 161, the water in the rinsing bucket 12 flows out from the inner gate 14, and the pig's trotters in the rinsing bucket 12 are blocked by the steel wire of the network structure formed by the crisscrossing ...

Embodiment 3

[0085] like figure 2 , 3 As shown in the figure, the difference between this embodiment and the above-mentioned embodiment is that a work panel 5 is provided between the rotary type rinsing device 1 and the batch unloading device 2, and the work panel 5 is provided with a water outlet and a discharge port, and the rinsing device The water flowing out of the water outlet of the bucket 12 flows into the water outlet, and the material falling from the lower material opening of the rinsing bucket 12 falls into the discharging opening. A water guide plate 51 is installed on the bottom of the working panel 5, the projection of the water outlet in the vertical direction completely falls on the water guide plate 51, and a water guide channel is opened on the water guide plate 51, and the terminal end of the water guide channel is far away from the conveying Band 3.

[0086] The invention realizes the different direction transmission of water and pig's trotters through the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com