Peach kernel manufacturing device and working method thereof

A production device and peach kernel technology are applied in the fields of vegetable or fruit peeling, food shaping, food science, etc., which can solve the problems of peaches not being able to realize automatic production, waste of human resources, and damage to the surface of peaches, so as to achieve safe and convenient use, Reduce the waste of manpower and facilitate the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

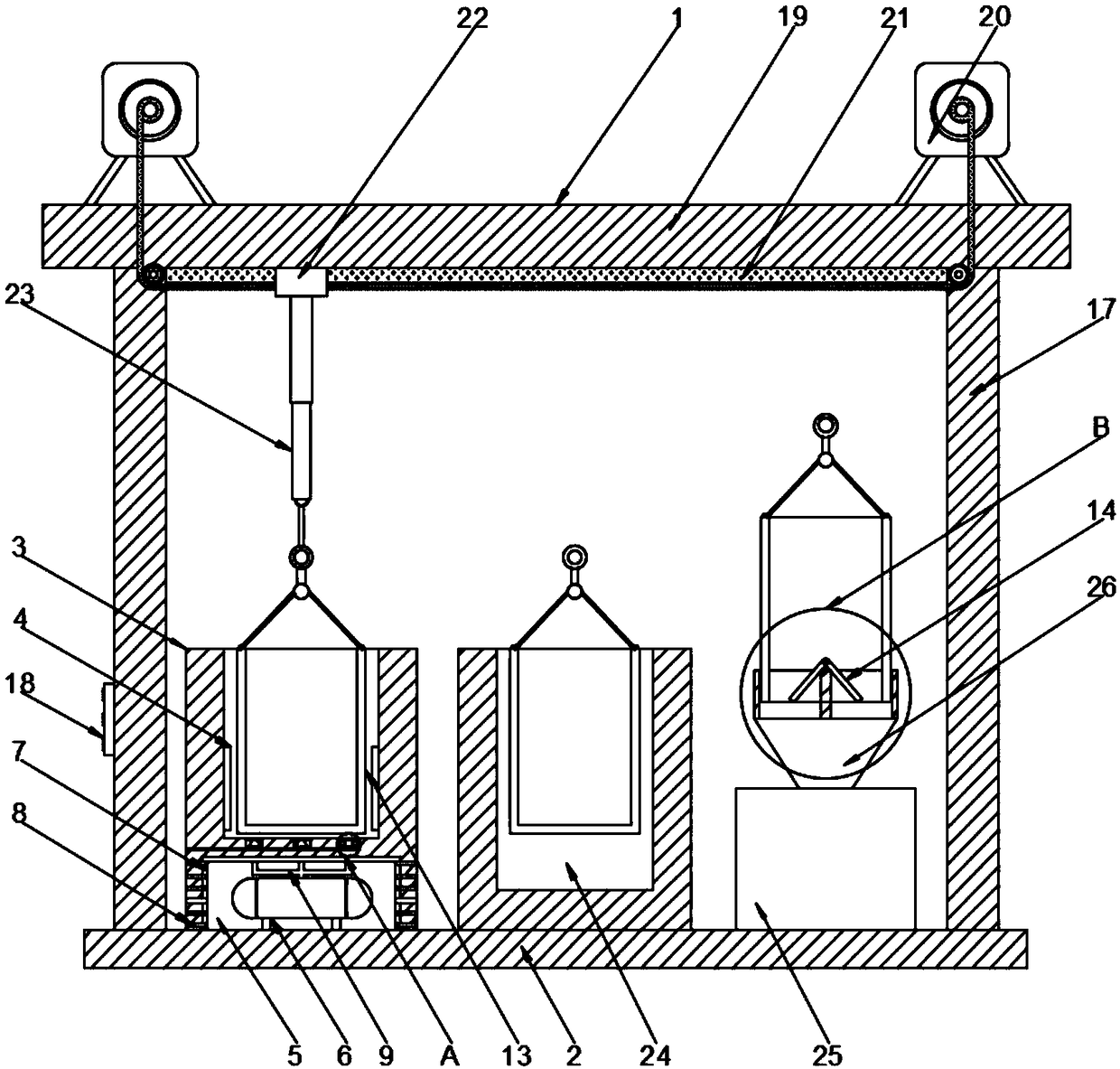

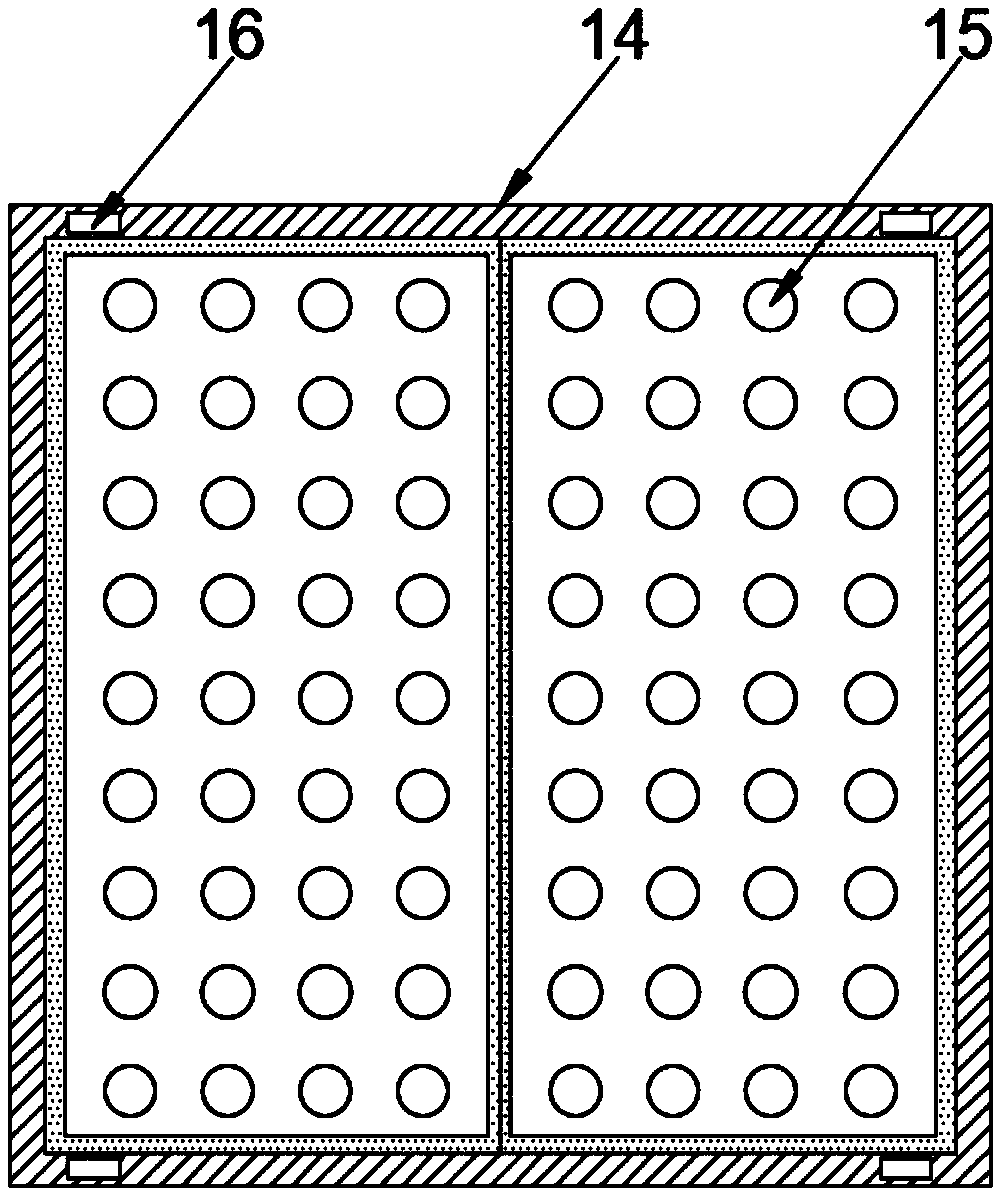

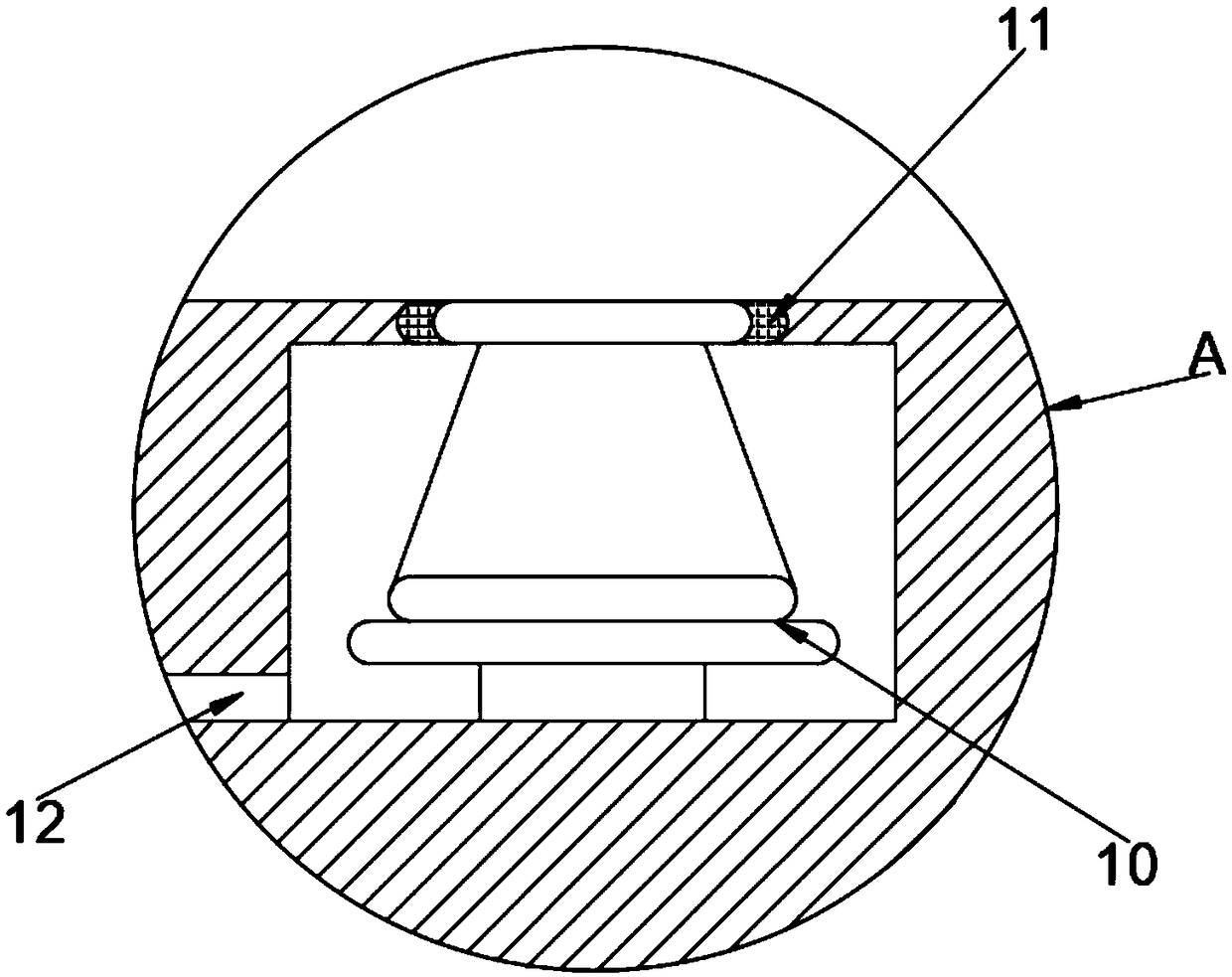

[0020] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, an integrated peach kernel production device, including a device body 1, a bottom plate 2, a boiling water chamber 3, a heating plate 4, a stirring chamber 5, an air compressor 6, soundproof cotton 7, Cooling holes 8, high-pressure air transmission pipes 9, high-pressure air nozzles 10, sealing rubber rings 11, diversion grooves 12, transport baskets 13, folding plates 14, mesh holes 15, rollers 16, support rods 17, control switches 18, beams 19 , transmission motor 20, slide rail 21, slide block 22, electric telescopic rod 23, cold water chamber 24, peeling machine 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com