Processing fixture for milling plane of upper cover plate

A plane processing and fixture technology, which is applied in the field of top cover milling plane processing fixtures, can solve the problems that the top cover cannot be clamped at the same time, the depth and dimension cannot be guaranteed, and the applicability is poor, and the production cost is reduced, the operation is simple, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

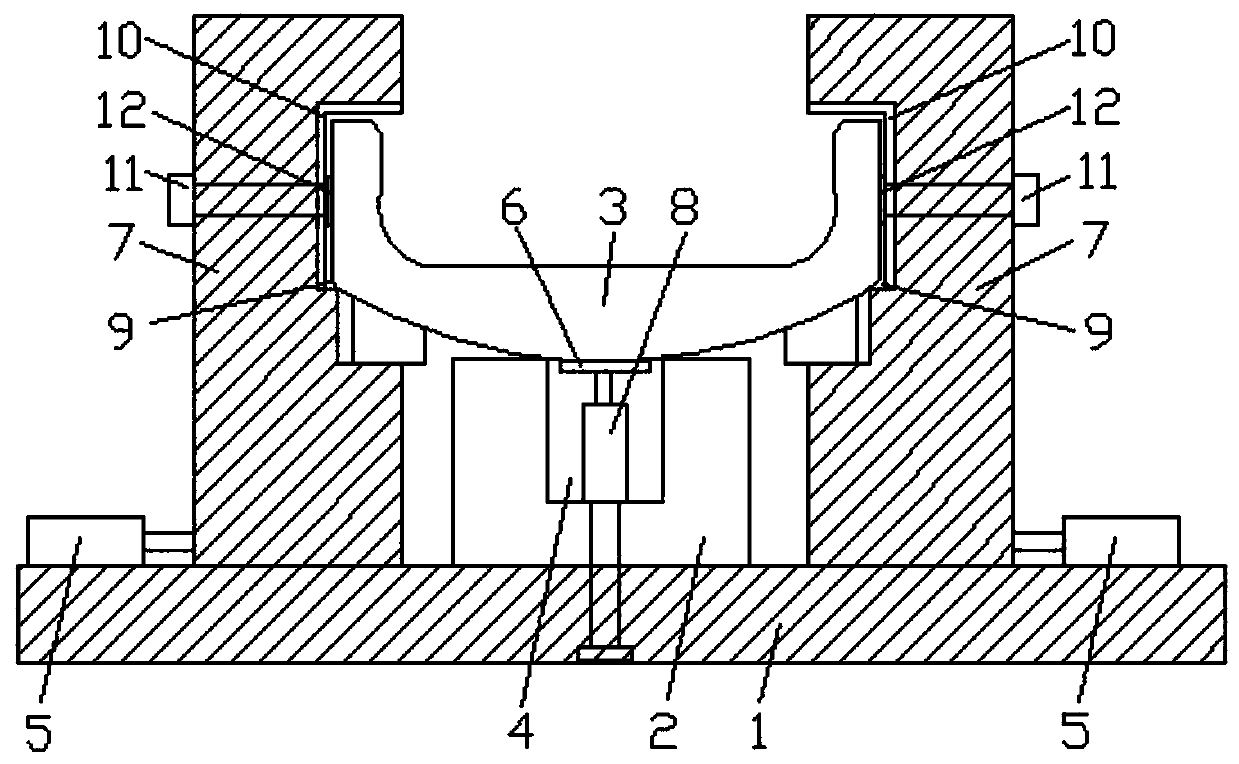

[0039] Such as figure 1 As shown, in this embodiment, each set of clamping assemblies also includes a driving assembly, and the driving assembly includes a horizontally arranged driving cylinder 8. The driving cylinder 8 is arranged on the end of the slide rail away from the upper cover plate 3 and its telescopic end is in contact with the clamping plate. 7 connection (welding), the driving cylinder 8 is welded on one end of the slide rail, which is convenient for disassembly and assembly. When clamping, the horizontal reciprocating movement on the base 1 of the clamping plate 7 is realized by driving the cylinder 8, thereby clamping the upper cover 3 or loosening the upper cover 3, the operation is simple and the degree of automation is high, no manual operation is required, saving Save time and effort.

Embodiment 2

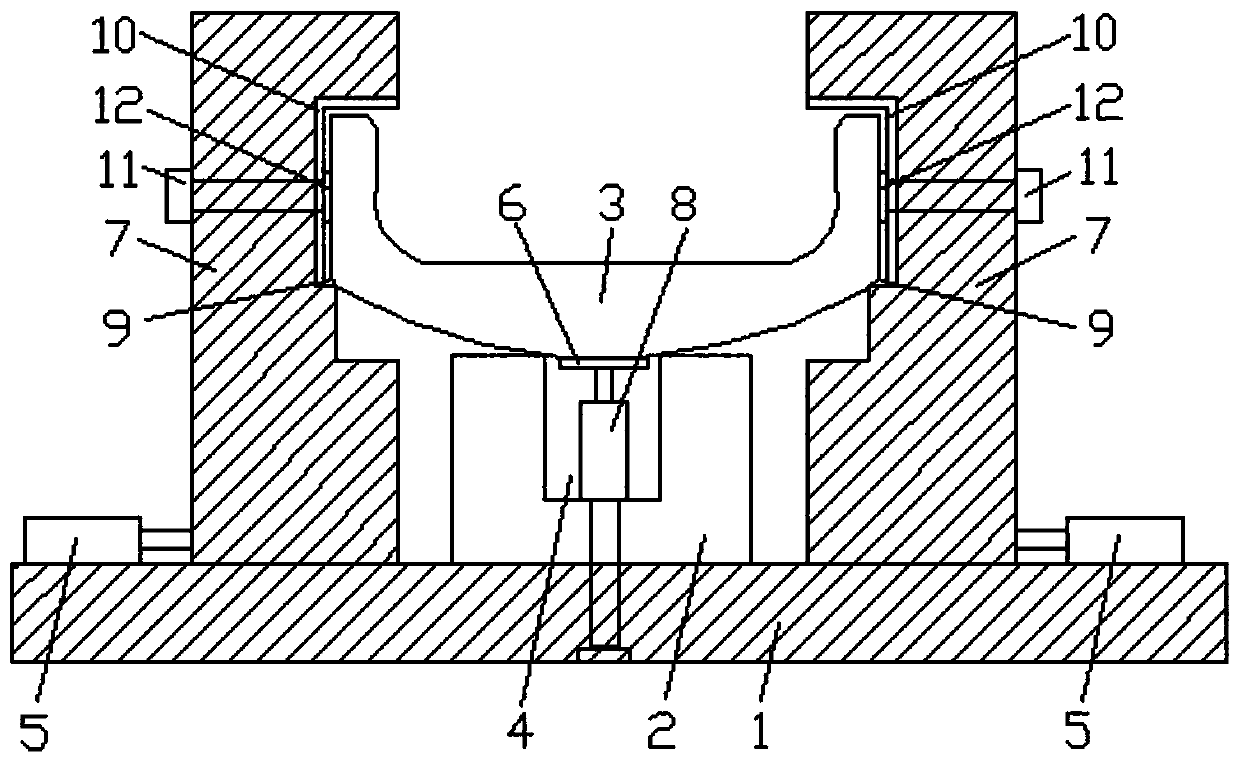

[0041] Such as figure 2As shown, the difference between this embodiment and Embodiment 1 is that the driving assembly includes a motor and a screw rod, and a bar-shaped guide groove is provided on the base 1, and the screw rod is horizontally installed in the guide groove, and one end of the screw rod is connected with the guide groove. One end is rotationally connected, and the other end is welded together with the driving end of the motor installed at the other end of the guide groove; the motor is installed on the other end of the guide groove through welding or bolt connection. A nut is threaded on the screw mandrel, and the slide block on the lower end of the clamping plate 7 is welded together with the nut on the screw mandrel. When clamping, the motor drives the screw to rotate, and the screw converts its own rotation into the linear movement of the nut on it. The two clamping plates move along the corresponding screw with the two nuts and move closer to or farther awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com