A filter device for processing whey fermentation liquid and its application method

A whey fermented liquid and filtration device technology, which is applied in the field of food processing, can solve problems such as unsatisfactory, heavy workload, and reduced profits, and achieve the effects of reducing labor costs, expanding profits, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

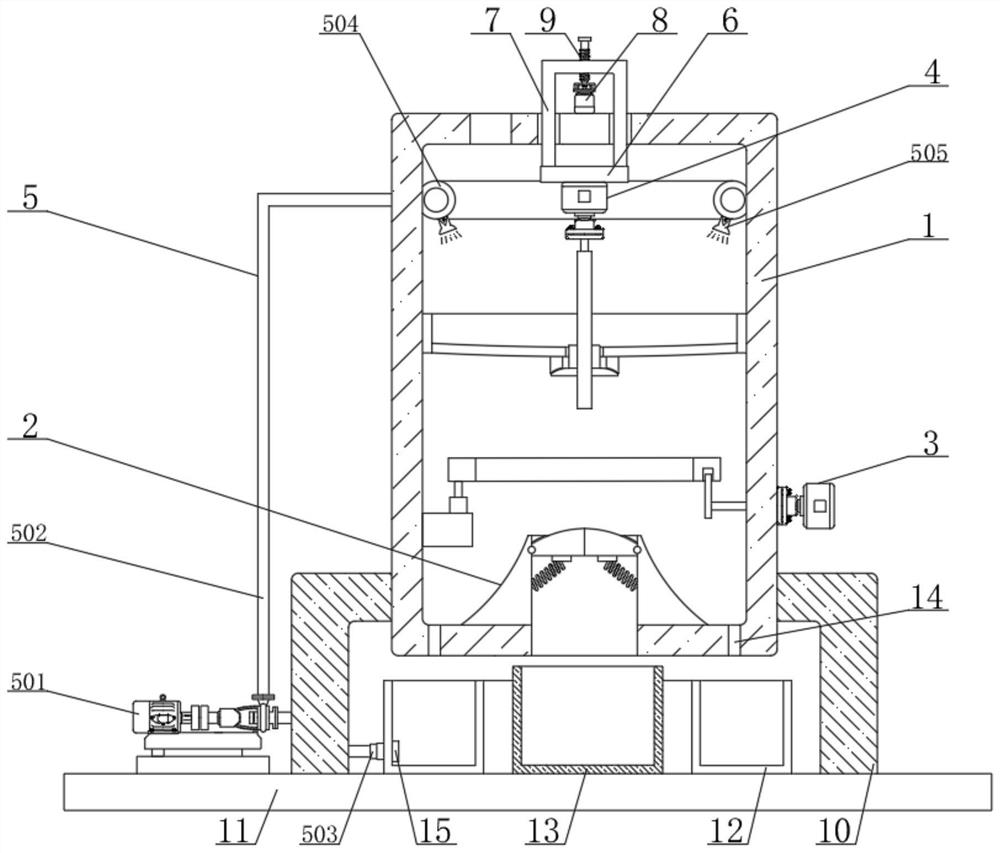

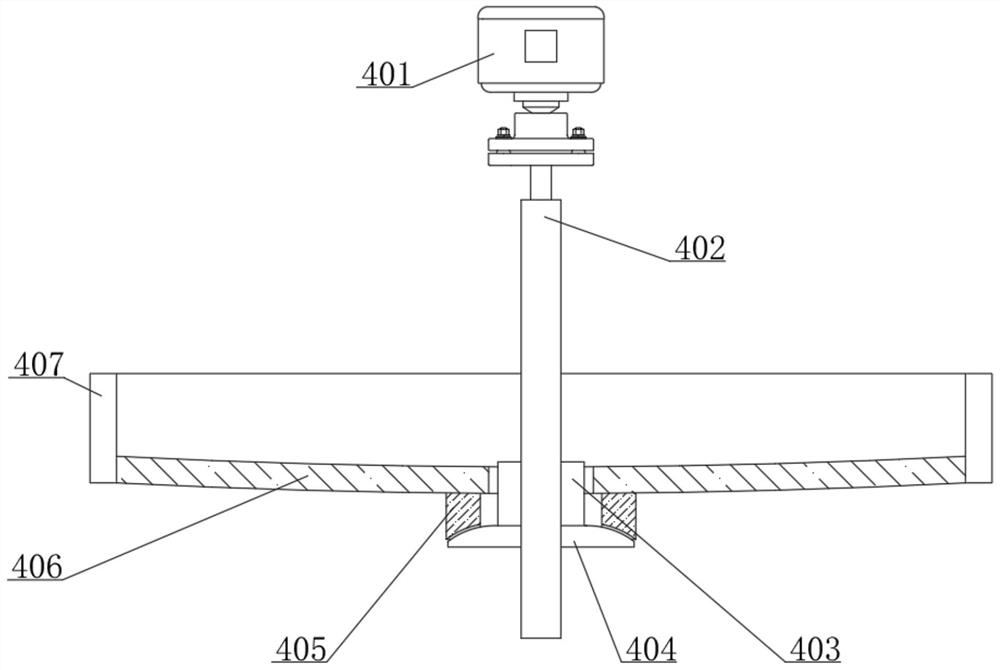

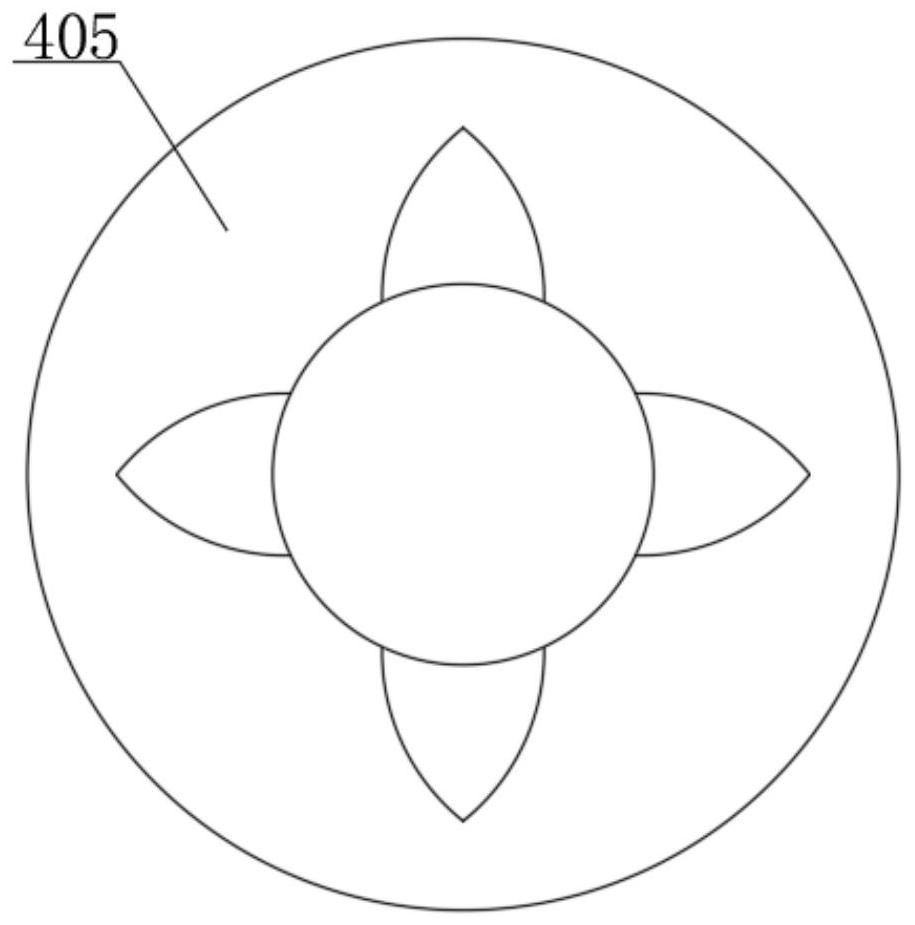

[0027] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0028]A filter device for processing whey fermentation liquid and its use method, comprising a filter tank 1 and a support plate 11, fixed seats 10 distributed left and right are fixedly connected to the bottom of the outer side of the filter tank 1, and the other end of the fixed seat 10 is fixedly connected to a support plate 11. The lower end surface of the filter tank 1 is fixedly connected with a blanking mechanism 2. The blanking mechanism 2 includes a blanking tube 201 and a rotating baffle 202. The lower surface of the blanking tube 201 is fixedly connected with the filter tank 1. The inner side is rotatably connected with a rotating baffle 202 distributed up and down, and a stopper 203 is arranged above the rotating baffle 202. The setting of the stopper 203 prevents the rotating baffle 202 from moving upward, and the lower end surface of ...

Embodiment 2

[0036] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0037] A filter device for processing whey fermentation liquid and its use method, comprising a filter tank 1 and a support plate 11, fixed seats 10 distributed left and right are fixedly connected to the bottom of the outer side of the filter tank 1, and the other end of the fixed seat 10 is fixedly connected to a support plate 11. The lower end surface of the filter tank 1 is fixedly connected with a blanking mechanism 2. The blanking mechanism 2 includes a blanking tube 201 and a rotating baffle 202. The lower surface of the blanking tube 201 is fixedly connected with the filter tank 1. The inner side is rotatably connected with a rotating baffle 202 distributed up and down, and a stopper 203 is arranged above the rotating baffle 202. The setting of the stopper 203 prevents the rotating baffle 202 from moving upward, and the lower end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com