Automatic pesticide mixing and spraying device for gardens

A spraying device and pesticide technology, applied in spraying devices, devices for catching or killing insects, applications, etc., can solve the problems of high labor intensity and easy harm to the human body, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

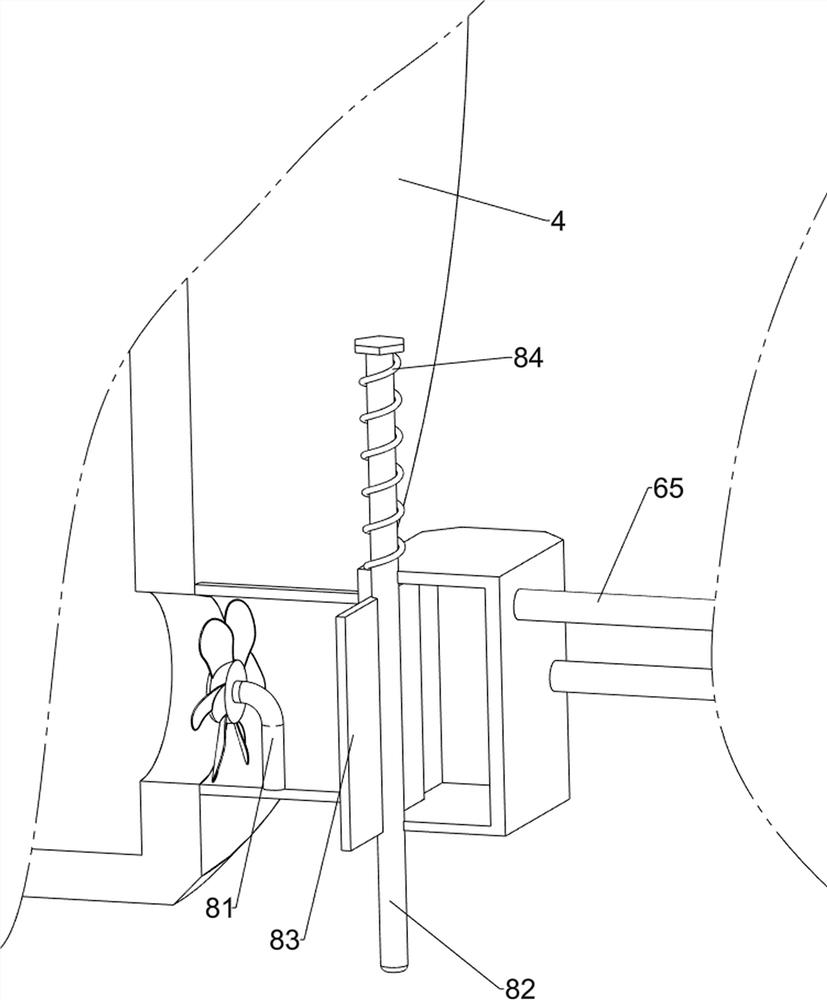

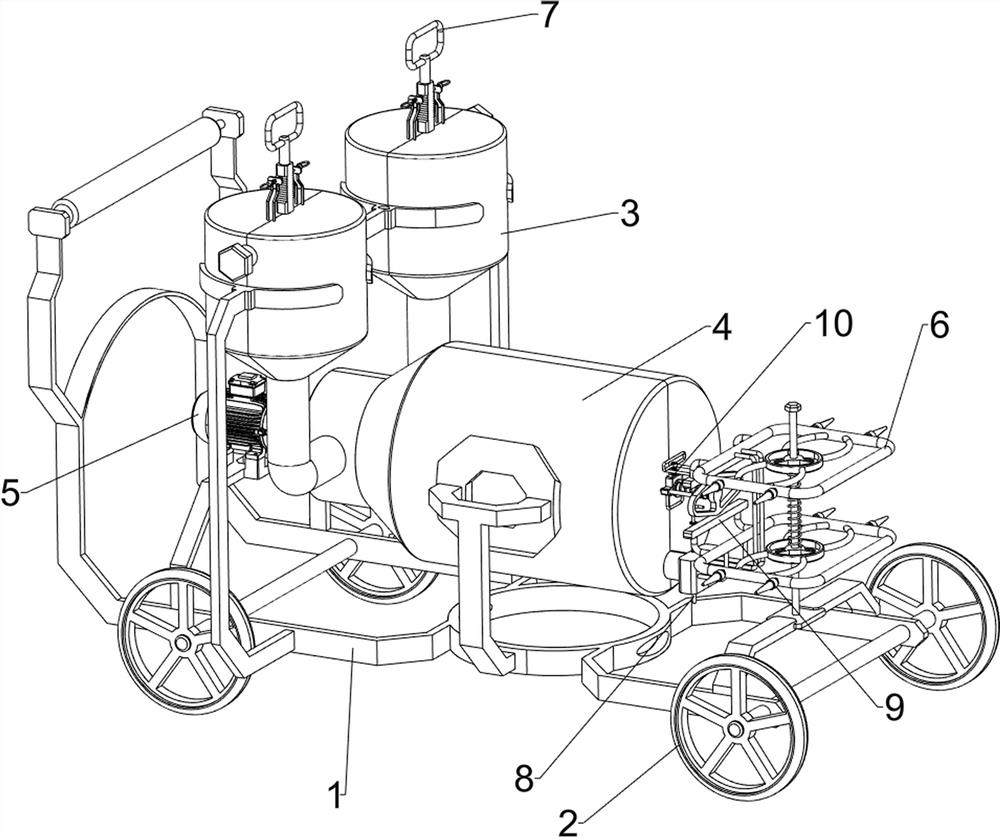

[0066] A gas-mixed spraying device for pesticides in garden, such as figure 1As shown, including the firmware 1, the wheel 2, the discharge chamber 3, the stirring casing 4, the stirring mechanism 5, and the spray mechanism 6, and the rotating type wheel is provided in the left and right side of the firmware 1, and there are two on the left side of the firmware 1. A discharge box 3, the firmware 1 has a stirring box body 4, and the left side of the stirring casing 4 is fixed to the lower side of the two discharge boxes 3, and the firmware 1 is provided with a stirring mechanism 5, firmware. 1 The right side is provided with a spray mechanism 6 between the right side of the stirring casing 4.

[0067] When people need to spray the garden plant, it is possible to use this garden to automatically mix the spraying device. First, hold the hand on the firmware 1, then push the firmware 1 to operate, so that the wheel 2 is rotated, and the place where the pesticide needs to be sprayed Th...

Embodiment 2

[0069] On the basis of Example 1, such as figure 2 with image 3 As shown, the stirring mechanism 5 includes a servo motor 51, a first rotating shaft 52, and a stirred leaf 53, and a servo motor 51 is attached to the left side of the firmware 1, and the mixing case 4 is rotatable with the first axis 52, the first axis 52 Connect to the output shaft of the servo motor 51, the first shaft 52 is provided with a stirred leaf 53.

[0070] When the pesticide flows into the stirring casing 4, the servo motor 51 is activated, and the output shaft of the servo motor 51 is rotated, so that the stirred blade 53 is rotated so that the stirring leaf 53 can stir the pesticide to achieve the effect of stirring. , Close the servo motor 51 without stirring.

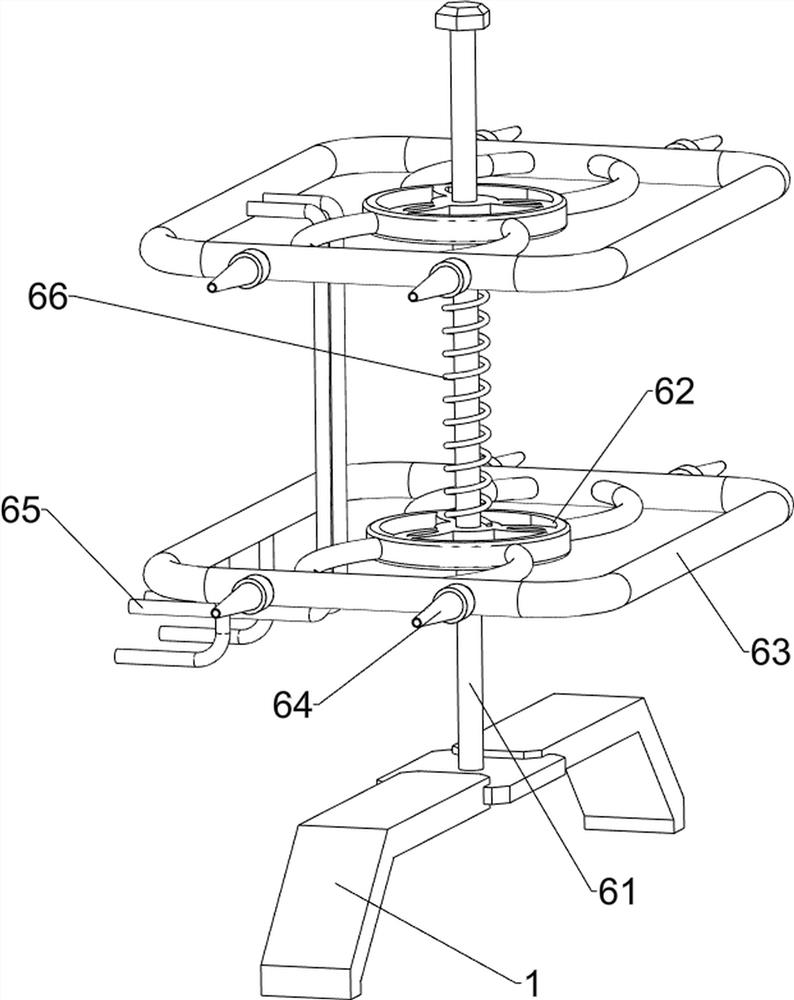

[0071] The spray mechanism 6 includes a first bracket 61, a fixing frame 62, a hard spray water pipe 63, a nozzle 64, a soft water pipe 65, and a first spring 66, and the firmware 1 is provided on the upper right side of the first bracket 61, ...

Embodiment 3

[0074] On the basis of Example 2, such as Figure 4 - Figure 7 As shown, there is a discharge mechanism 7, the discharge mechanism 7 includes a second bracket 71, a lever 72, a first baffle 73, a second spring 74, a first insert 75, and a third spring 76, two discharge The top of the box 3 is known as the second bracket 71, and the two discharge boxes 3 are slided in the middle, and the two tie rods 72 are provided with a first baffle 73, and the two tie rods 72 have a second spring. 74. The second spring 74 is connected to the discharge box 3 and the first baffle 73, respectively, and both of the two second brackets on both sides are symmetrically symmetric, and the first latch 75 is equipped with the first latch. The tie rod 72 is in contact with the first pin 75, and the third spring 76 is connected to the second bracket 71 and the first latch 75, respectively.

[0075] One can pull the first pin 75 back to movement, the third spring 76 is stretched, and then the pulling rod 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com