Rotary cutting machine

A technology of rotary cutting machine and rolling rod, which is applied in the direction of circular rotary machine, veneer chip manufacturing, wood processing equipment, etc. It can solve the problems of blocking fibers, not being able to be used as the surface of plywood, and difficult to detach.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

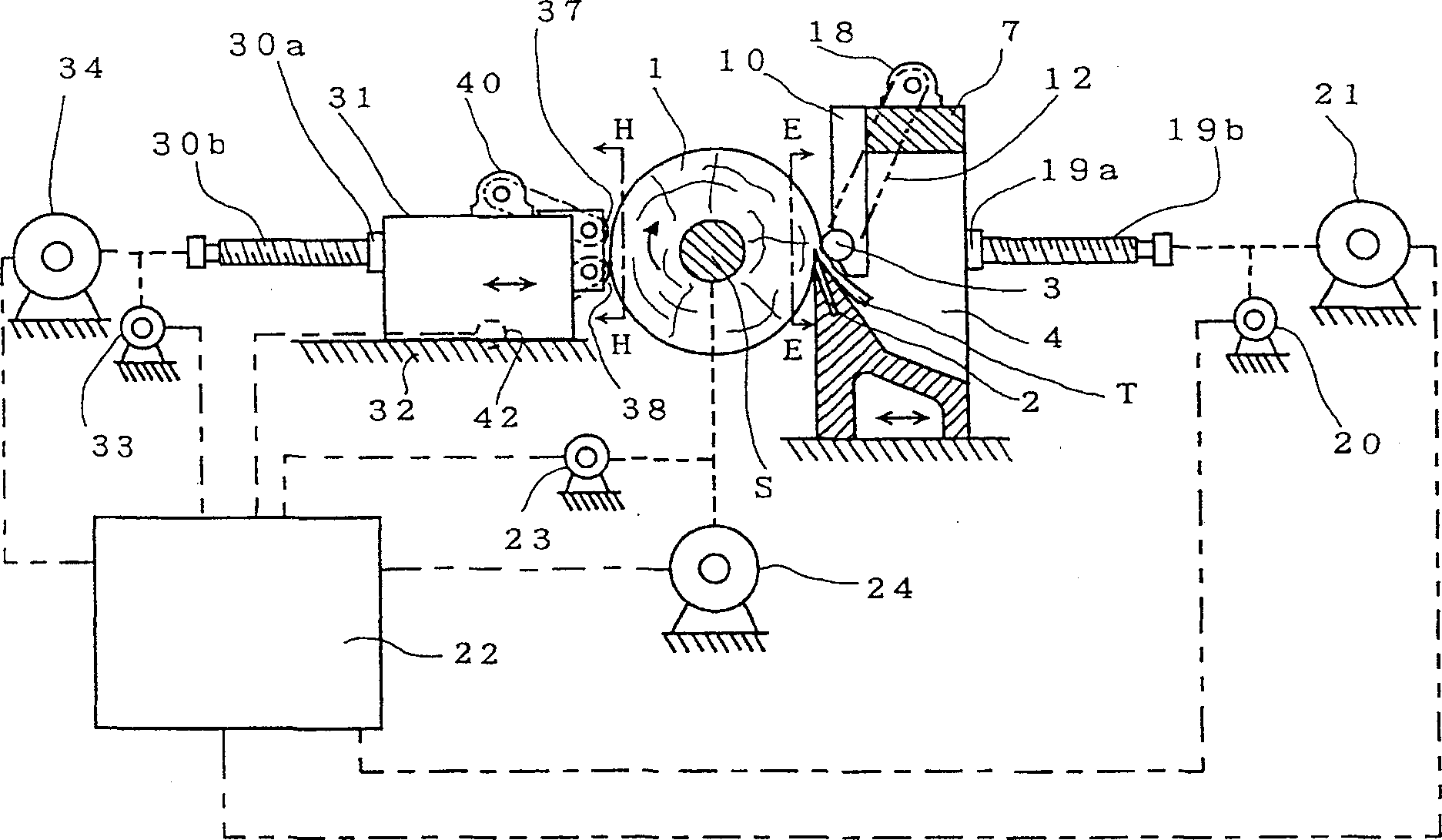

[0047] Embodiments of the present invention will be described below.

[0048] like figure 1 As shown in the side explanatory diagram, a planer table 4 is arranged on the rotary cutting machine formed, on which a pair of pillars S, a cutter 2 and a rolling bar 3 are arranged, and a pair of pillars S is arranged so that it can move freely in the direction of the axis of the log 1. Advance and retreat, the log 1 is supported by the prop S freely rotating, and the cutter 2 cuts the log 1 .

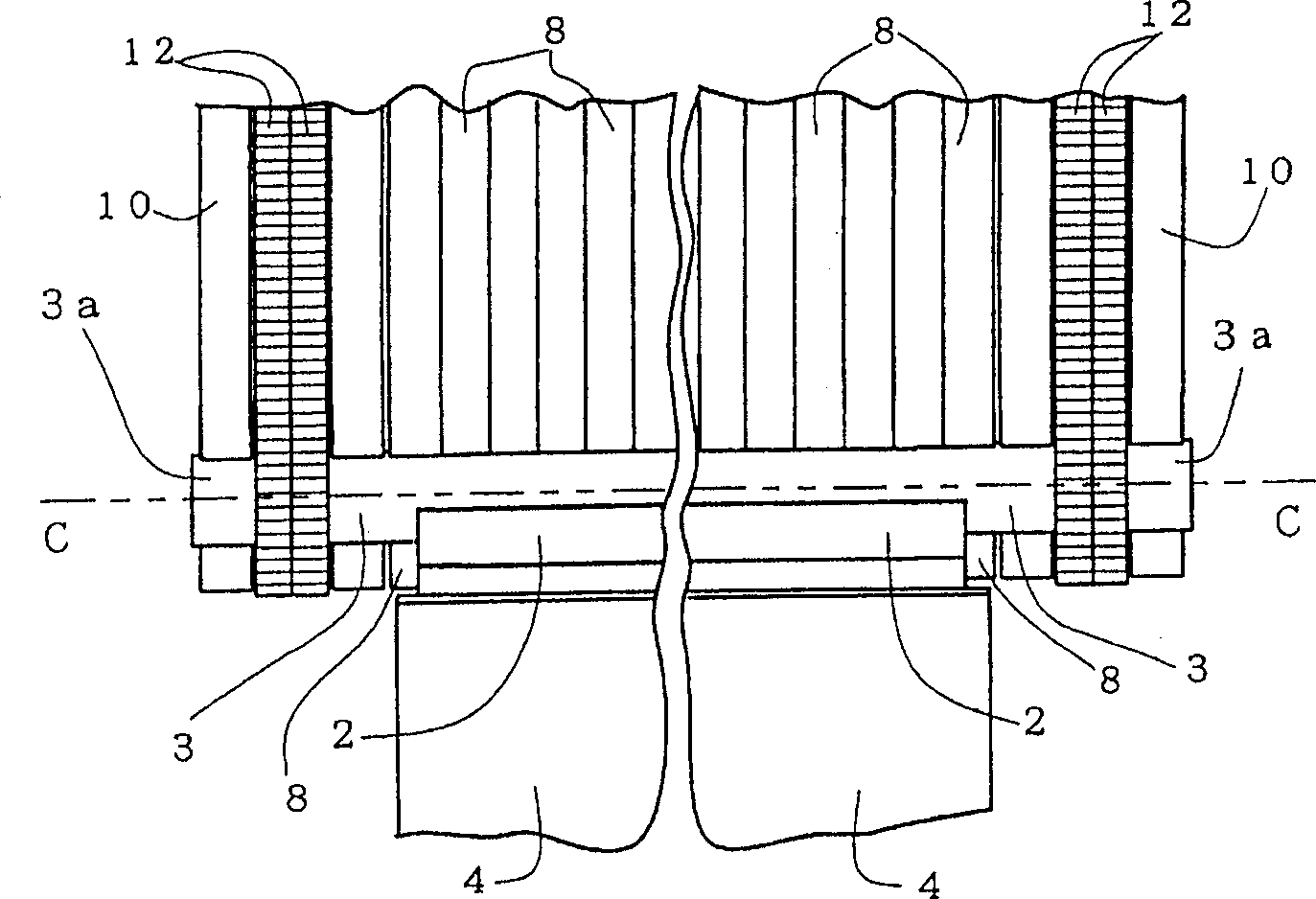

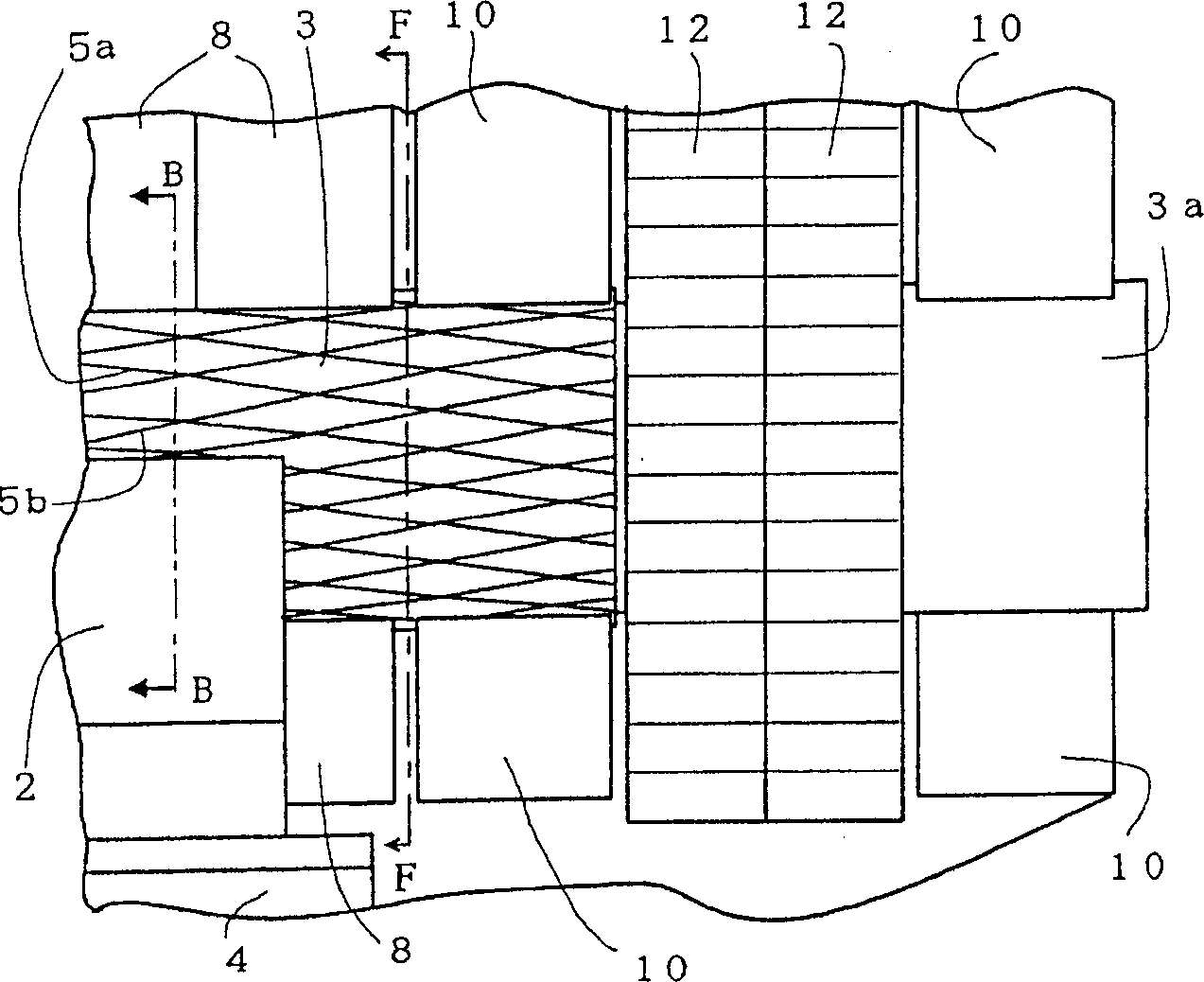

[0049] figure 2 is in figure 1 The front explanatory view with the log 1 removed and a part omitted, viewed from the direction of the dot-dash line E-E arrow; image 3 Yes figure 2 Partial enlargement near the right. by figure 2 and image 3 As shown, the roller bar 3 is arranged parallel to the tip of the tool 2 .

[0050] Figure 4 Yes image 3 Partial front view of the end of middle roll bar 3; Figure 5 From Figure 4 An enlarged explanatory diagram of a partial cross-sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com