Integral wood processing system

A processing system and wood technology, applied in wood processing equipment, manufacturing tools, bark, etc., can solve the problems affecting plate processing, slow cutting speed, inconsistent cutting length, etc., to improve production efficiency and product quality, reduce production Cost, reduction of operator effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

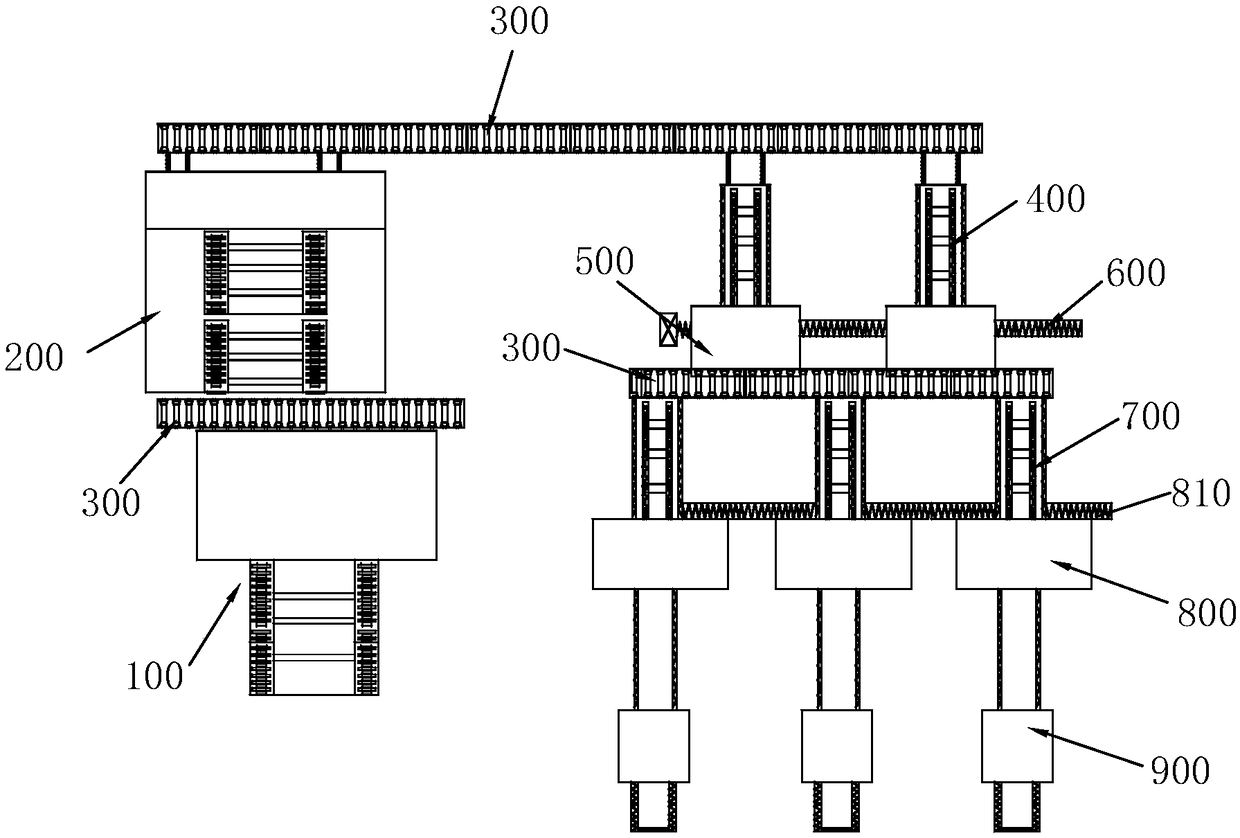

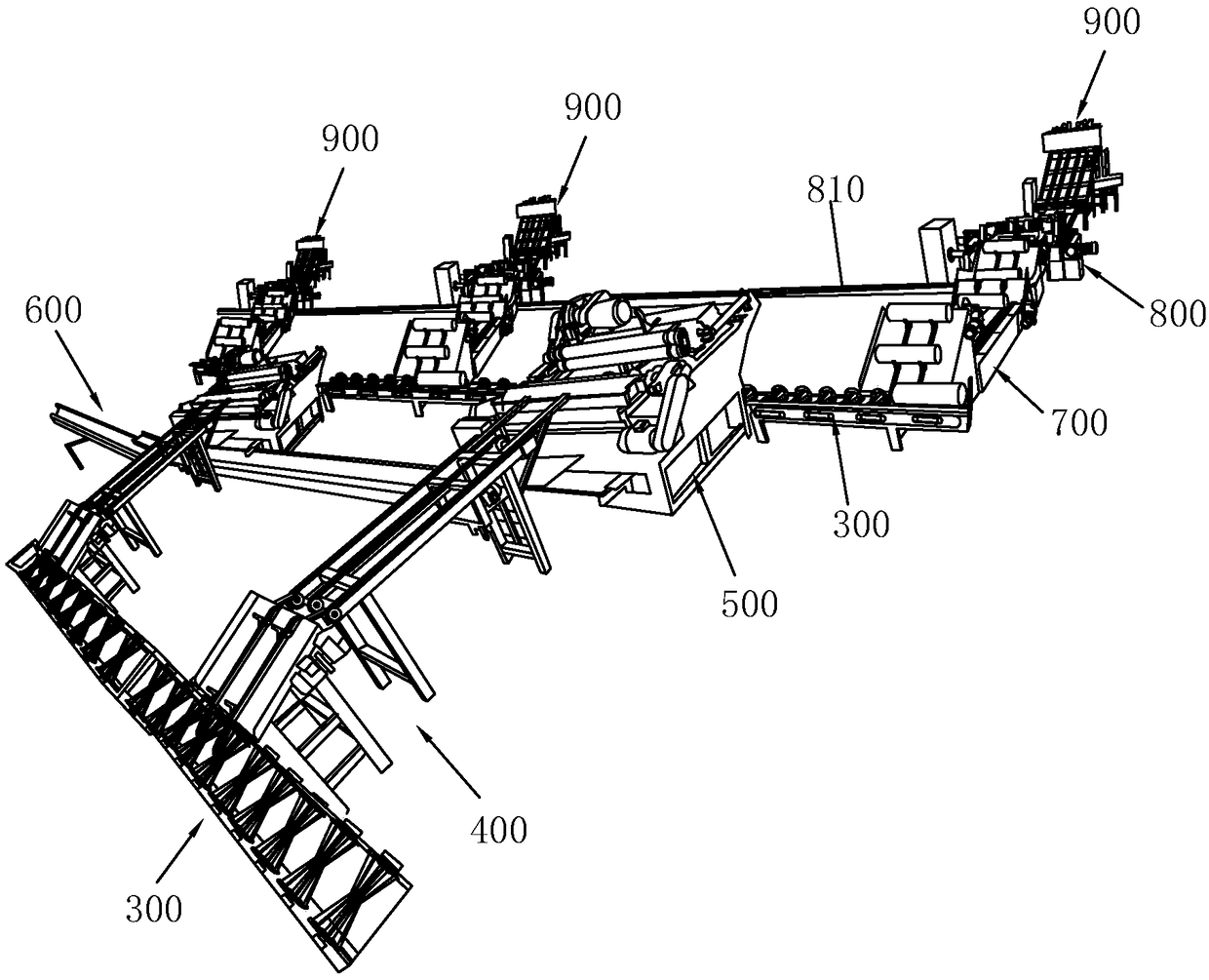

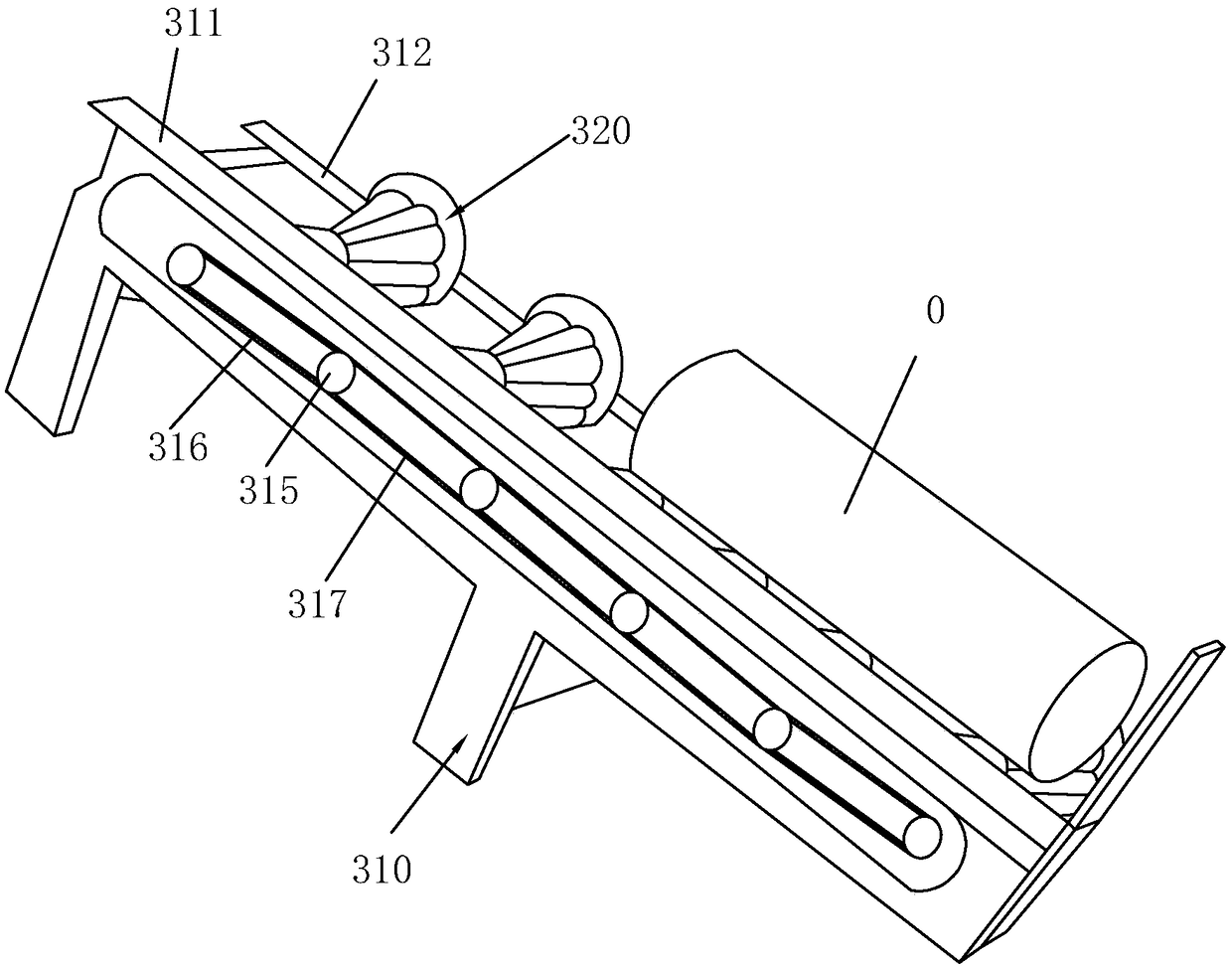

[0022] Such as figure 1 with figure 2 As shown, the integrated wood processing system of the present invention includes a round log feeding device 100, a sorting and cutting device 200, a pulsator type wood conveying device 300, a transport connecting device 400, a throwing and rounding device 500, a waste lifting device 600, Wave-type feeding device 700, high-speed rotary slicing device 800, and waste removal device 900. The round log feeding device 100 is used for manual initial loading of the round logs. After the round logs to be processed are manually moved to the round log feeding device 100, the round log feeding device 100 will transfer them to the next process. bit.

[0023] Such as figure 1 with figure 2As shown, the round log feeding device 100 and the sorting and cutting device 200 are matched and connected through the pulsating wood conveying device 300, and the rear end of the sorting and cutting device 200 is also matched with a pulsating wood conveying de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com