Round stick processing machinery

A technology for processing machinery and round wood bars, which is applied in the field of processing machinery for processing round wood bars of different specifications, can solve the problems of unadjustable feeding speed of round bar machines, reduced product qualification rate, complicated operation, etc., so as to ensure the utilization rate of raw materials, Increase the processing range and eliminate the effect of gap shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

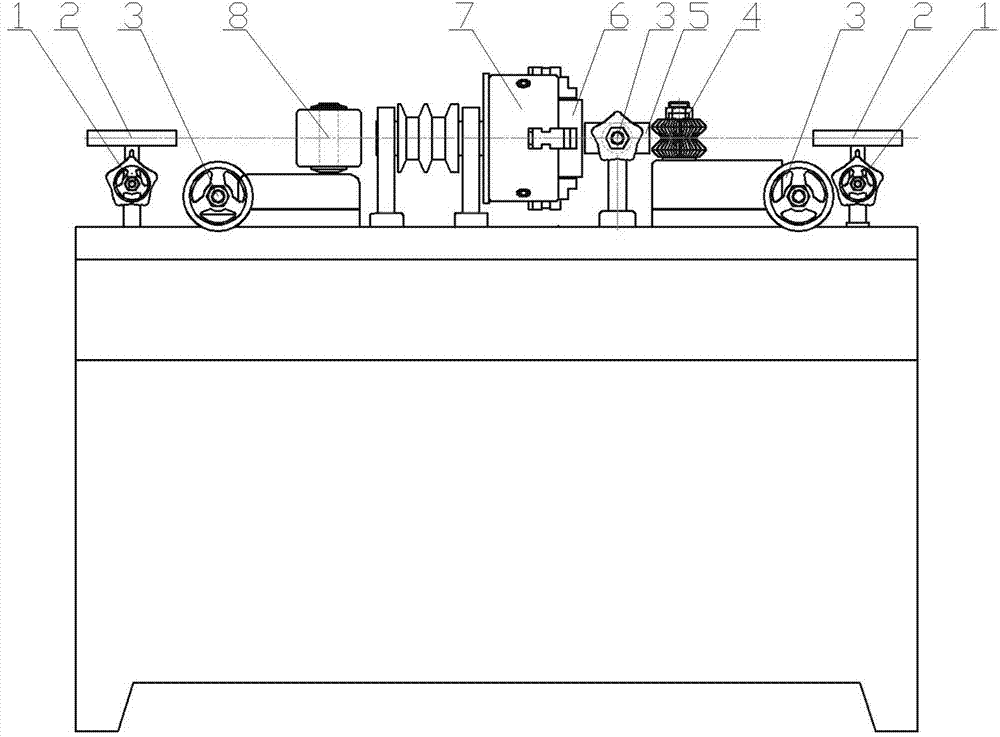

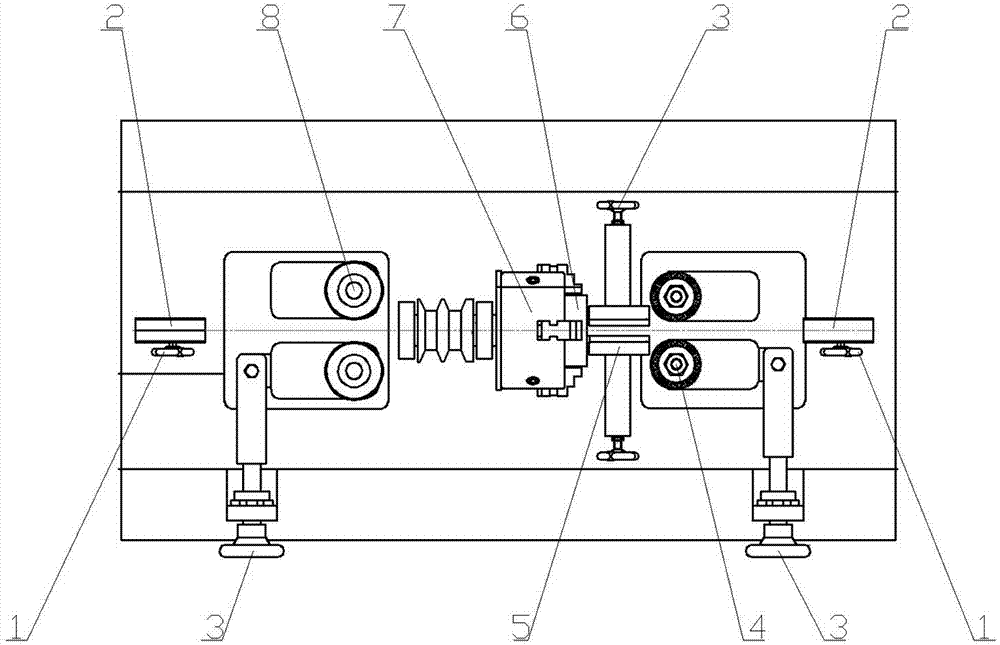

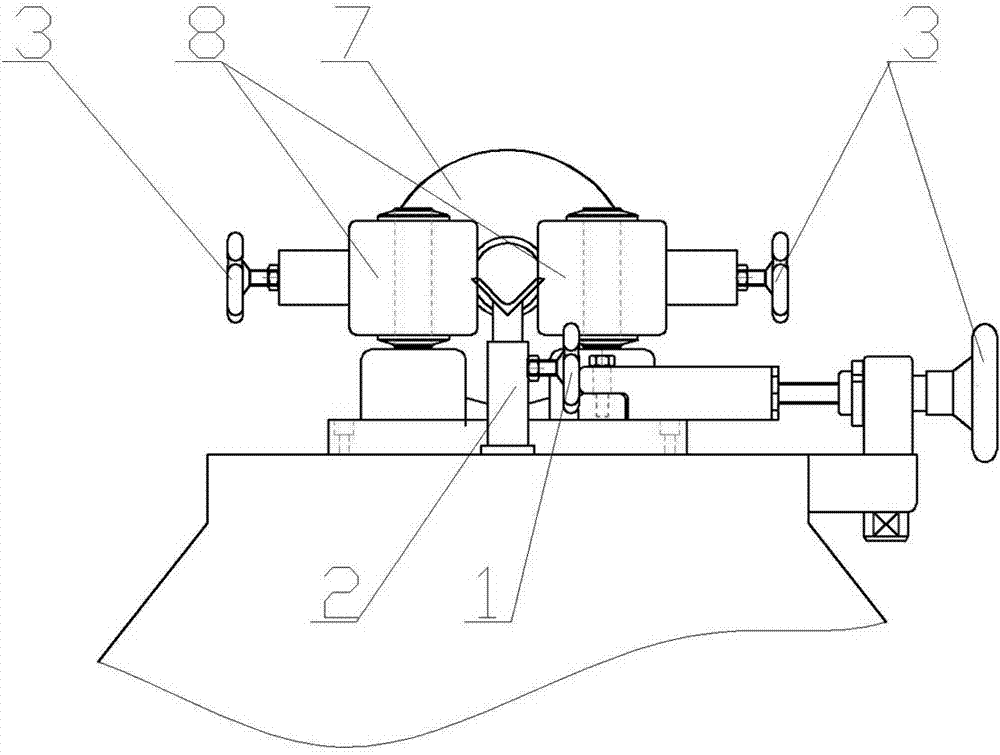

[0020] The structure of round wood rod processing machinery is as follows: figure 1 , 2 , 3 and 4 are composed of a support frame 2 installed on the workbench of the round wood processing machine, a feed clamping roller 4, a V-shaped guide clamp 5, a processing tool 6, a three-claw disc 7 and a dial wheel 8. .

[0021] The structure of processing tool 6 is as Figure 5 , the center of the tool is a material passing hole 9 matching the diameter of the round wooden rod to be processed, and the front end of the tool is provided with cutter teeth 10. The processing tool 6 is fixed at the axis position of the three-jaw disc 7 .

[0022] The front and rear ends of the workbench are respectively provided with support racks 2 for lifting the wooden sticks to be processed and the processed round wooden sticks. The support rack 2 is provided with a support rack adjustment hand wheel 1 for adjusting the position of the support rack. .

[0023] The place ahead of processing tool 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com