Rod rounding machine cutter

A round bar machine and cutting tool technology, applied in the direction of rotary machines, manufacturing tools, rotary cutting tools, etc., can solve the problems of round bar fluffing and large cutting resistance, and reduce cutting resistance, improve production efficiency, and achieve high smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

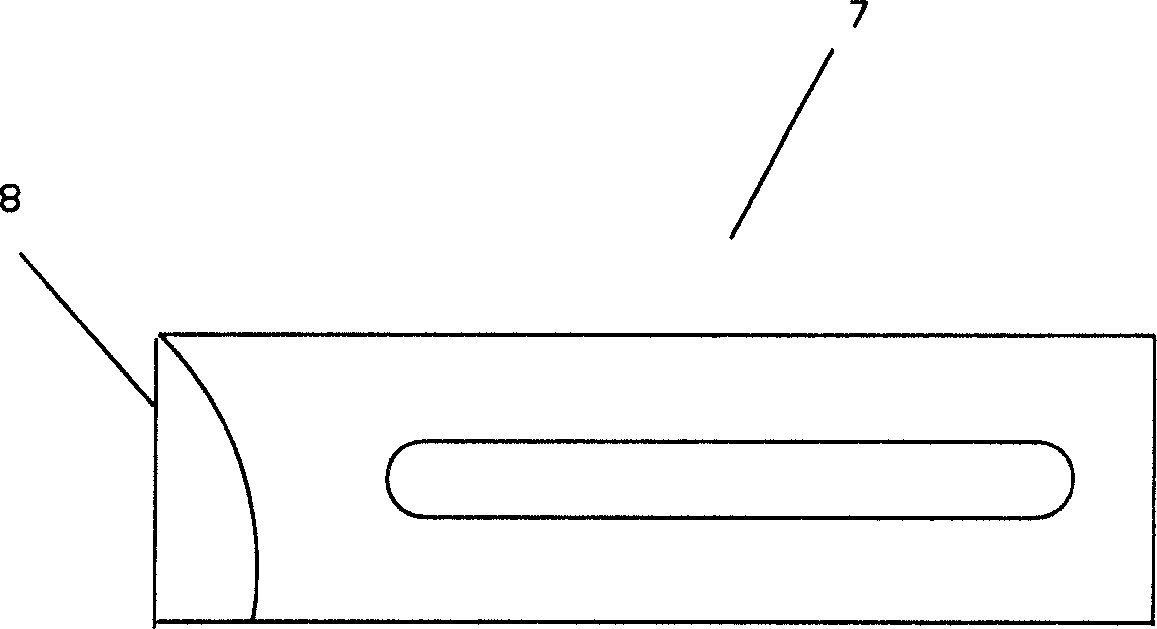

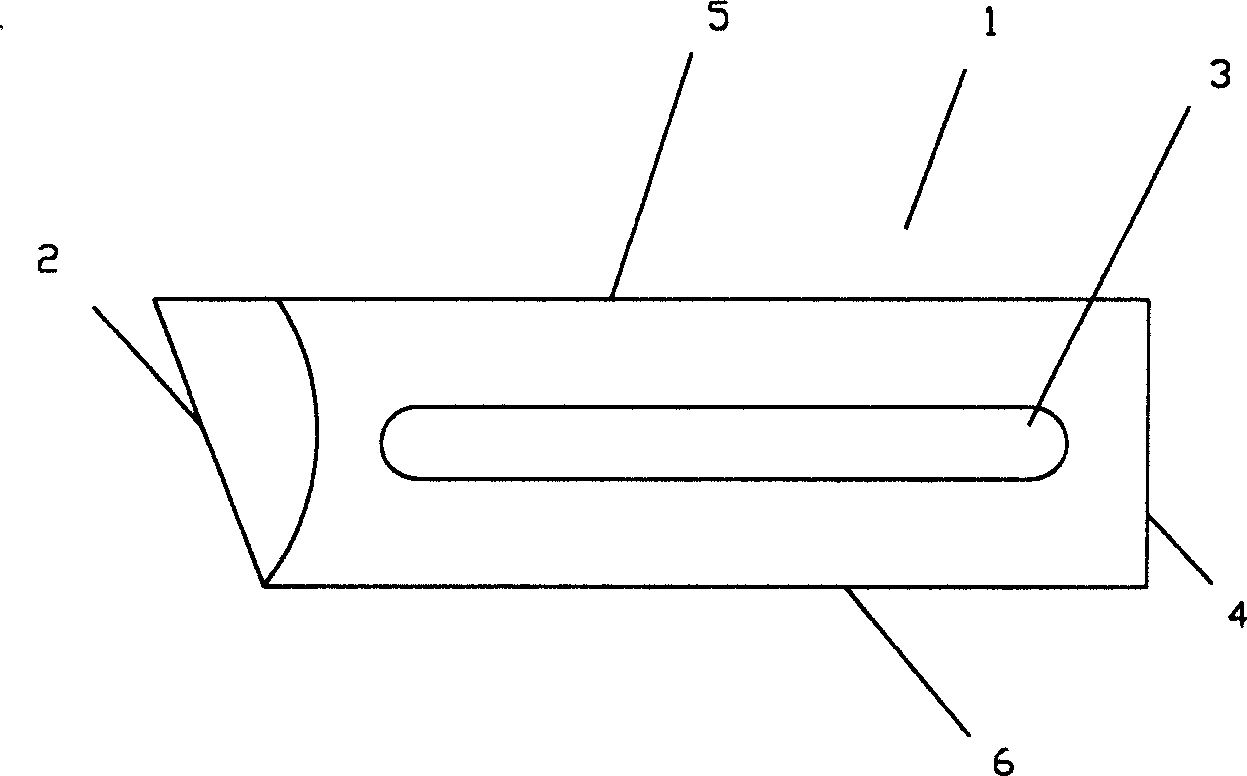

[0014] see figure 2 , figure 2 Shown is a structural diagram of the present invention, a round bar machine tool, including a tool body 1, the tool body 1 includes a knife edge 2, the knife edge 2 is an angled knife edge 2, the knife edge 2 and the tool body 1. The included angle in the parallel direction of the bottom surface is an acute angle. In this embodiment, the length of the long side 5 is 74mm, the length of the short side 6 is 52mm, and the length of the bottom surface 4 is 30mm; at the same time, the blade edge 2 is adjusted according to the difference in wood processing. acute angle.

[0015] The central portion of the tool body 1 is provided with an adjustment mounting hole 3, the cross-sectional shape of the adjustment mounting hole 3 is that the two ends are arc-shaped, and the middle part is a long strip shape. In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com