Improved MicroUSB (universal serial bus) interface and manufacturing method thereof

An improved, interface technology, applied in the field of usb interface, can solve problems such as shell cracking, and achieve the effect of increasing the solder area, avoiding high production costs, and increasing the stability of the solder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below and described in detail with accompanying drawings.

[0048] In order to overcome the high production cost and complicated process caused by the Insert Molding process; the solder feet of the product are easily deformed and many other poor quality. The invention proposes an improved assembly structure, that is, high-strength flat terminals are directly assembled into the colloid, and no vertical injection molding machine is needed for insert molding, which avoids the problems of high production cost and unstable quality caused by the insert molding process.

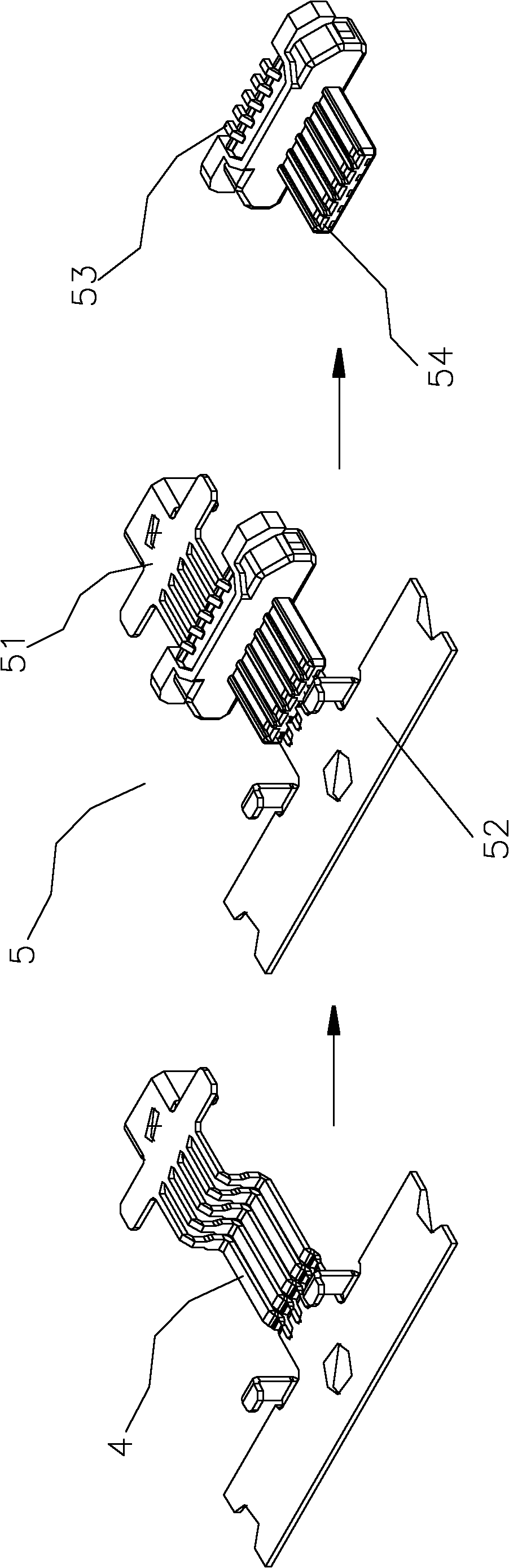

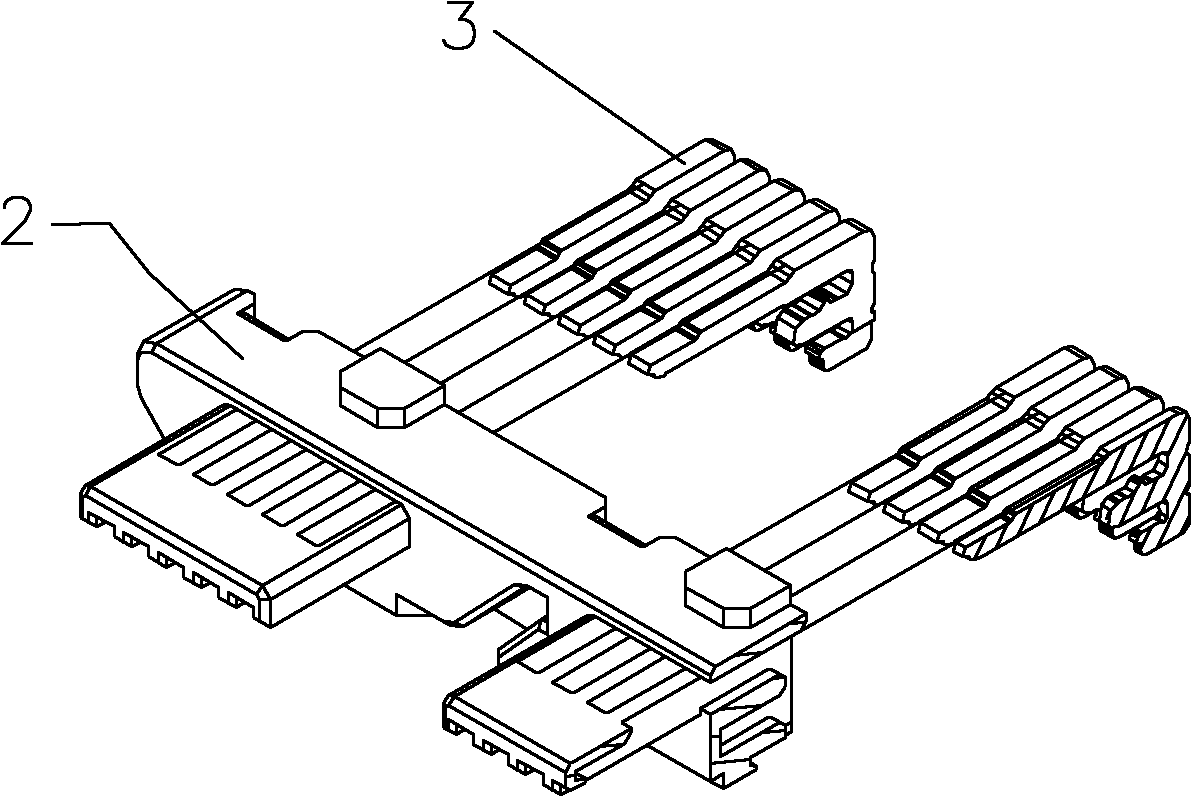

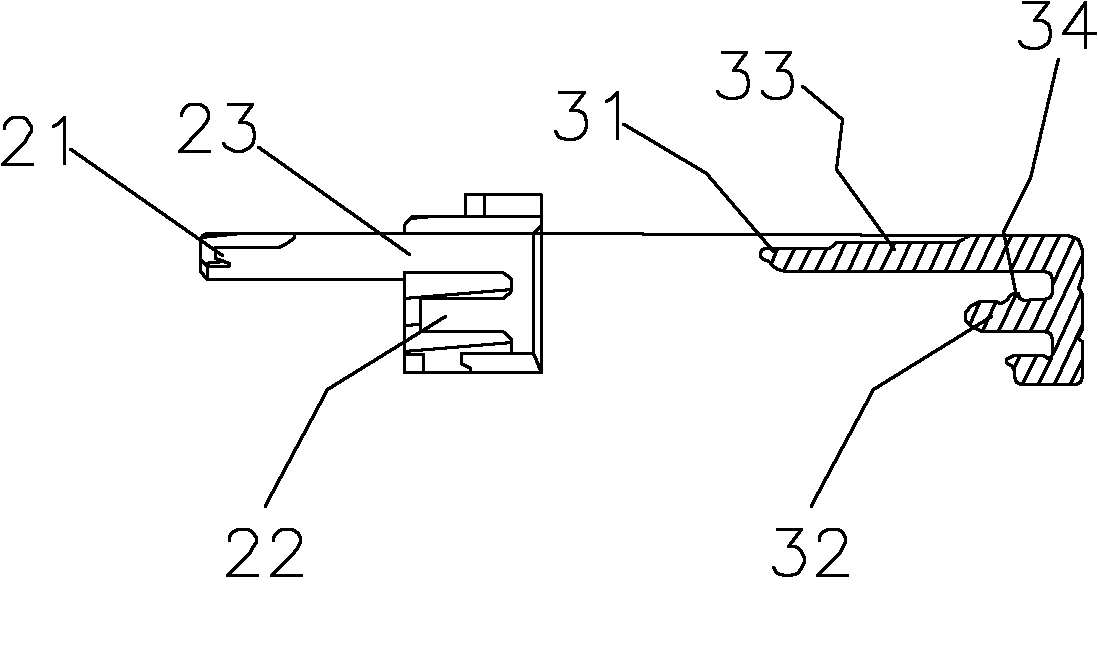

[0049] Such as Figure 2a , Figure 2b and Figure 2c As shown, it is the assembly structure of a specific embodiment of the improved Micro USB of the present invention. The terminal 3 is inserted into the colloid 2 in parallel, wherein the colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com