Preparation method of salmon viscus fish oil

A technology of salmon and viscera, which is applied in the field of preparation of salmon viscera fish oil, can solve the problems of lower oil extraction rate, turbid oil body, obvious fishy smell, etc., improve sensory properties and quality, reduce oxidative rancidity, and overcome incomplete extraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

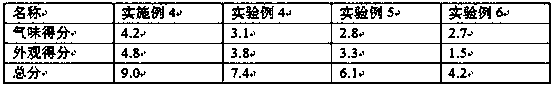

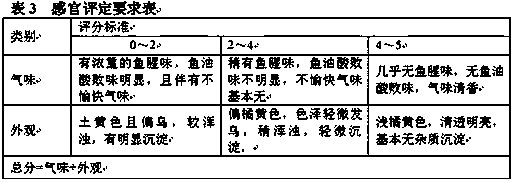

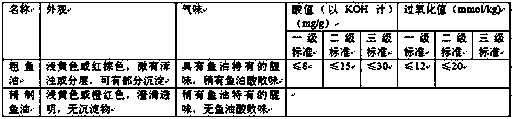

Examples

Embodiment 1

[0033] A preparation method of salmon offal fish oil, the steps are as follows:

[0034] (1) Raw material pretreatment: Take about 2 kg of fresh salmon viscera to remove the gallbladder and swim bladder, squeeze out the feces in the fish intestines, cut them into small pieces of 1-3 cm, weigh 1.82 kg, and set aside.

[0035] (2) One stage of enzymatic hydrolysis: mix the visceral tissue obtained in step (1) with water at a mass ratio of 1:0.5, add 1.0wt% calcium chloride based on the mass of water added, and the amount of lipase added is based on the mass of the reaction system Measure 100u / g, enzymolysis temperature is 40°C, pH 7.0, let stand for 2 hours, then heat at 90°C for 10 minutes to inactivate the enzyme, cool to below 25°C, centrifuge at 6000r / min for 15min, collect the crude fish oil in the upper layer.

[0036] (3) Two-stage enzymatic hydrolysis: The remaining reaction system after collecting fish oil in step (2) is subjected to proteolysis. Add animal protease to...

Embodiment 2

[0039] A preparation method of salmon offal fish oil, the steps are as follows:

[0040] (1) Raw material pretreatment: Take 1.5Kg of frozen salmon viscera, thaw, remove the gallbladder and swim bladder, squeeze out the feces in the fish intestines, weigh 1.3Kg, and set aside.

[0041](2) One stage of enzymatic hydrolysis: mix the visceral tissue obtained in step (1) with water at a mass ratio of 1:2, add 1.3wt% calcium chloride based on the mass of water added, and the amount of lipase added is based on the mass of the reaction system Total 160u / g, enzymolysis temperature is 55°C, enzymolysis is 1h at pH 8.5, stirring continuously during enzymolysis, stirring speed is 80r / min; Centrifuge at 6000r / min for 15min to collect the crude fish oil in the upper layer.

[0042] (3) Two-stage enzymatic hydrolysis: The remaining reaction system after collecting fish oil in step (2) is subjected to proteolysis. Add animal protease to the reaction system, the addition amount is 2500 u / g ...

Embodiment 3

[0045] A preparation method of salmon offal fish oil, the steps are as follows:

[0046] (1) Raw material pretreatment: Take 1.5Kg of frozen salmon viscera, thaw, remove the gallbladder and swim bladder, squeeze out the feces in the fish intestines, weigh 1.25Kg, and set aside.

[0047] (2) One stage of enzymatic hydrolysis: Mix the visceral tissue obtained in step (1) with water at a mass ratio of 1:2, add 1.2wt% calcium chloride based on the mass of water added, and the amount of lipase added is based on the mass of the reaction system Total 160u / g, enzymolysis temperature is 55°C, enzymolysis is 1h at pH 8.5, stirring is continued during the enzymolysis process, stirring speed is 100r / min; after enzymolysis, heat at 95°C for 5min to inactivate the enzyme, and cool within 20min After reaching below 25°C, centrifuge at 6000r / min for 15min to collect the crude fish oil in the upper layer.

[0048] (3) Two-stage enzymatic hydrolysis: The remaining reaction system after collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com