Method for extracting magnetic particles from honeybee

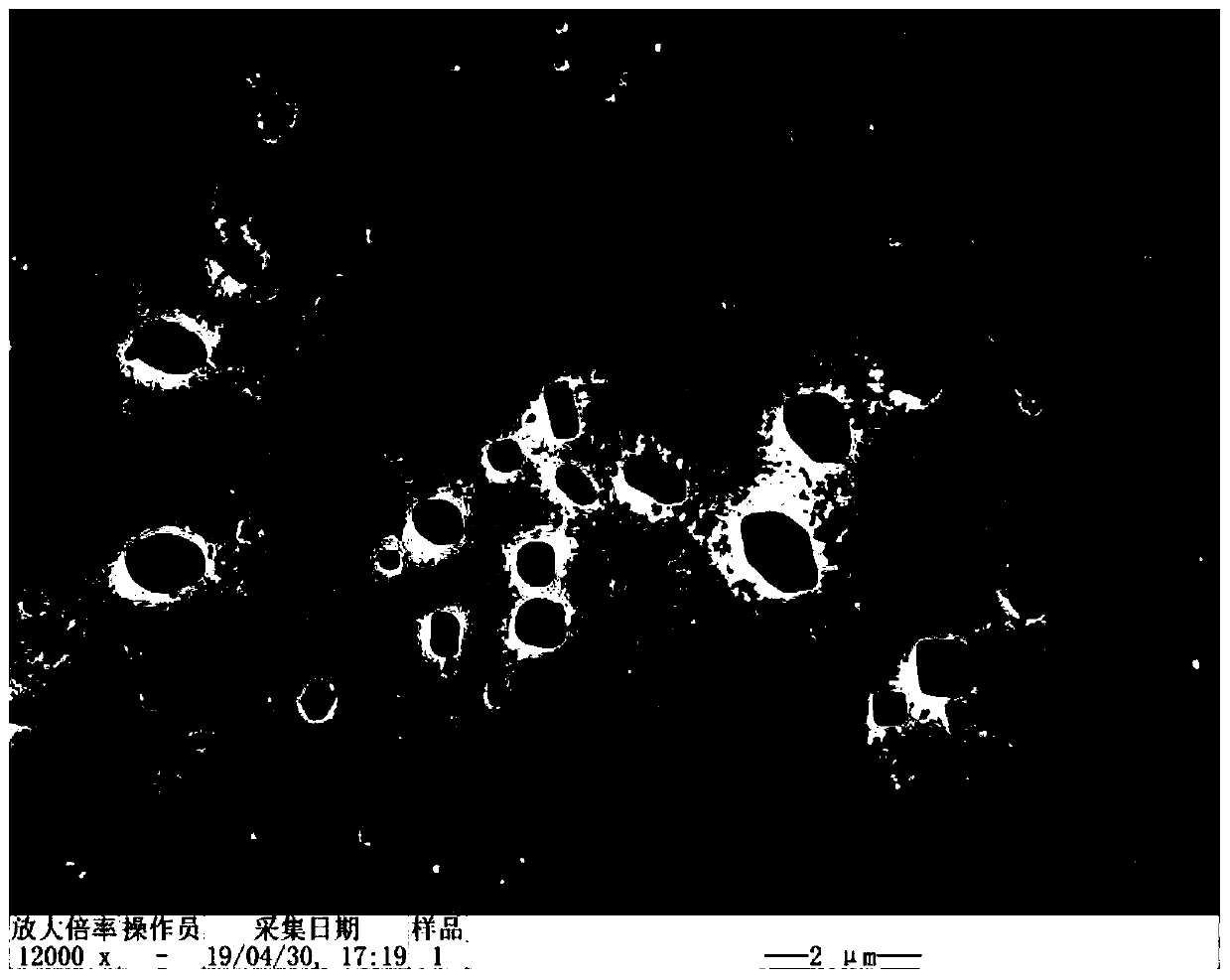

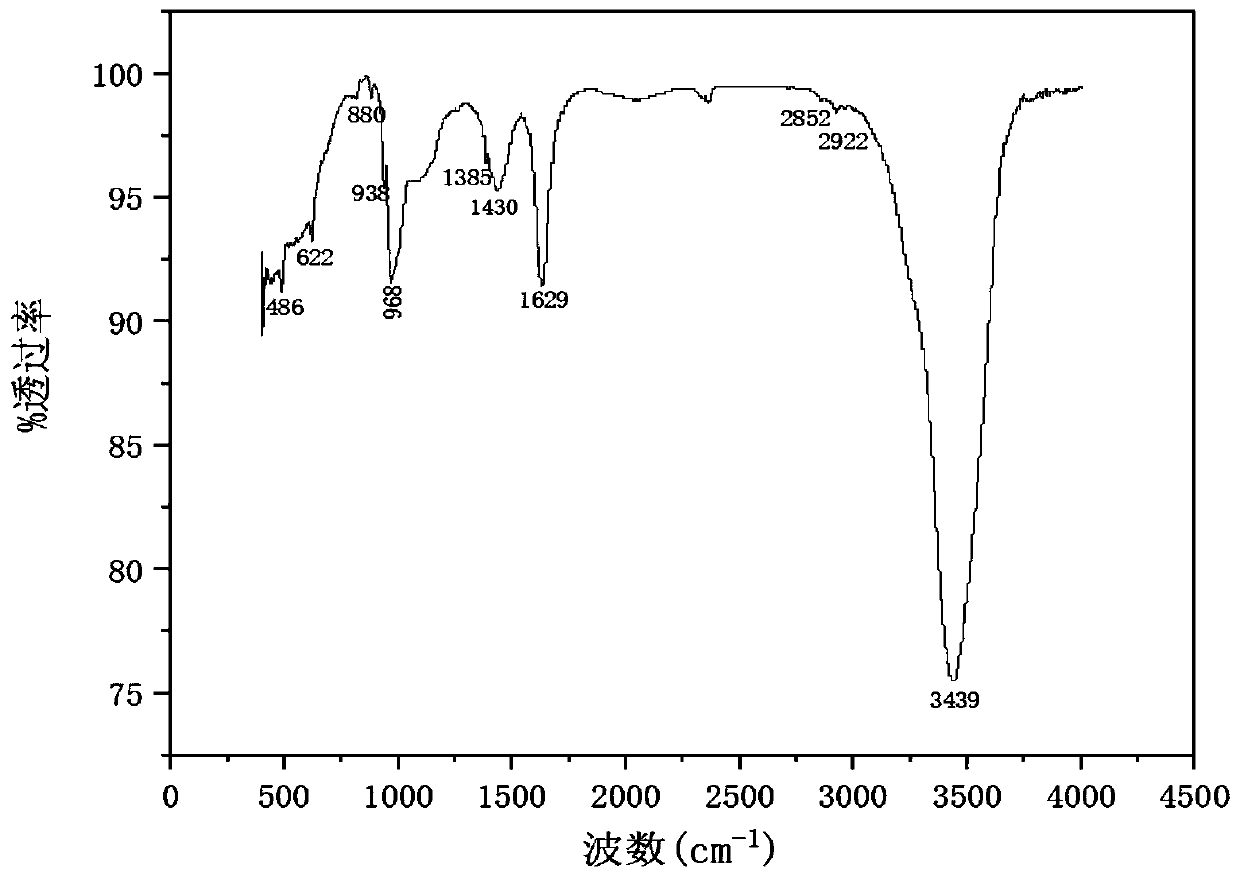

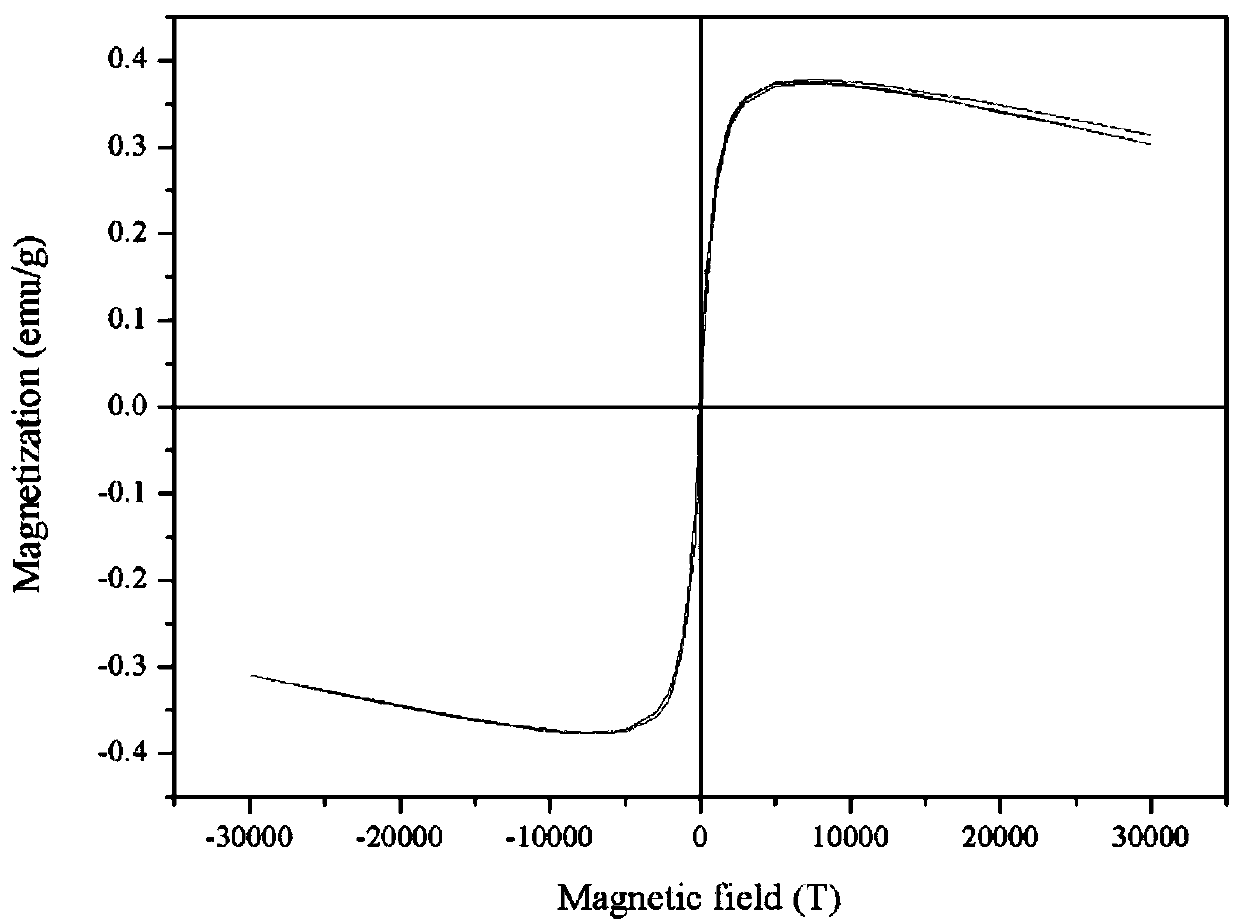

An extraction method and magnetic particle technology, which is applied in the field of magnetic particle extraction in bees, can solve the problems of low extraction rate and complicated operation of magnetic particles, and achieve the effect of overcoming long extraction period, good monodispersity and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Honeybee pretreatment: the honeybee is washed with 80% (v / v) ethanol solution and then dried, the head and chest are removed, and the abdomen is taken.

[0049] 2) Liquid nitrogen grinding treatment: the bee abdomen obtained in step 1) was placed in a mortar and continuously added with liquid nitrogen, and ground for 4-6 minutes until it was completely powdered.

[0050] 3) Sodium hypochlorite solution treatment: put the honeybee abdomen powder obtained in step 2) and the sodium hypochlorite solution containing PMSF at a mass ratio of 1:2 in a 2ml centrifuge tube, and soak at 4°C for 48h. In the sodium hypochlorite solution, the mass fraction of sodium hypochlorite is 4.2%. The concentration of PMSF was 8 mg / L.

[0051] 4) Extraction of magnetic particles by high-speed centrifugation: centrifuge the honeybee abdomen powder treated in 3) at a speed of 7000rpm for 6min, pour off the supernatant, and add a sodium hypochlorite solution with a mass fraction of 4.2% (whic...

Embodiment 2

[0055] 1) Honeybee pretreatment: the honeybee is washed with 80% (v / v) ethanol solution and then dried, the head and chest are removed, and the abdomen is taken.

[0056] 2) Liquid nitrogen grinding treatment: the bee abdomen obtained in step 1) was placed in a mortar and continuously added with liquid nitrogen, and ground for 4-6 minutes until it was completely powdered.

[0057] 3) Sodium hypochlorite solution treatment: put the honeybee belly powder obtained in step 2) and the sodium hypochlorite solution containing PMSF at a mass ratio of 1:2 in a 2ml centrifuge tube, soak at 4°C for 72h. In the sodium hypochlorite solution, the mass fraction of sodium hypochlorite is 6.3%, and the concentration of PMSF is 8mg / L.

[0058] 4) Extraction of magnetic particles by high-speed centrifugation: Centrifuge the honeybee abdomen powder treated in 3) at a speed of 9000rpm for 8min, pour off the supernatant, and add a sodium hypochlorite solution with a mass fraction of 6.3% (which con...

Embodiment 3

[0062] 1) Honeybee pretreatment: the honeybee is washed with 80% (v / v) ethanol solution and then dried, the head and chest are removed, and the abdomen is taken.

[0063] 2) Liquid nitrogen grinding treatment: the bee abdomen obtained in step 1) was placed in a mortar and continuously added with liquid nitrogen, and ground for 4-6 minutes until it was completely powdered.

[0064] 3) Sodium hypochlorite solution treatment: the bee belly powder obtained in step 2) and the sodium hypochlorite solution containing PMSF were placed in a 2mL centrifuge tube at a mass ratio of 1:2, and soaked at 4°C for 96h. In the sodium hypochlorite solution, the mass fraction of sodium hypochlorite is 8.4%, and the concentration of PMSF is 8 mg / L.

[0065] 4) Extraction of magnetic particles by high-speed centrifugation: Centrifuge the honeybee abdomen powder treated in 3) at a speed of 10000rpm for 10min, pour off the supernatant, and add a sodium hypochlorite solution with a mass fraction of 8.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com