Continuous preparation method of antioxidant 1076

A technology of antioxidant and catalyst, which is applied in the field of continuous preparation of antioxidant 1076, which can solve the problems of high equipment requirements, long reaction time, and high production cost, and achieve the effects of low equipment requirements, short reaction time, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

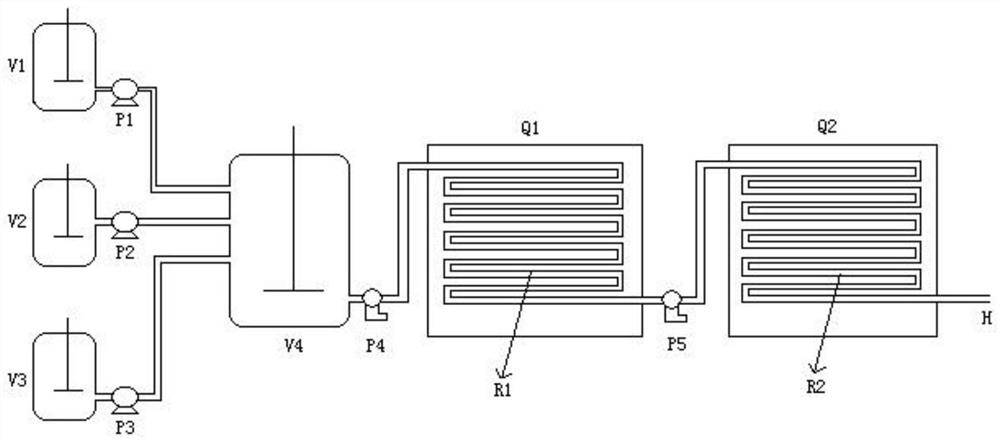

Method used

Image

Examples

Embodiment 1

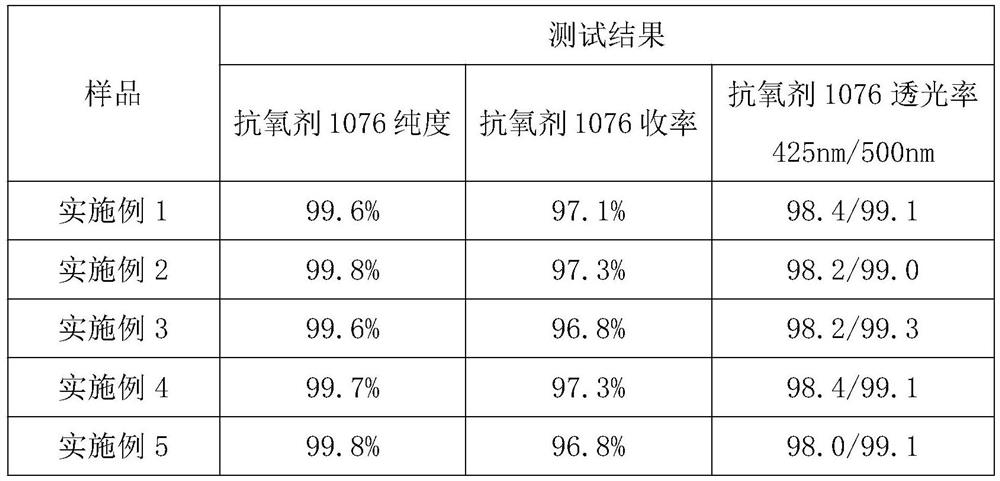

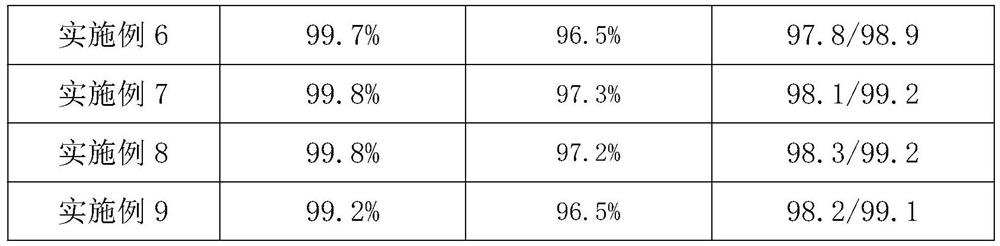

[0029] The molar ratio of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate to n-octadecyl alcohol is 1.1:1, the catalyst lithium amide and β-(3,5-di-tert-butyl) The mass ratio of methyl-4-hydroxyphenyl) propionate was 1:100, the temperature of the first tube reactor was 100°C, the pressure was 5bar, the residence time was 10min, the temperature of the second tube reactor was 150°C, and the pressure was 5bar, The residence time is 10min, the crude product of antioxidant 1076 is prepared by removing toluene, then adding methanol to fully dissolve, adding acetic acid to adjust the pH to neutrality, filtering and crystallizing at a constant temperature of 35 ° C to obtain the product of antioxidant 1076, the yield is 97.1%, through the gas phase Chromatographic analysis, the purity is 99.6%, and other test results are shown in Table 1.

Embodiment 2

[0031] The molar ratio of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate to n-octadecyl alcohol is 1.1:1, the catalyst sodium methoxide and β-(3,5-di-tert-butyl) The mass ratio of methyl-4-hydroxyphenyl) propionate was 1:100, the temperature of the first tube reactor was 150°C, the pressure was 1bar, the residence time was 30min, the temperature of the second tube reactor was 200°C, and the pressure was 1bar, Residence time 30min. Toluene was removed from the prepared 1076 crude product, methanol was added to fully dissolve it, acetic acid was added to adjust the pH to neutrality, acetic acid was added to adjust the pH to neutrality, and after filtration, the product was obtained by crystallization at a constant temperature of 45° C. to obtain antioxidant 1076 product with a yield of 97.3%. Gas chromatographic analysis, the purity is 99.8%, other test results are shown in Table 1.

Embodiment 3

[0033] The molar ratio of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate to n-octadecyl alcohol is 1.2:1, the catalyst lithium amide and β-(3,5-di-tert-butyl) The mass ratio of methyl-4-hydroxyphenyl) propionate was 1:100, the temperature of the first tube reactor was 150°C, the pressure was 1bar, the residence time was 30min, the temperature of the second tube reactor was 200°C, and the pressure was 1bar, Residence time 30min. Toluene was removed from the prepared 1076 crude product, methanol was added to fully dissolve it, formic acid was added to adjust the pH to neutrality, and after filtration, the product was crystallized at a constant temperature of 39 ° C to obtain antioxidant 1076 product, the yield was 96.8%, and the purity was 99.6% by gas chromatography analysis, Other test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com