Alum-free fresh and wet potato vermicelli and preparation method thereof

A technology of potato starch and potato, which is applied in the field of alum-free potato fresh wet vermicelli vermicelli and its preparation, can solve the problems of unfavorable production enterprises' actual operation, few types of modifiers, and many types of modifiers, etc., and achieve improved tensile strength. Strength and cooking resistance, low cost, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

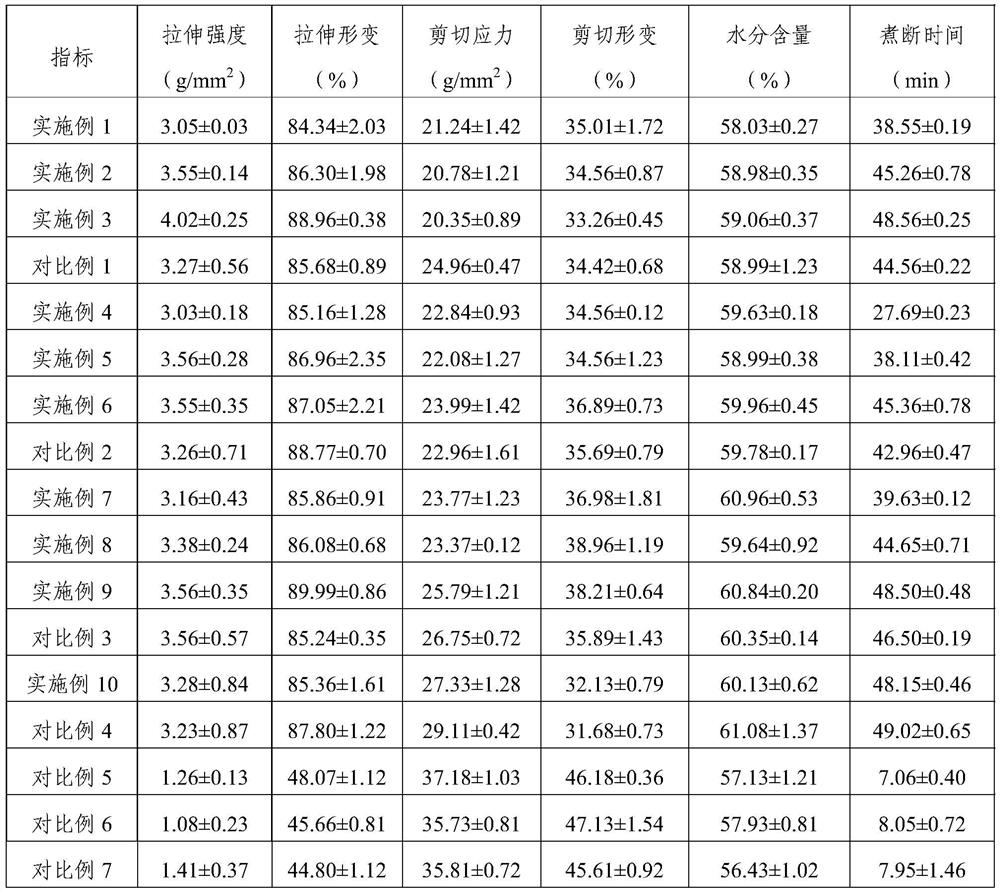

Examples

Embodiment 1

[0045]This embodiment provides an orthosary, fresh and damp fan, which is prepared from a weight of the following weight: 80 sweet potato starch, 0.5 parts of food grade sulfate, and water.

[0046]This embodiment also provides the preparation method of the above-mentioned non-Ming iodaro, fresh and damp fan, including the following steps:

[0047](1) Put 7% of the sweet potato starch, add 10 times the temperature of 65 ° C to a powder, and then constantly stirred in a water bath having a temperature of 97 ° C, form a starch paste;

[0048](2) Weigh food grade sulfate, add 5 times the temperature of its mass for room temperature, thoroughly stir the dissolution, and to obtain a hydrogen solution of minerals;

[0049](3) The starch paste is lowered to 45 ° C, which is mixed with the mineral saline solution and the remainder of sweet potato starch to form a uniform and smooth powder;

[0050](4) Put the powder group into the noodle machine, after extrusion, after 1 min in boiling water, remove it in...

Embodiment 2

[0052]This embodiment provides an orthosary, fresh and damp fan, prepared from the following weight of raw materials: 80 sweet potato starch, 0.6 parts of food grade calcium salt complex;

[0053]Among them, the food grade calcium salt complex is prepared from a method comprising the following steps: mixing food grade sulfate and food grade phosphate dilot potassium in w: w = 1: 1, dissolved in 650ml water After stirring at 25 ° C for 24 h, filtration, fresh deposit, dry to constant weight,

[0054]This embodiment also provides the preparation method of the above-mentioned non-Ming iodaro, fresh and damp fan, including the following steps:

[0055](1) Put 7% of the sweet potato starch, add 10 times the temperature of 65 ° C to a powder, and then constantly stirred in a water bath having a temperature of 97 ° C, form a starch paste;

[0056](2) Weigh the food-grade calcium salt complex, add 5 times the temperature of its mass to room temperature, thoroughly stir the dissolve, and the mineral sal...

Embodiment 3

[0060]This embodiment provides an unbamputted fresh-wet filament powder strip, prepared from the weight of the following weight: 80 sweet potato starch, 0.6 parts of food grade calcium magnesium salt complex;

[0061]Among them, the food grade calcium magnesium salt complex is prepared from a method comprising the following steps: calcium food grade sulfate, dihydrogen phosphate di potassium and food grade W: W: W = 1: 1: 0.3 The proportion was uniform, dissolved in 650 ml of water, stirred at 25 ° C for 24 h, filtrate, precipitate, dried to constant weight, ie.

[0062]This embodiment also provides the preparation method of the above-mentioned non-Ming iodaro, fresh and damp fan, including the following steps:

[0063](1) Put 7% of the sweet potato starch, add 10 times the temperature of 65 ° C to a powder, and then constantly stirred in a water bath having a temperature of 97 ° C, form a starch paste;

[0064](2) Weigh the food-grade calcium salt complex, add 5 times the temperature of its ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com