Patents

Literature

36results about How to "Increase color value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

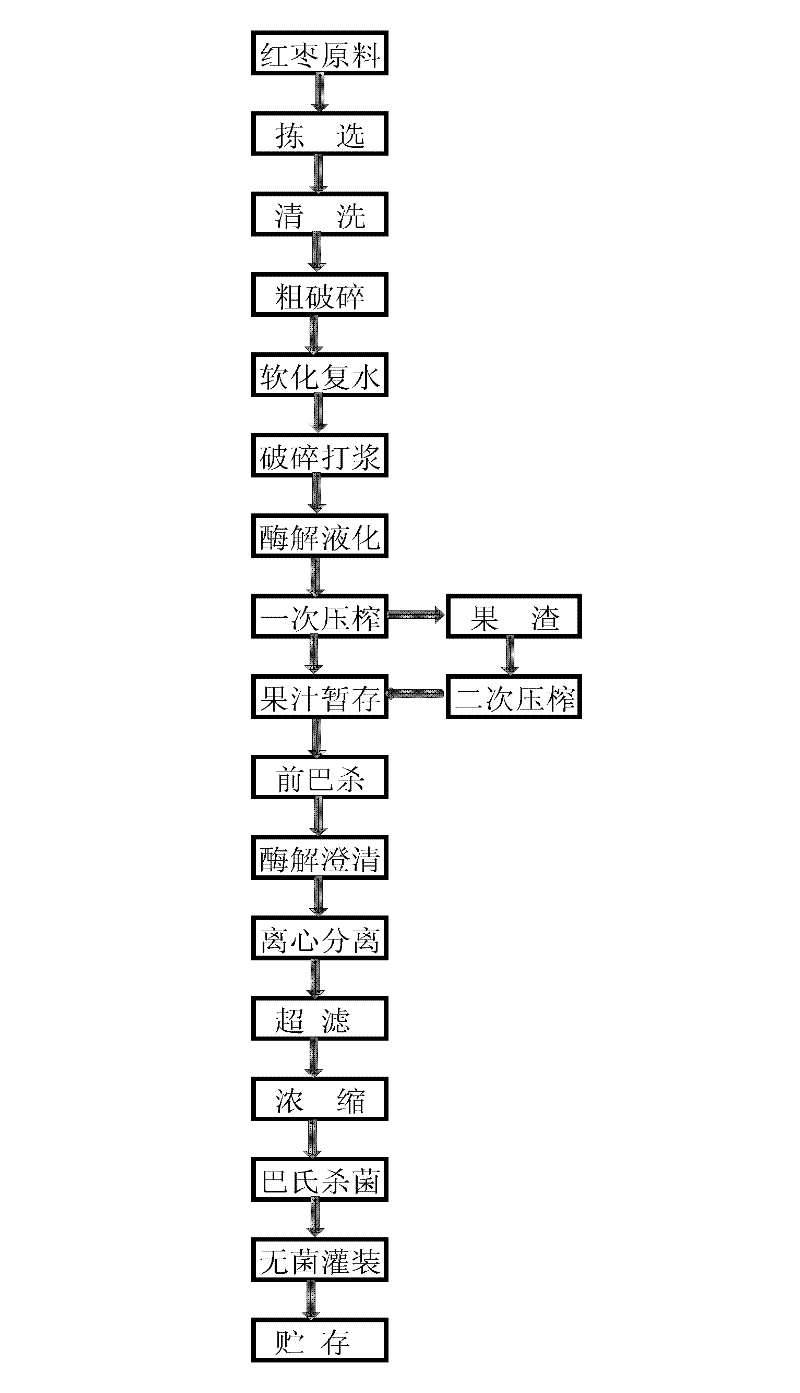

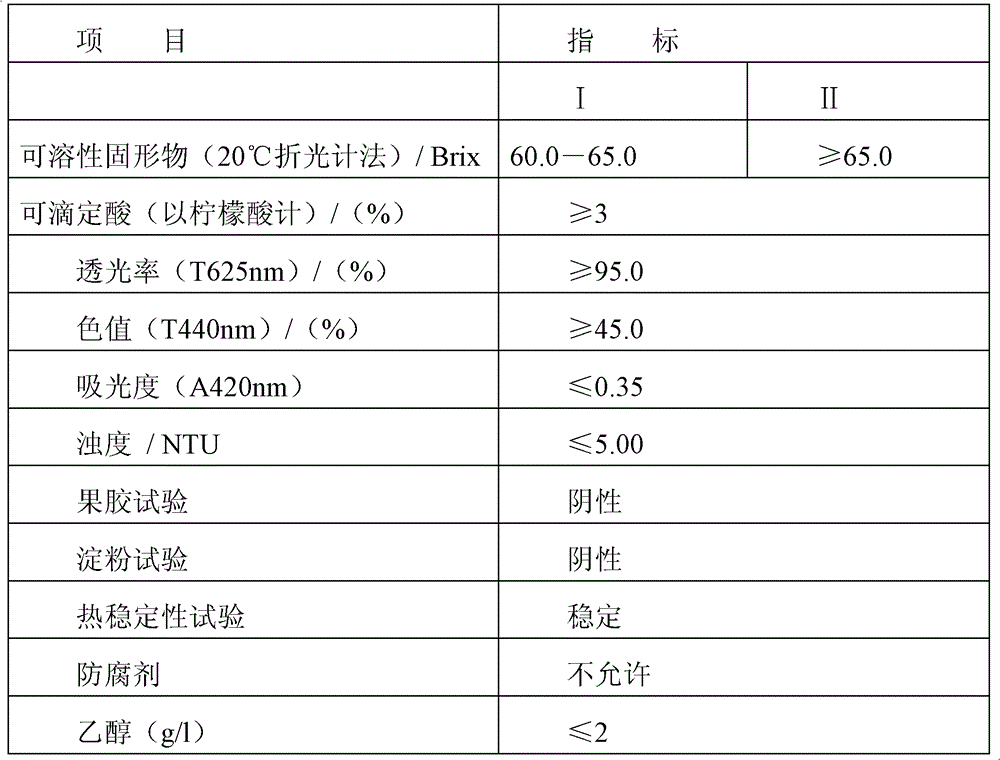

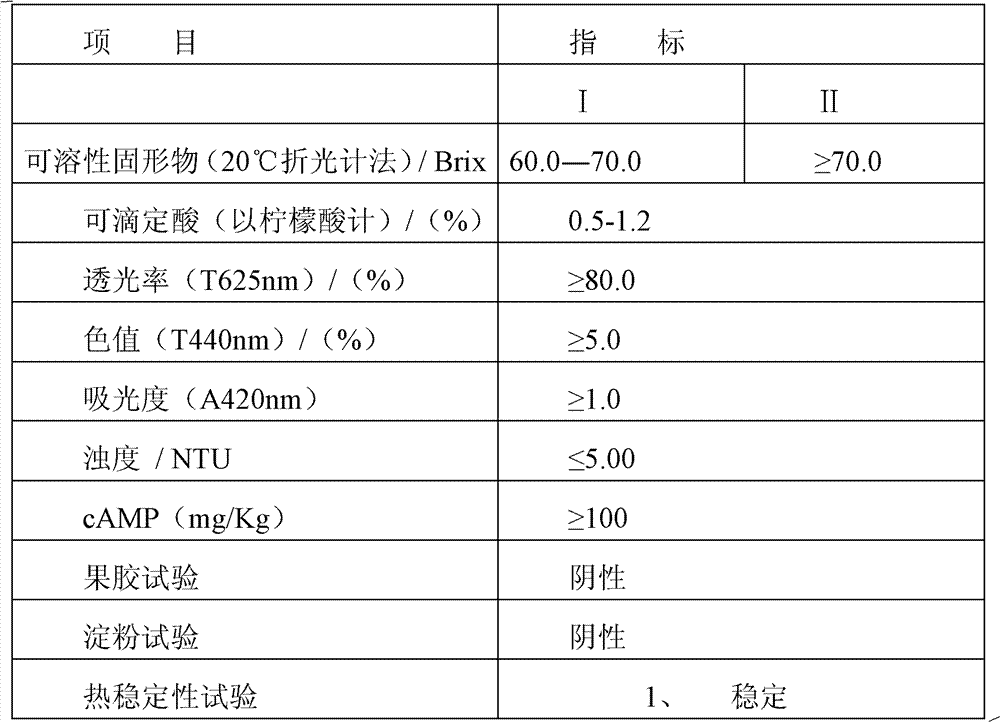

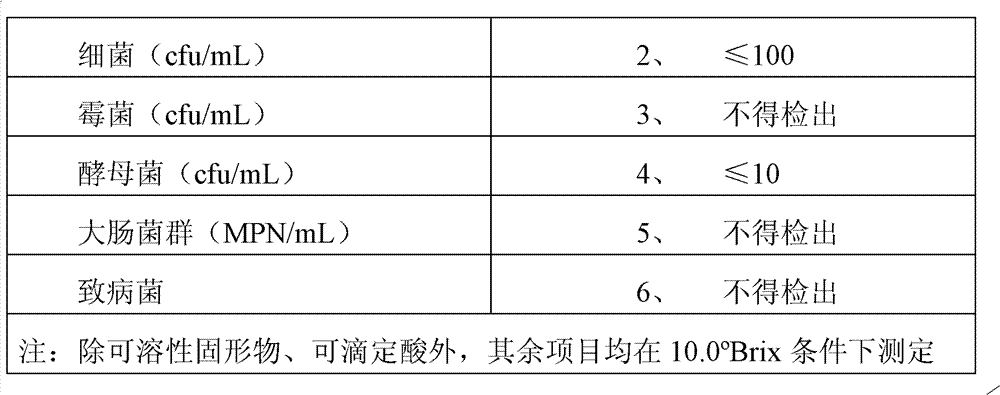

Method of preparing concentrated clear red jujube juice with high cAMP content

The invention discloses a method of preparing concentrated clear red jujube juice with high cAMP content, which comprises the following steps: taking out red jujube after rehydration, denucleating and then crushing pulp for preparing the red jujube thick liquid; conveying the red jujube after enzymolysis by pectinase into a juicer for squeezing, and filtering to obtain the red jujube juice; adding pectinase, amylase and cellulose into the red jujube juice for heat-preservation and enzymolysis for 60-90 minutes; and clearing, conducting concentration sterilization, and finally bulking. The concentrated clear red jujube juice prepared by the invention is clear and transparent, has the cAMP content being larger than or equal to 100 mg / Kg and soluble solid state material being larger than or equal to 60.0 Brix, is deposit-free and suspension-free, has brownish red color and does not have impurities which can be seen by naked eyes; and the concentrated juice is diluted to the soluble solidstate material being 60.0 Brix, and the juice has inherent fragrance and flavor of red jujubes and is free from extraneous odor.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

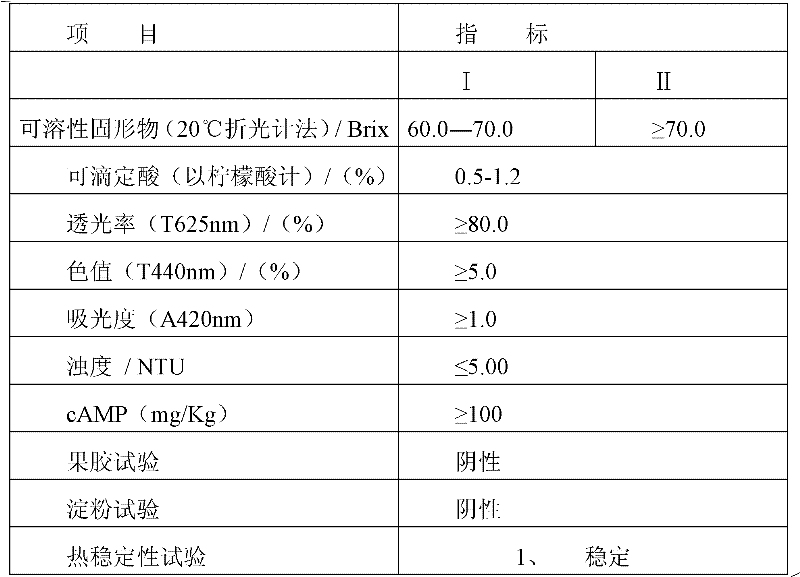

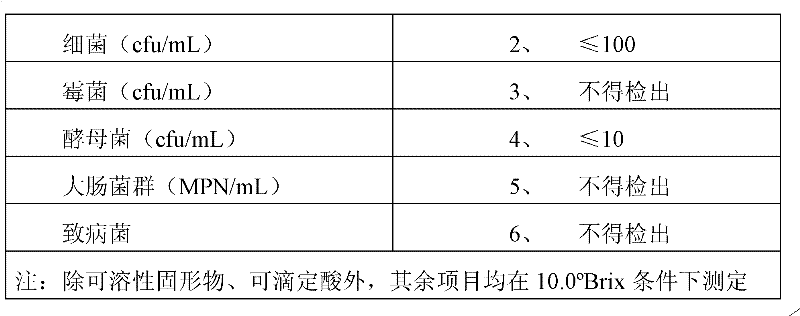

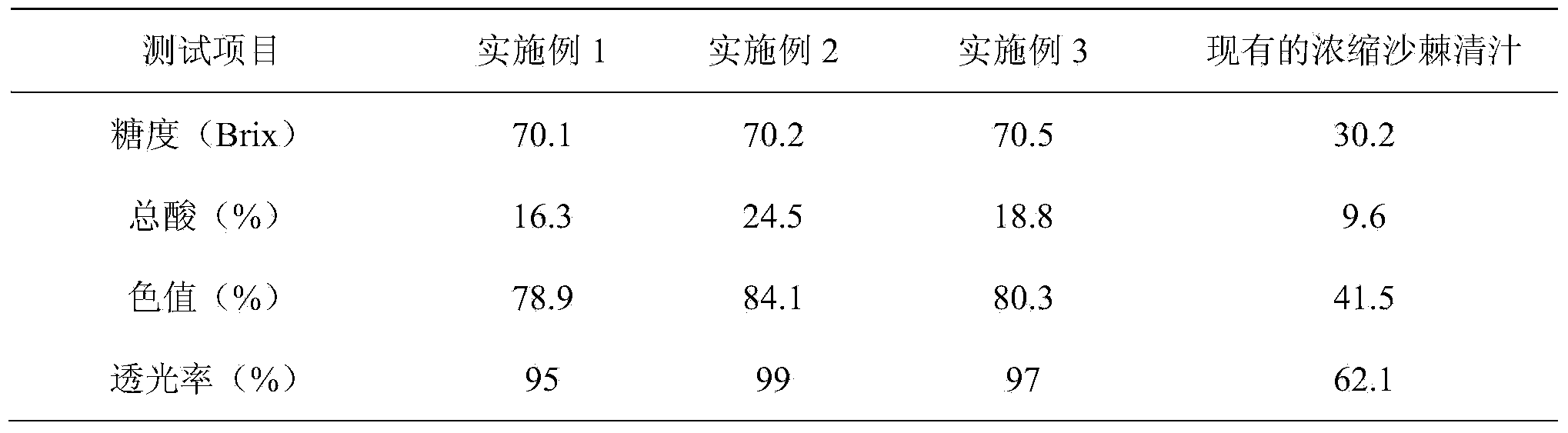

Concentrated sea-buckthorn clear juice and preparation method thereof

InactiveCN104366618AHigh extraction rateIncrease the sugar contentFood scienceFruit juiceEnzymatic hydrolysis

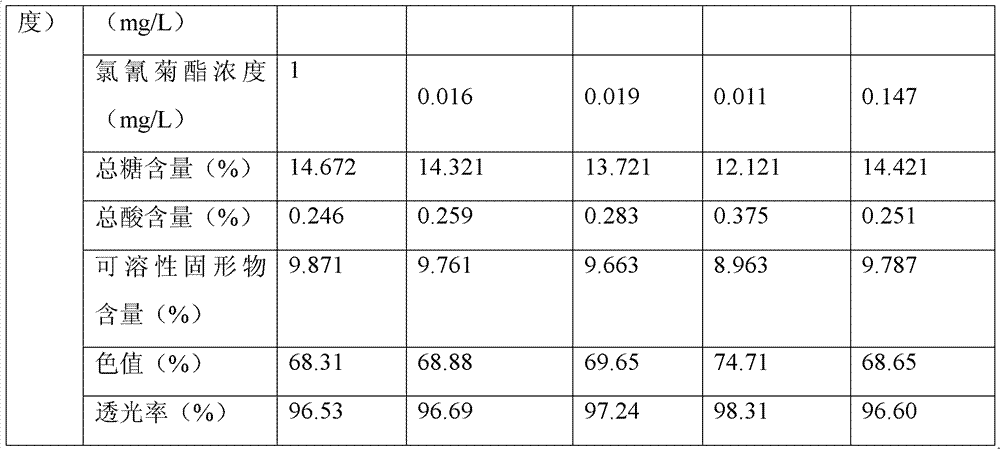

The invention discloses a concentrated sea-buckthorn clear juice and a preparation method thereof. The preparation method comprises the following steps: (1) washing, crushing, enzymatically hydrolyzing and squeezing sea-buckthorn fruits orderly, separating out fruit residue to obtain a raw sea-buckthorn juice, and rehydrating the fruit residue and squeezing again to obtain the raw sea-buckthorn juice; (2) pasteurizing the sea-buckthorn juice, adding an enzymic preparation for further enzymatic hydrolysis, and separating out the extracted sea-buckthorn fruit oil to obtain the sea-buckthorn juice; (3) orderly performing ultrafiltration, decoloration, reverse osmosis membrane concentration and concentration by use of a quadruple effect vacuum evaporator on the sea-buckthorn juice, thereby obtaining the concentrated sea-buckthorn clear juice. According to the preparation method of the concentrated sea-buckthorn clear juice, twice enzymatic hydrolysis, twice squeezing and twice concentration are adopted in the process of preparing the concentrated sea-buckthorn clear juice, and therefore, the fruit juice extraction rate is increased and nutritional ingredients in the fruit juice are not damaged and lost; meanwhile, the preparation method is energy-saving, low in consumption and low in production cost; the prepared sea-buckthorn clear juice has relatively high sugar degree, acidity, color value and light transmittance, and is stable in quality and easy to store.

Owner:承德宇航人高山植物应用技术有限责任公司

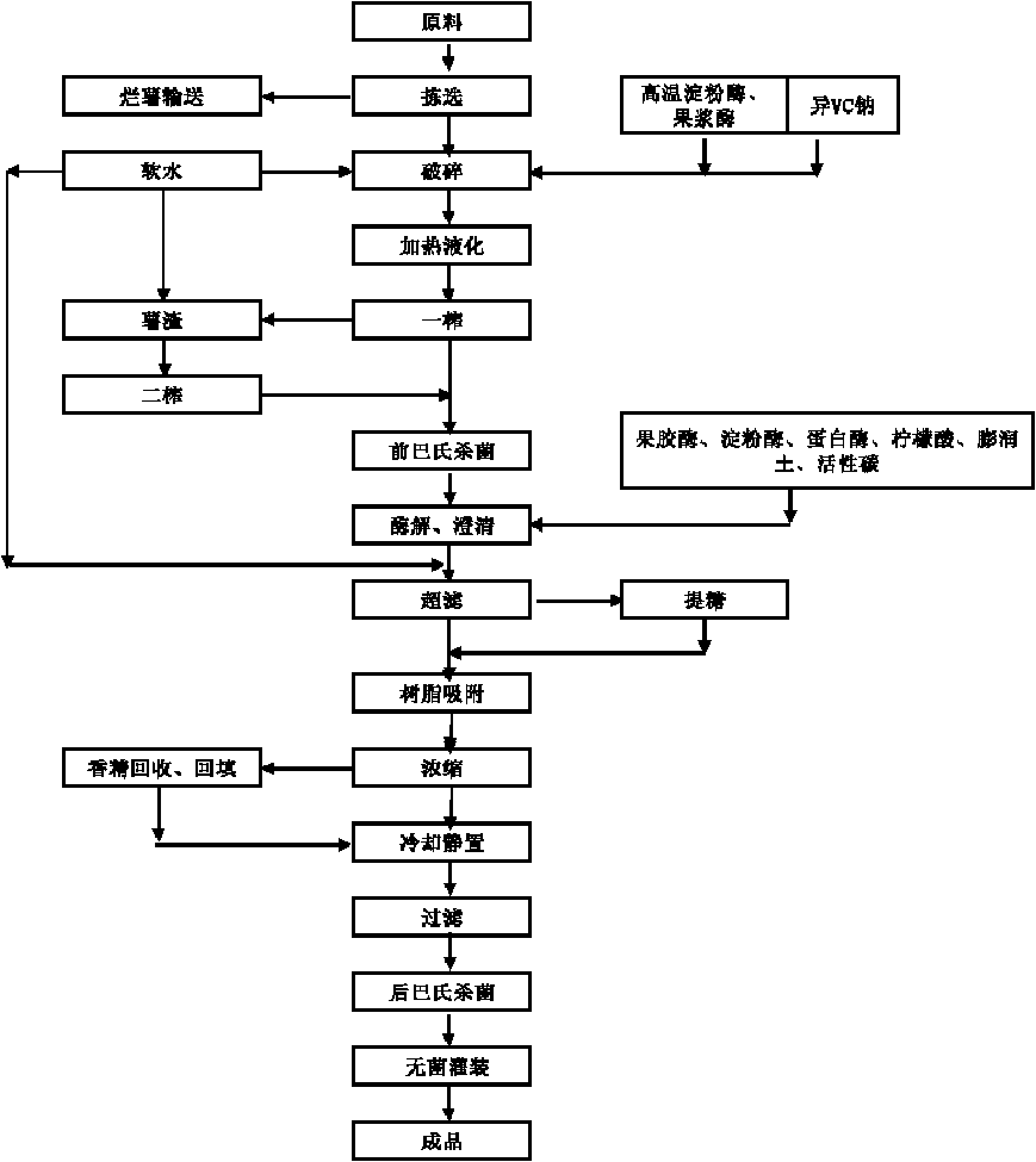

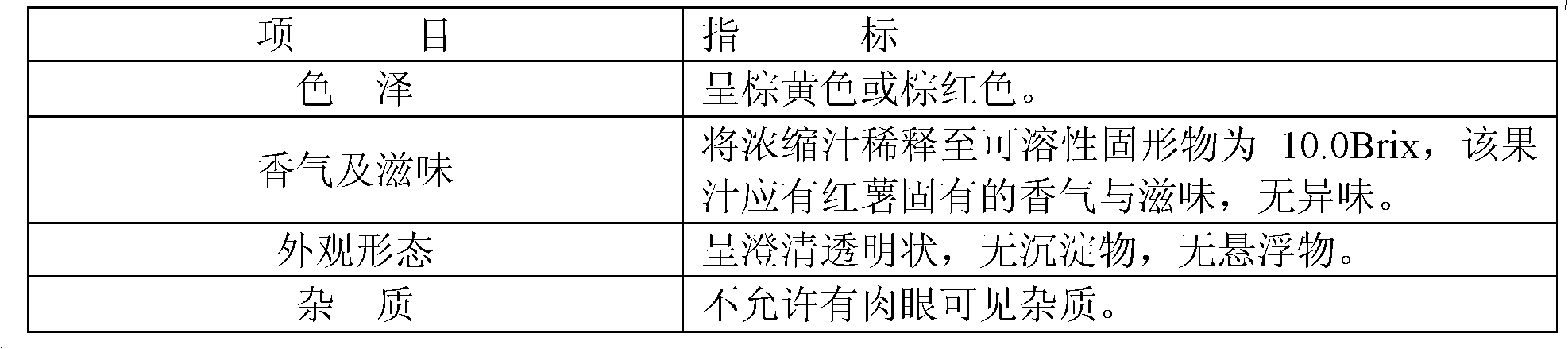

Preparation method of concentrated clear sweet potato juice with high color value

InactiveCN102349632AGood squeezing effectOvercoming the pitfalls of enzymatic browningFood preparationAmylaseFlavor

The invention discloses a preparation method of concentrated clear sweet potato juice with high color value. The preparation method has the following beneficial effects: mechanical peeling is omitted in the processing course; the pressability of the sweet potato pulp can be improved and the juice yield can be increased by adding amylase and pulp enzyme when the sweet potatoes are broken; soft water is further added to the sweet potato residues obtained after pressing to carry out secondary pressing to increase the juice yield; during enzymolysis, the amylase, the pulp enzyme and protease are unitedly used, thus achieving better clear juice clarifying effect; after being clarified, the raw juice is adsorbed by macroporous resins to adsorb the pigment, thus increasing the color value of theclear juice, and such substances as polyphenol, pectin, proteins, pesticide residues and the like are further adsorbed and removed, thus avoiding secondary turbidity; and while concentrating the sweet potato juice, essences are backfilled in the concentrated sweet potato juice, thus improving the flavor of the sweet potato juice.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

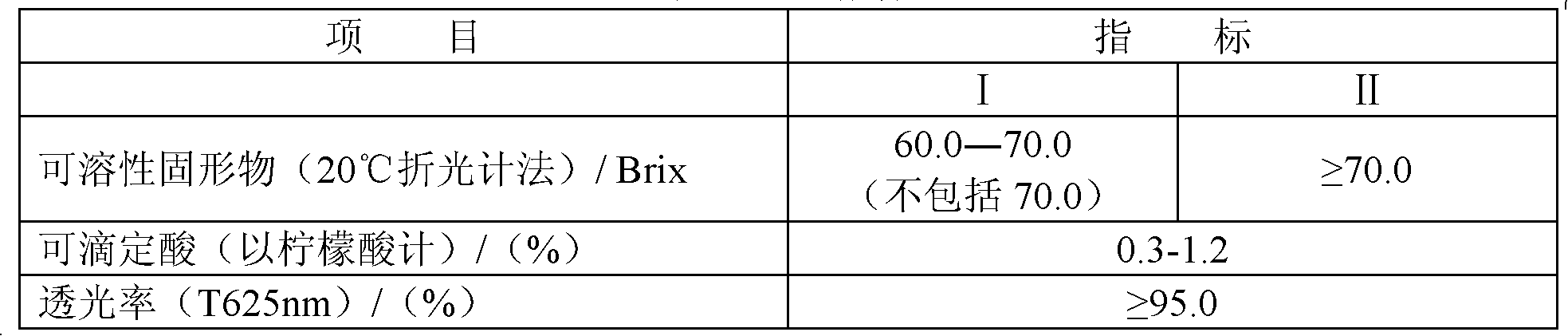

Polyester resins with a special co-catalyst for high melt poly and SSP reactivity with enhanced color values

InactiveUS20060293493A1Improve performanceGood lookingEnvelopes/bags making machineryOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceAntimony

The present invention relates to a PET resin and a process for producing polyethylene terephthalate (PET) resin having conventional catalysts such as antimony, titanium, tin or germanium compounds and a glycol insoluble tungsten compound or tungsten trioxide or tungsten carbide as co-catalyst. The tungsten compound as a co catalyst increases the rates of solid state polymerization and improves the ‘L’ color value.

Owner:EI DU PONT DE NEMOURS & CO

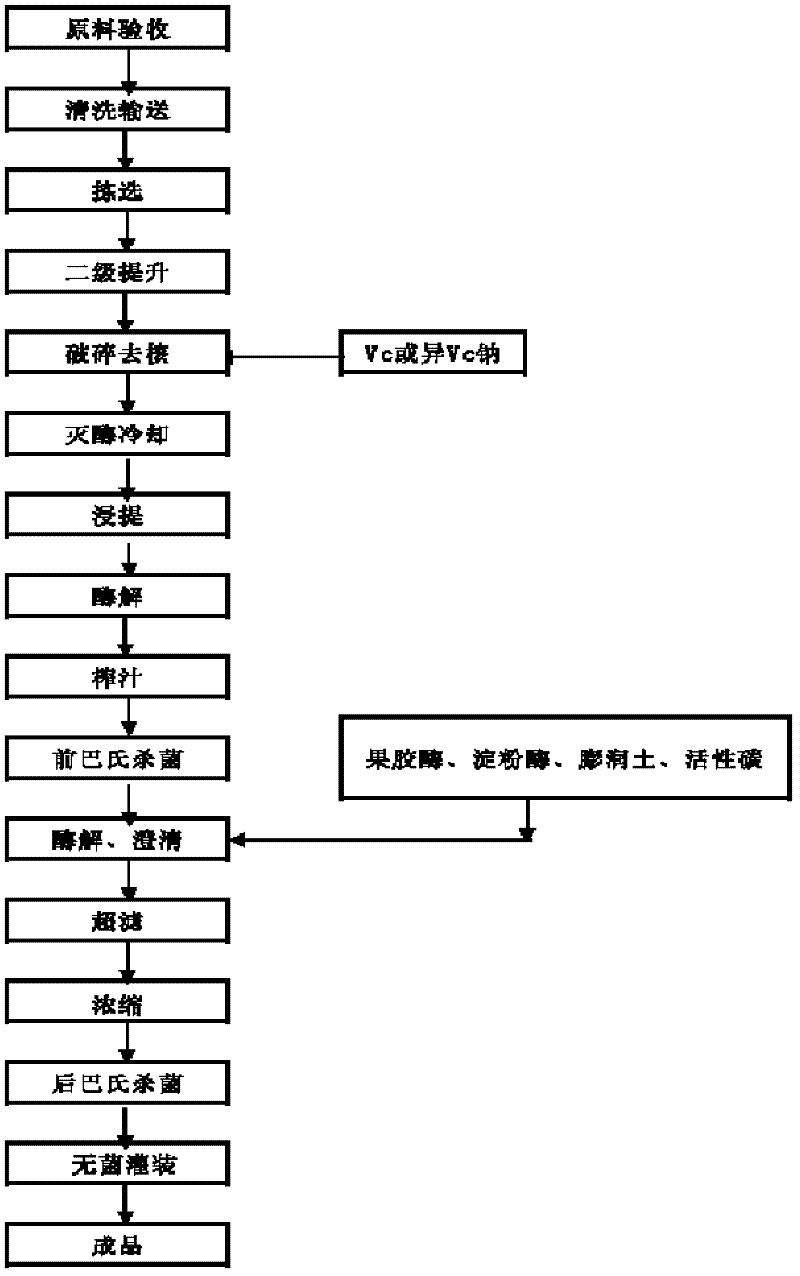

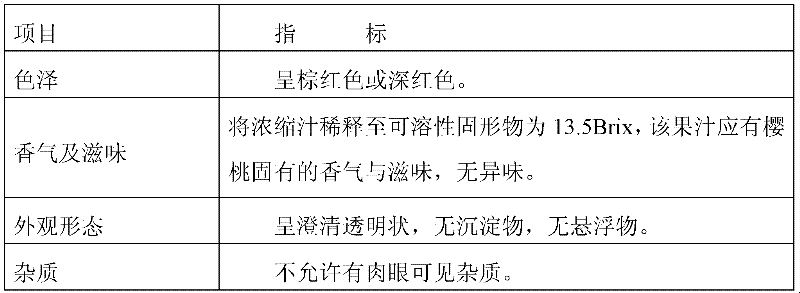

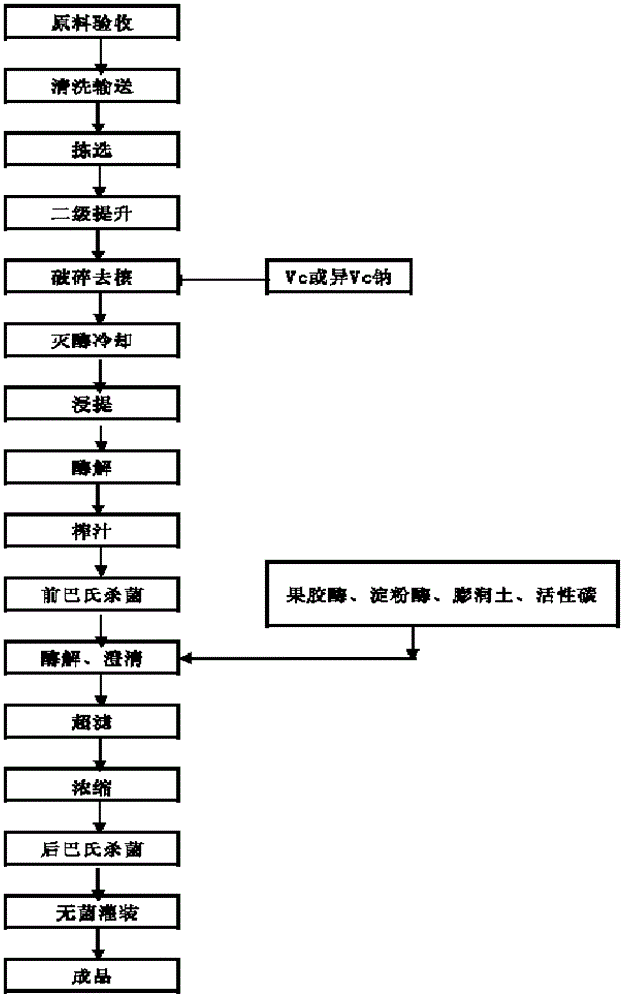

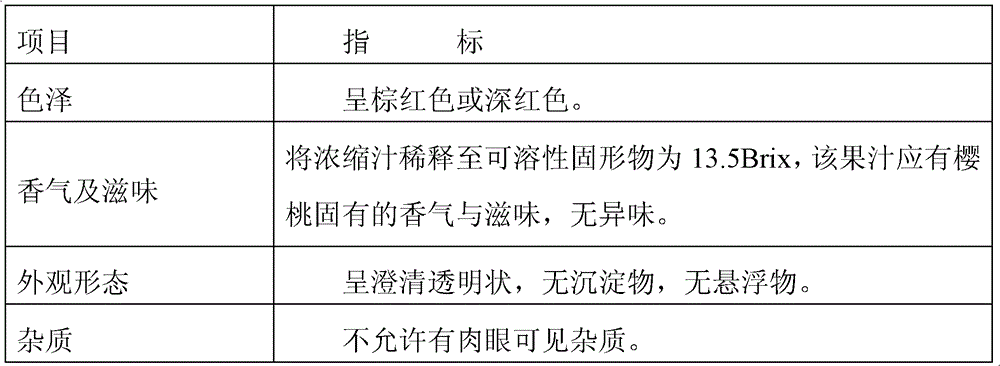

Process for producing cherry juice concentrate

The invention discloses a process for producing a cherry juice concentrate. The process comprises the steps as follows: washing cherries, crushing, removing stones, inactivating enzymes, cooling, leaching, cooling, performing enzymolysis, juicing, performing pasteurization, clarifying enzymatic hydrolysates, performing ultrafiltration, concentrating, performing pasteurization again, and packaging. The process improves the quality of the cherry juice concentrate. The cherry juice concentrate has a red brown or scarlet color, and is clear and free of sediments or suspended substances. The content of soluble solids is more than 60.0 Brix. When diluted until the content of soluble solids is 13.5 Brix, the cherry juice concentrate maintains the fragrance and flavor of cherries and smells good.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

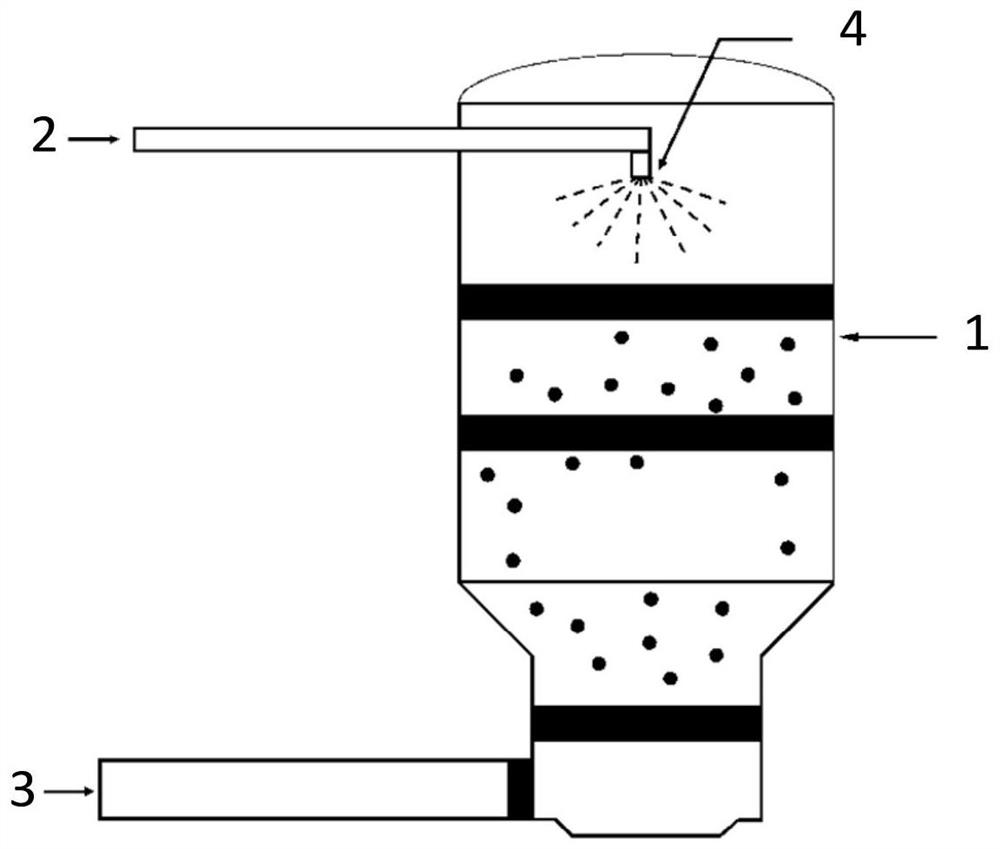

Processing method for preventing concentrated apple juice from being browning

InactiveCN1537476AProlong adsorption stability timeDrop in colorFood preservationActivated carbonFruit juice

A process for preventing concentrated apple juice from browning includes such steps as squeezing apple to obtain apple juice, sufficient browning for 0.5-1.5 hr, gelatinizing, adding pectiase or amylase, enzymolyzizing, adding activated carbon particles, adsorbing for 6-8 hr, ultrafilter and concentrating.

Owner:YANTAI NORTH ANDRE JUICE

Processing method of granny smith apple juice

InactiveCN107691913AReduced activityDoes not affect BrixFood ingredient as antioxidantFood adsorptionFiberFruit juice

The invention relates to a processing method of a granny smith apple juice. The method is characterized in that polyphenol enzyme activity is reduced by pretreatment such as blanching; nitrogen is filled during a squeezing process, so that a juice is isolated from the oxygen as much as possible before enzymolysis, and a browning reaction is inhibited; pectase is added for enzymolysis so as to enhance clarity; pH value is reduced by the action of ascorbic acid and malic acid; and the color value of the juice is improved by ion-exchange fiber adsorption.

Owner:ANHUI FUNAN CHANGHUI FOOD

Novel technique for processing apple-pear juice and product

The present invention relates to fruit juice beverage, and is especially one kind of new apple pear juice and its producing process. The new apple pear juice is produced with new apple pear, pectase accounting for 0.01-0.012 % of juice weight, and amylase accounting for 0.003-0.004 % of juice weight. The new apple pear juice is yellowish, sour and sweet, and rich in fruity fragrance. It has the health functions of moistening lung, eliminating phlegm, relieving cough, promoting the secretion of saliva to quench thirst, etc.

Owner:辽宁省果树科学研究所

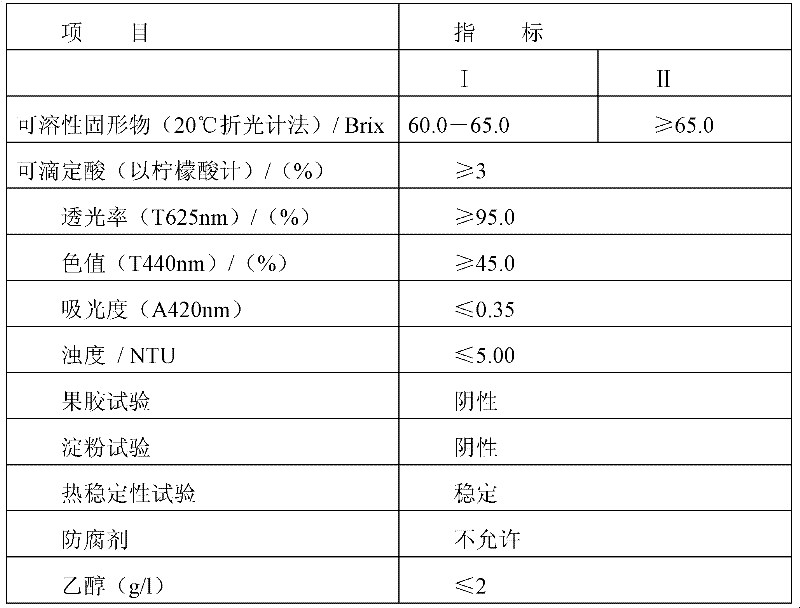

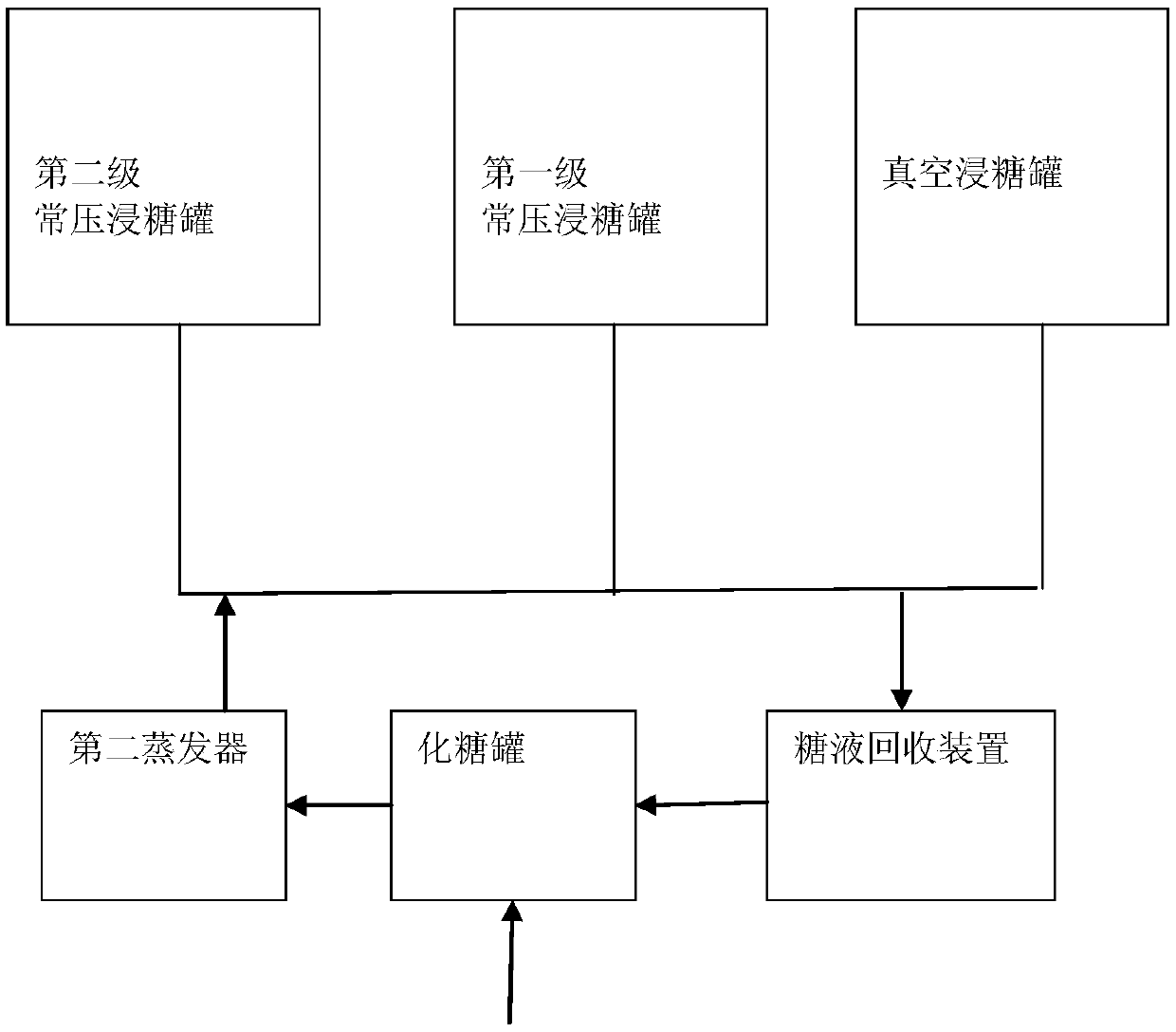

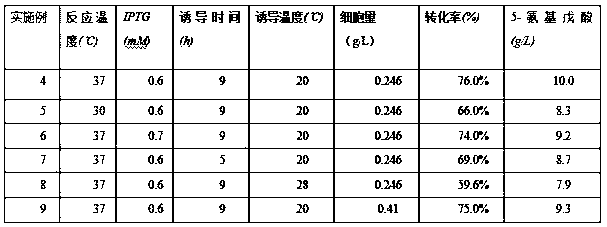

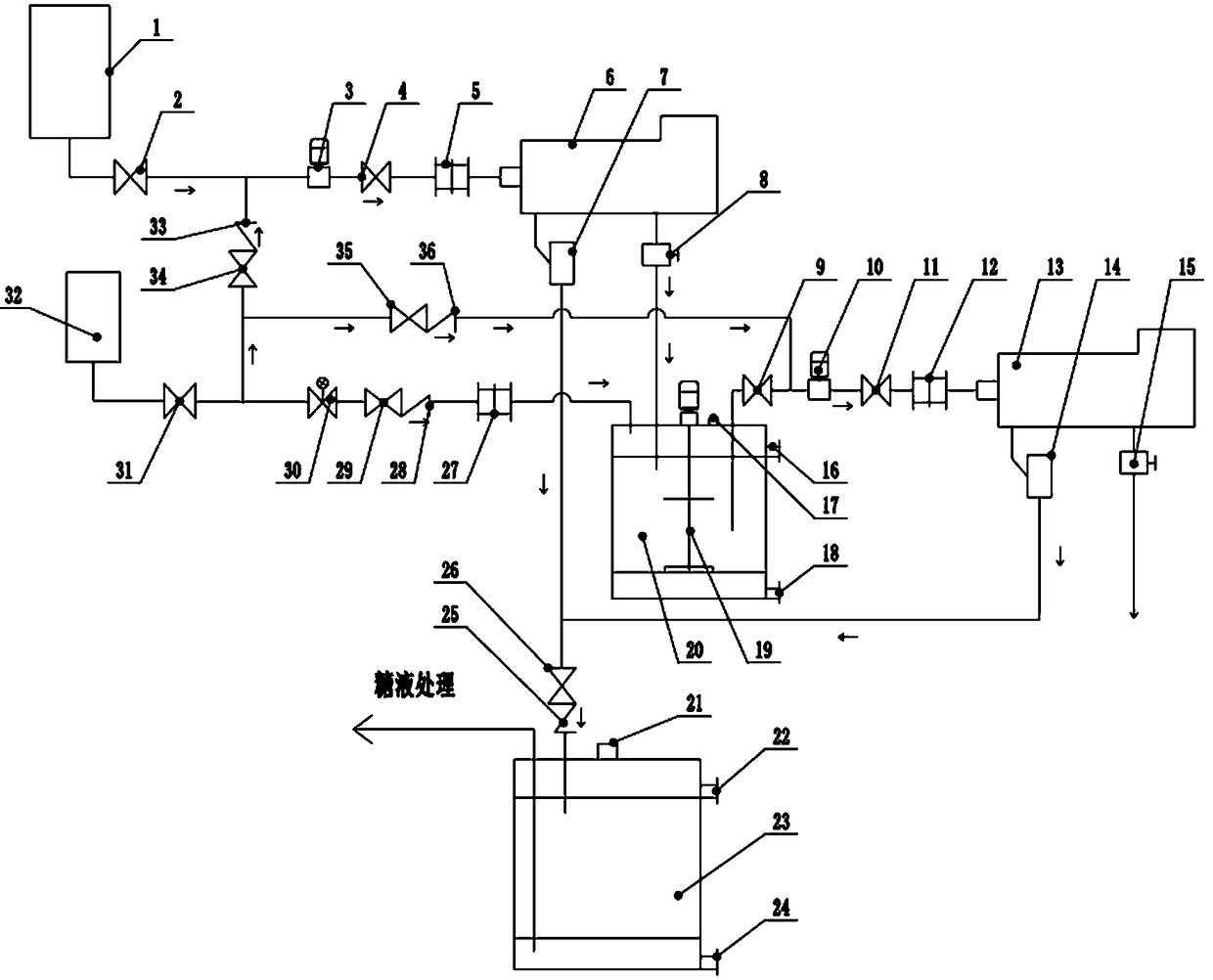

Preserved fruit cycle sugar soaking system and sugar soaking method thereof

PendingCN107897478AIncrease color valueReduce processing costsConfectionerySweetmeatsBiotechnologyEngineering

The present invention discloses a preserved fruit cycle sugar soaking system and a sugar soaking method thereof. The sugar soaking system comprises sugar soaking tanks, a sugar melting tank, a first evaporator and a sugar liquid recovery device, and the sugar melting tank and first evaporator are used for providing prepared sugar liquid for the sugar soaking tanks; the sugar soaking tanks comprises a vacuum sugar soaking tank, a first-class normal pressure sugar soaking tank and a second-class normal pressure sugar soaking tank, the vacuum sugar soaking tank, first-class normal pressure sugarsoaking tank and second-class normal pressure sugar soaking tank are respectively connected with the first evaporator, the sugar melting tank and sugar soaking tanks are respectively connected with the sugar liquid recovery device, and after sugar soaking, the sugar liquid is subjected to a sugar liquid recovery device treatment and then returned to the sugar melting tank; washed clean preserved fruits are successively subjected to vacuum sugar soaking and two-class normal pressure sugar soaking treatments, and the treated preserved fruits are taken out; sugar soaking liquid in the vacuum sugar soaking tank and two-class normal pressure sugar soaking tanks passes the sugar liquid recovery device, then enters into the sugar melting tank to be subjected to a sugar melting treatment, and thenreturns to the vacuum sugar soaking tank and two-class normal pressure sugar soaking tanks to form cycle sugar soaking. The preserved fruit cycle sugar soaking system greatly improves preserved fruitsugar soaking efficiency and preserved fruit yield and quality, and the preserved fruits after the sugar soaking are more beautiful on surfaces.

Owner:承德华朗食品有限公司

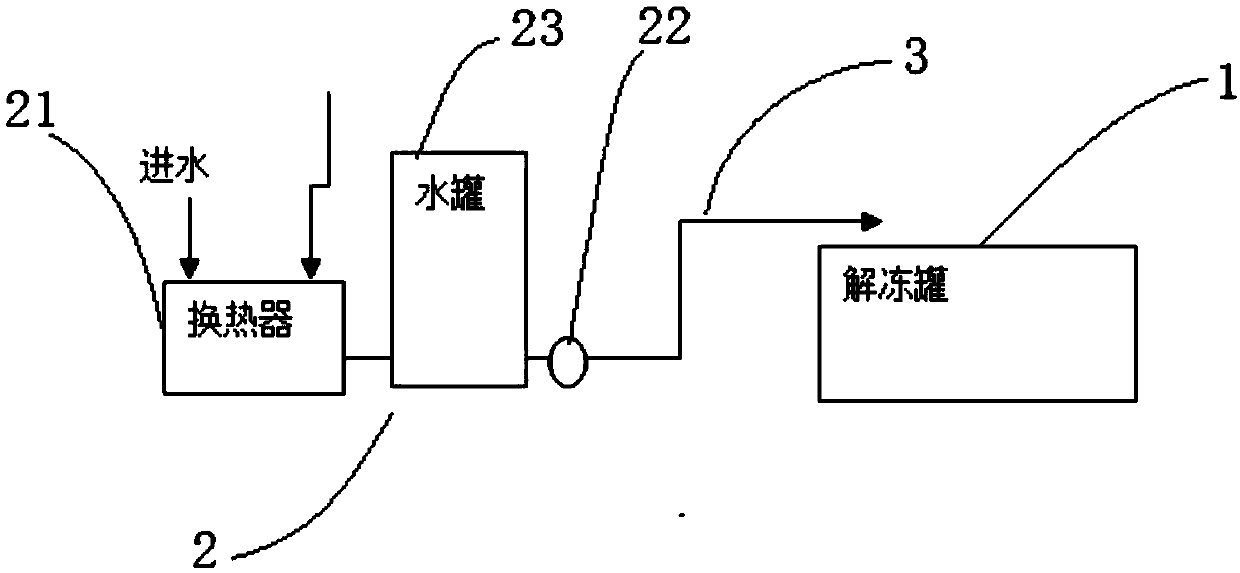

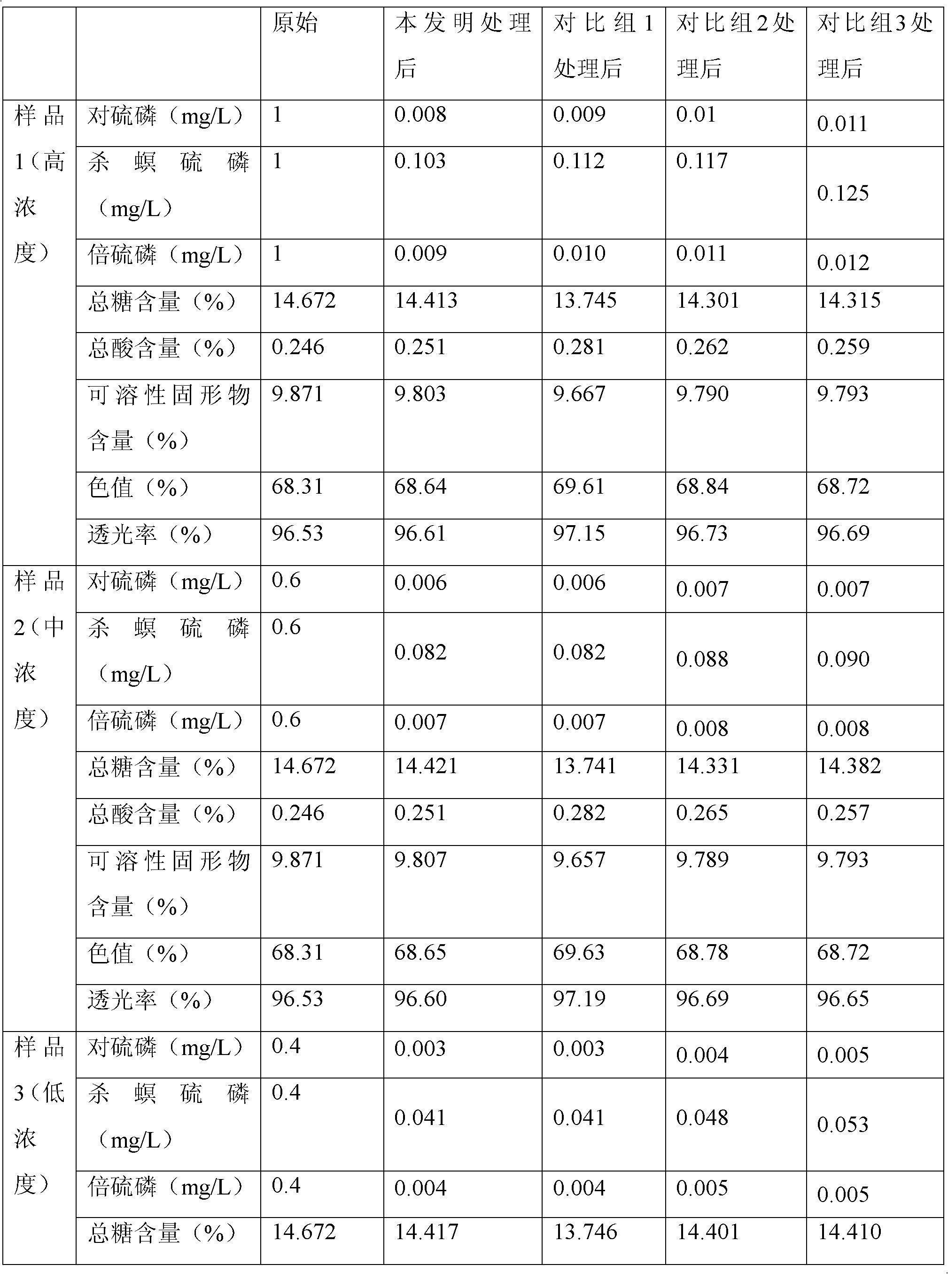

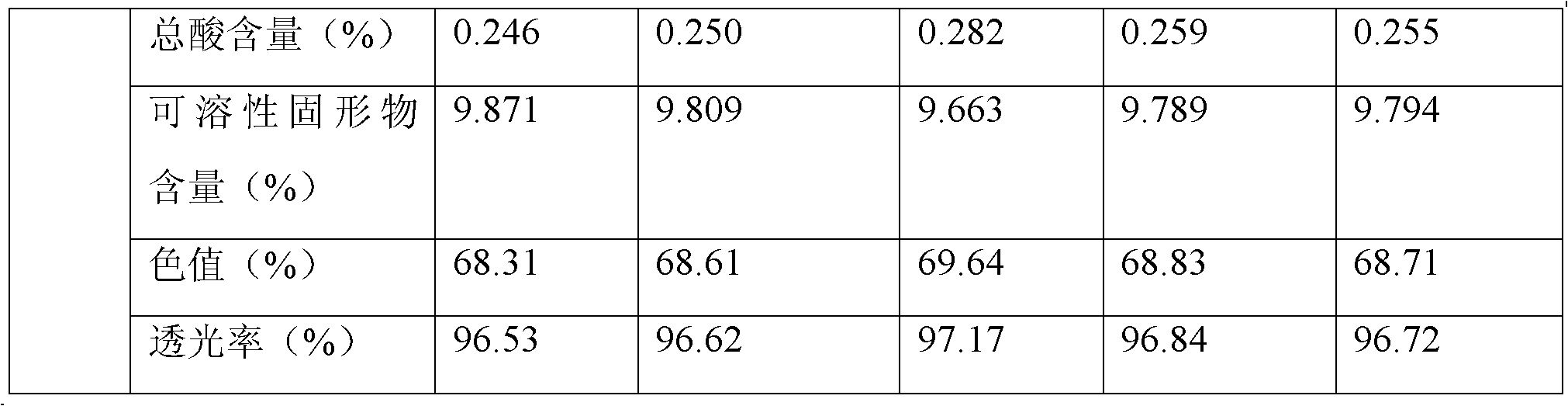

Method for controlling organophosphorus pesticide residue in bayberry juice through irradiation degradation

The invention discloses a method for controlling organophosphorus pesticide residue in bayberry juice through irradiation degradation. The method comprises the following steps of: 1) precooling the bayberry juice at the temperature of between 1 and 4DEG C for 100 to 140 minutes; and 2) putting the precooled into an enclosed container, irradiating by using 60Co-gamma rays as a radiation source, wherein the irradiation dose is 4.8-5.2kGy and the irradiation dose rate is 780-820cGy / min. By the method, the organophosphorus pesticide residue can be effectively, quickly and safely reduced or eliminated from the bayberry juice, so that the maximum organophosphorus pesticide residue in the bayberry juice reaches the national limit standard.

Owner:ZHEJIANG UNIV

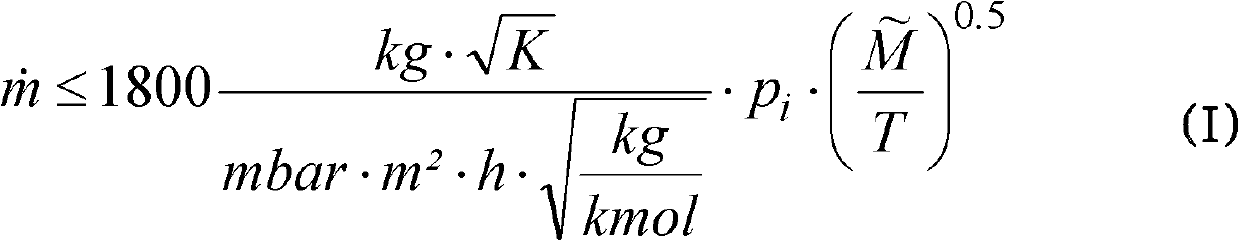

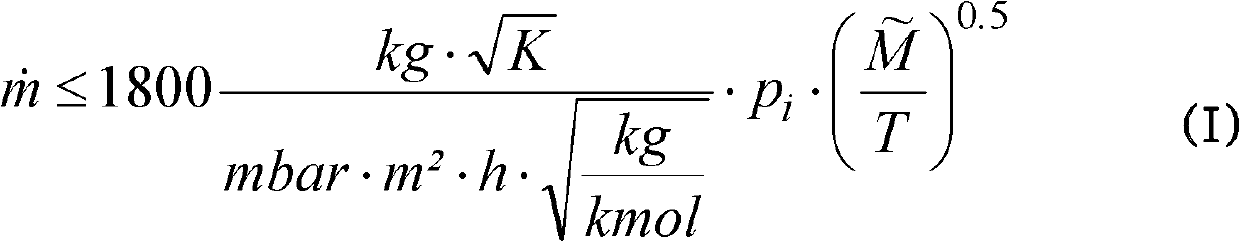

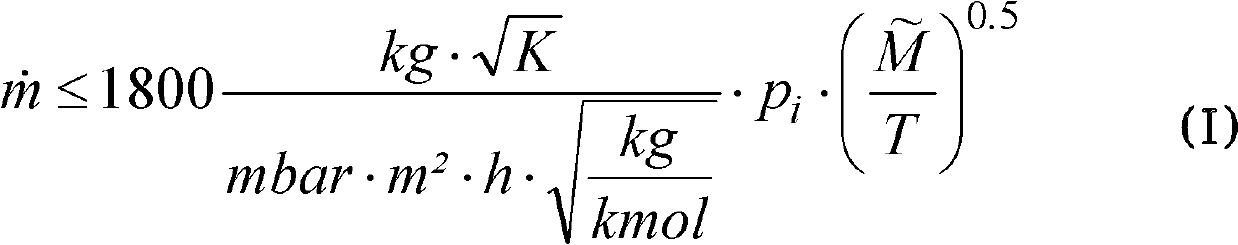

Method and system for purifying monomers

InactiveCN102395554AIncrease color valueOrganic compound preparationDistillation regulation/controlChemistryEvaporator

The present invention relates to a method for purifying monomers, wherein at least part of the monomers present in a starting composition is evaporated and is subsequently condensed, characterized in that at least part of the starting composition is evaporated in a short path evaporator, wherein the mass flow density of the vapors m is selected according to the relation (I), where M is the average molecular mass of the vapors in the short path evaporator in kg / kmol, T is the temperature of the vapors in K, pi is the pressure in the short path evaporator in mbar, and m is the mass flow density of the vapors in kg / (m2.h). The present invention further relates to a system for carrying out the method.

Owner:EVONIK ROEHM GMBH

Decolorizing agent for reducing brown stain index of yellow pear juice

InactiveCN107252028AImprove appearance qualityImprove the safety of useFood sciencePear juiceMolecular sieve

The invention discloses a decolorizing agent for reducing the brown stain index of yellow pear juice, and relates to the technical field of processing of yellow pear juice. A modified molecular sieve is used as a carrier, poloxamer / crospovidone is used as an adsorbent, a microwave impregnation method is used, and the decolorizing agent is prepared. The decolorizing agent disclosed by the invention is prepared through using the modified molecular sieve after modification strengthening treatment as the carrier; the decolorizing agent is specially used for reducing the brown stain index of the pear juice; and in the respect of the occurred brown stain of the yellow pear juice, after the decolorizing agent is used, the color value of the yellow pear juice is effectively increased, so that the appearance quality of the yellow pear juice is improved.

Owner:安徽好多多饮品有限公司

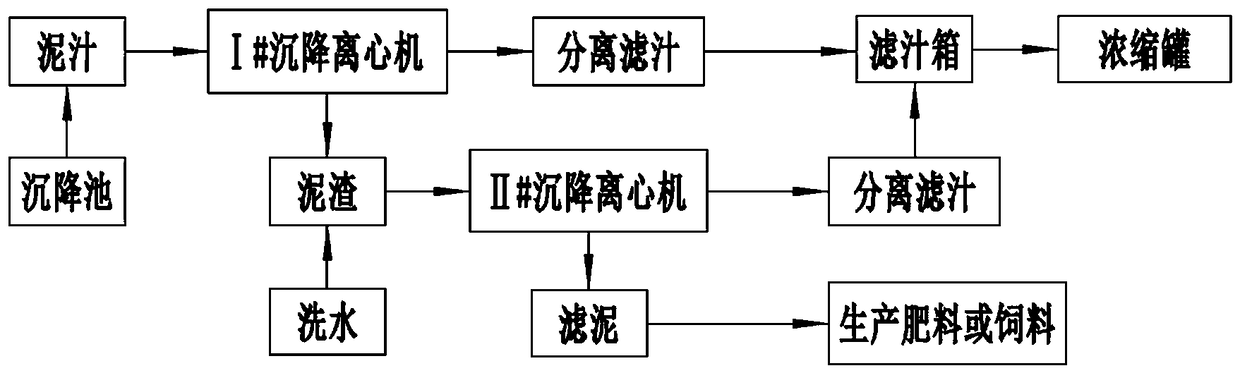

Centrifugal filtering method of paste juice in cane sugar factory

The invention relates to a centrifugal filtering method of paste juice in a cane sugar factory. The centrifugal filtering method comprises the following steps: (1) transporting paste juice obtained ina settling pond in a settling manner to a number-I centrifugal machine, separating the paste juice, transporting obtained filtered juice into a filtered juice box, and discharging obtained paste slaginto a paste slag and water stirring tank; (2) adding water into the mud slag and water stirring tank, and stirring; (3) transporting a material in the mud slag and water stirring tank to a number-IIcentrifugal machine, separating solids and liquid, transporting obtained filtered juice into a filter juice box, mixing the obtained filtered juice with the filtered juice in step (1), then transporting to a concentrating tank, and transporting obtained filtered paste to be used for producing organic fertilizer or feed, wherein the water content of the obtained filtered paste is less than 55 percent, and a sugar degree of the filtered paste is less than 4.5 percent. By adopting the method, the solids and the liquid of the paste juice in the cane sugar factory can be rapidly separated, the treatment time of the materials is shortened, the production efficiency is increased, the cane sugar loss of the filtered paste is reduced, the washing water amount is reduced, the energy is saved, the further comprehensive utilization of the filtered paste can be promoted, and the problems that the water content of the filtered paste is high, the filtered paste is difficult to transport and the clean production of the environment is influenced can be solved.

Owner:横县东糖糖业有限公司

Sugar dissolving process in raw sugar machining by using double-carbonic acid method

ActiveCN103173580AReduce soluble salt contentIncreased soluble salt contentSugar productsSucroseDecomposition

The invention discloses a sugar dissolving process in raw sugar machining by using a double-carbonic acid method. In the sugar dissolving process, raw sugar granules, water and lime milk or whitewash are synchronously mixed in a fair current mode so as to prepare raw syrup of which the pH value is 8.0 to 9.0. By utilizing the sugar dissolving process, the decomposition of cane sugar in the sugar dissolving process is reduced, the sugar loss is lowered, the inversion quantity of reducing sugar is reduced by more than 50%; the color value increase is reduced, that is, only 10%, so that the product quality is stably improved. According to the sugar dissolving process, the pH value of the raw syrup is adjusted by using the lime milk or whitewash; as the clearing agent used in the carbonic acid method raw sugar machining is just the lime milk which is added in advance in the sugar dissolving process, the amount of the lime milk can be reduced in a later lime milk adding procedure; and moreover as the lime added in the sugar dissolving process is changed into calcium carbonate in a later full filling procedure, the lime milk can be eliminated in a filtering procedure; and meanwhile by adopting the lime milk or the whitewash, the content of dissoluble salt in the syrup is not increased when the pH value is adjusted.

Owner:ZUOYUAN GRP

Process for producing cherry juice concentrate

The invention discloses a process for producing a cherry juice concentrate. The process comprises the steps as follows: washing cherries, crushing, removing stones, inactivating enzymes, cooling, leaching, cooling, performing enzymolysis, juicing, performing pasteurization, clarifying enzymatic hydrolysates, performing ultrafiltration, concentrating, performing pasteurization again, and packaging. The process improves the quality of the cherry juice concentrate. The cherry juice concentrate has a red brown or scarlet color, and is clear and free of sediments or suspended substances. The content of soluble solids is more than 60.0 Brix. When diluted until the content of soluble solids is 13.5 Brix, the cherry juice concentrate maintains the fragrance and flavor of cherries and smells good.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

Method of preparing concentrated clear red jujube juice with high cAMP content

InactiveCN102551137BPrevent thermal degradationHigh retention rateFood preparationPectinaseFruit juice

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

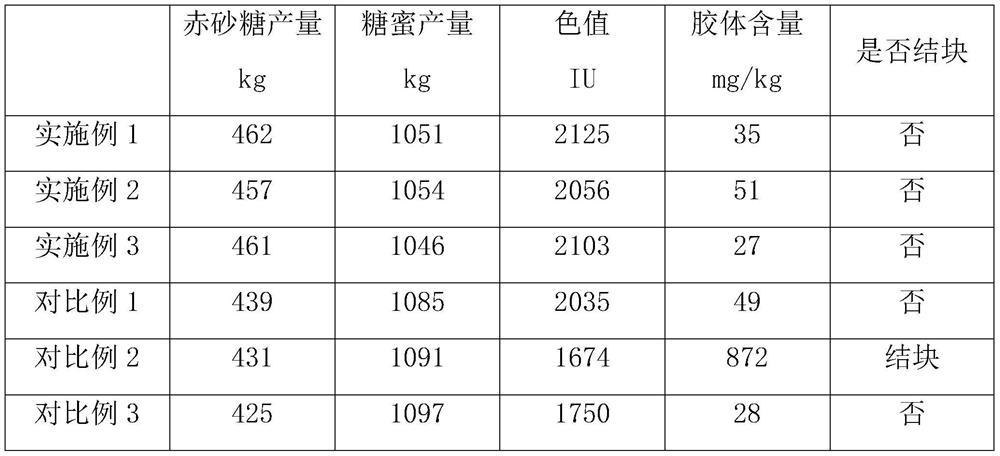

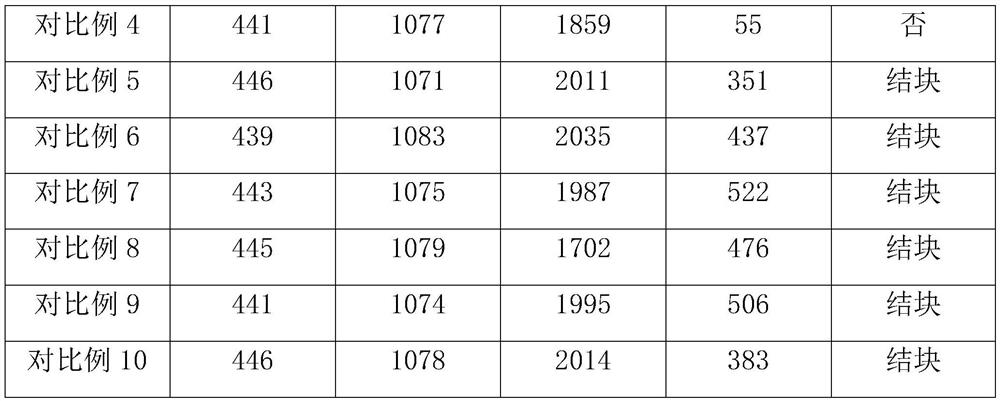

Preparation method of high-quality brown granulated sugar

ActiveCN112899409ALow viscositySolve easy cakingSugar crystallisationSugar juice boiling/evaporationSucroseEngineering

The invention provides a preparation method of high-quality brown granulated sugar, the method comprises the working procedures of raw material juice extraction, sugar juice clarification, evaporation, sugar boiling, crystallization assisting, honey separation and drying, in the triose boiling process of the post-stage sugar boiling working procedure, a compound enzyme preparation is added after diose honey starts to be added, molasses is added in the triose paste crystallization assisting process, and the triose paste is treated by immobilized sucrase, the brown granulated sugar produced by the method is high in yield, deep in color and not easy to cake.

Owner:勐腊县勐捧糖业有限责任公司

Method for preparing pectin through double-effect combined extraction technology

The invention discloses a method for preparing pectin through a double-effect combined extraction technology. The method integrates respective advantages of inorganic acid extraction and resin ion exchange technology extraction, overcomes the disadvantages of long production cycle, low yield, low quality and difficult process control of traditional pectin, has the advantages of high extraction efficiency, energy saving, high yield, small destroys to the molecular chain and the gelling degree of pectin, and simple production control, and is very suitable for large-scale and industrialized production.

Owner:安徽亿源生物工程有限公司

Enzymatic hydrolysate decolorization resin for natural pectin extraction

InactiveCN106854293AGood regeneration performanceStrong decolorization abilityCoatingsMethacrylateHydrolysate

Relating to the technical field of resin processing, the invention discloses an enzymatic hydrolysate decolorization resin for natural pectin extraction. The enzymatic hydrolysate decolorization resin is prepared from the following raw materials by weight: 60-65 parts of cyclohexyl methacrylate, 40-45 parts of ethylene glycol dimethacrylate, 30-40 parts of divinyl benzene, 20-30 parts of a pore-forming agent, 5-10 parts of caprylic capric triglyceride, 4-8 parts of sodium carboxymethyl starch, 4-8 parts of microcrystalline cellulose, 3-6 parts of Carbomer 934, 3-6 parts of di-octadecyl dimethyl ammonium chloride, 2-4 parts of magnesium aluminum silicate, 2-4 parts of triallyl cyanurate, 1-2 parts of isopropyl myristate, 1-2 parts of an initiator, 0.5-1 part of polyaspartic acid, 15-20 parts of ethanol, and 200-250 parts of water. The resin prepared according to the invention is specifically used for enzymatic hydrolysate decolorization in a natural pectin extraction process, can effectively remove colored impurities from the enzymatic hydrolysate and coal ash brought in during pomace drying, and can reach a decolorization rate up to more than 98%, thereby significantly improving the color value and purity of the obtained pectin.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

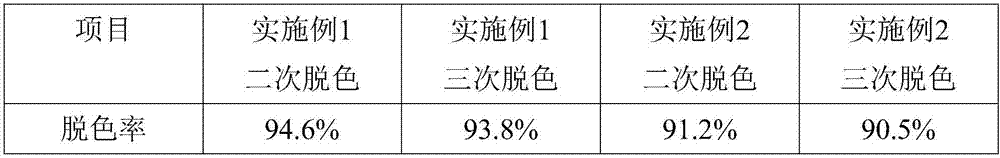

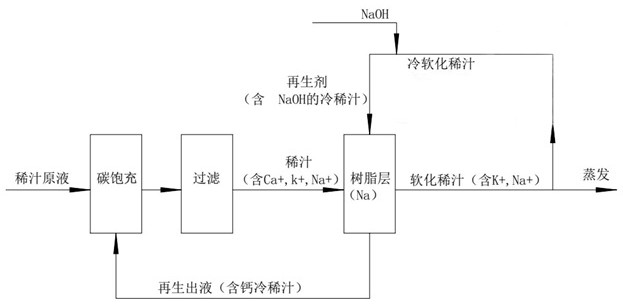

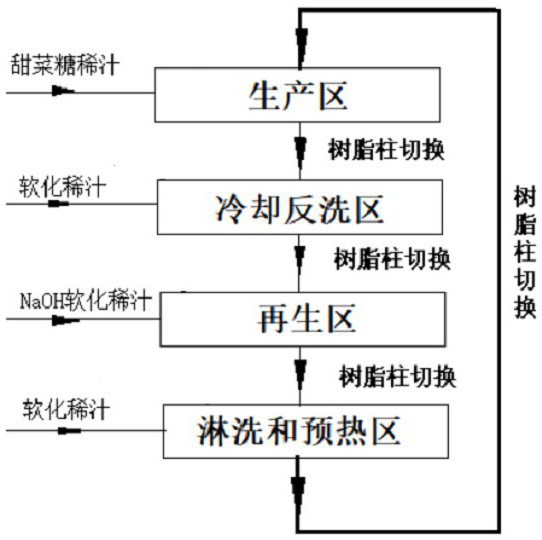

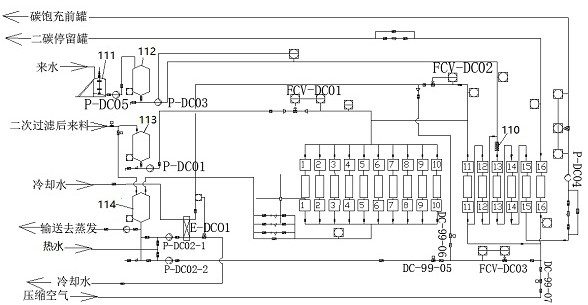

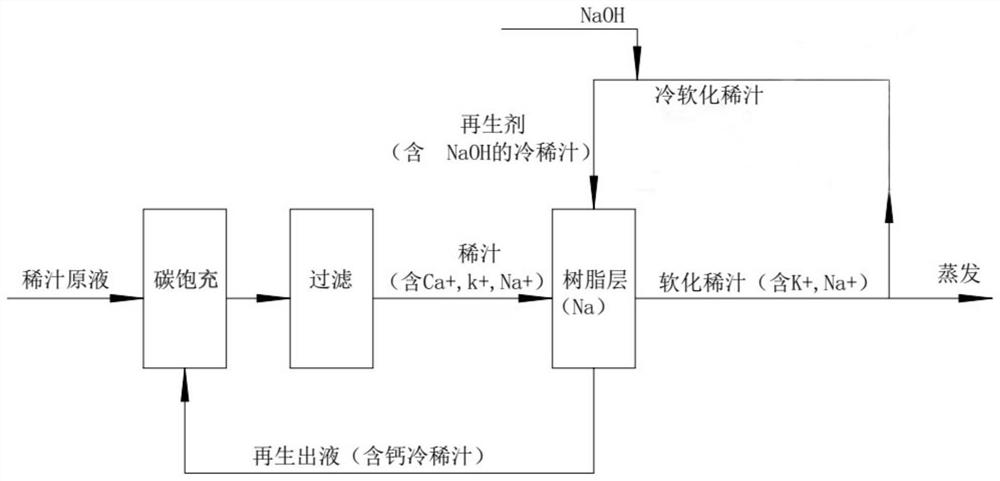

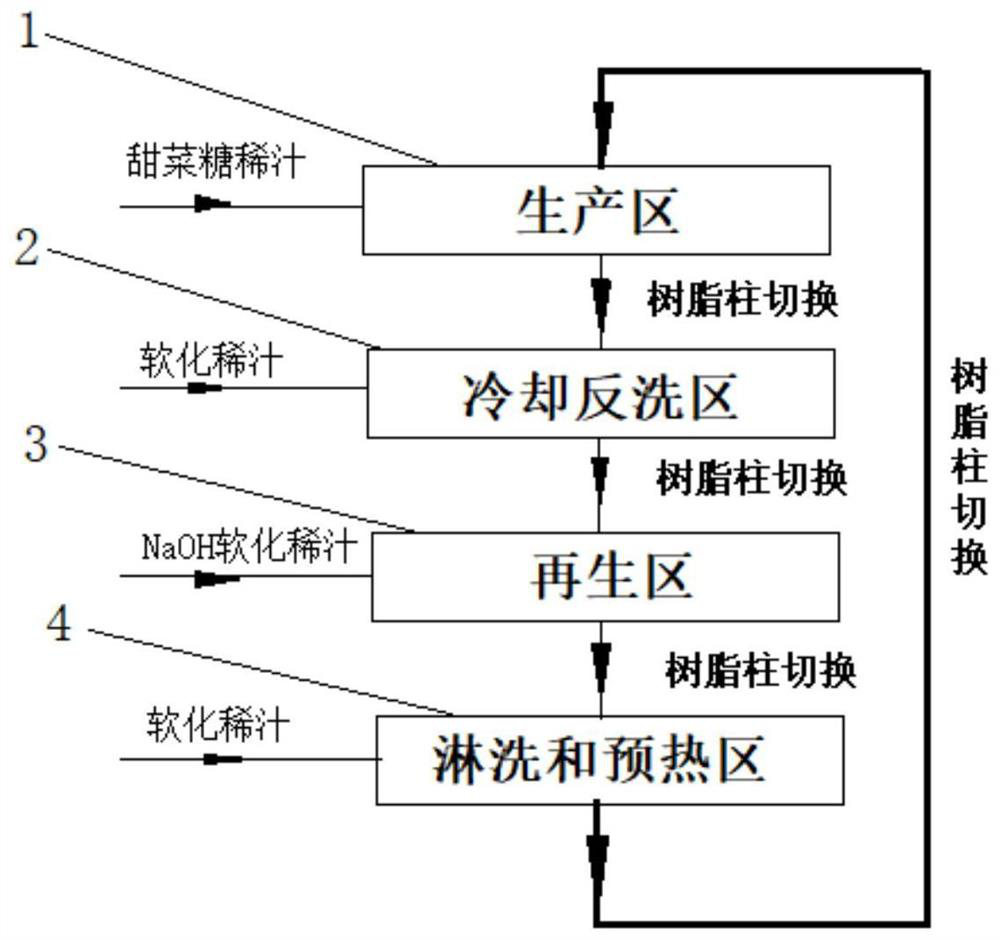

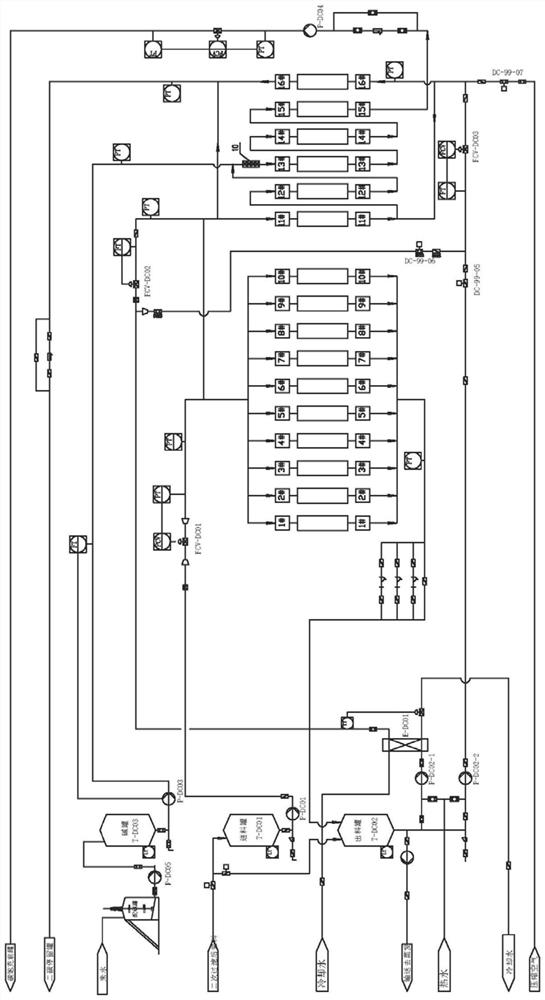

Beet sugar decalcification system

PendingCN114606350ARealize continuous productionReduce foulingIon-exchange process apparatusIon-exchanger regenerationIon exchangeProcess engineering

The invention discloses a beet sugar decalcification system. A production area comprises a plurality of ion exchange resin columns which are arranged in parallel; the cooling backwashing area comprises a failed ion exchange resin column switched from the production area; the regeneration area comprises an ion exchange resin column switched from the cooling backwashing area, and NaOH softening thin juice is used for regenerating resin in the ion exchange resin column subjected to backwashing; the leaching and preheating zone comprises an ion exchange resin column switched from the regeneration zone, and the softening thin juice leaches and preheats resin in the ion exchange resin column. After the softened thin juice obtained through the beet sugar thin juice softening method enters a subsequent evaporator and other procedures, the scaling phenomenon of the evaporator and crystallization sugar boiling equipment is reduced, the situation that production is stopped due to descaling of the evaporator and other equipment is avoided, continuous production of beet sugar is achieved, and labor cost is saved. And meanwhile, the service lives of the evaporator and the crystallization sugar boiling equipment are prolonged.

Owner:OUSHANGYUAN PROCESS & EQUIP INTELLIGENT CO

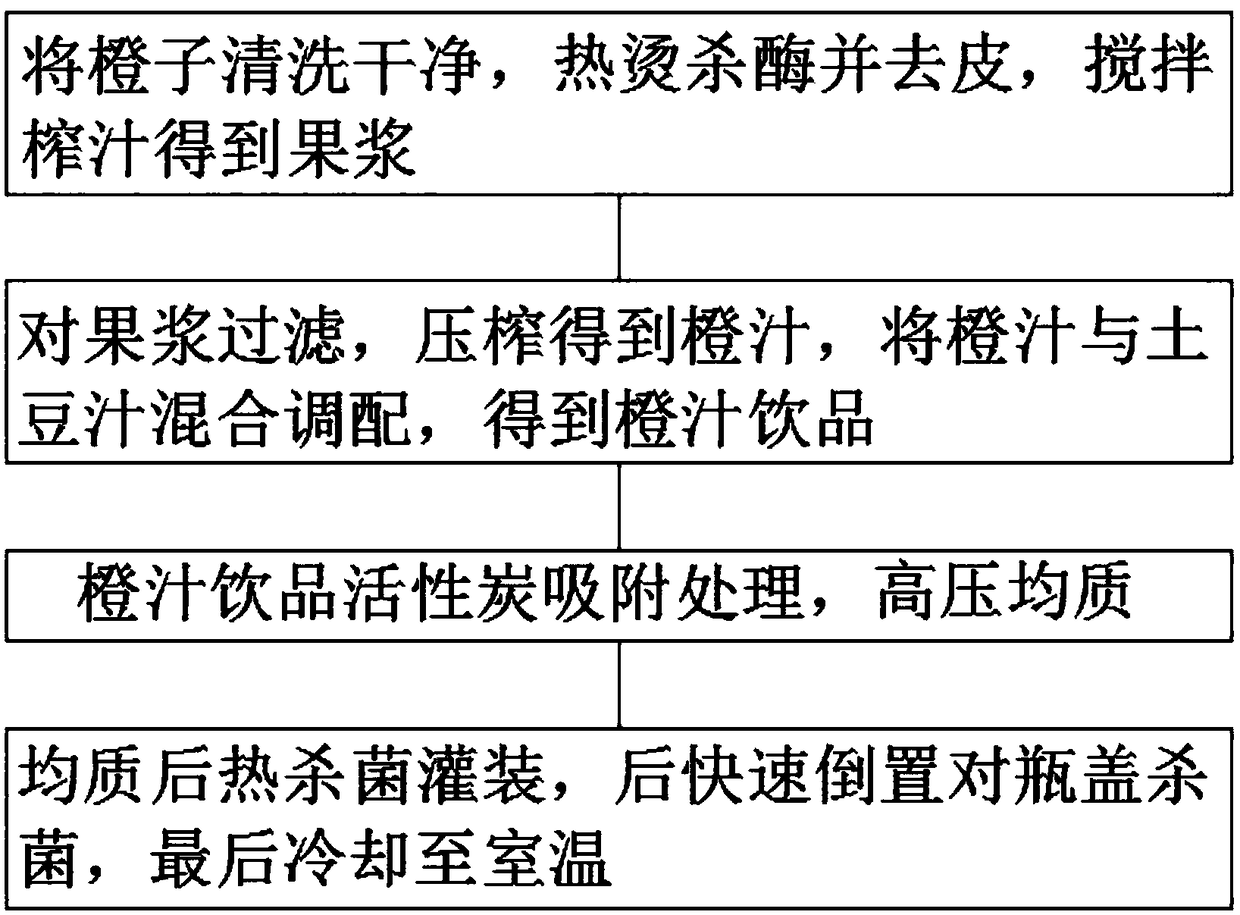

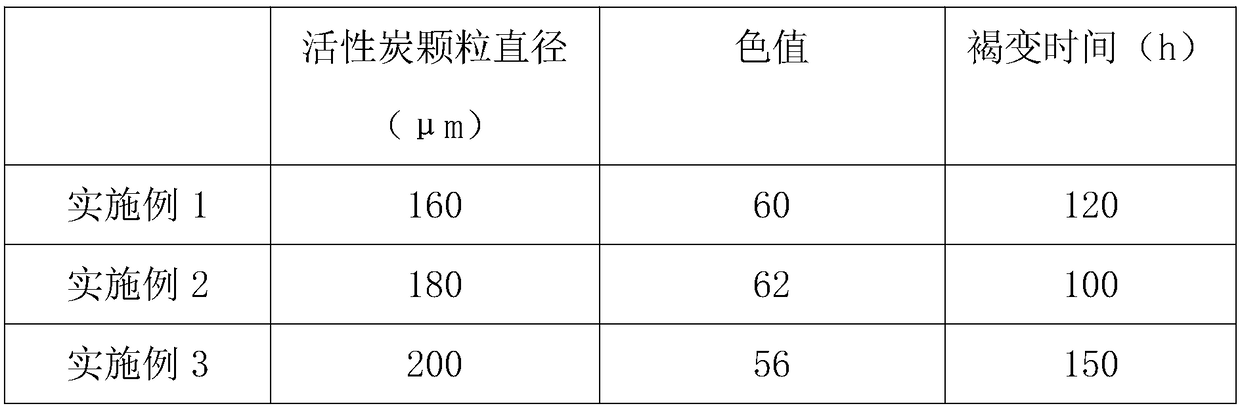

Preparation method of orange juice beverage

PendingCN109480133AExtended storage timeGuaranteed tasteFood ingredient as antioxidantFood thermal treatmentActivated carbonFruit juice

The invention discloses a preparation method of an orange juice beverage. The preparation method comprises the following steps: cleaning oranges, blanching the oranges at 75 DEG C to deactivate enzymes and peel the oranges to remove cortex and tangerine pith, and juicing the oranges with stirring to obtain fruit pulp at rotation speed of 550 r / min for 5 min; filtering the fruit pulp, pressing thefruit pulp to obtain orange juice; and mixing and blending the orange juice with potato juice to obtain the orange juice drink, wherein the mixing and blending comprises pouring a first orange juice into a stainless steel tank, stirring the first orange juice and adding a second orange juice in turn. The method for preparing the orange juice beverage can better inhibit browning, improve the storage time of the orange juice, and better maintain the taste of the orange juice, and at the same time, carotenoid can better improve the nutritional content of the product; besides, activated carbon canadsorb phenolic substances in the fruit pulp, vitamin C and other pigment substances to further inhibit browning of orange juice, and increase the color value of the orange juice to bring better useprospects.

Owner:安徽伟航饮品有限公司

Method for delaying quality deterioration of raw sugar during storage

The invention relates to the technical field of food processing, and discloses a method for delaying the quality deterioration of raw sugar during storage. The method for delaying the quality deterioration of raw sugar in the storage process of the present invention comprises the step of adding metal oxides and / or metal hydroxides to the raw sugar, so that the pH value of the mixed raw sugar is 6.8-8.5, wherein , the metal is a Group IA or Group IIA metal element. The method provided by the invention can simply and conveniently adjust the pH value of the raw sugar, and significantly delay the deterioration of the quality of the raw sugar during storage without increasing the process.

Owner:COFCO GROUP +3

Sugar dissolving process in raw sugar machining by using double-carbonic acid method

ActiveCN103173580BReduce soluble salt contentIncreased soluble salt contentSugar productsSucroseCarbonic acid

The invention discloses a sugar dissolving process in raw sugar machining by using a double-carbonic acid method. In the sugar dissolving process, raw sugar granules, water and lime milk or whitewash are synchronously mixed in a fair current mode so as to prepare raw syrup of which the pH value is 8.0 to 9.0. By utilizing the sugar dissolving process, the decomposition of cane sugar in the sugar dissolving process is reduced, the sugar loss is lowered, the inversion quantity of reducing sugar is reduced by more than 50%; the color value increase is reduced, that is, only 10%, so that the product quality is stably improved. According to the sugar dissolving process, the pH value of the raw syrup is adjusted by using the lime milk or whitewash; as the clearing agent used in the carbonic acid method raw sugar machining is just the lime milk which is added in advance in the sugar dissolving process, the amount of the lime milk can be reduced in a later lime milk adding procedure; and moreover as the lime added in the sugar dissolving process is changed into calcium carbonate in a later full filling procedure, the lime milk can be eliminated in a filtering procedure; and meanwhile by adopting the lime milk or the whitewash, the content of dissoluble salt in the syrup is not increased when the pH value is adjusted.

Owner:ZUOYUAN GRP

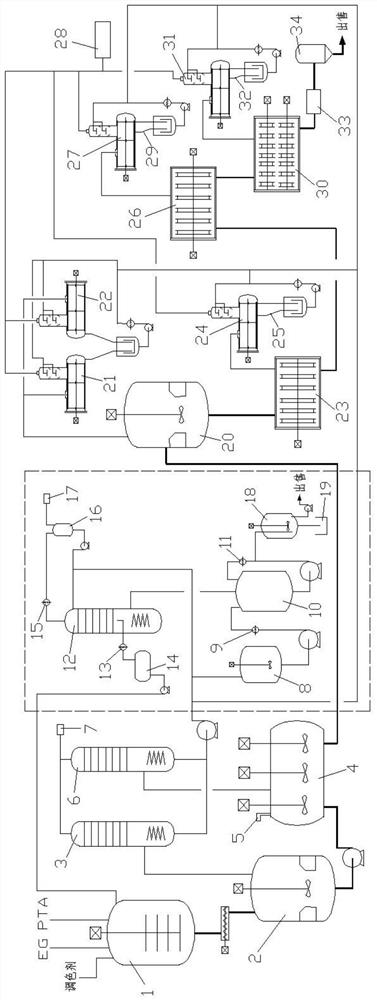

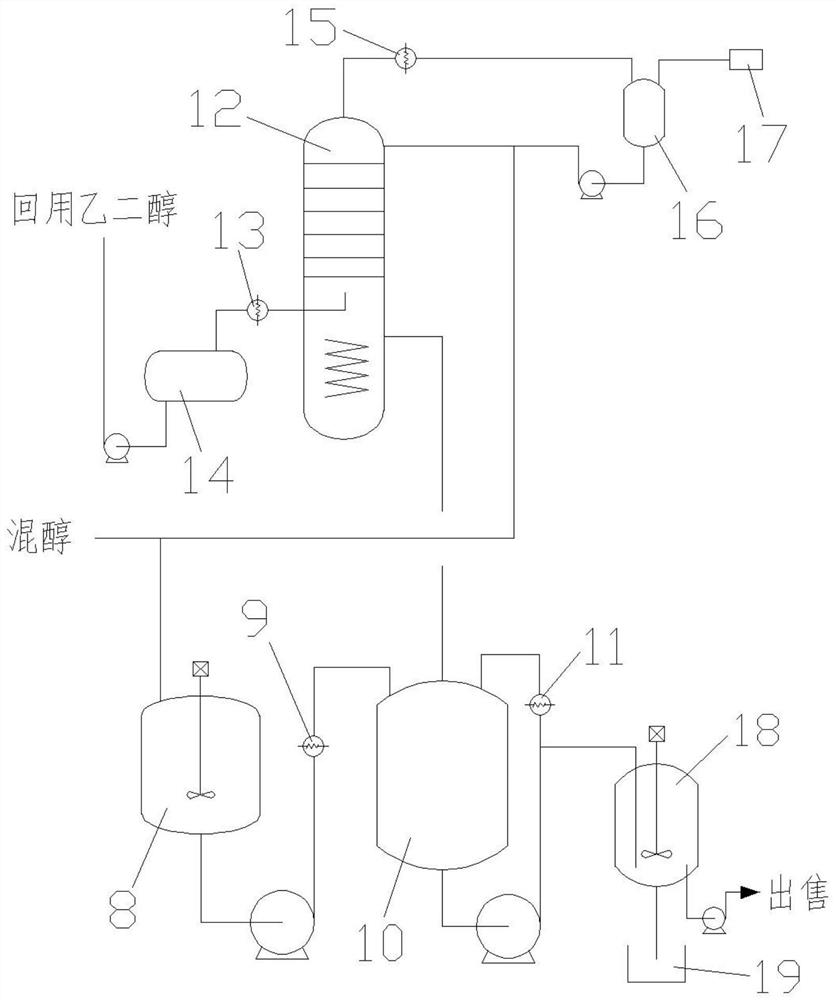

High-viscosity copolyester production system and method with mixed alcohol separation and recovery functions

ActiveCN114011357AReduce degradationIncrease color valueProcess control/regulationOrganic compound preparationAlcoholProcess engineering

The invention discloses a high-viscosity copolyester production system and method with mixed alcohol separation and recovery functions, and the system comprises a slurry blending tank, a first esterification kettle, a second esterification kettle, a rectification process tower, a first pre-polycondensation kettle, a second pre-polycondensation kettle, a final polycondensation kettle, a high-viscosity kettle, a pelletizing system and a pelletizing collection bin. A mixed alcohol vacuum rectification system is arranged between the rectification process tower and the slurry blending tank, and the mixed alcohol vacuum rectification system comprises a mixed alcohol collecting tank, a vacuum refining tank, an EG waste liquid collecting tank, an EG vacuum refining tower, a refined EG collecting tank and a condensate collecting tank. According to the system and the method disclosed by the invention, the high-viscosity kettle, the double-scraper condenser, the double-atmospheric-leg pipeline, the independent material adding system and the mixed alcohol vacuum distillation system are arranged, so that a six-kettle low-temperature long-flow process flow is formed, the reaction process is high in efficiency and good in controllability, the recovery purity of EG is high, the unit consumption of raw materials is low, the product viscosity is high, and the quality is continuous and stable.

Owner:JIANGSU HONGGANG PETROCHEMICAL CO LTD

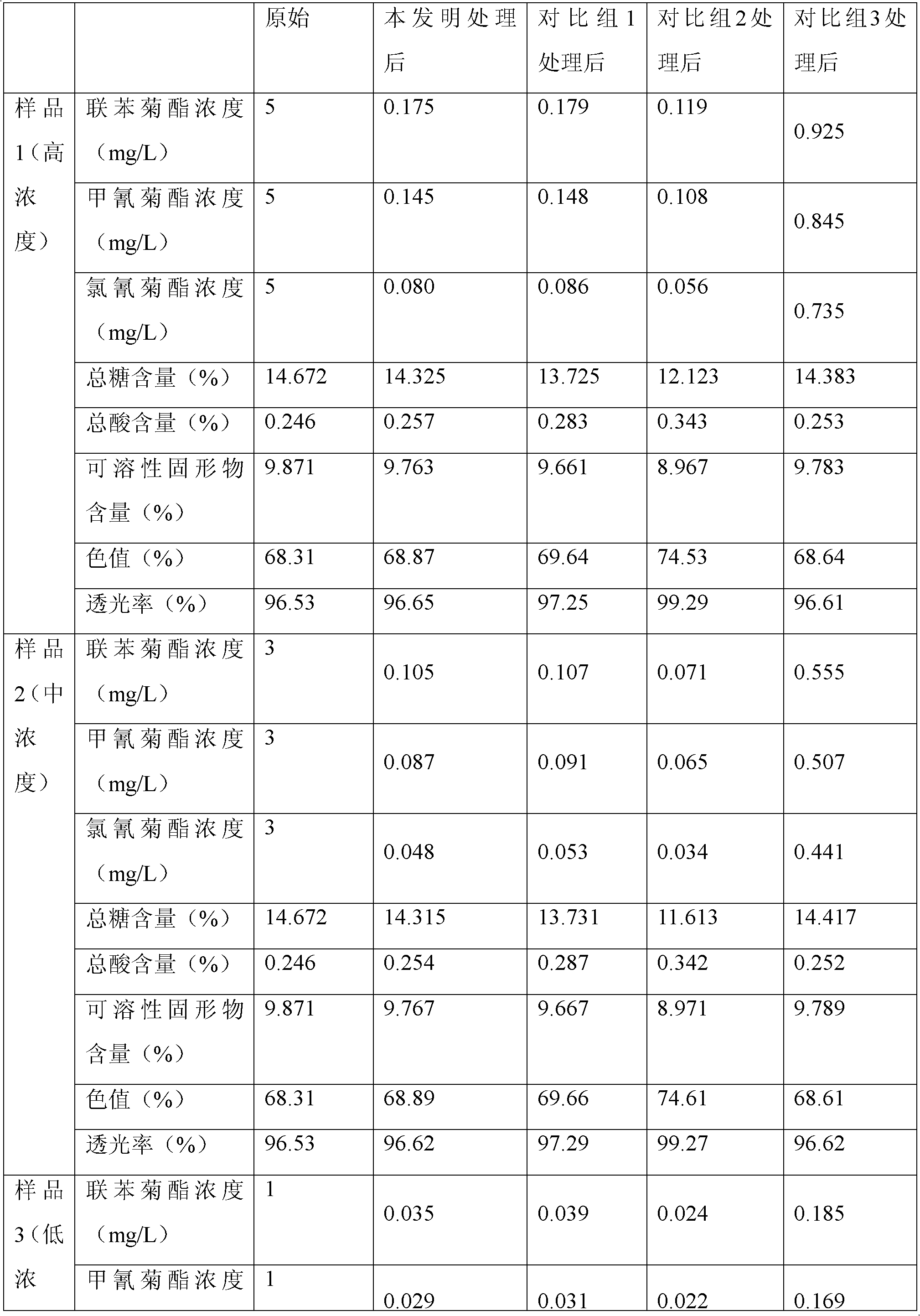

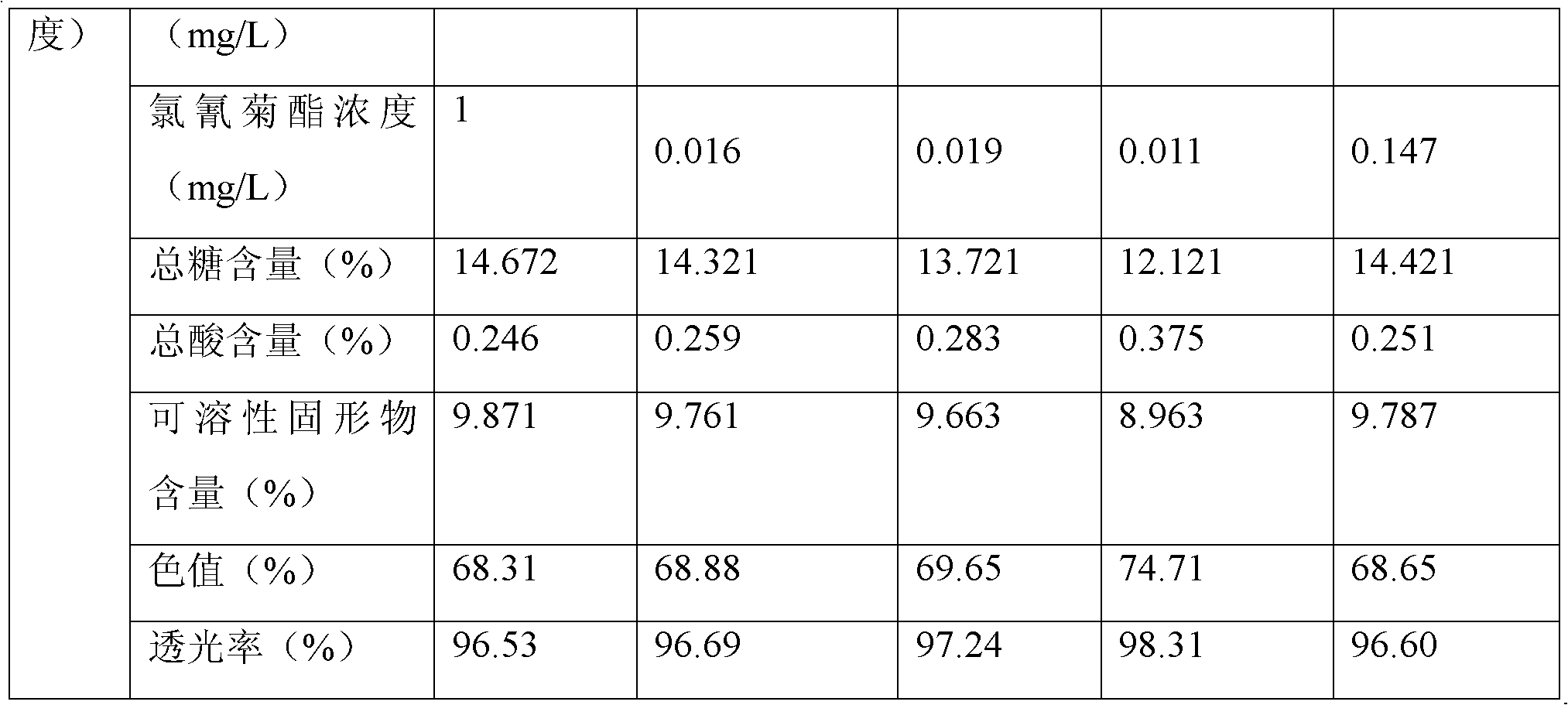

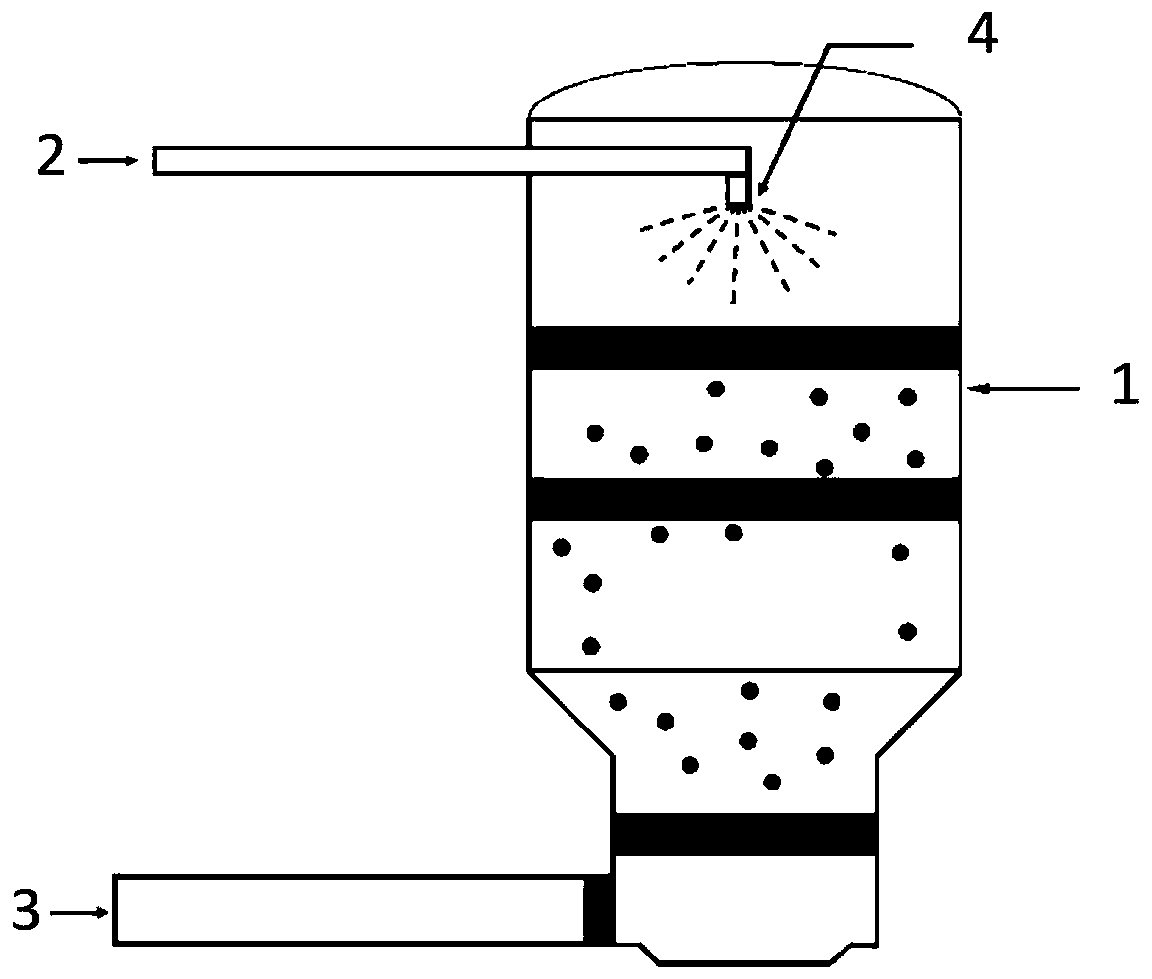

Method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation

InactiveCN102488288AResidue reduction or elimination of pyrethroid pesticidesGuaranteed qualityFood scienceDose rateGamma ray

The invention discloses a method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation. The method comprises the following steps of 1, pre-cooling red bayberry juice at a temperature of 1 to 4 DEG C for 100 to 140 minutes, and 2, putting pre-cooed red bayberry juice into an enclosed container, and carrying out irradiation by a 60Co-gamma ray as a radiation source, wherein an irradiation dose is in a range of 6.2 to 7.2kGy and a dose rate is in a range of 1200 to 1250cGy / min. The method can effectively, fast and safely reduce or eliminate pyrethroid pesticide residues in red bayberry juice so that a maximum residual value of the pyrethroid pesticide residues in the red bayberry juice reaches the EU standard. The invention discloses a method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation. The method comprises the following steps of 1, pre-cooling red bayberry juice at a temperature of 1 to 4 DEG C for 100 to 140 minutes, and 2, putting pre-cooed red bayberry juice into an enclosed container, and carrying out irradiation by a 60Co-gamma ray as a radiation source, wherein an irradiation dose is in a range of 6.2 to 7.2kGy and a dose rate is in a range of 1200 to 1250cGy / min. The method can effectively, fast and safely reduce or eliminate pyrethroid pesticide residues in red bayberry juice so that a maximum residual value of the pyrethroid pesticide residues in the red bayberry juice reaches the EU standard.

Owner:ZHEJIANG UNIV

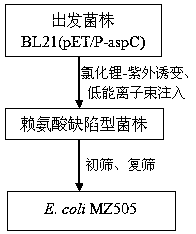

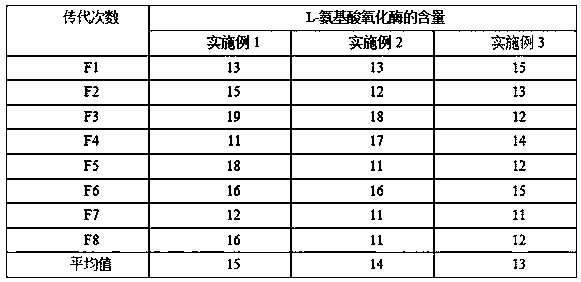

A high-yield l-amino acid oxidase strain and its application

ActiveCN105087443BIncrease color valueImprove conversion rateBacteriaMicroorganism based processesEscherichia coliL-amino-acid oxidase

The invention relates to a strain with a high L-amino acid oxidase yield. The classification name of the strain is escherichia coli MZ505. The invention further provides a screening method of the strain, a method for producing L-amino acid oxidase with the strain, and application of L-amino acid oxidase produced by the strain to production of 5-aminovaleric acid.

Owner:NANJING TECH UNIV

Method for delaying quality deterioration in raw sugar storage process

The invention relates to the technical field of food processing, and discloses a method for delaying quality deterioration in a raw sugar storage process. The method for delaying the quality deterioration in the raw sugar storage process comprises a step of adding a metal oxide and / or a metal hydroxide into raw sugar to make the pH value of the mixed raw sugar to be 6.8 to 8.5, wherein the metal is a metal element from Group IA or Group IIA. The method provided by the invention can adjust the pH value of the raw sugar simply and conveniently, and can significantly delay the quality deterioration in the raw sugar storage process without adding a procedure.

Owner:COFCO GROUP +3

Method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation

The invention discloses a method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation. The method comprises the following steps of 1, pre-cooling red bayberry juice at a temperature of 1 to 4 DEG C for 100 to 140 minutes, and 2, putting pre-cooed red bayberry juice into an enclosed container, and carrying out irradiation by a 60Co-gamma ray as a radiation source, wherein an irradiation dose is in a range of 6.2 to 7.2kGy and a dose rate is in a range of 1200 to 1250cGy / min. The method can effectively, fast and safely reduce or eliminate pyrethroid pesticide residues in red bayberry juice so that a maximum residual value of the pyrethroid pesticide residues in the red bayberry juice reaches the EU standard. The invention discloses a method for controlling pyrethroid pesticide residues in red bayberry juice by irradiation degradation. The method comprises the following steps of 1, pre-cooling red bayberry juice at a temperature of 1 to 4 DEG C for 100 to 140 minutes, and 2, putting pre-cooed red bayberry juice into an enclosed container, and carrying out irradiation by a 60Co-gamma ray as a radiation source, wherein an irradiation dose is in a range of 6.2 to 7.2kGy and a dose rate is in a range of 1200 to 1250cGy / min. The method can effectively, fast and safely reduce or eliminate pyrethroid pesticide residues in red bayberry juice so that a maximum residual value of the pyrethroid pesticide residues in the red bayberry juice reaches the EU standard.

Owner:ZHEJIANG UNIV

Beet sugar decalcification system

InactiveCN114277196ARealize continuous productionReduce foulingIon-exchange process apparatusIon-exchanger regenerationIon exchangeProcess engineering

The invention discloses a beet sugar decalcification system. A production area comprises a plurality of ion exchange resin columns which are arranged in parallel; the cooling backwashing area comprises a failed ion exchange resin column switched from the production area; the regeneration area comprises an ion exchange resin column switched from the cooling backwashing area, and NaOH softening thin juice is used for regenerating resin in the ion exchange resin column subjected to backwashing; the leaching and preheating zone comprises an ion exchange resin column switched from the regeneration zone, and the softening thin juice leaches and preheats resin in the ion exchange resin column. After the softened thin juice obtained through the beet sugar thin juice softening method enters a subsequent evaporator and other procedures, the scaling phenomenon of the evaporator and crystallization sugar boiling equipment is reduced, the situation that production is stopped due to descaling of the evaporator and other equipment is avoided, continuous production of beet sugar is achieved, and labor cost is saved. And meanwhile, the service lives of the evaporator and the crystallization sugar boiling equipment are prolonged.

Owner:欧尚元(天津)有限公司

Centrifugal filtering system for mud juice from cane sugar factory

The invention discloses a centrifugal filtering system for mud juice from a cane sugar factory. The centrifugal filtering system comprises a sugar mud settling pond, a first centrifuge, a second centrifuge, a stirring tank, a storage tank and a washing water tank, wherein the sugar mud settling pond is connected with a feeding opening of the first centrifuge by a pipeline; a liquid outlet of the first centrifuge is connected with the storage tank by a pipeline provided with a first exhaust tank; a solid outlet of the first centrifuge is connected with the stirring tank through a guide pipe; the stirring tank is connected with a feeding opening of a second centrifuge by a pipeline; a liquid outlet of the second centrifuge is connected with the storage tank by a pipeline provided with a second exhaust tank; a discharging pipe for importing sludge is arranged at a solid outlet of the second centrifuge; the stirring tank is also connected with the washing water tank through a pipeline. Thesystem has the advantages that solid-liquid rapid separation of the mud juice from the cane sugar factory is realized, treatment time of materials is shortened, production efficiency is improved, loss of filtered mud sucrose content and washing water amount are reduced, and energy is saved.

Owner:横县东糖糖业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com