Beet sugar decalcification system

A technology of beet sugar and ion exchange resin, applied in the field of beet sugar decalcification system, can solve the problems of difficult treatment of regenerated waste liquid and difficult removal of calcium salt, and achieve the effects of saving labor costs, prolonging service life and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

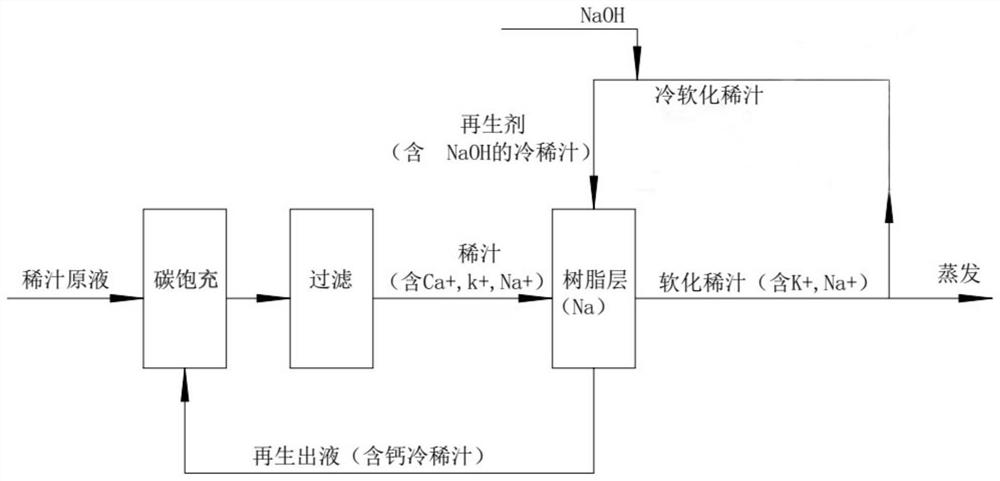

Method used

Image

Examples

Embodiment 1

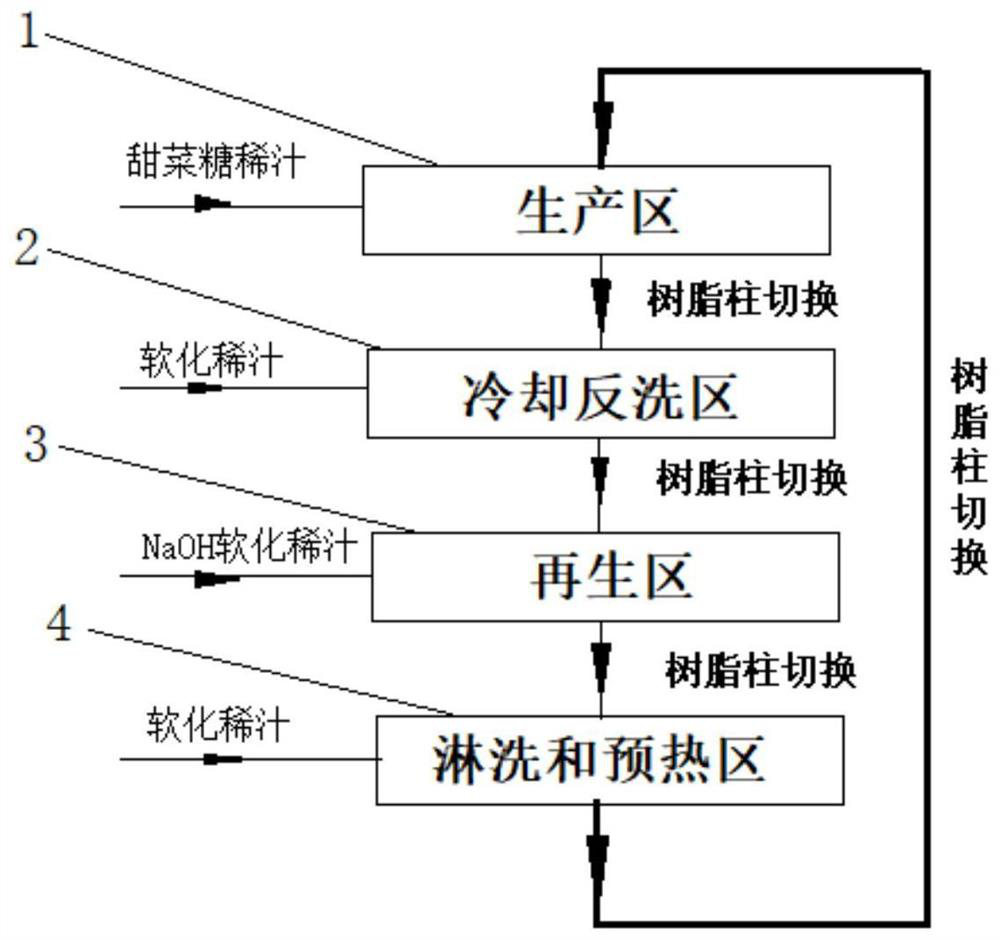

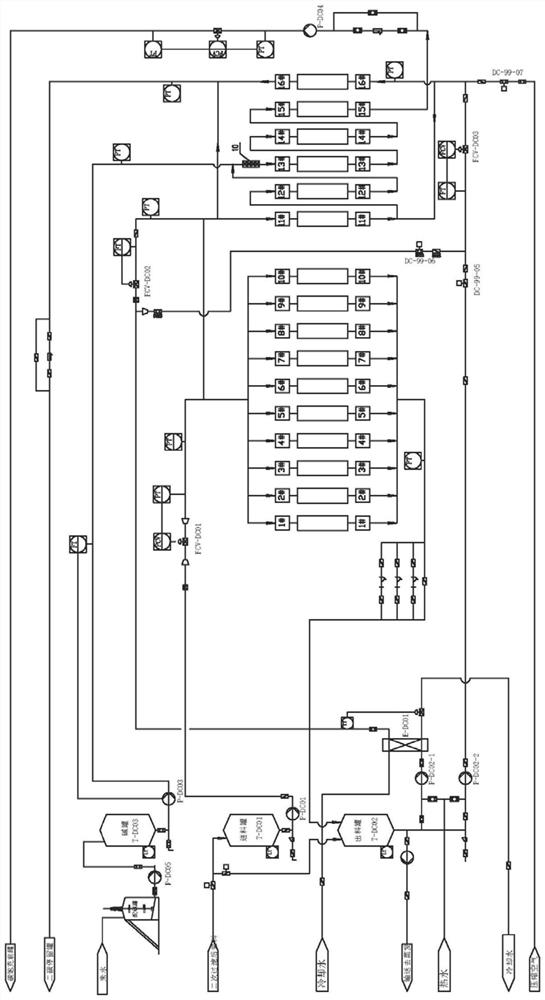

[0045] Such as image 3 As shown, this embodiment is designed according to 16 columns, and the simulated movement of the ion exchange resin column is realized by switching the valve array, and the operation is continuous. The 16 resin columns are assigned to the 1#-16# process position, respectively:

[0046] Production area (1#——10#): 10 resin columns are connected in parallel to run, and the beet syrup juice passes through the resin layer of these 10 resin columns in parallel for ion exchange to achieve the purpose of decalcification, and the regenerated resin column is switched into This area starts from the 10# process position and switches to the 1# process position one by one, and the degree of resin failure gradually deepens until it fails; although this embodiment uses 10 resin columns, it is not to limit the number of resin columns in the production area. The quantity can be set according to the amount of material processed, etc.

[0047] The feed tank T-DC01 is con...

Embodiment 2

[0063] Example 2 Resin Regeneration Test: Regenerate Saturated Resin Using NaCl and NaOH to Soften Dilute Juice

[0064] The control group used 10% NaCl solution as the resin regeneration solution, 200g of salt per liter of resin regeneration, 20g of CaO per liter of thin juice, and 10g of salt was consumed for removing 1g of CaO.

[0065] The experimental group used 6% NaOH softened dilute juice as the resin regeneration solution, 136.8g of NaOH per liter of resin regeneration, 20g of CaO per liter of the dilute juice, and 7.1g of NaOH per 1g of CaO removal.

[0066] The comparative indicators of beet sugar decalcification regeneration methods are as follows:

[0067]

Embodiment 3

[0068] The comparison of embodiment 3 traditional ion-exchange resin column and the small-diameter ion-exchange resin column of the present invention

[0069] In the multi-unit continuous separation system, when using 16 small columns with a diameter of 1.2m, the resin filling volume of the entire system is 28m 3 Left and right, the running line speed is 30m / h, and the flow rate of the material is 340m 3 / h.

[0070] In a traditional fixed bed, when two large columns with a diameter of 3.45m are used, the resin filling volume of the entire system is still 28m 3 Left and right, the running line speed is 30m / h, and the flow rate of the material is 280m 3 / h.

[0071] In comparison, it can be seen that with the same resin loading, the multi-unit continuous ion exchange system can obviously handle more materials.

[0072] At the same time, due to the small diameter of the ion exchange resin column, the efficiency of backwashing and regeneration is higher, and the eluent and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com