Centrifugal filtering method of paste juice in cane sugar factory

A technology of centrifugal filtration and cane sugar, applied in the direction of separation method, filtration separation, filtration circuit, etc., can solve the problems of increasing the transportation and processing capacity of enterprises, unfavorable environmental cleaning, unfavorable material handling, etc., achieve stable and sustainable economic benefits, reduce chemical The effect of changing and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

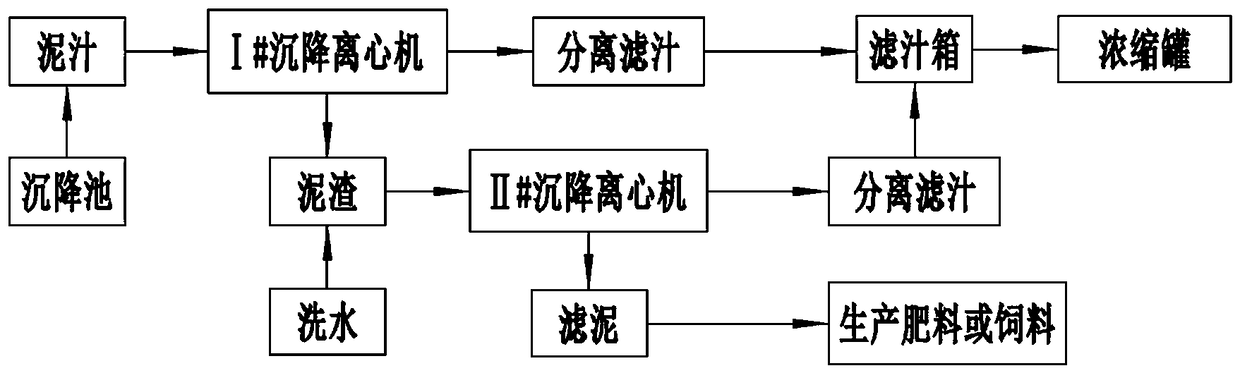

[0021] The following steps can be used to complete the filtration of sugary sludge in sugarcane sugar factory:

[0022] (1) Transport the sugar-containing sludge obtained from the sedimentation of the settling tank to the Ⅰ# horizontal sedimentation centrifuge for sludge separation. There are about 95% sugar juice in the sludge, and the separated filtered juice is transported into the filter juice box for separation The sludge obtained is discharged into the sludge and water mixing tank;

[0023] (2) Add washing water to the water mixing tank containing sugar mud and slag and stir; the amount of washing water added is 3.06% (the weight ratio of washing water to sugarcane);

[0024] (3) Transport the material in the mixing tank containing sugar sludge and water to Ⅱ# horizontal sedimentation centrifuge for solid-liquid separation, and the separated filtered juice is transported into the filtered juice box to mix with the filtered juice in step (1), and then transported Go to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com