Centrifugal filtering system for mud juice from cane sugar factory

A technology of centrifugal filtration and cane sugar, applied in the direction of filtration separation, filtration loop, separation method, etc., can solve the problems of increasing the transportation capacity of enterprises, unfavorable environmental cleaning, unfavorable material handling, etc., and achieve stable and sustainable economic and environmental benefits. Significantly reduce the loss of sucrose in the filter mud and the effect of the amount of filter mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

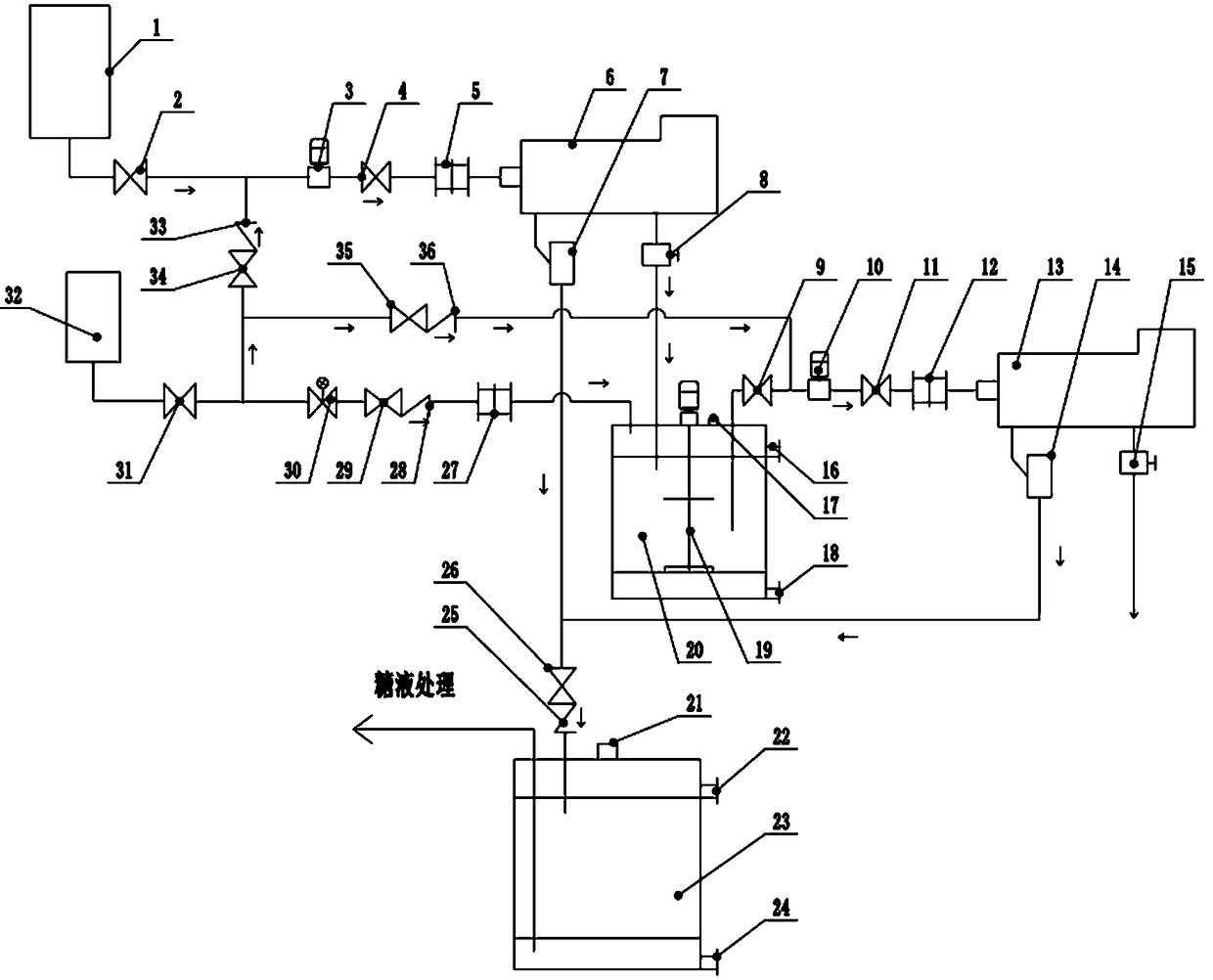

[0037] The centrifugal filtration system of sugarcane sugar mill mud juice of the present invention, it comprises sugar mud settling tank 1, I# centrifuge 6, II# centrifuge 13, stirring tank 20, storage tank 23 and washing water tank 32, described sugar mud Sedimentation tank 1 is connected to the feed port of I# centrifuge 6 through pipelines; the pipeline between sugar sludge sedimentation tank 1 and I# centrifuge 6 is sequentially installed with conveying regulating valve 4 and conveying Flow meter 5; the liquid outlet of I# centrifuge 6 is connected to the storage tank 23 through the pipeline equipped with I# exhaust tank 7; the solid outlet of I# centrifuge 6 is connected to the stirring tank 20 through a conduit; the stirring tank 20 passes through the pipeline It is connected to the feed port of Ⅱ# centrifuge 13; on the pipeline between the stirring tank 20 and Ⅱ# centrifuge 13, a feed pump 10, a regulating valve 11 and a feed flow meter 12 are installed sequentially fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com