Preparation method of concentrated clear sweet potato juice with high color value

A technology of sweet potato juice and sweet potato, which is applied in the field of preparation of sweet potato concentrated clear juice with high color value, which can solve the problems of low juice yield, loss of nutrients, difficulty in pressing, etc., to avoid secondary turbidity, improve pressing performance, and clear juice clarification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

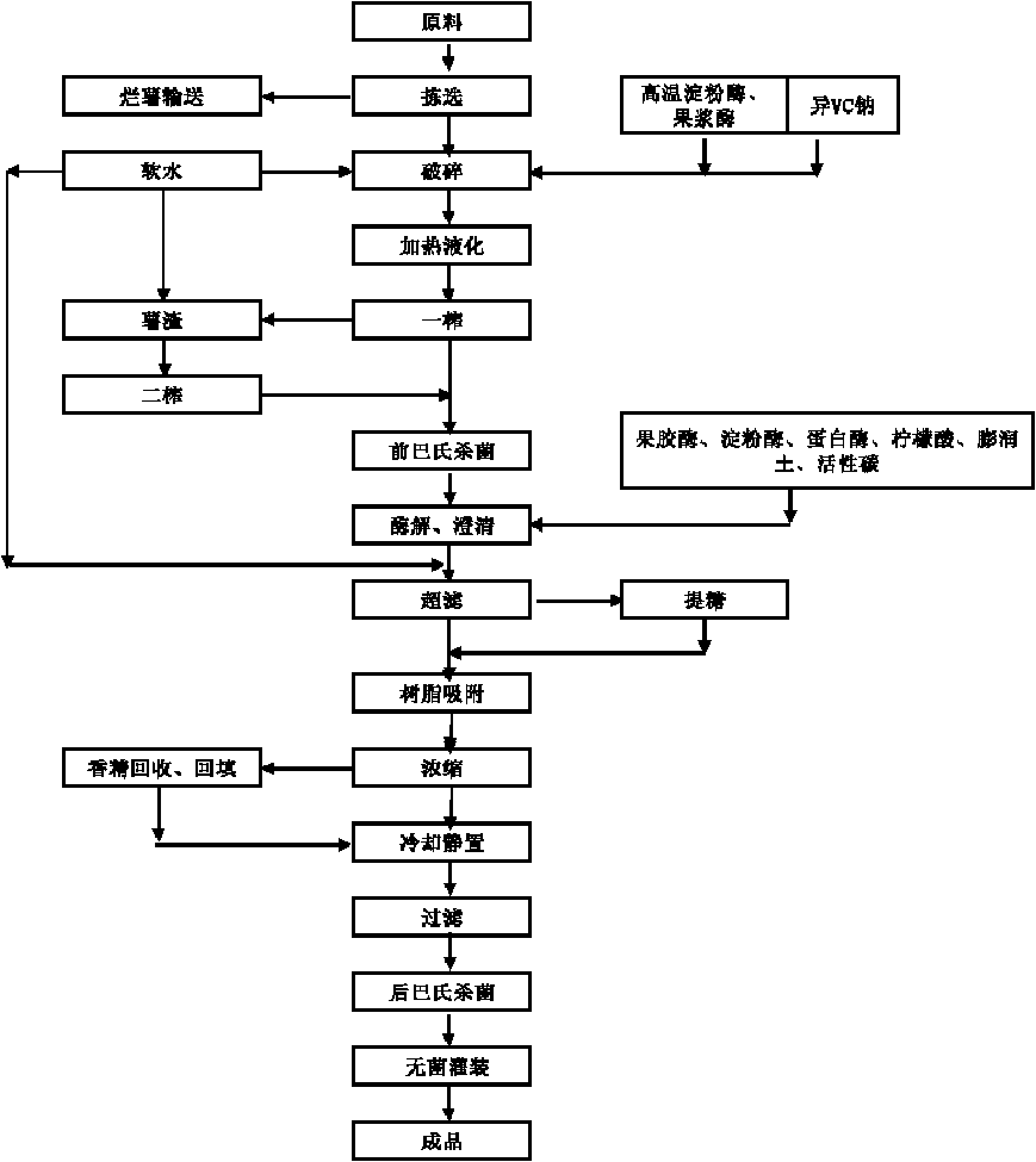

[0033] see figure 1 , a preparation method of sweet potato concentrated clear juice with high color value, comprising the following steps:

[0034] 1. Selection and cleaning of raw materials:

[0035] 1.1 Check and accept the sweet potato raw materials, use the water flow to transport, and the flow water is replaced every 8 hours;

[0036] 1.2 After a first-level upgrade, enter the sorting table to pick out rotten, pests, black skin, and black spot sweet potatoes;

[0037] 1.3 Enter the floating washing tank for cleaning after the second level of lifting;

[0038] 1.4 After three stages of lifting, it enters the roller bar for spray cleaning.

[0039] 2. Crushing and beating

[0040] 2.1 When crushing, add soft water with the amount of sweet potato: water = 1:2, and the crushing particle size is controlled at 2-3 mm;

[0041] 2.2 The raw material feed rate is 5t / h, which is determined by the production efficiency of the crusher;

[0042] 2.3 While crushing the sweet pota...

Embodiment 2

[0085] 1. Raw material acceptance

[0086] 1.1 Check and accept the sweet potato raw materials, use the water flow to transport, and the flow water is replaced every 8 hours;

[0087] 1.2 After a first-level upgrade, enter the sorting table to pick out rotten, pests, black skin, and black spot sweet potatoes;

[0088] 1.3 Enter the floating washing tank for cleaning after the second level of lifting;

[0089] 1.4 After three stages of lifting, it enters the roller bar for spray cleaning.

[0090] 2. Broken

[0091] 2.1 When crushing, add soft water with the amount of sweet potato: water = 1: 1.5, and the crushing particle size is controlled at 2-3 mm;

[0092] 2.2 The raw material feed rate is 5t / h, which is determined by the production efficiency of the crusher;

[0093] 2.3 While crushing the sweet potatoes, add 0.20kg / t of Isodimensional C sodium to the sweet potatoes, and dissolve the Isodimensional C sodium and water at a ratio of 1:10, and add it into the potato pulp...

Embodiment 3

[0135] 1 raw material acceptance

[0136] 1.1 Check and accept the sweet potato raw materials, use the water flow to transport, and the flow water is replaced every 8 hours;

[0137] 1.2 After a first-level upgrade, enter the sorting table to pick out rotten, pests, black skin, and black spot sweet potatoes;

[0138] 1.3 Enter the floating washing tank for cleaning after the second level of lifting;

[0139] 1.4 After three stages of lifting, it enters the roller bar for spray cleaning.

[0140] 2 broken

[0141] 2.1 When crushing, add soft water with the amount of sweet potato: water = 1:2, and the crushing particle size is controlled at 2-3 mm;

[0142] 2.2 The raw material feed rate is 5t / h, which is determined by the production efficiency of the crusher;

[0143] 2.3 While crushing the sweet potatoes, add 0.25kg / t of Isodimensional C Sodium to the sweet potatoes. The Isodimensional C Sodium and water are prepared by dissolving at a ratio of 1:10. Use a hose to add into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com