Pressing device used for fragrance processing

The technology of spice and pressing plate is applied in the field of pressing device and the pressing device of spice processing, which can solve the problems of inconvenient material removal, inconvenient installation and disassembly, and lower product quality, etc., and achieves the effect of simple structure, convenient installation and disassembly, and compact connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

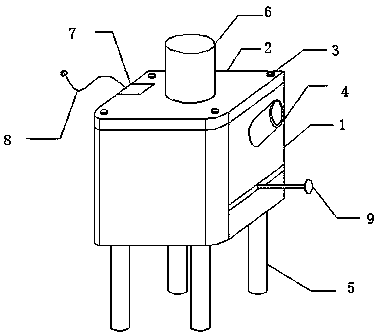

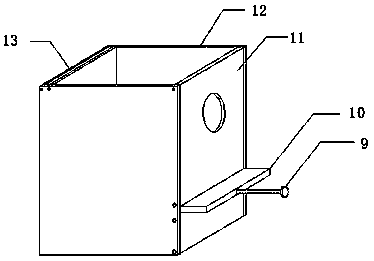

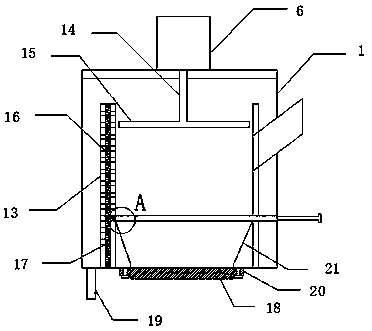

[0024] see Figure 1-4 As shown, a pressing device for spice processing includes a device shell 1, a pressing plate 15, a feed pipe 4, a support leg 5, a hydraulic pump 6 and a filter plate 16, and a cover 2 is installed on the top of the device shell 1, and the cover 2 A hydraulic pump 6 is set in the middle, a number of support legs 5 are set under the device shell 1, a feed pipe 4 is set on one side of the device shell 1, a control panel 7 is set on one side of the hydraulic pump 6, a power connection 8 is set on the side of the control panel 7, and the feed tube 4. A tie rod 9 is arranged at the bottom, a bottom plate 10 is set at one end of the pull bar 9, a connecting plate 11 is set in the middle of the bottom plate 10, side plates 12 are set at both ends of the connecting plate 11, two filter plates 13 are set at one end of the side plate 12, and a filter plate 13 is installed between the two filter plates 13. Net 16, and several filter holes 17 are arranged inside the...

Embodiment 2

[0026] In addition, refer to Figure 1-4 , different from the above-mentioned embodiment 1, the hydraulic pump 6 is connected to the power connection 8 through the control panel 17, and the hydraulic pump 6 is electrically connected to the control panel 17. -T206M) Start and stop hydraulic pump 6. The filter plate 13, the side plate 12 and the connecting plate 11 form a cuboid groove, and the cuboid groove matches the pressure plate 15. The pressure plate 15 moves up and down through the hydraulic rod 14. The hydraulic pump 6 drives the hydraulic rod 14 to rise and fall, and the pressure plate 15 presses down. The material is squeezed during the process, and rises after the squeeze is completed. An inner groove 22 is set in the middle of the filter plate 13, and the bottom plate 10 is movably connected with the filter plate 13 through the inner groove 22. After the pressing is completed, waste materials are accumulated on the bottom plate 10, and the bottom plate 10 is pulled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com