Patents

Literature

72results about How to "Good squeezing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

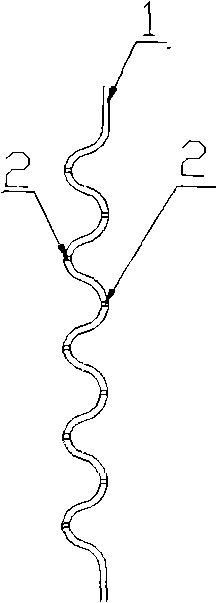

Strap filter-press dehydration technique and device

ActiveCN101306273AEnhanced dehydration pressTo achieve the purpose of pressing and dehydrationPressesMoving filtering element filtersSludgeEngineering

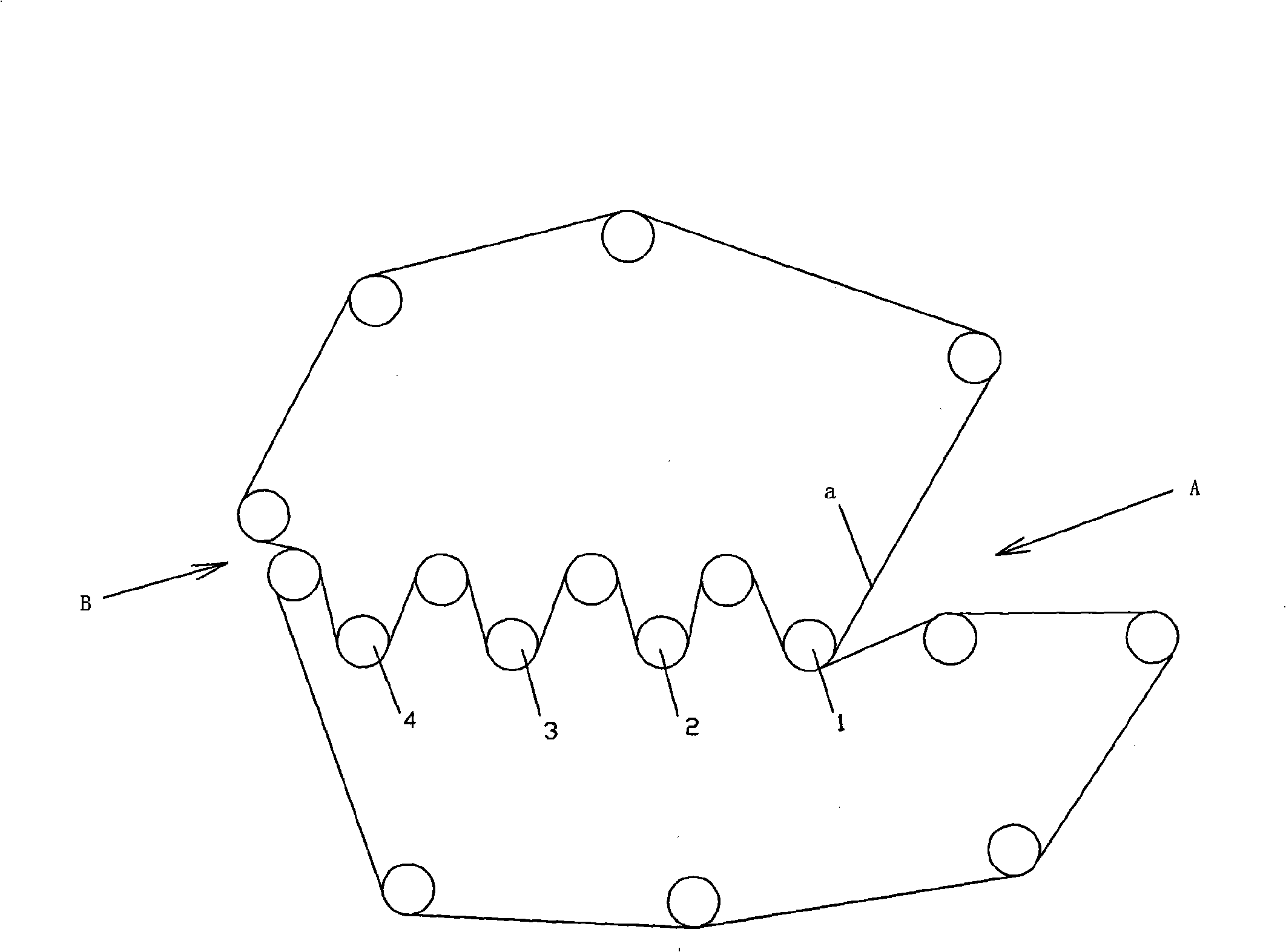

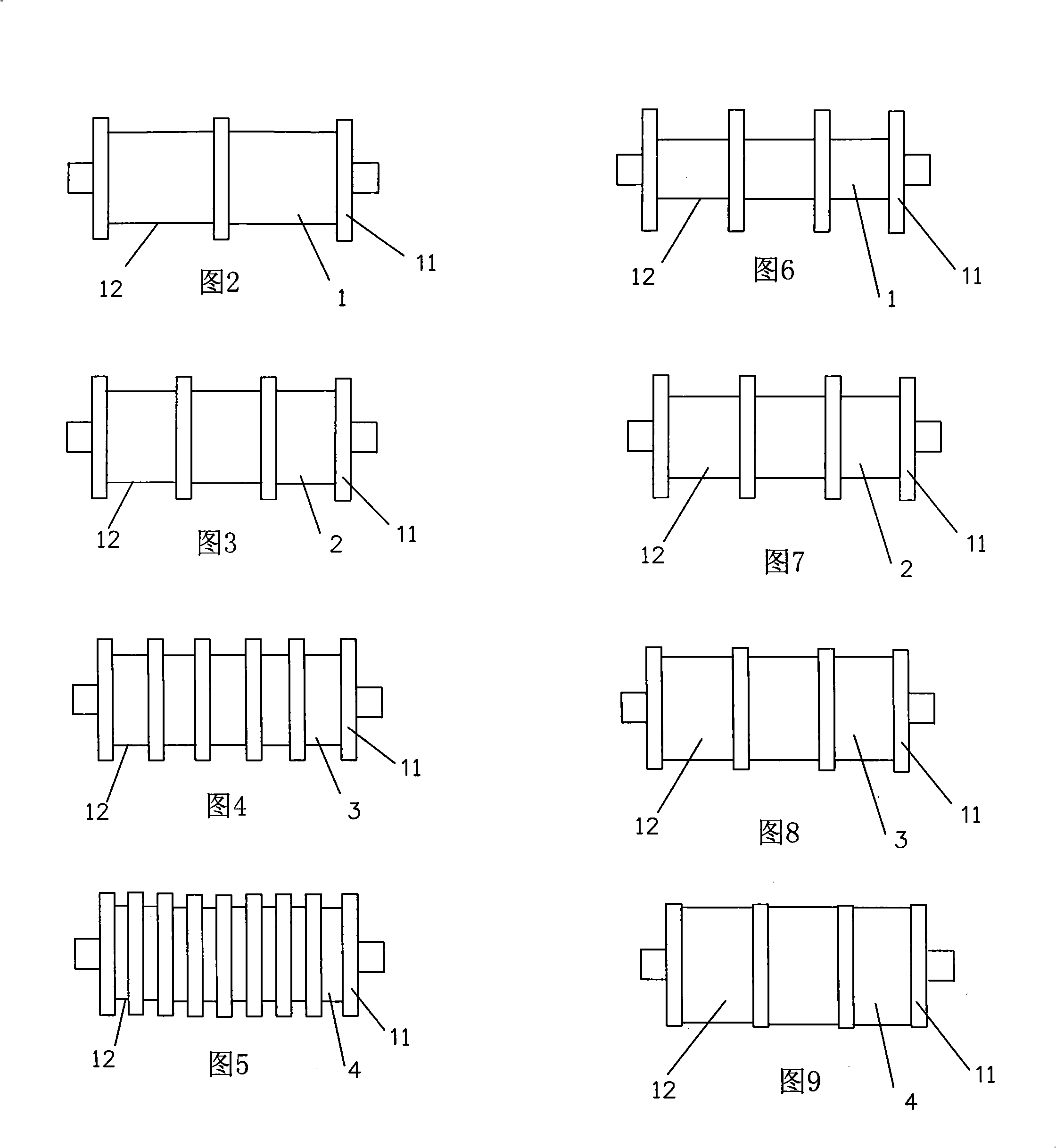

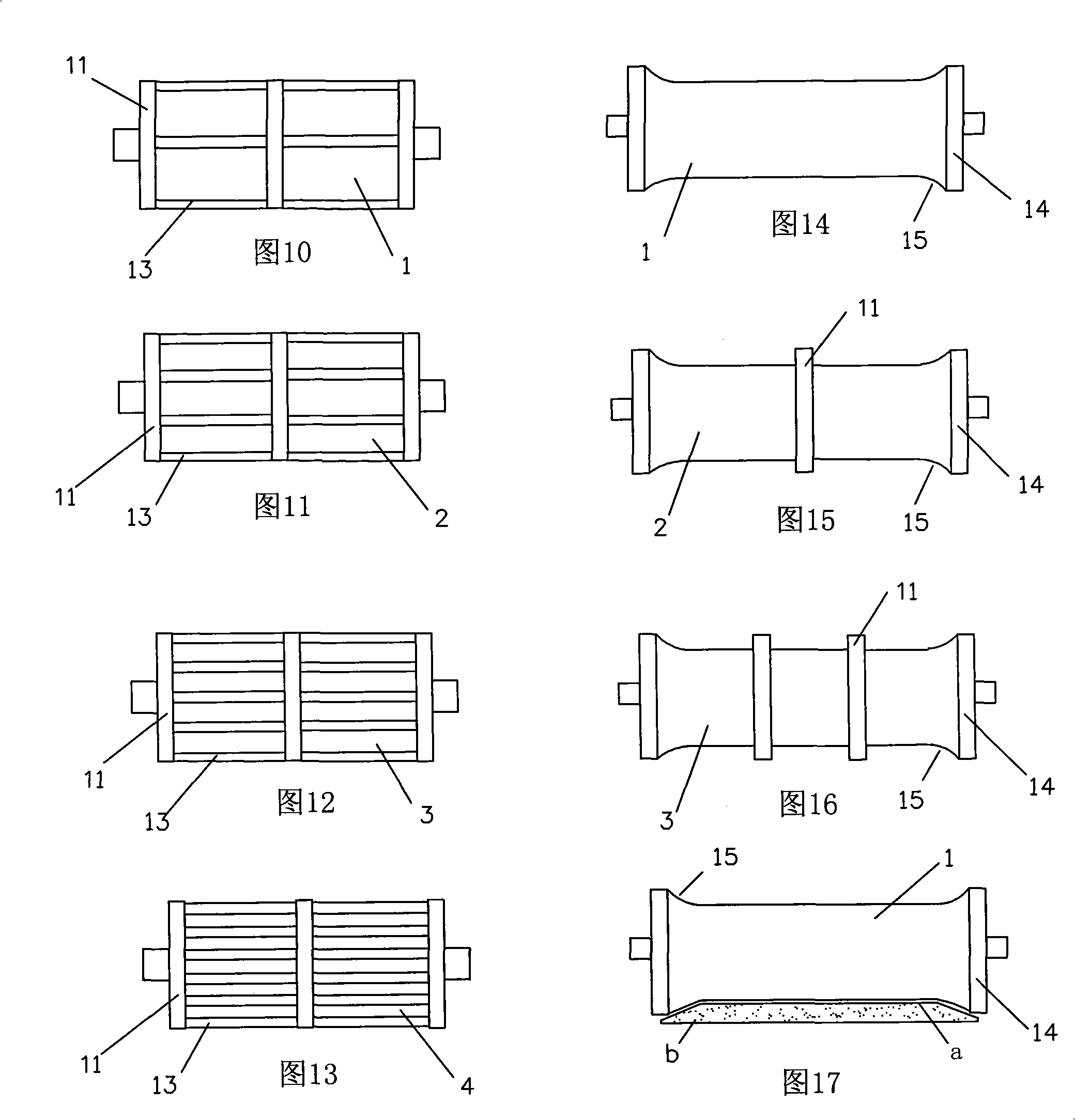

The invention discloses a belt press filtering dehydration process and a device. The belt press filter dehydration process increases the area of pressure for press filtering dehydration of dehydrated materials from small to large according to the running direction of a filter belt, and the received dehydration pressure is gradually increased from small to large according to the running direction of the filter belt. The outside diameter of a press roller body of the belt press filtering dehydration device is constant, two or more bosses or grooves are formed on the surface of the roller body, and the surface area of the press roller body is gradually increased from small to large according to the running direction of the filter belt. The process of the invention can gradually strengthen the dehydration press of the dehydrated materials under the condition of keeping the tension and the diameter of the press roller unchanged, and has the advantages of convenient implementation and good press effect; and the device of the invention can simplify the structure of a belt press filter, and avoid the phenomena that the filter belt becomes looser and looser or tighter and tighter, and sludge leaking, creasing or lengthening of the filter belt and so on occur in the operation of the prior art on the premise of ensuring the press effect, thereby effectively preventing the sludge from transverse leaking and improving the efficiency of the press dehydration.

Owner:ZHEJIANG HUAZHANG TECH

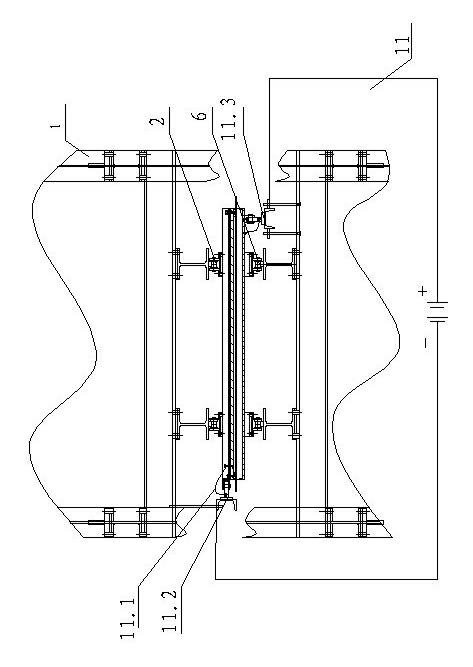

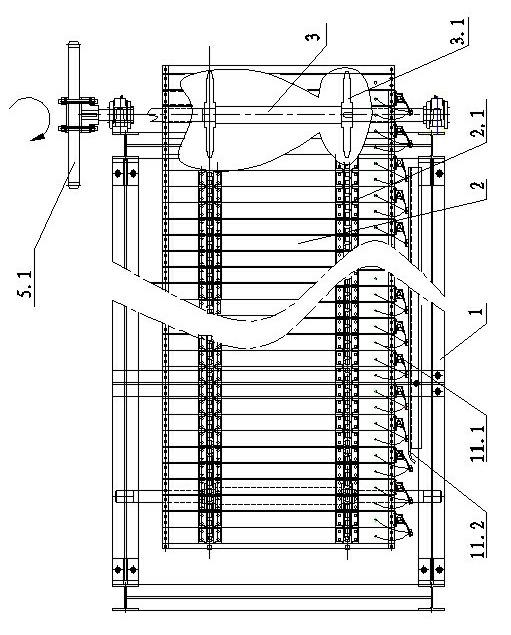

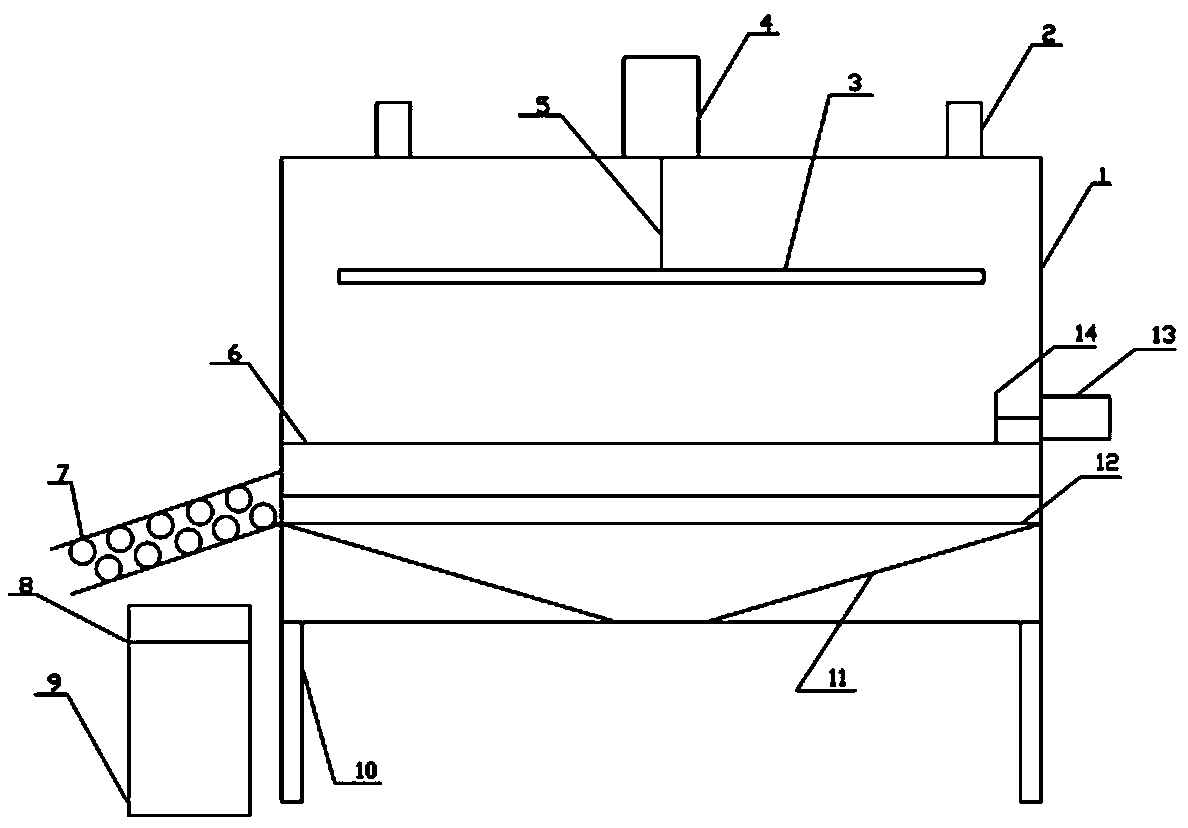

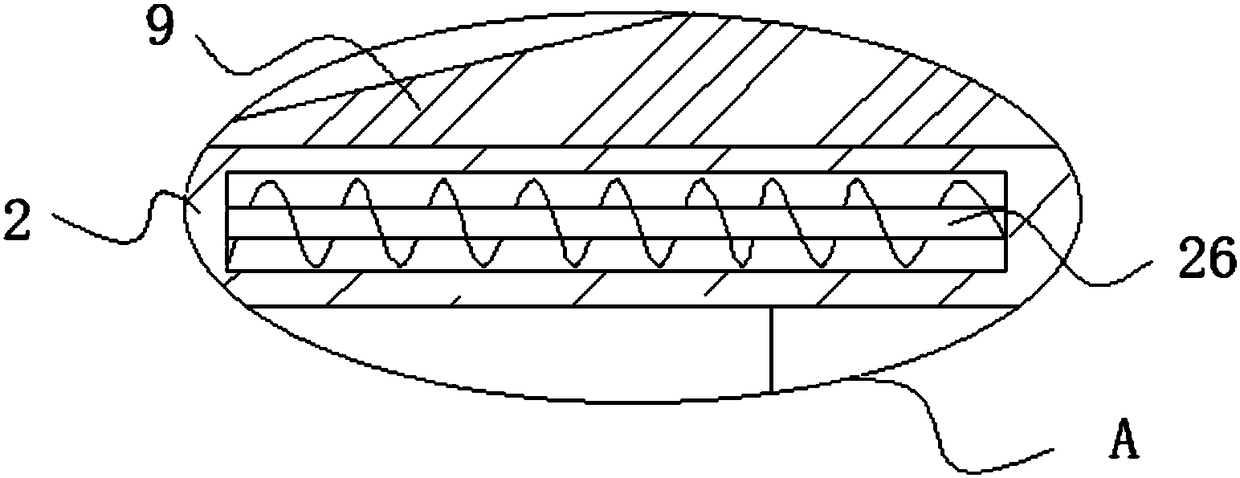

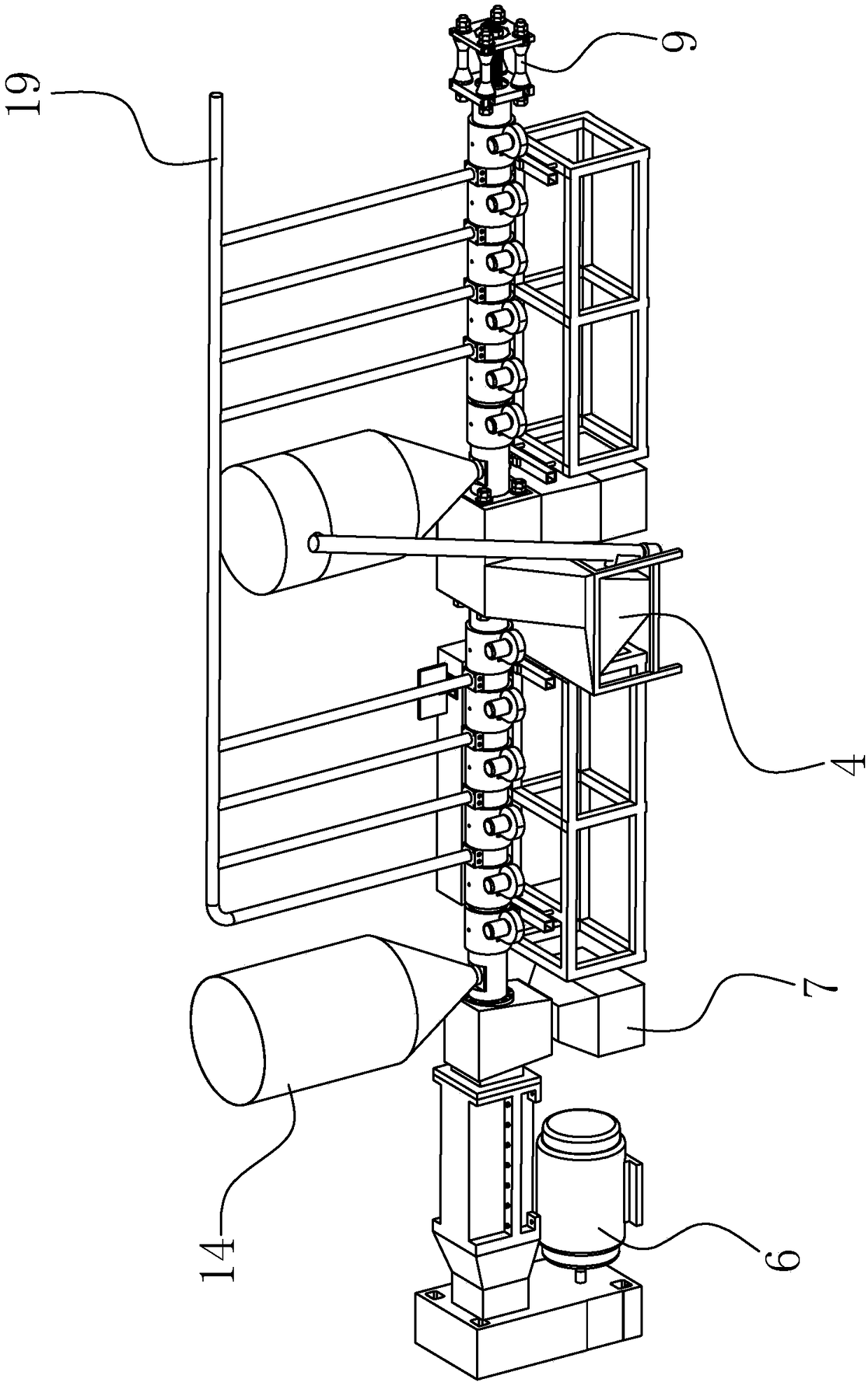

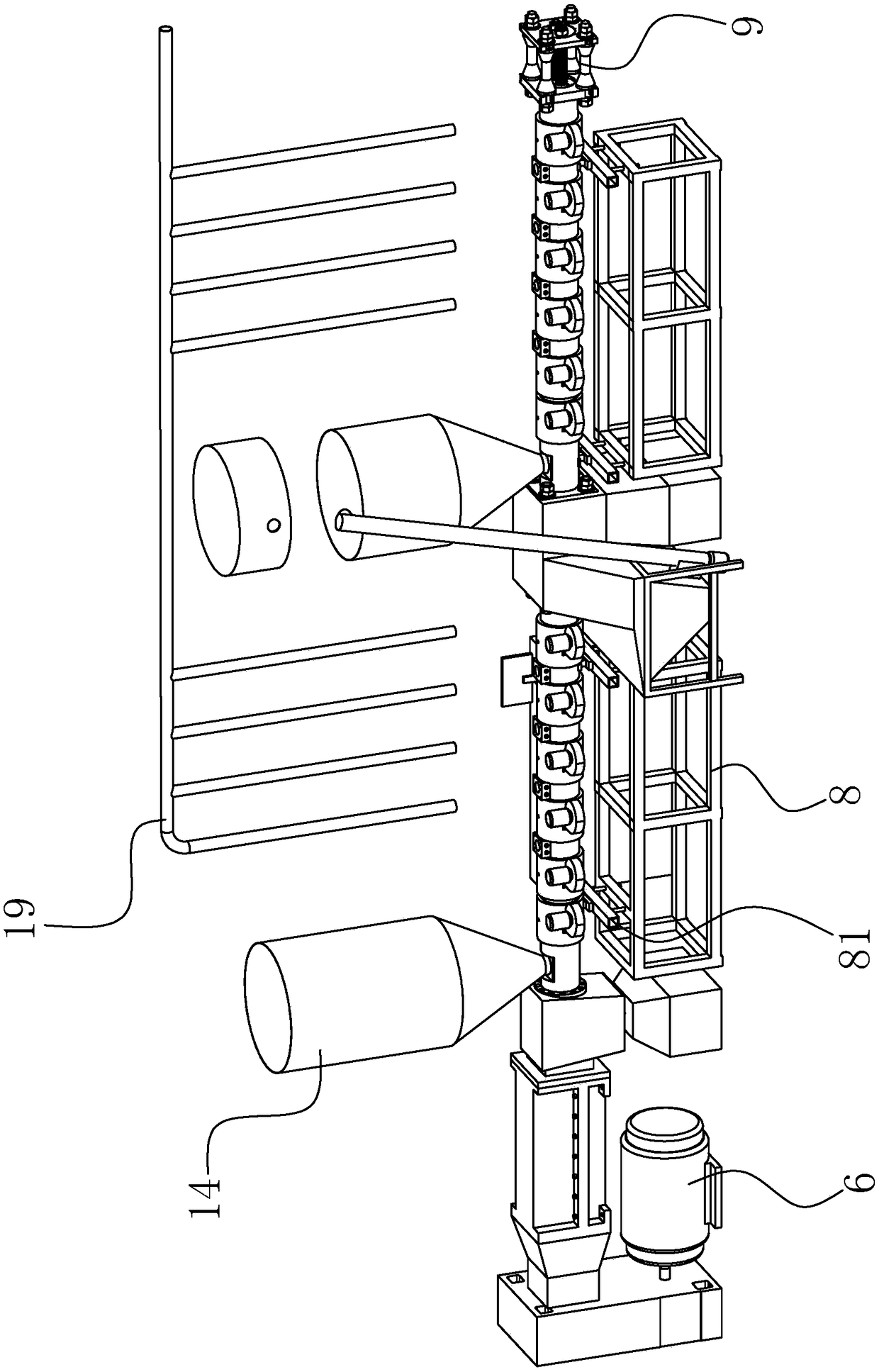

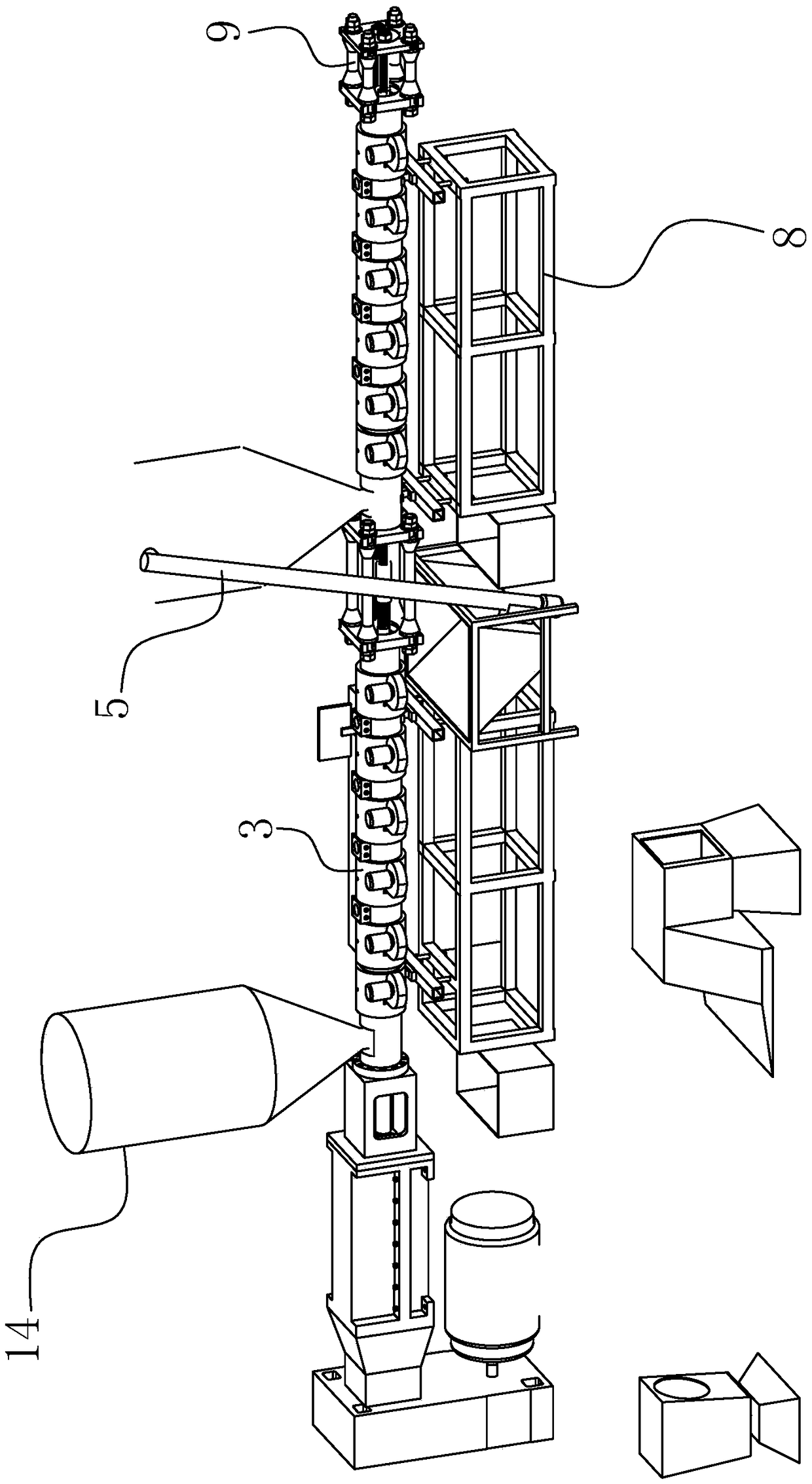

Electroosmosis belt type squeezing sludge dehydration equipment

ActiveCN102653438ASignificant reductionFacilitate flowSludge treatment by de-watering/drying/thickeningSludge cakeDrive shaft

The invention discloses electroosmosis belt type squeezing sludge dehydration equipment, which comprises a stander, an upper squeezing belt, transmission shafts, a scraper blade, power machinery, a lower squeezing belt, a tension device, a rectification device, a filter belt, supporting wheels and a power supply, wherein the upper squeezing belt and the lower squeezing belt which are supported and driven by the transmission shafts have the same structure, namely a track type structure which consists of two chains arranged at an interval and an upper bridge plate and / or a lower bridge plate which are / is transversely arranged according to pitches of the chains; the upper squeezing belt and the lower squeezing belt are respectively connected with the positive electrode and the negative electrode of the direct current power supply and clamp the filter belt to enter a wedged flat groove of the stander, namely a squeezing region under an electrophoresis condition, so that water molecules in sludge flow towards the lower bridge plates with negative levels; and therefore, the squeezing dehydration efficiency is greatly improved, the sludge is reduced obviously, and the produced high-dryness sludge cake is favorable for later-stage recycling application.

Owner:江苏百新环境工程有限公司

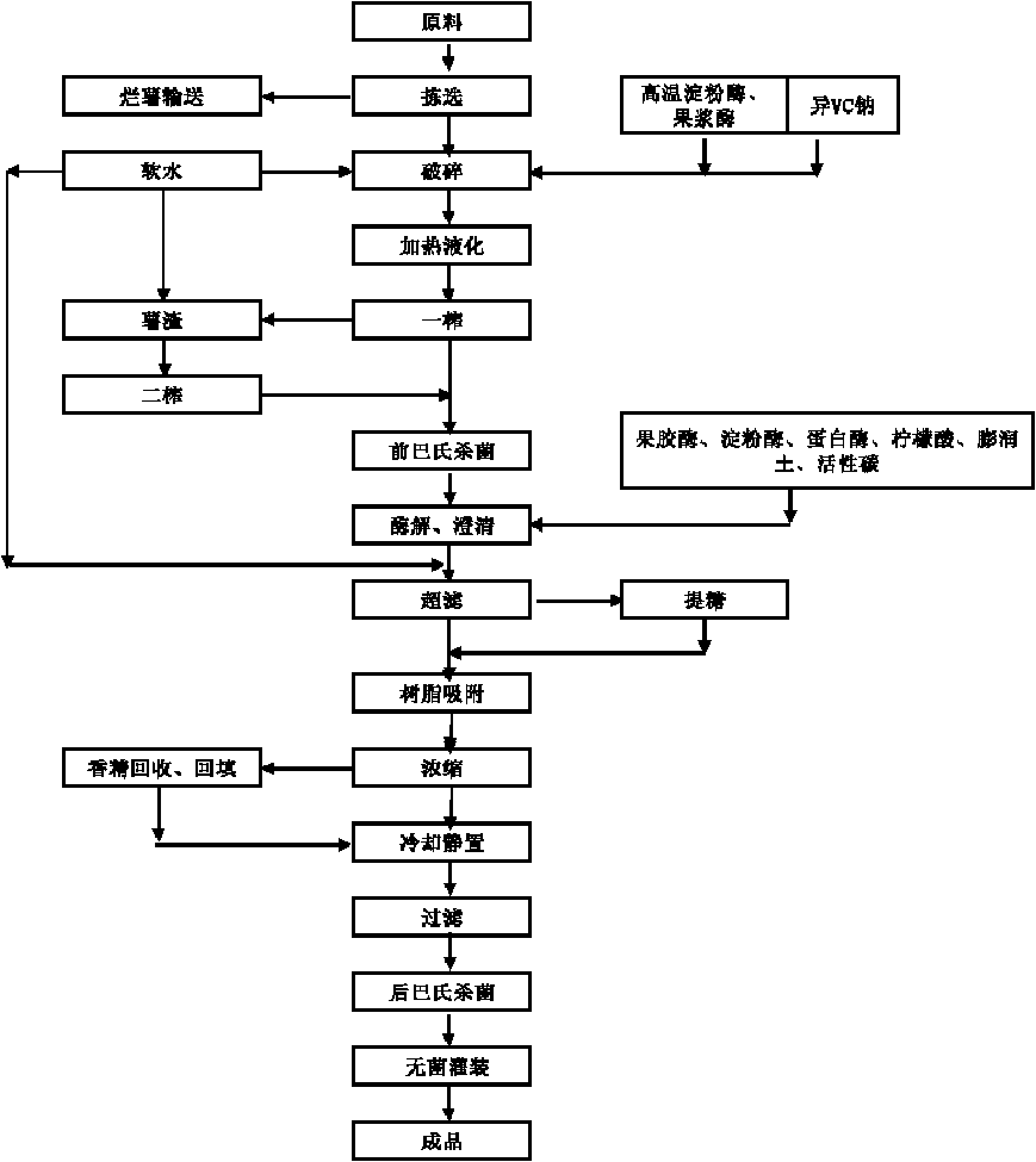

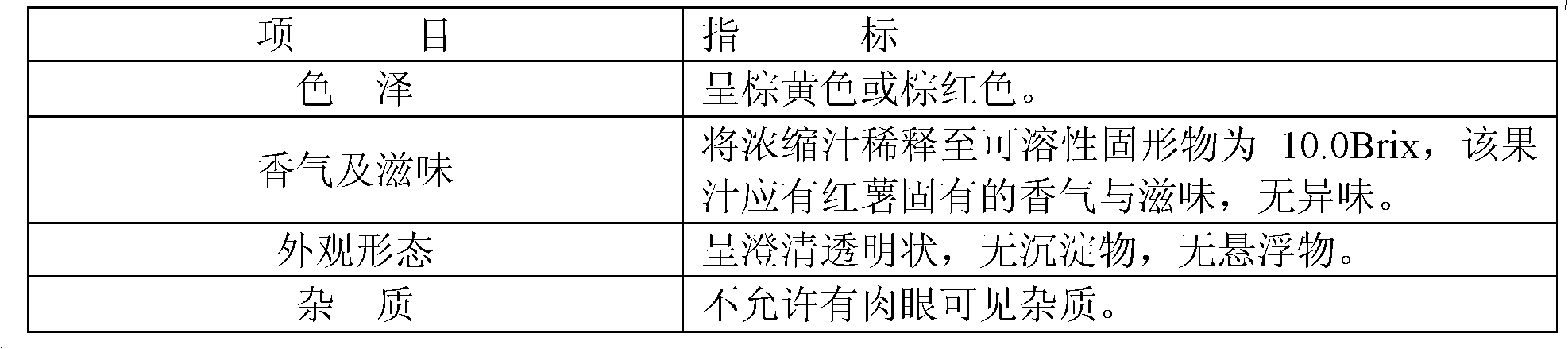

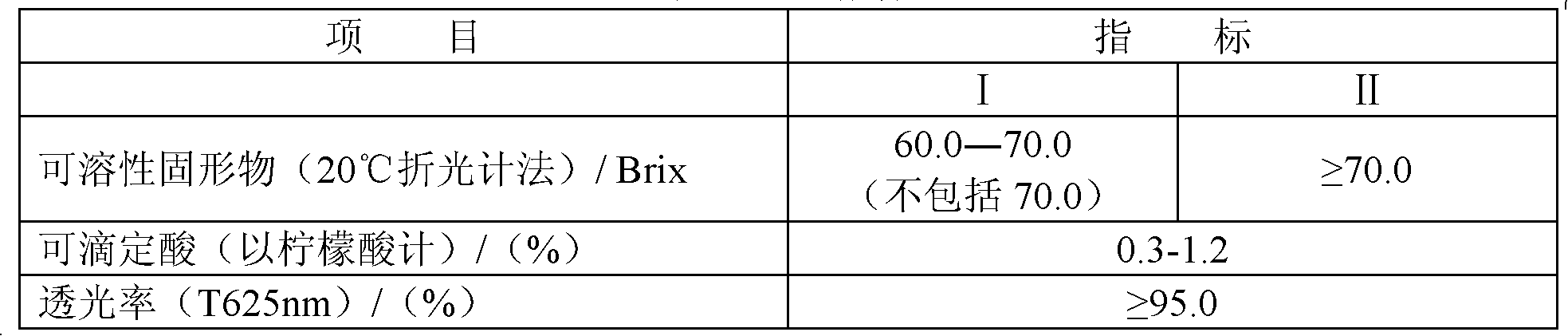

Preparation method of concentrated clear sweet potato juice with high color value

InactiveCN102349632AGood squeezing effectOvercoming the pitfalls of enzymatic browningFood preparationAmylaseFlavor

The invention discloses a preparation method of concentrated clear sweet potato juice with high color value. The preparation method has the following beneficial effects: mechanical peeling is omitted in the processing course; the pressability of the sweet potato pulp can be improved and the juice yield can be increased by adding amylase and pulp enzyme when the sweet potatoes are broken; soft water is further added to the sweet potato residues obtained after pressing to carry out secondary pressing to increase the juice yield; during enzymolysis, the amylase, the pulp enzyme and protease are unitedly used, thus achieving better clear juice clarifying effect; after being clarified, the raw juice is adsorbed by macroporous resins to adsorb the pigment, thus increasing the color value of theclear juice, and such substances as polyphenol, pectin, proteins, pesticide residues and the like are further adsorbed and removed, thus avoiding secondary turbidity; and while concentrating the sweet potato juice, essences are backfilled in the concentrated sweet potato juice, thus improving the flavor of the sweet potato juice.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

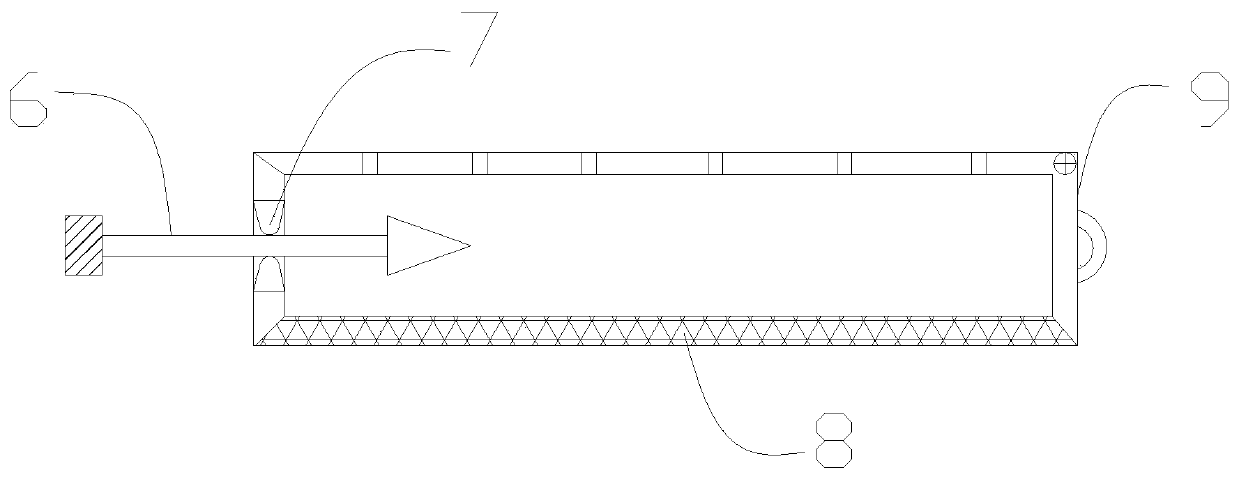

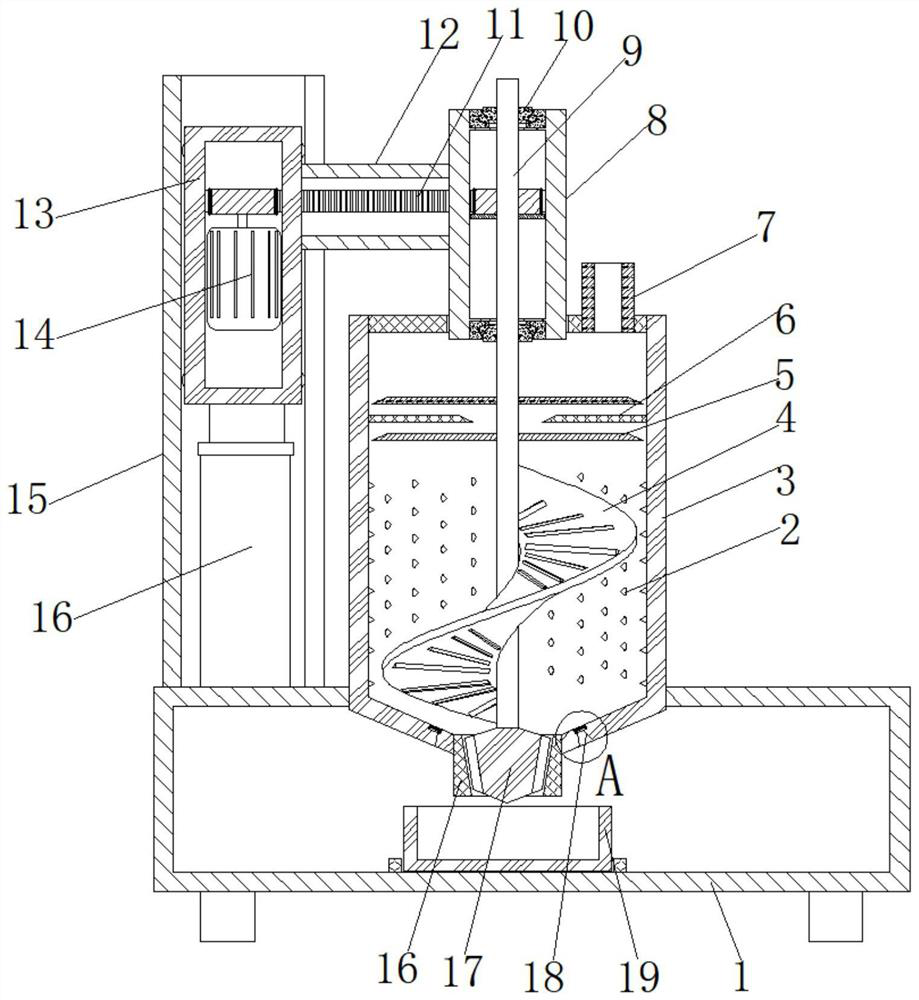

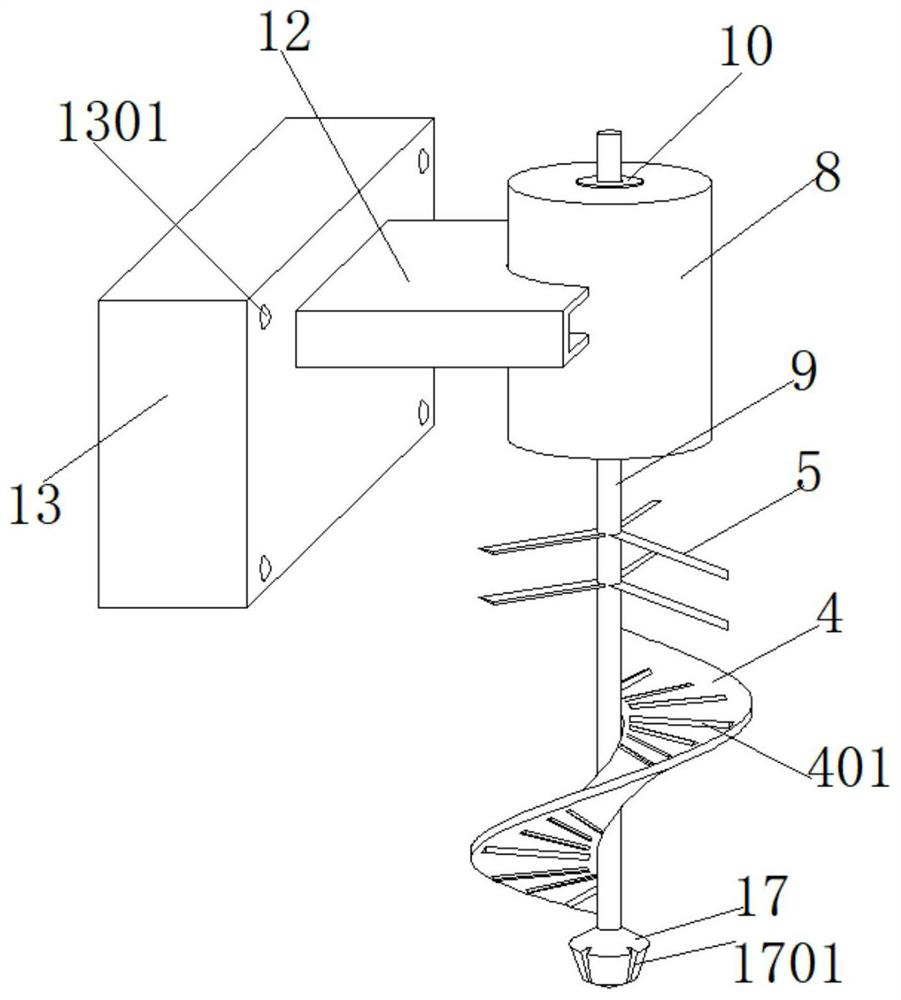

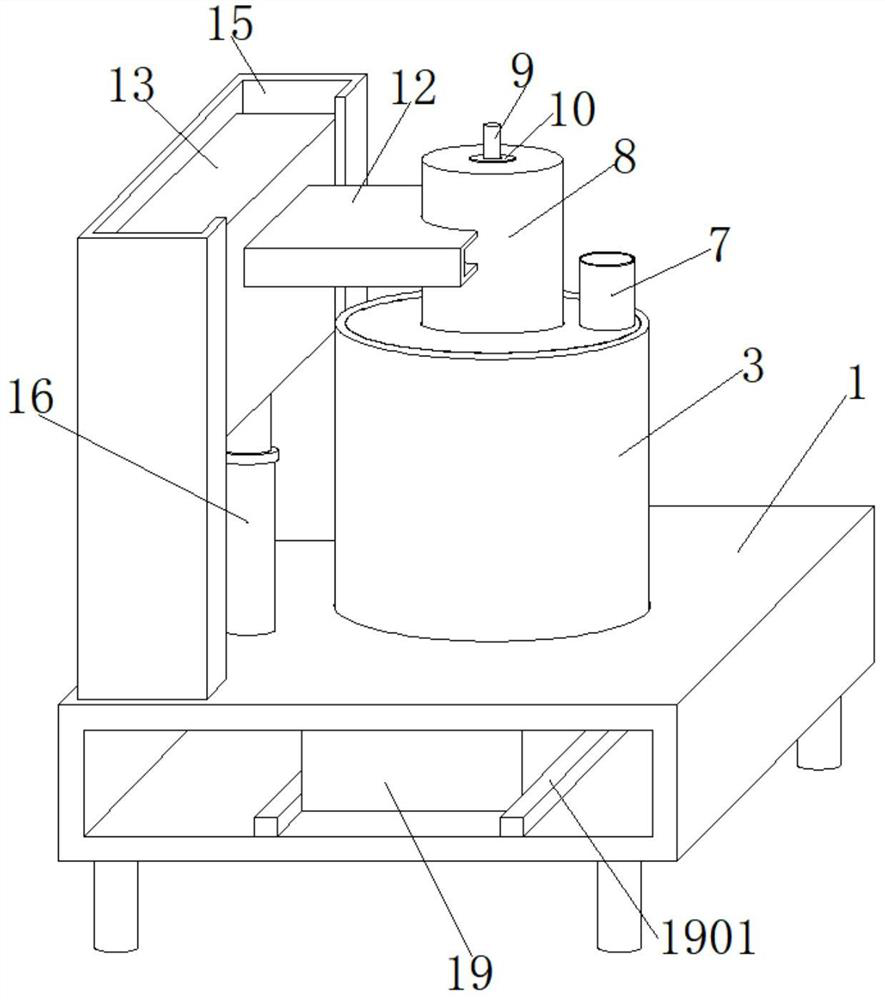

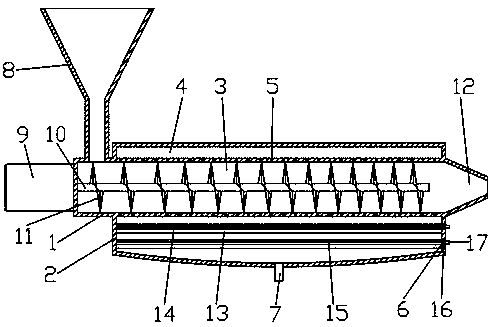

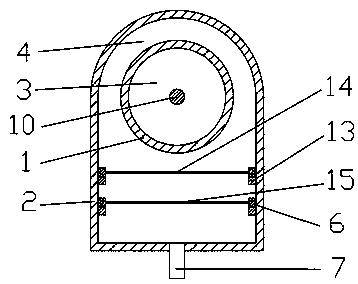

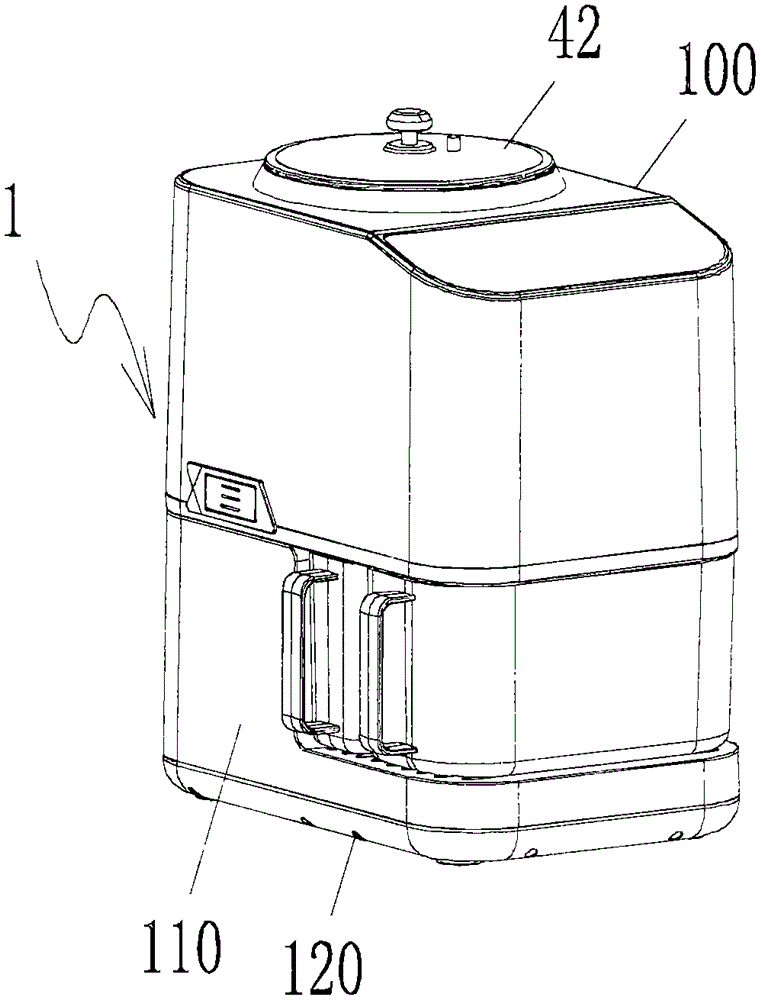

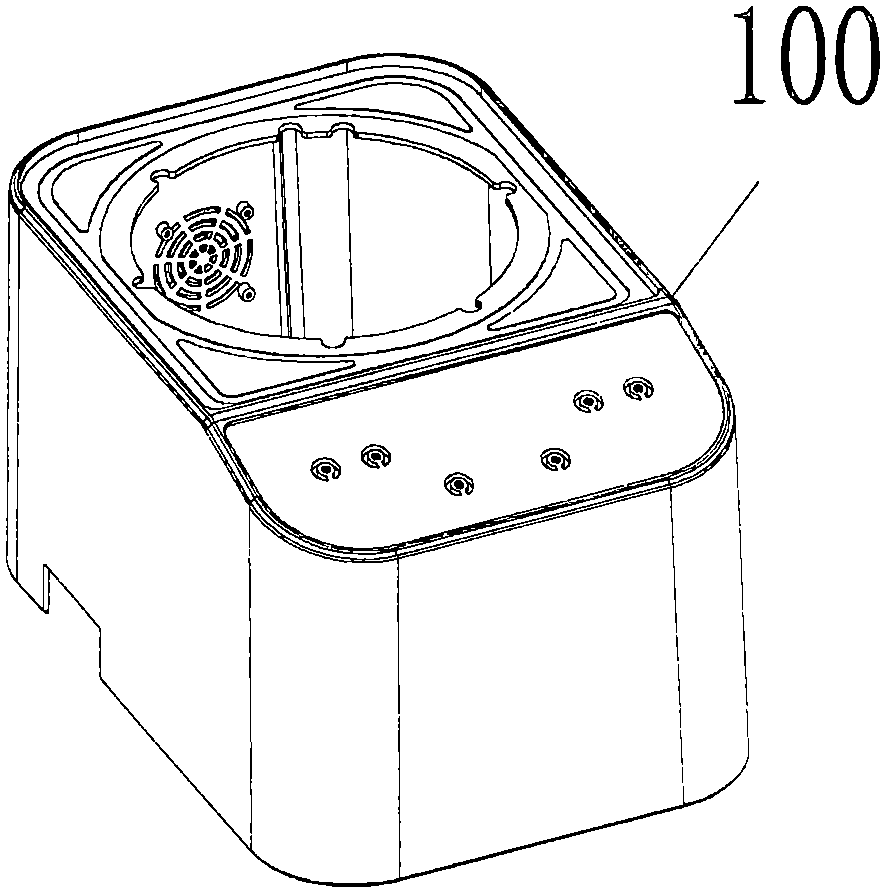

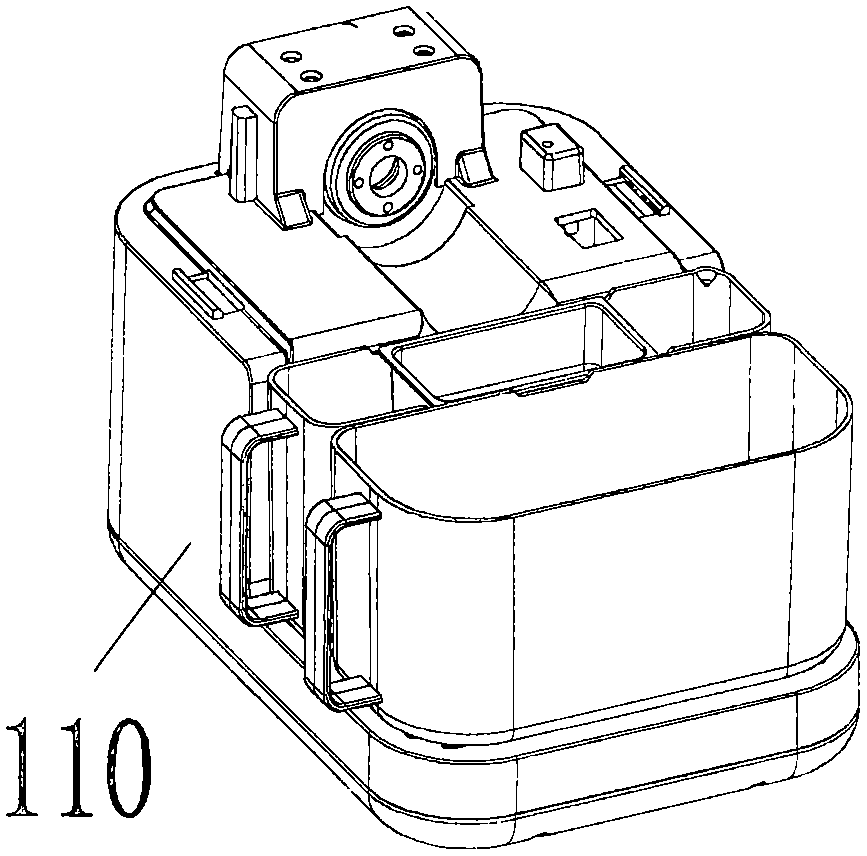

Spiral juicer

InactiveCN107713700AReduced local storage spaceImprove work efficiencyStrainersEngineeringFood processing

The invention relates to a food processing device, in particular to a spiral juicer which includes a machine frame. A feeding box, a juicing barrel, a residue discharging box and a spindle penetratingthe feeding box, the juicing barrel and the residue discharging box are sequentially arranged on the machine frame. The upper side of the feeding box is provided with a feeding port, and an inner cavity of the feeding box is communicated with the juicing barrel. The lower side of the juicing barrel is provided with a juice outlet. The periphery of a section of the spindle in the juicing barrel isprovided with a spiral juicing blade, the outer side of the spiral juicing blade is sleeved with a screen barrel, and gaps are reserved between the outer wall of the screen barrel and the inner wallof the juicing barrel. The lower side of the residue discharging box is provided with a residue outlet, and a vertically-arranged elastic pressure cover plate is disposed between the juicing barrel and the residue discharging box. The spiral juicer is characterized in that the external diameter of the section of the spindle in the juicing barrel is gradually increased in the feeding direction. Thespiral juicer is high in working efficiency and completely squeezes fruits and vegetables, discharged residue can be subjected to secondary utilization, and resource waste can be reduced.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

Extraction method for improving oil yield of tea seed

The invention relates to an extraction method for improving the oil yield of tea seeds. The tea seeds are subjected to the treatment of screening, winnowing, impurity removal and shelling; and the material is dried at a temperature between 70 and 75 DEG C so that the water content of the material reaches between 3 and 4 percent; and 5 percent of bran coat is added into the material and is extracted. The method can overcome the disadvantages that tea seeds are vulnerable to adhesion and agglomeration, so as to form hard lumps and produce caramelization due to high content of tea saponine, and can increase oil yield by 3 to 4 percentage points.

Owner:浙江泰谷农业科技有限公司

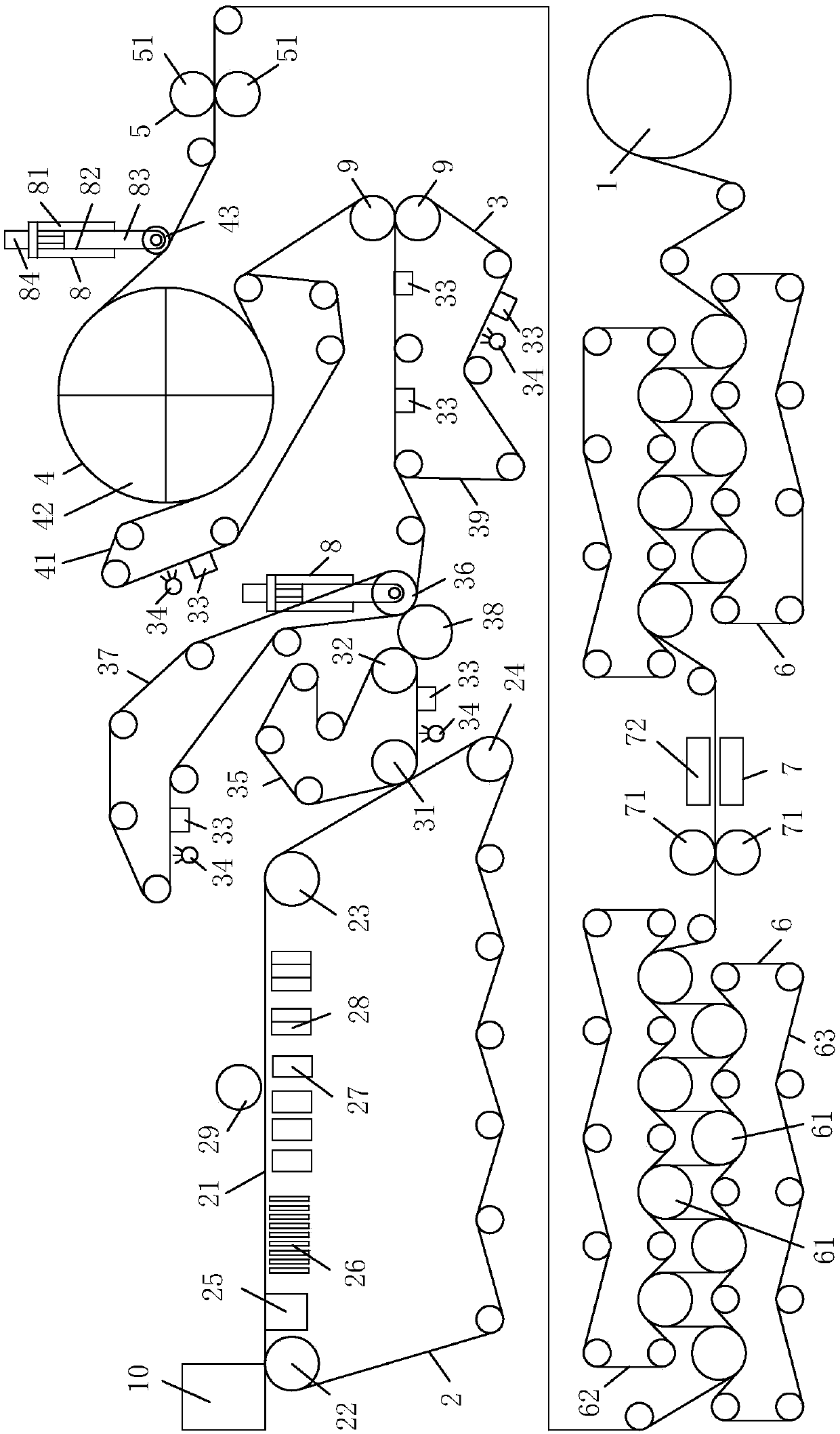

Digital printing thermal transfer printing body paper making machine and paper making method

InactiveCN108677588ASmall Distortion DeformationExtended service lifeDryer sectionMachine wet endEngineeringPulp and paper industry

The invention aims to provide a digital printing thermal transfer printing body paper making machine and a paper making method. The digital printing thermal transfer printing body paper making machinecomprises a paper making device provided with a long net, a breast roller, a couch roller and new driving roller arranged below the couch roller, a paper reeling cylinder, a pressing device, a largedrying cylinder front drying device, a surface sizing device and two small drying cylinder rear drying devices which are sequentially arranged between the paper making machine and the paper reeling cylinder, and a coating device arranged between the two small drying cylinder rear drying devices. The digital printing thermal transfer printing body paper produced by the digital printing thermal transfer printing body paper has the advantages that the transverse stretching ratio is small, and when a thermal transfer printing pattern is printed, the pigment cannot permeate into the paper sheet tocause the paper sheet to stretch transversely, and the distortion of the pattern is small when the thermal transfer printing is carried out.

Owner:浙江永鑫特种纸有限公司

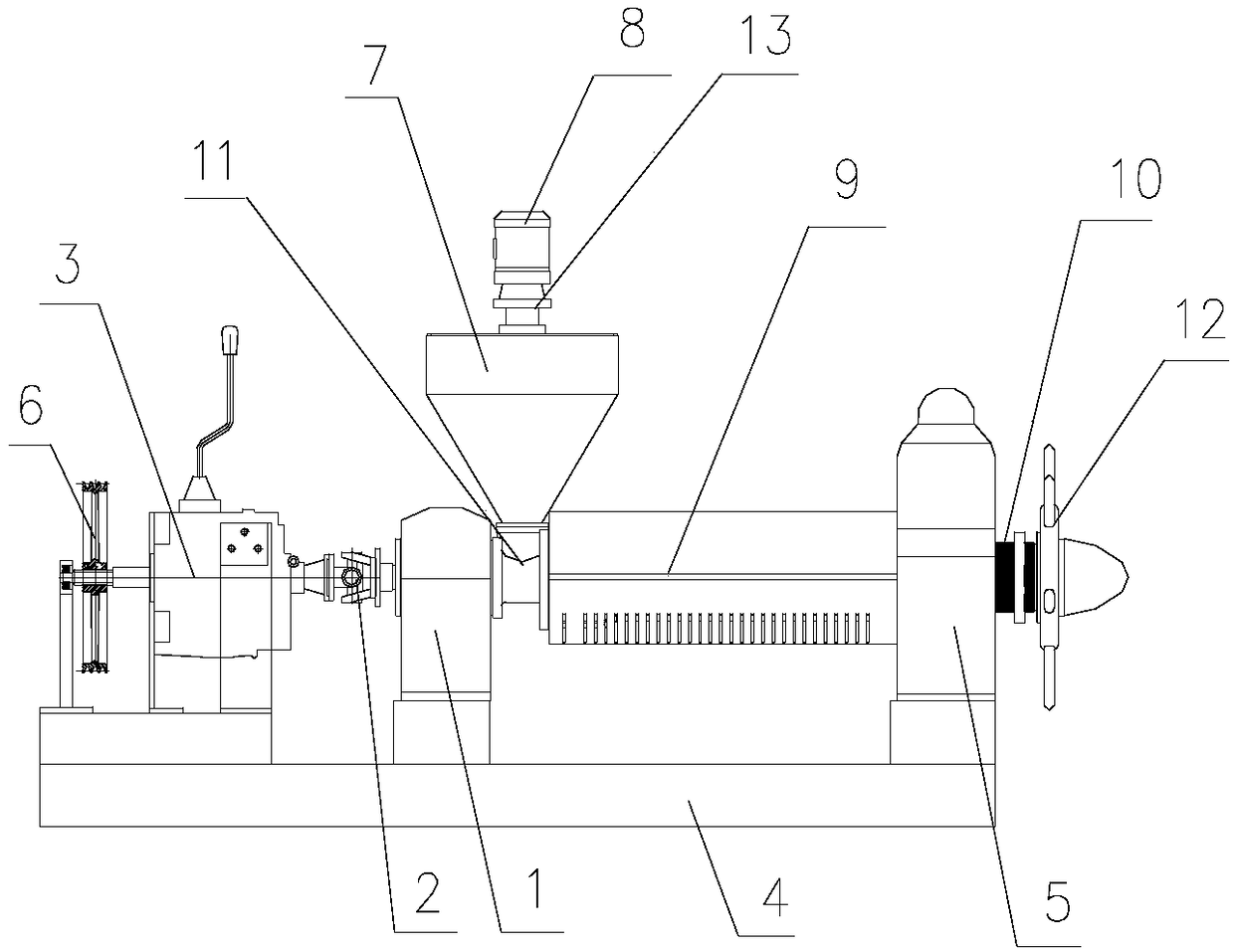

Convenient-speed-adjusting type screw oil press

PendingCN108202496ARealize overload protectionGood squeezing effectFatty-oils/fats productionPressesCouplingEngineering

The invention provides a convenient-speed-adjusting type screw oil press. A rack is mounted above the right end of a bottom plate, a base is arranged in the middle, the right side of the base is connected with a feeding nozzle, a hopper is fixedly mounted above the feeding nozzle, and a feeder and a motor assembly are mounted above the hopper. A press bar circular cage bar assembly is fixedly connected between the rack and the feeding nozzle, a press screw assembly is mounted in the rack, the press bar circular cage bar assembly and the base, the left side of the base is fixedly connected witha locomotive gearbox through a coupling, and the left end of the locomotive gearbox is connected with a V-belt pulley through a rotating shaft. The rotating speed can be adjusted to multiple gears, and the screw oil press is durable.

Owner:湖北财圣机械科技有限公司

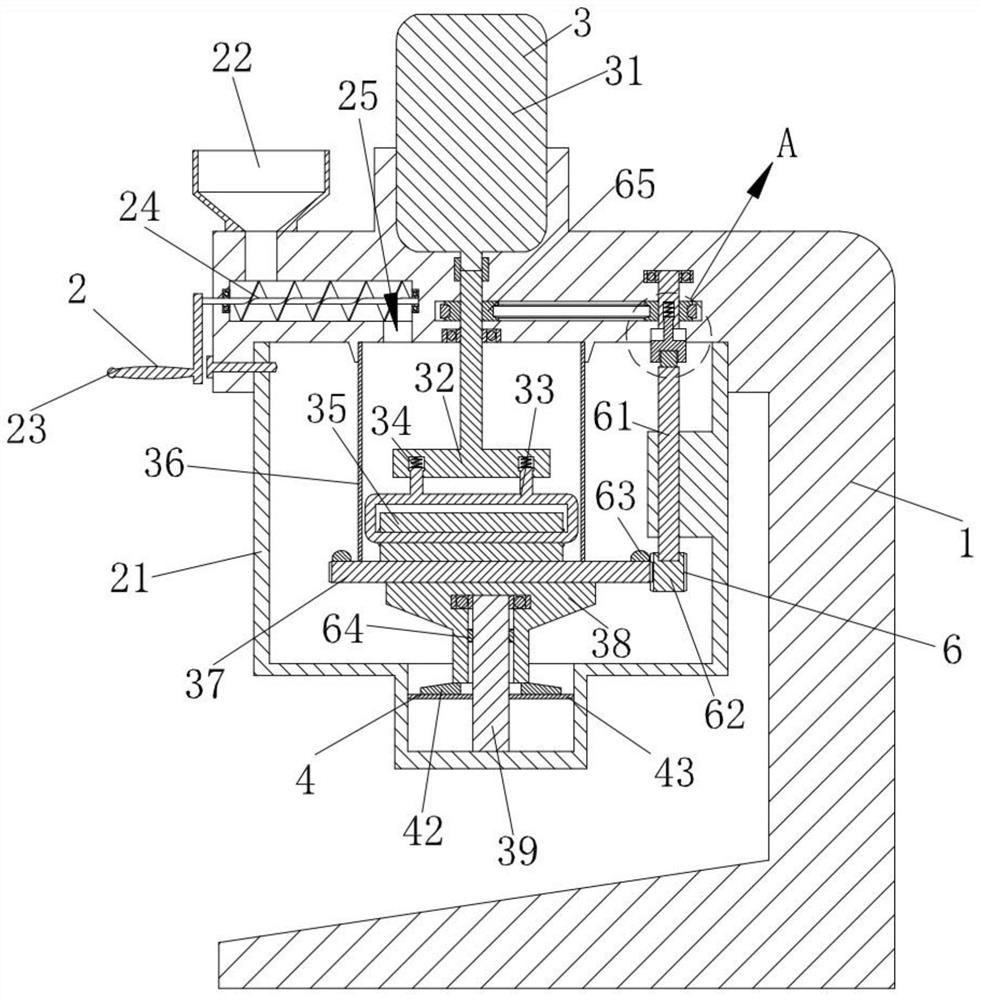

Double-kettle turning type supercritical fluid extraction device

ActiveCN106833883AFully contactedAvoid it happening againFatty-oils/fats productionSolid solvent extractionDrive shaftEngineering

The invention relates to a double-kettle turning type supercritical fluid extraction device. A motor is arranged on a first support seat; a transmission shaft is arranged on a power output shaft of the motor; a second support seat and a third support seat are arranged on the transmission shaft; a fixing disc is fixed on the upper part of the second support seat; a walking mechanism is arranged at the bottom of the second support seat; the transmission shaft passes through the fixing disc; a rotating disk and an extraction kettle support rod are sequentially and fixedly arranged on the transmission shaft; the two ends of the extraction kettle support rod are respectively and fixedly provided with a left extraction kettle and a right extraction kettle; one end opening of a fifth three-way valve arranged on the rotating disc communicates with a liquid inlet hole formed in the fixing disc through a pipeline, and the other two end openings respectively communicate with the left extraction kettle and the right extraction kettle through pipelines; one end opening of a sixth three-way valve arranged on the rotating disc communicates with a liquid outlet hole formed in the fixing disc, and the other two end openings respectively communicate with the left extraction kettle and the right extraction kettle through pipelines.

Owner:SHAANXI NORMAL UNIV

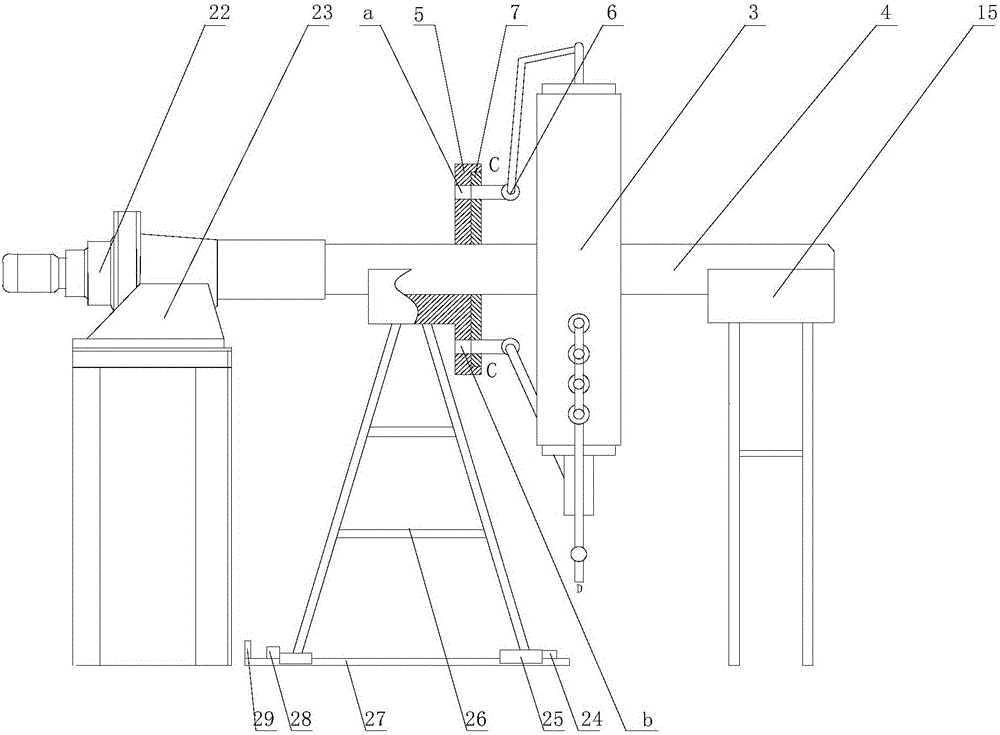

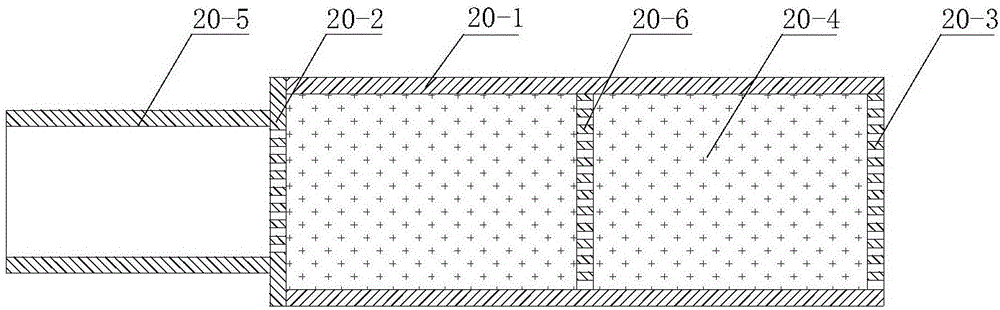

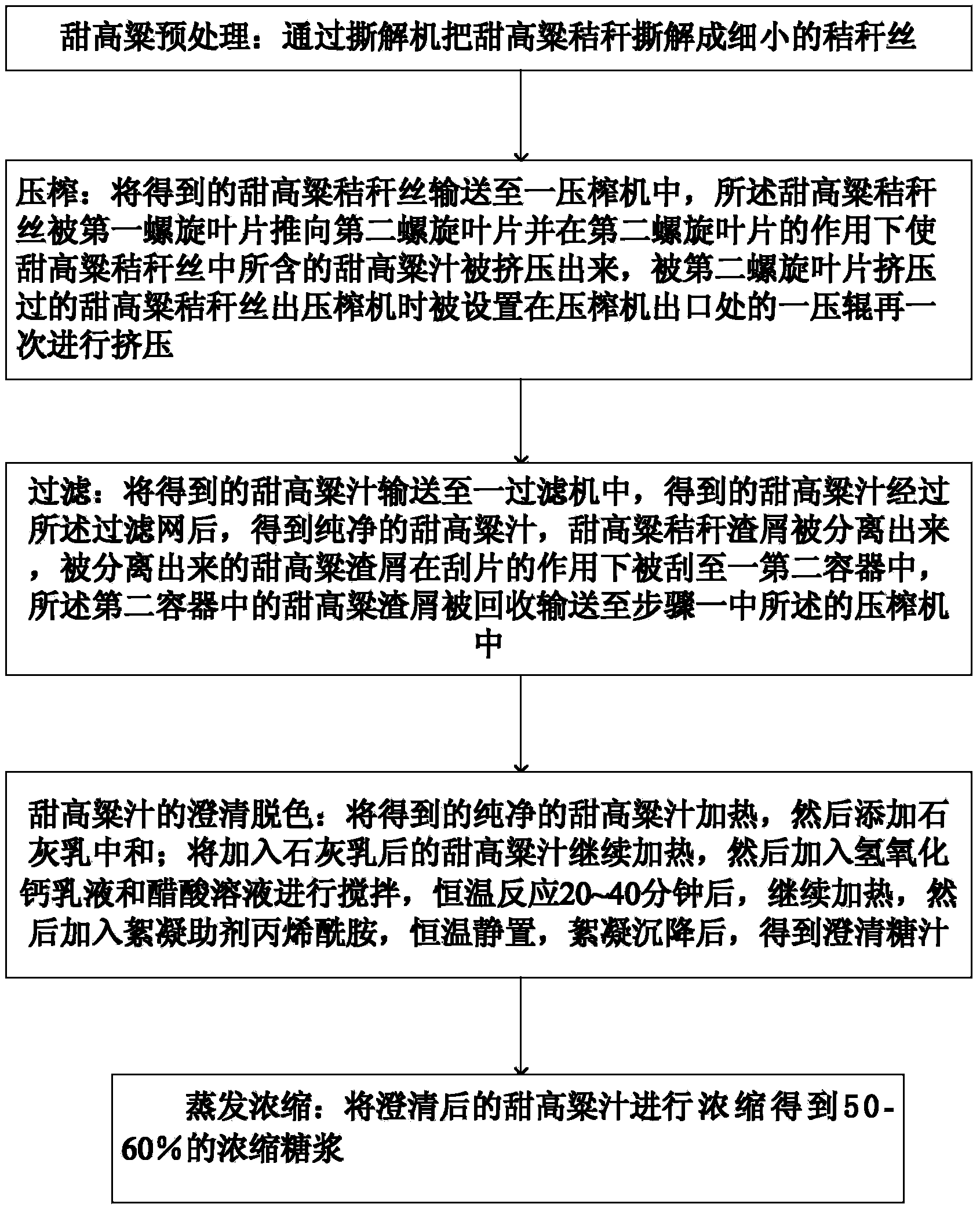

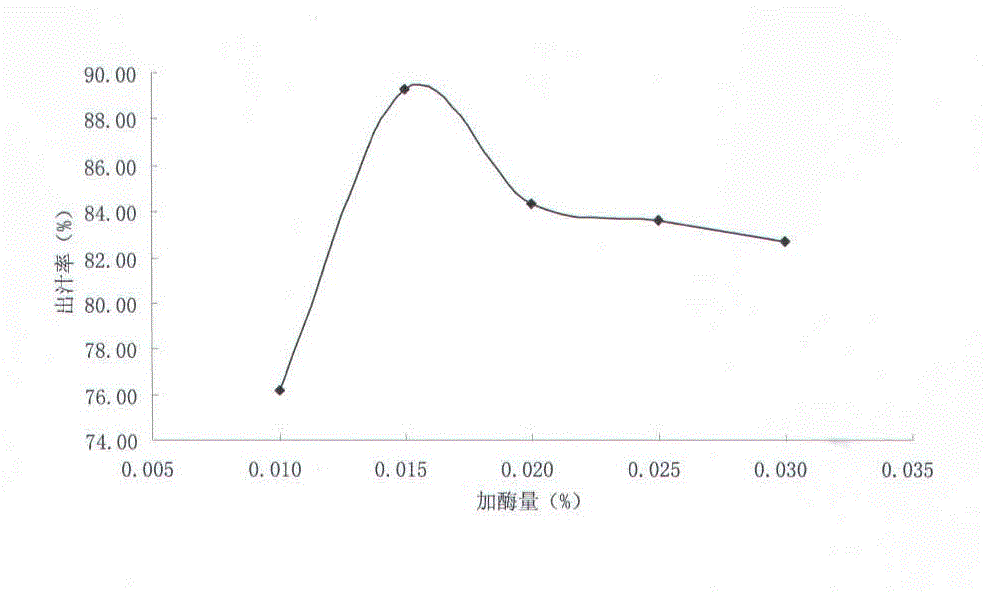

Process for making sugar by using sorgo

ActiveCN103710467AEfficient separationIncrease the juice yieldPurification using alkaline earth metal compoundsStationary filtering element filtersFlocculationCalcium hydroxide

The invention discloses a process for making sugar by using sorgo. The process comprises the following steps: pretreatment: tearing sorgo straws into straw filaments; squeezing: delivering the obtained sorgo straw filaments to a squeezer, extruding sorgo juice after three times of squeezing, letting the sorgo juice flow out of sieve pores on the wall of a chamber body of the squeezer and collecting the sorgo juice in a first container; filtration: delivering the obtained sorgo juice to a filter to obtain pure sorgo juice, separating the sorgo straw dregs and scraping the dregs with a first scrape blade to a second container; clearing: heating the obtained pure sorgo juice, adding lime milk to neutralize the juice, adding calcium hydroxide emulsion and acetic acid solution to stir, reacting at a constant temperature for 20-40 minutes, heating the solution, then adding a flocculation additive acrylamide, statically keeping the solution at a constant temperature, flocculating and settling to obtain clear sugar juice, and finally concentrating the sorgo juice to obtain concentrated syrup. The process has a good squeezing effect, a high juice yield, a good filtration effect, a good decolorization effect and little filtering sludge, and saves time and labor.

Owner:陈凤花

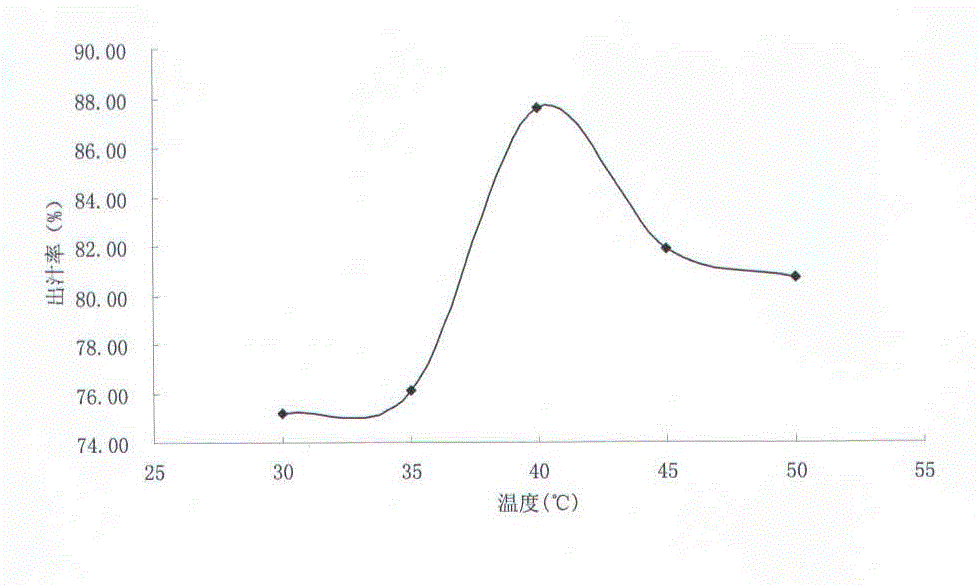

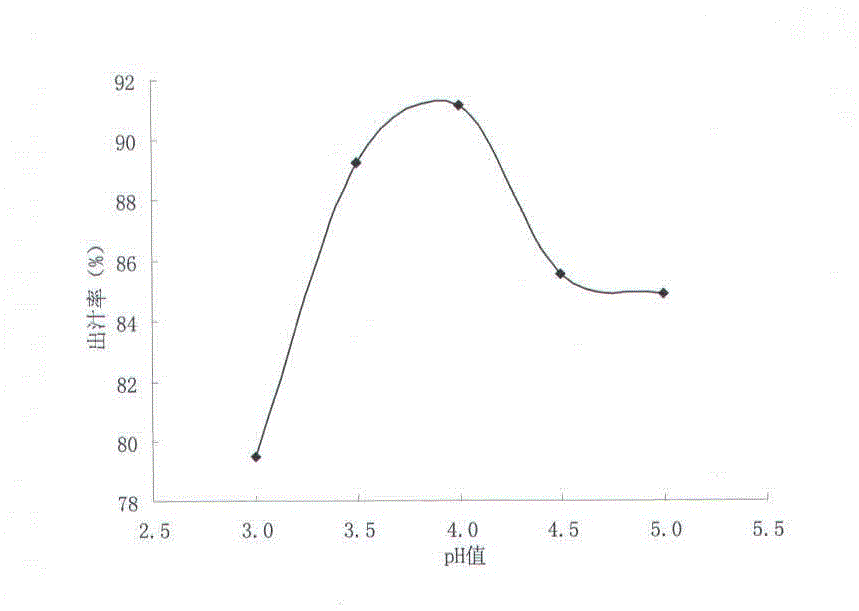

Method for preparing Chinese flowering crabapple fruit juice by using pectinase

InactiveCN102972828AIncrease the juice yieldEasily damagedFood sciencePectinaseChinese flowering crabapple

The invention relates to a method for improving juice yield of Chinese flowering crabapple fruits by using pectinase. The method comprises the following steps: selecting completely mature and plump high-quality Chinese flowering crabapple fruits, cleaning, dicing, pulping, performing enzymolysis with the pectinase, separating pomace, and thus obtaining original Chinese flowering crabapple fruit juice. The juice yield can be improved by adopting the pectinase for enzymolysis of the Chinese flowering crabapple fruits, the juice yield of the Chinese flowering crabapple fruits can reach 92.18 percent, and the juice yield is improved by 18.26 percent compared with the blank experiment (73.92 percent) of the Chinese flowering crabapple fruits which are not treated by using the pectinase.

Owner:新疆林科院园林绿化研究所 +1

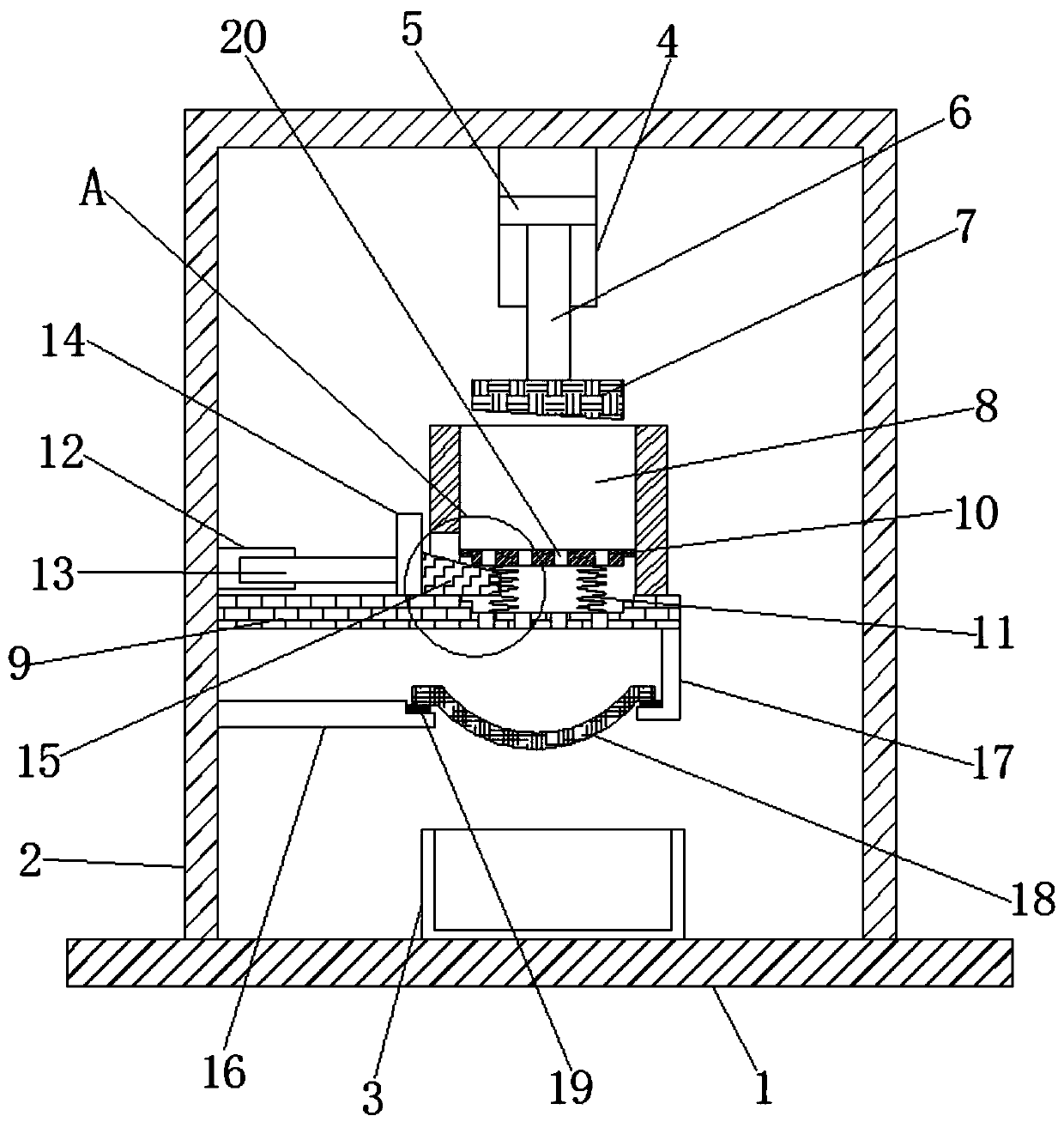

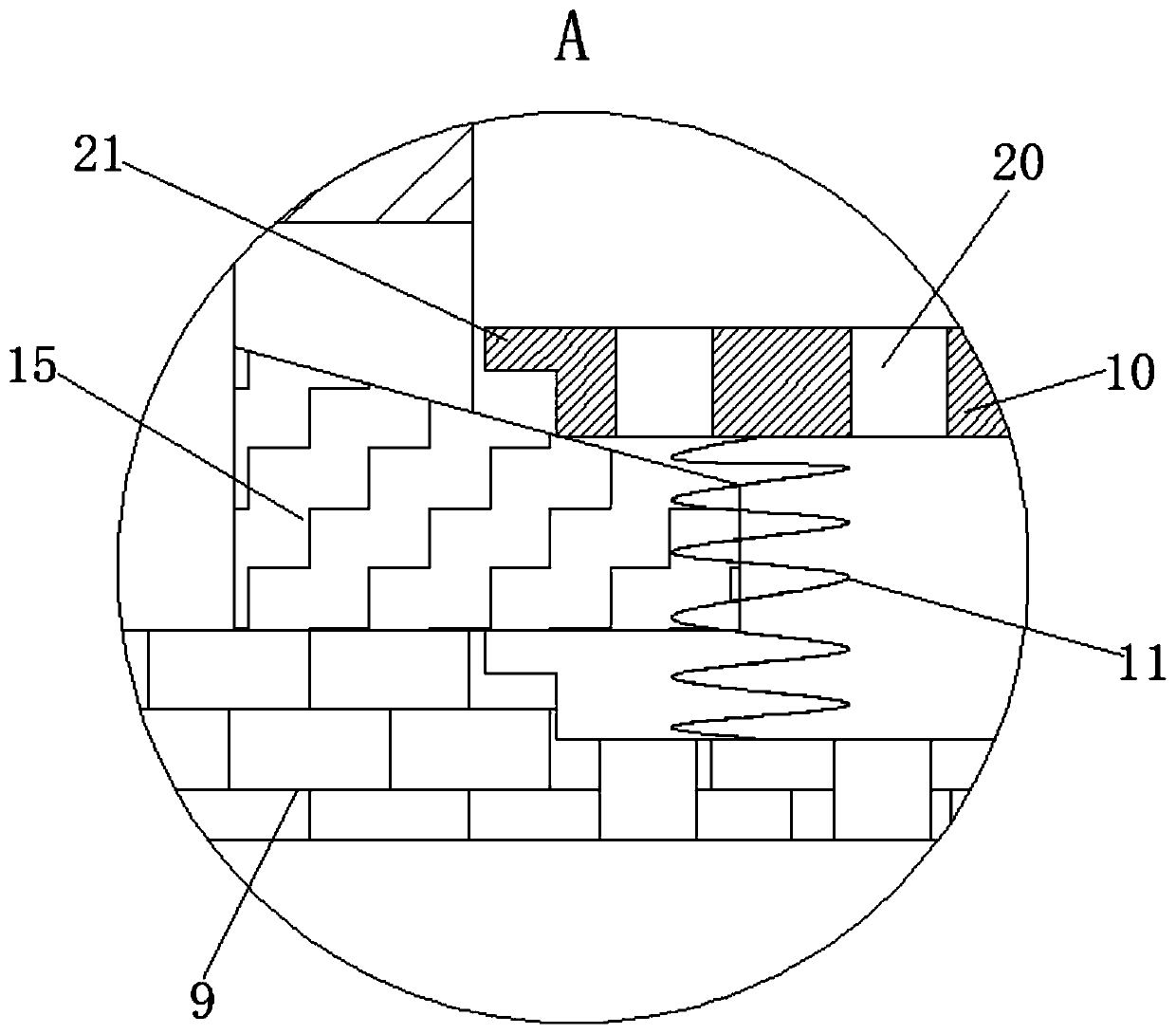

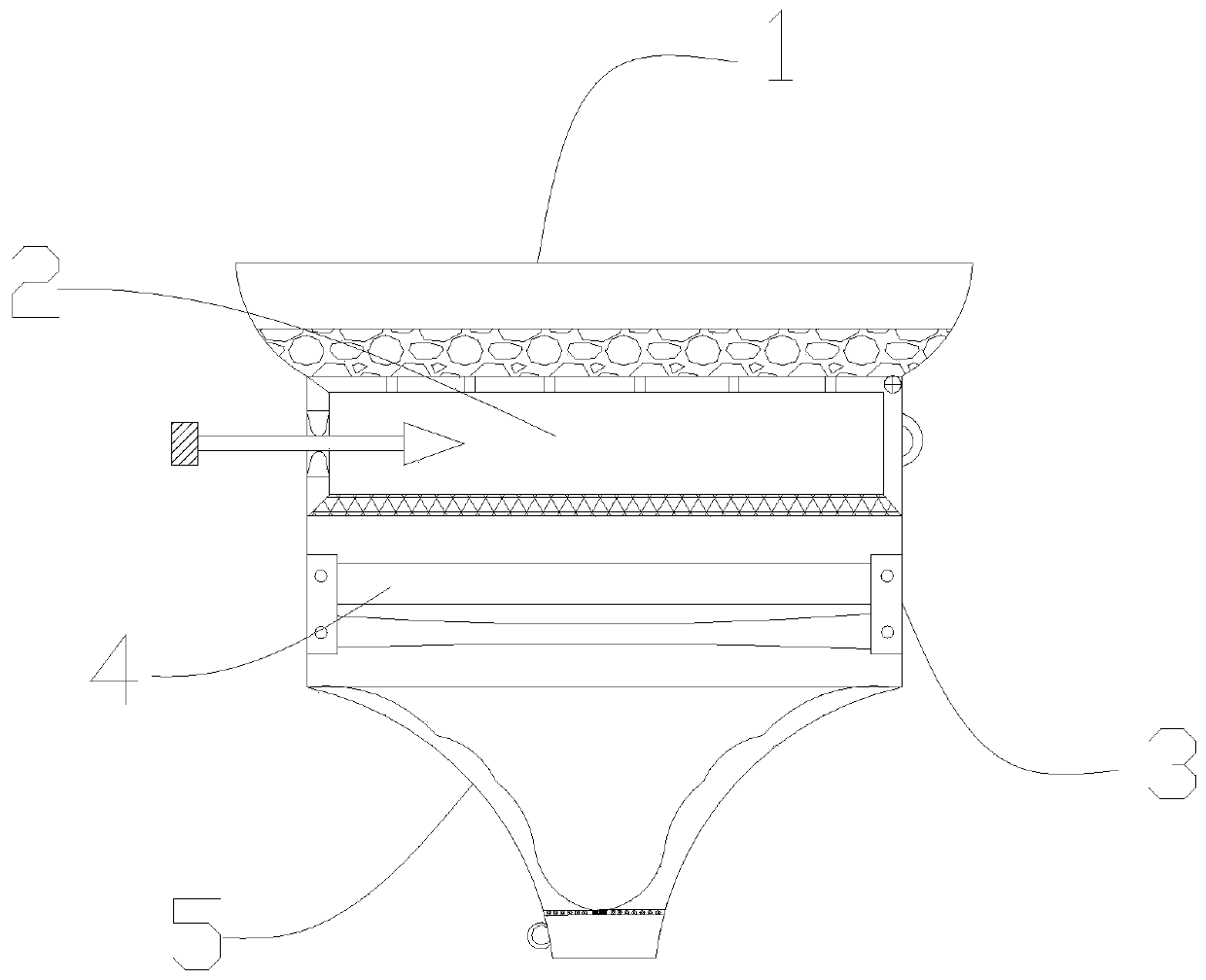

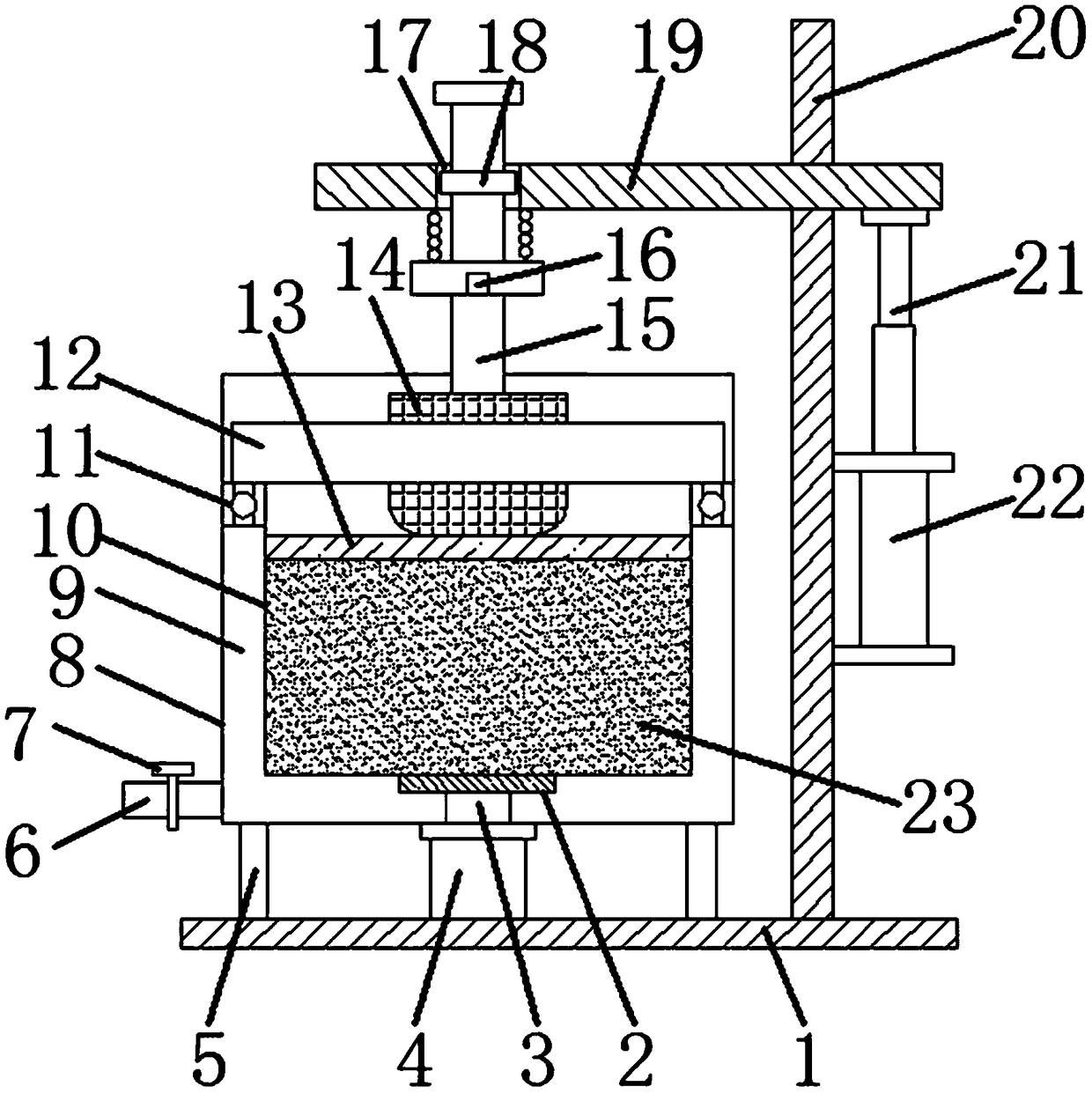

Oil pressing device for camellia seed oil production

ActiveCN110561809AGood for contact squeezeGood squeezing effectFatty-oils/fats productionPressesHydraulic cylinderOil production

The invention relates to the technical field of camellia seed oil production, and discloses an oil pressing device for camellia seed oil production. The oil pressing device for camellia seed oil production comprises a base plate and a shell. A first hydraulic cylinder is arranged on the top of the shell, a first hydraulic rod is arranged in the first hydraulic cylinder, and a press block is fixedly connected with the lower end of the first hydraulic rod. A middle plate is arranged in the middle of the shell, a volume cavity is formed in the middle plate, a pressure bearing plate is arranged inthe volume cavity, and springs are fixedly connected between the pressure bearing plate and the middle plate. A second hydraulic cylinder is fixedly arranged on the left portion of the shell, a second hydraulic rod is arranged inside the second hydraulic cylinder, a push block is fixedly connected with the right end of the second hydraulic rod, and a wedge block is fixedly connected with the right end of the push block. According to the oil pressing device for camellia seed oil production, the downward acting force and the upward acting force can be applied to an oil cake in the volume cavitythrough the movement of the press block and the wedge block correspondingly, and therefore the pressing effect can be better, and the oil pressing device for camellia seed oil production has the advantages that the multiple pressing operation can be conducted to enhance the pressing effect, and the camellia seed oil can be filtered.

Owner:湖南亚美茶油股份有限公司

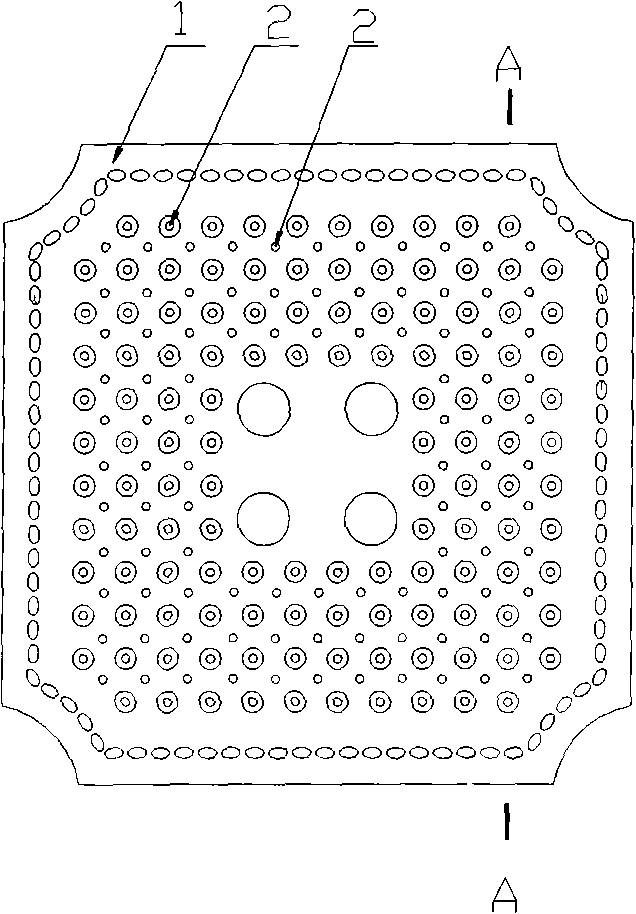

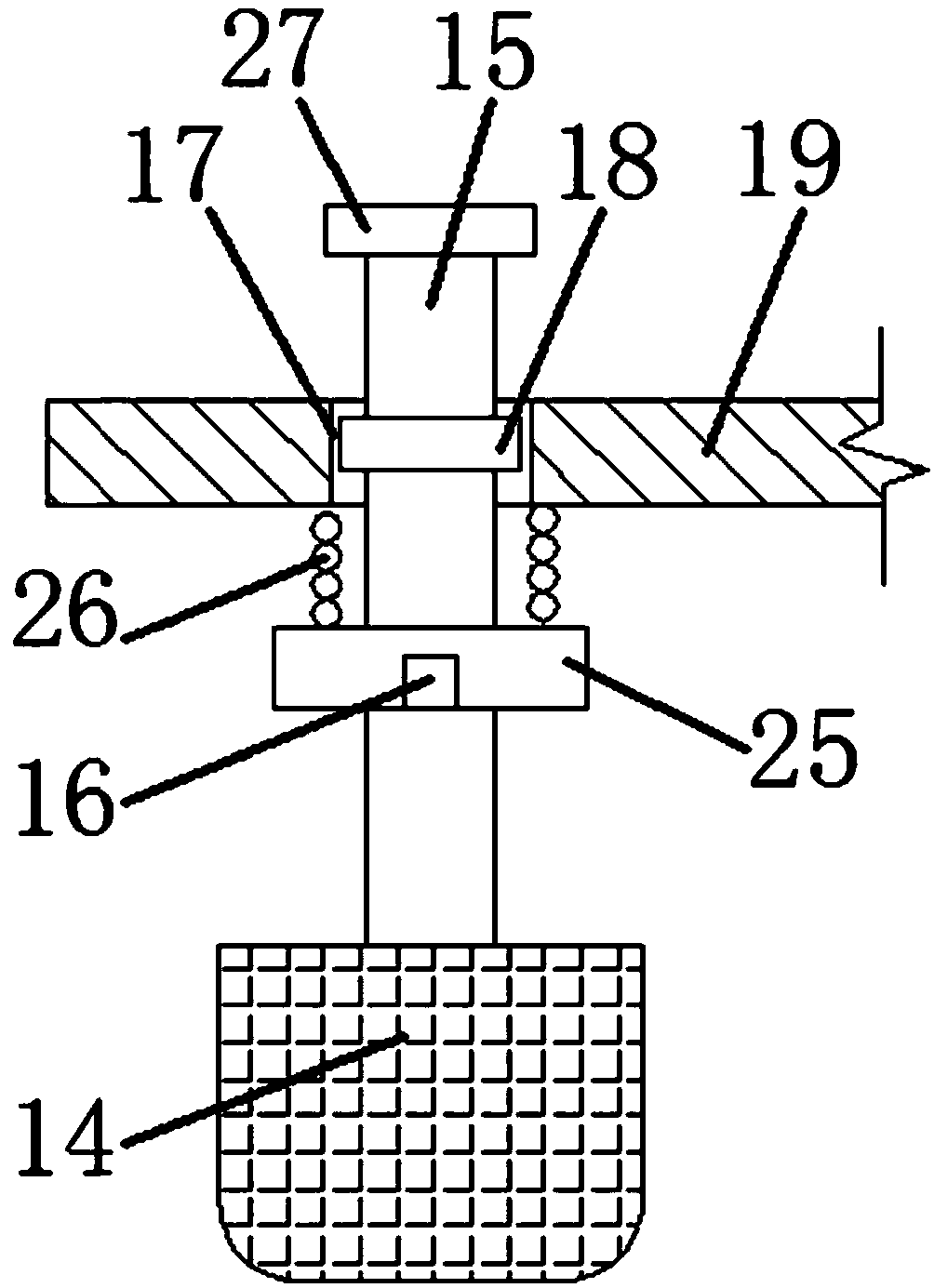

Filtering material filter sheet with micropore and strainer plate and blotter press

InactiveCN101249334AReduce consumptionElimination of pinched areasFiltration separationEngineeringFilter material

The invention relates to a micro-porous filter disc, a filter plate with a micro-porous filter plate and a filter press, a convex-concave point structure is arranged on the surface of the filter disc, flow guide holes are provided on the convex points or the concave points or the convex and concave points, the end part of a plate core is provided with a flow guide hole path, the side part of the core plate of the plate core is provided with a fluid channel to be communicated with the flow guide hole path, the filter disc is positioned on the plate core; a filter plate extrusion frame is arranged on a machine rack, an extrusion plate is positioned in the filter plate extrusion frame and connected with an extrusion device, the bottom part of the filter plate extrusion frame is provided with a liquid receiving groove and a cover in the upper part, and a plurality of micro-porous filter plates are positioned on one side of the extrusion surface of the extrusion plate in the filter plate extrusion frame.

Owner:HANGZHOU XINGYUAN FILTER TECH

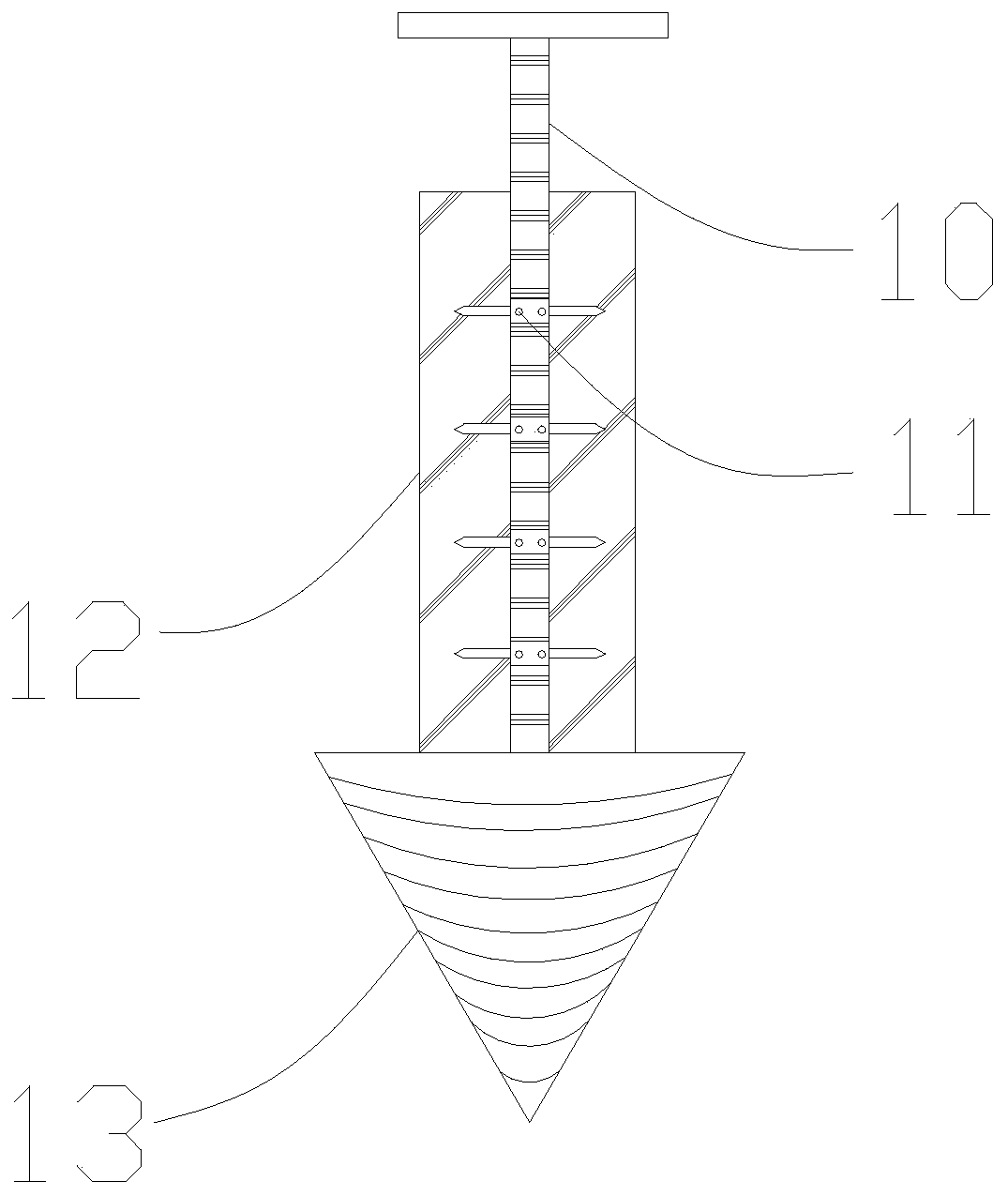

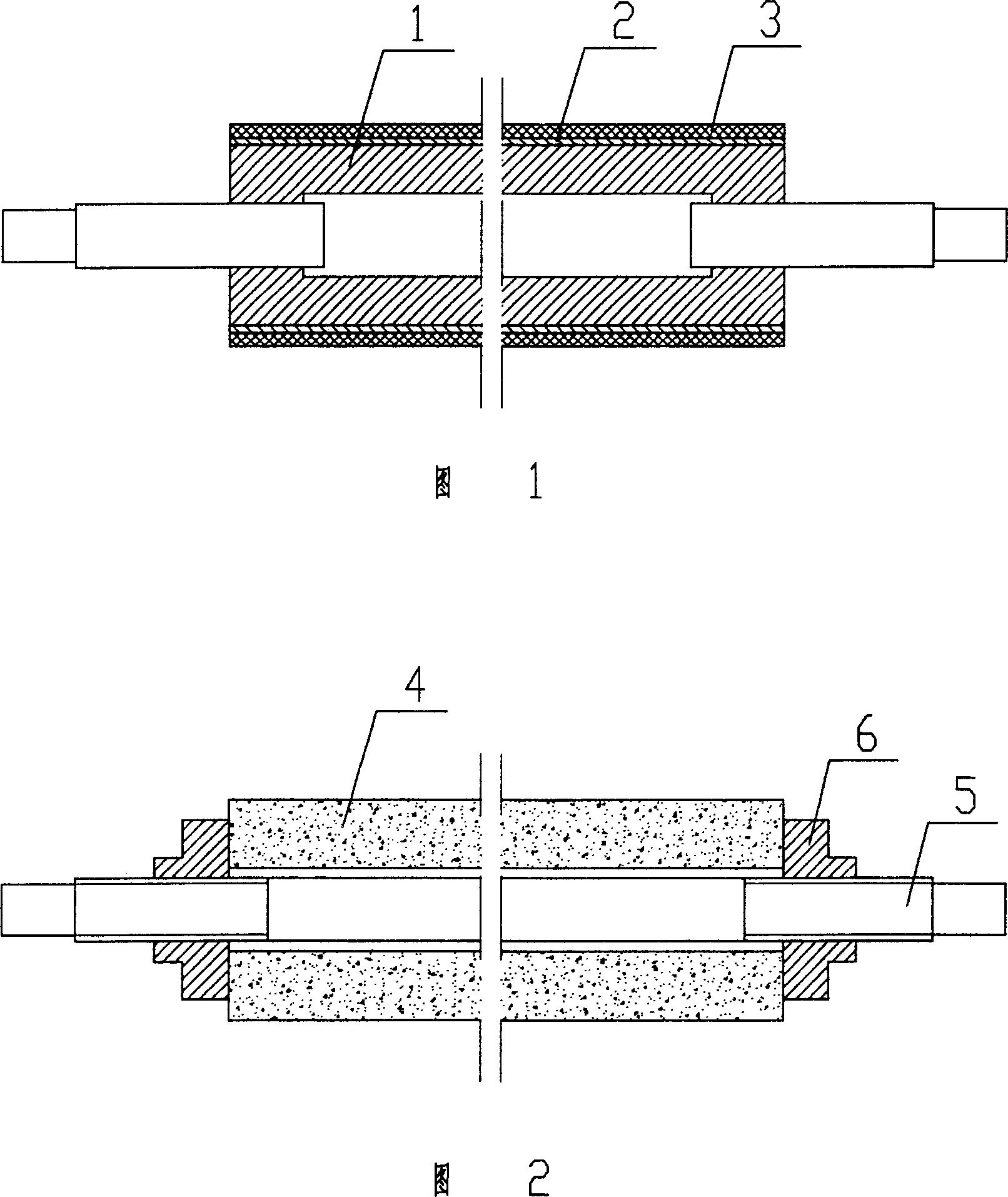

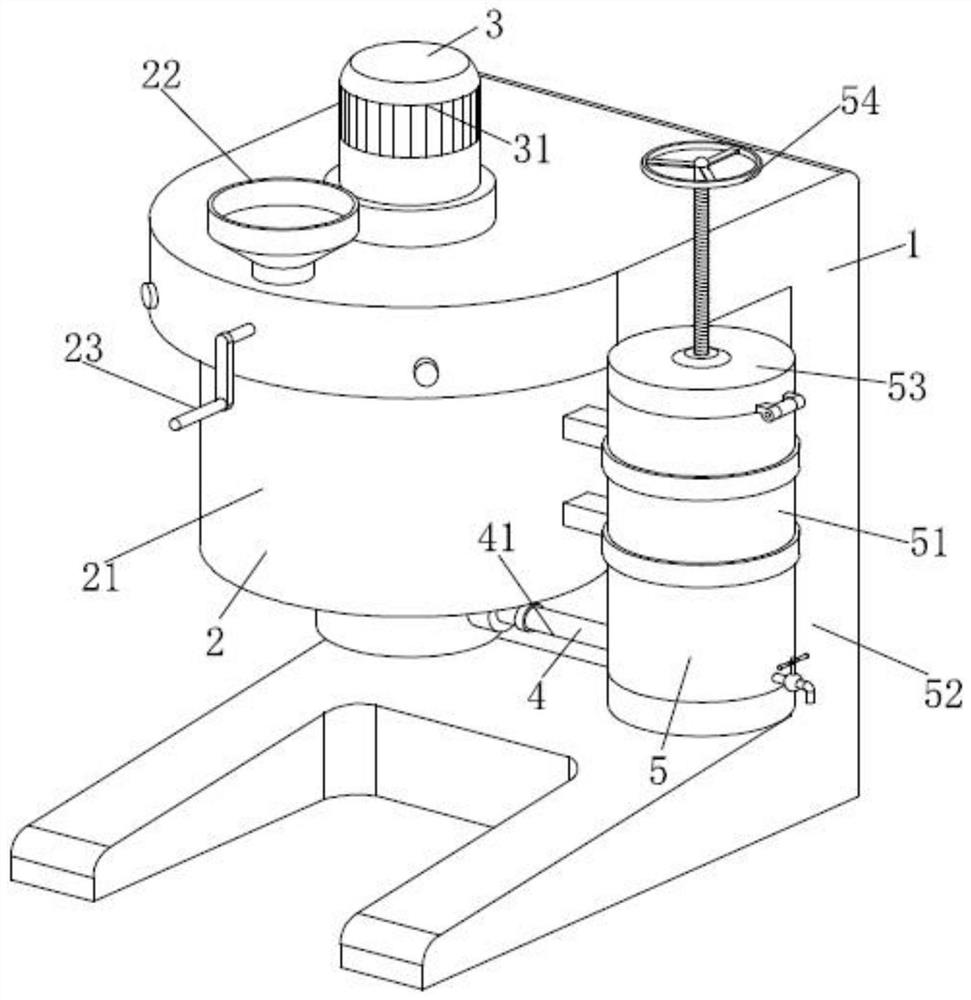

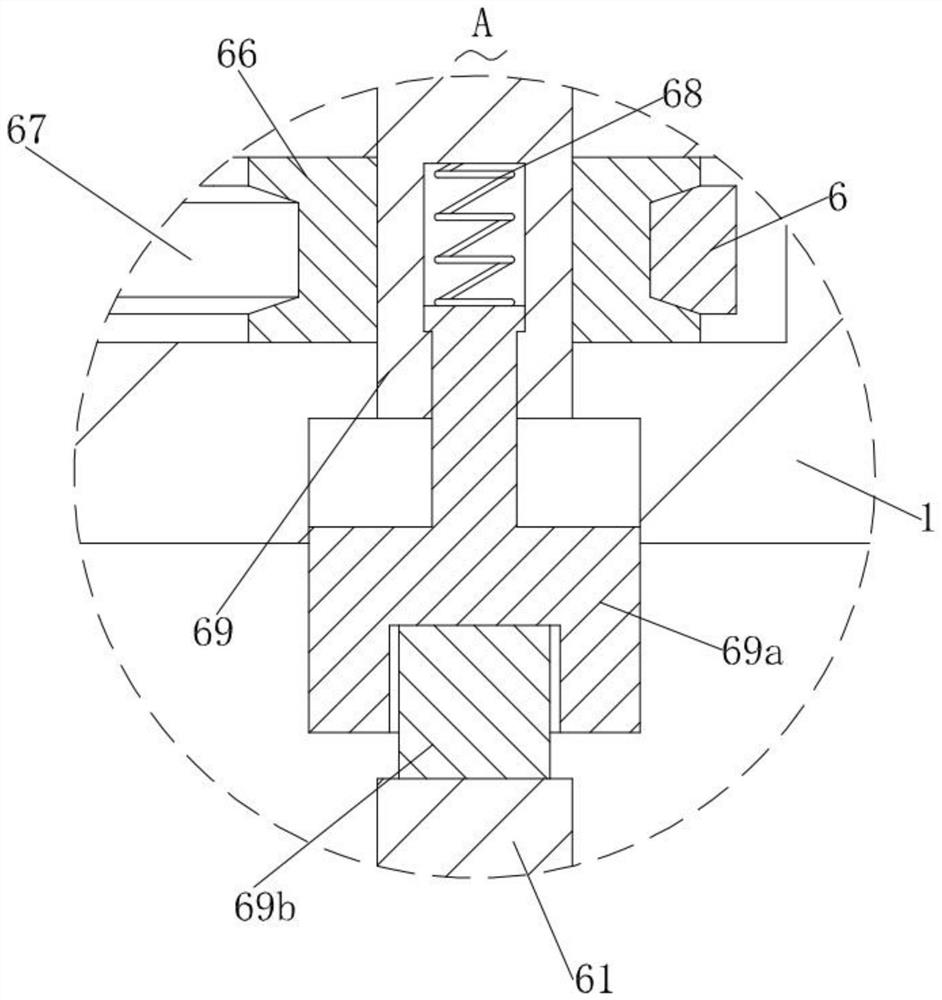

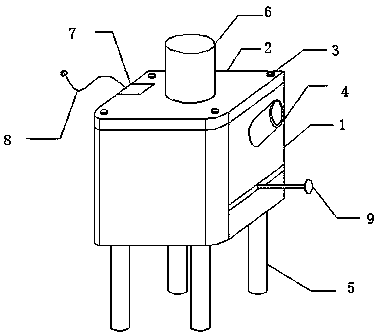

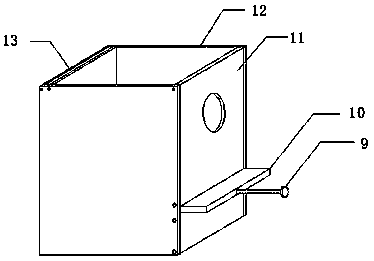

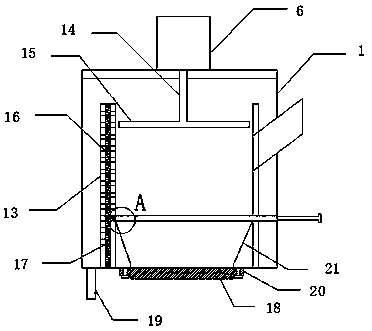

Ginseng squeezing device

ActiveCN110239135AIncrease pressureGood squeezing effectGrain treatmentsPressesBiomedical engineeringGinseng

The invention provides a ginseng squeezing device. The ginseng squeezing device comprises a reservoir, a cutting layer, a squeezing layer and a discharging layer. The reservoir is fixedly connected to the uppermost portion of the ginseng squeezing device. The cutting layer is fixedly connected to the bottom of the reservoir. The squeezing layer is fixedly connected to the bottom of the cutting layer. The discharging layer is fixedly connected to the bottom of the squeezing layer. A limiting nail with a gun head convex shape is arranged to reduce the contact area and increase the pressure intensity, so that the pressure of squeezing ginseng is increased. Meanwhile, the ginseng is limited through the limiting nail, so that the effect of repeated squeezing is achieved, and a better ginseng squeezing effect can be realized. A sickle-shaped cutting knife is arranged, and the radian and sharp hook of the cutting knife are adopted to quickly crush and cut the ginseng. Meanwhile, a cleaning block is arranged below the cutting knife to realize cleaning and better ginseng cutting. Inclined surfaces on the left side and right side of a bridge-shaped filter screen enable ginseng which is not squeezed to be guided back and to be subjected to extrusion processing again, so that the juice yield of the ginseng is increased.

Owner:张波

Medicine residue filter device

The invention belongs to the technical field of medicinal material processing, and particularly relates to a medicine residue filter device comprising a box body. The bottom of the box body is provided with supporting legs, the two ends of the top are y provided with feed inlets correspondingly, a first pressing device is arranged in the box body, a second pressing device arranged outside the boxbody, the first pressing device comprises a filter plate arranged in the box body in the horizontal direction, the two ends of the filter plate are fixedly connected with the box body, the top of thefilter plate is provided with a pressing head, the bottom end face, away from the box body, of the pressing head is connected with a first air cylinder arranged on the top of the box body through a piston head, medicine residue can be pressed for the first time through the first pressing device, medicine liquid pressed out is filtered and collected through a filter net, the medicine residue is pressed for the second time through the second pressing device, the pressing effect is good, and medicine liquid contained in the medicine residue can be thoroughly extracted. The whole process is simpleand convenient, the efficiency is high, and the company cost is greatly reduced.

Owner:张至柔

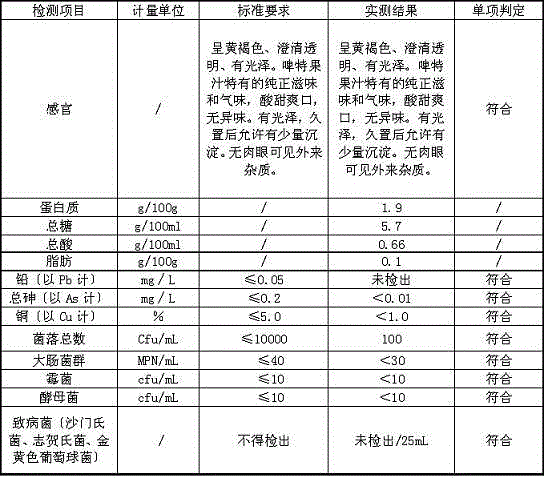

Processing method of Piteguo juice

The invention relates to a processing method of Piteguo juice. The method comprises the following steps of: (1) selecting raw materials: selecting Piteguo fruits which are not rotted, are black brown in color, and become soft in tissue structure as raw materials after the picked Piteguo are ripe under natural conditions for 15 days; (2) washing the Piteguo fruits with clean water twice, and crushing by adopting a cyclone-type fruit crusher, thereby obtaining particles smaller than 0.3*0.3*0.3cm; (3) putting the crushed particles into an enzymolysis tank, adding compound enzyme for enzymolysis, adjusting the pH value to be 4.0-4.5 by food-grade acid-base, and then squeezing, thereby obtaining fruit residues and juice liquids; and (4) adding pectinase into the juice liquids for enzymolysis, and adjusting the pH value to be 4.0-4.5 by food-grade acid-base, clarifying, and sterilizing by adopting UHT (ultra high temperature), thereby obtaining the Piteguo juice. The processing method of Piteguo juice provided by the invention is simple in technology, and can effectively improve the juice yield.

Owner:GANSU & THE EIGHT EIGHT PITEGUO GRP +3

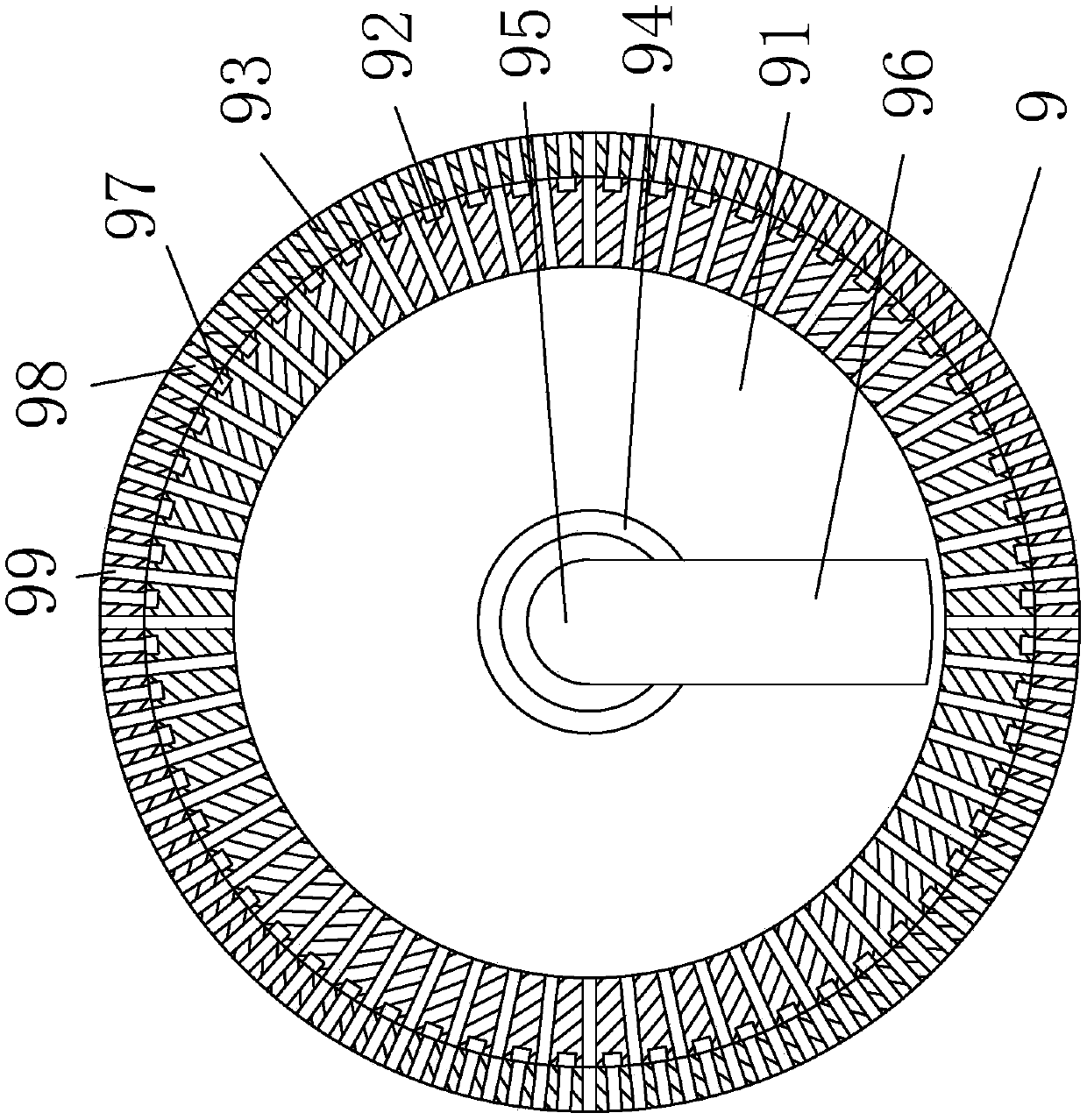

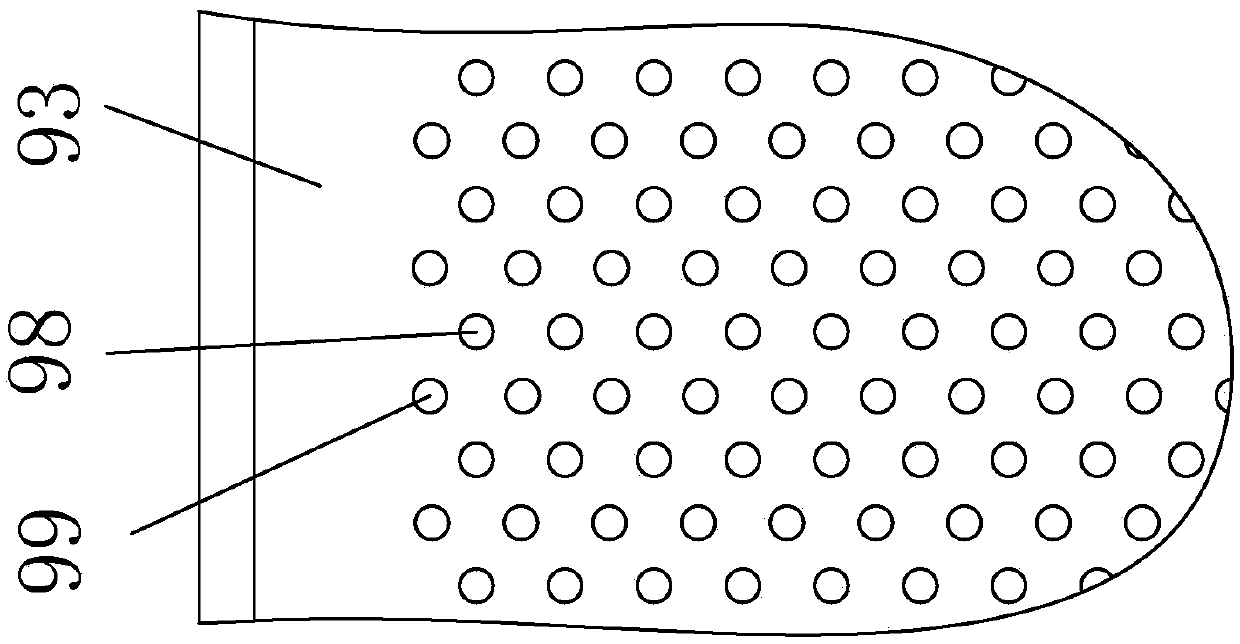

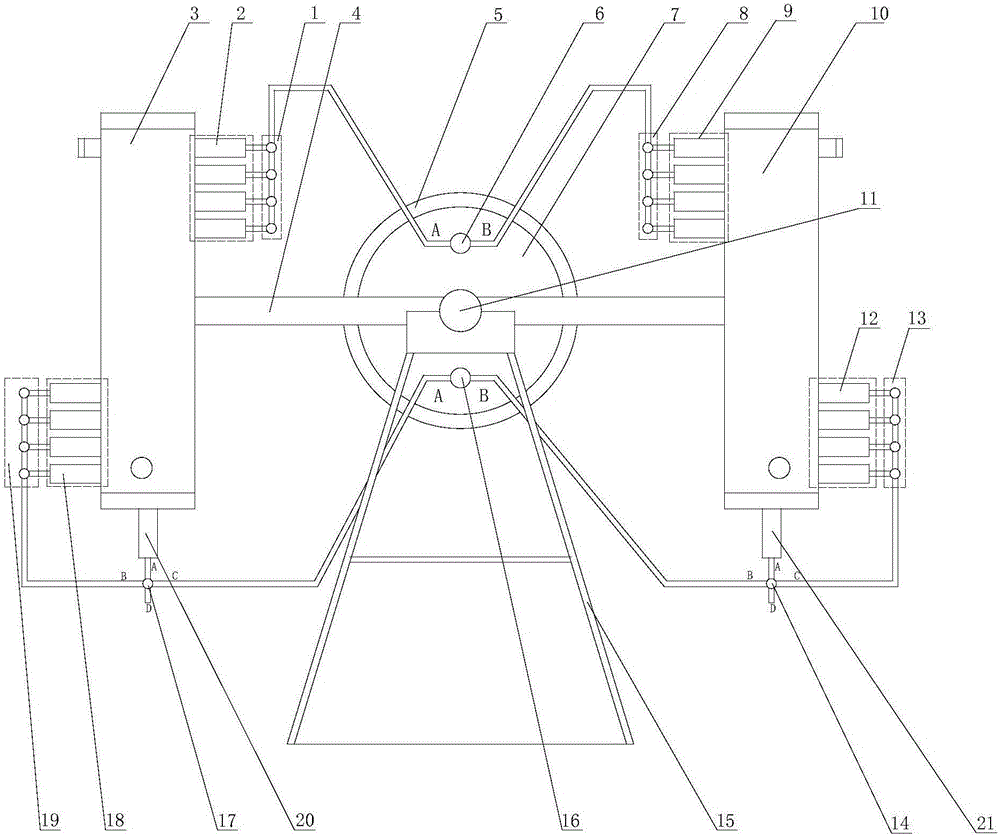

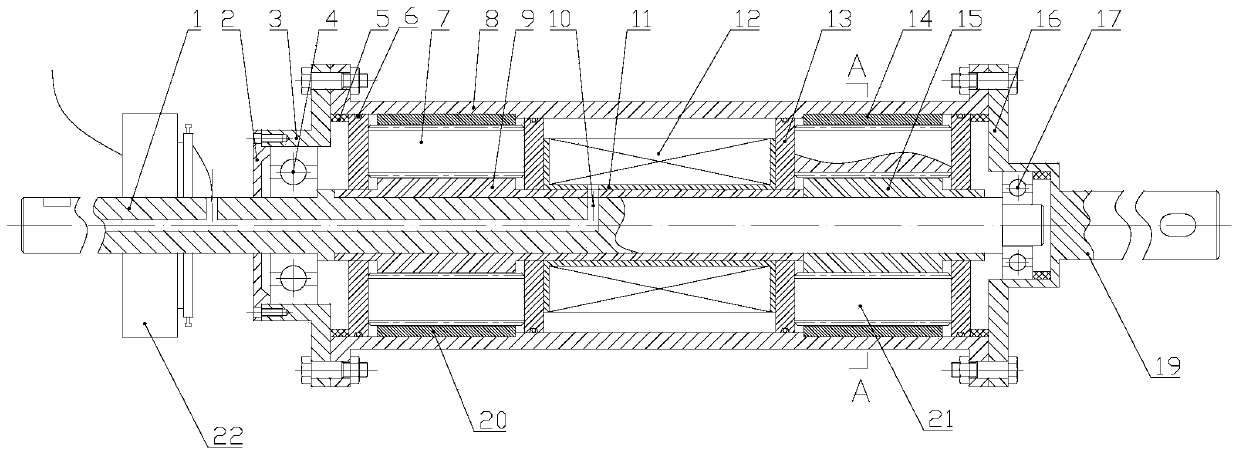

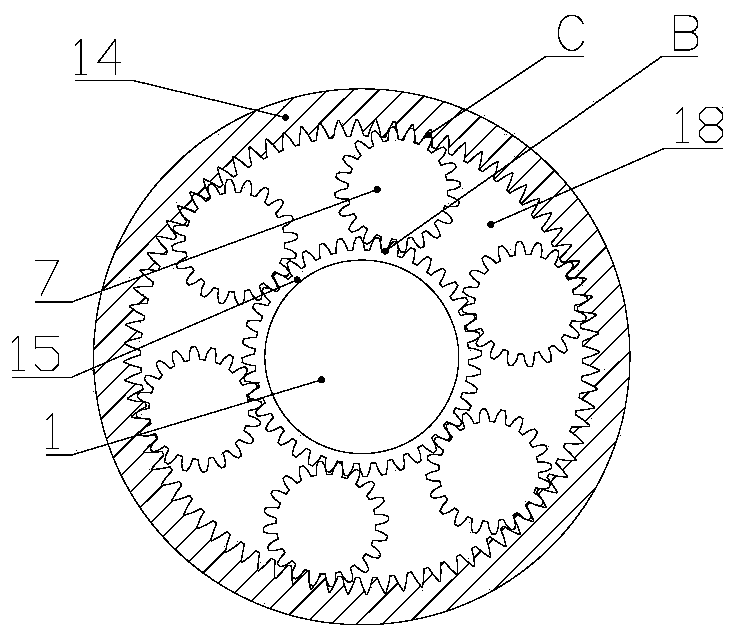

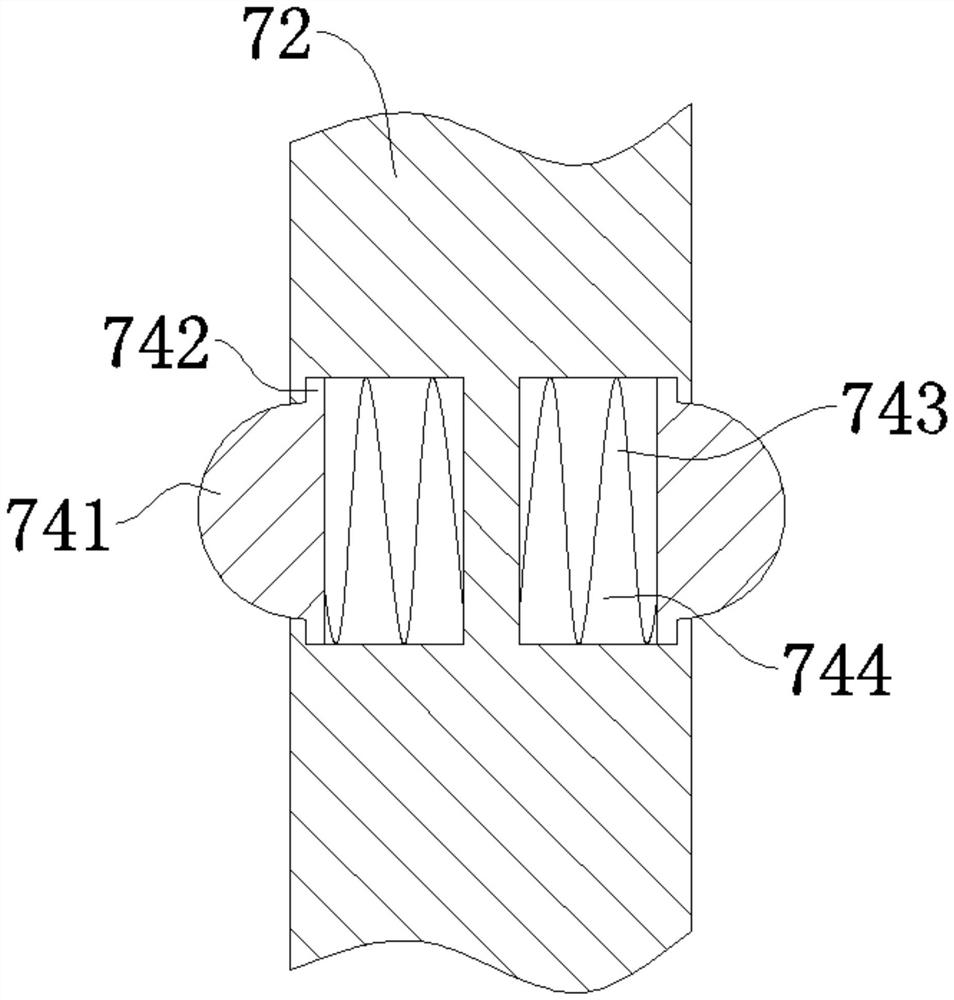

Planetary magnetorheological transmission device based on shear-extrusion effect

ActiveCN110925380AContinuous transmissionUniform transmissionFluid gearingsFluid clutchesGear wheelMagnetorheological fluid

The invention provides a planetary magnetorheological transmission device based on a shear-extrusion effect, and belongs to the technical field of mechanical transmission. According to the planetary magnetorheological transmission device based on the shear extrusion effect, a driven outer cylinder is assembled between a left end cover and a right end cover, wherein a gear ring sleeve is assembledon the inner wall of the driven outer cylinder; an input shaft is rotationally connected with the left end cover and the right end cover through bearings; an output shaft is arranged on the outer side of the right end cover; a magnetic conduction sleeve is arranged on the input shaft; a planetary gear is arranged between the magnetic conduction sleeve and the gear ring sleeve; the planetary gearis meshed with outer teeth of the magnetic conduction sleeve and inner teeth of the gear ring sleeve; the two ends of the magnetic conduction sleeve and the two ends of the gear ring sleeve are sealedthrough sealing assemblies to form a closed space; the closed space is filled with magnetorheological fluid; a coil framework is arranged on the input shaft; a magnet exciting coil is arranged on thecoil framework; and the magnet exciting coil is electrically connected with an external power supply. The planetary magnetorheological transmission device has the beneficial effects that large-torquetransmission can be realized, transmission is uniform, the magnetorheological fluid is not influenced by centrifugal force, and real-time adjustment of torque and rotating speed can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

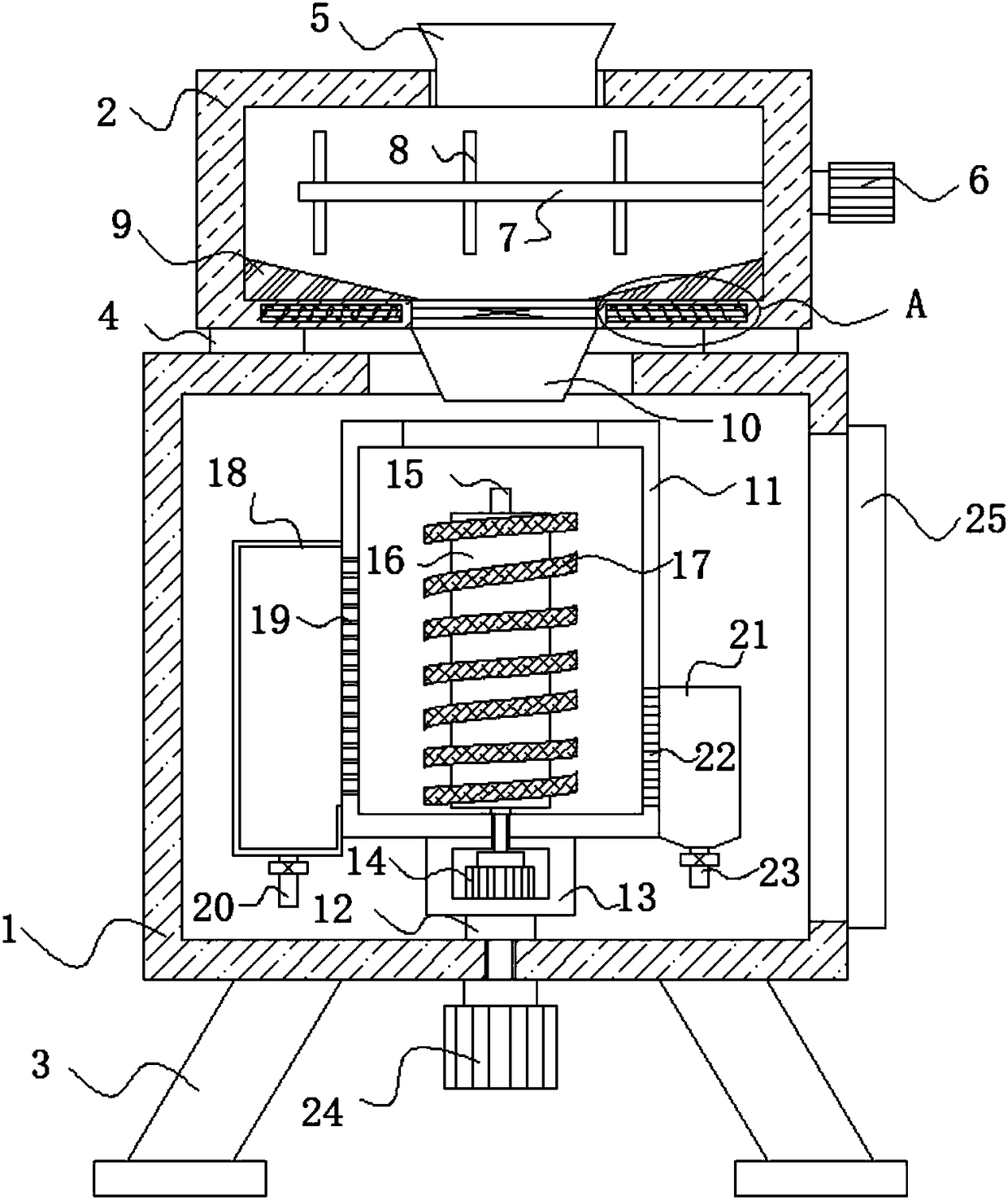

Pressing refining device for tea seed oil processing

PendingCN108504449ALow pressing efficiencyImprove oil yieldFatty-oils/fats productionPressesOil processingEngineering

The invention discloses a pressing refining device for tea seed oil processing. The device comprises a pressing box and a stir-frying box, four corners of the lower end of the stir-frying box are fixedly connected to the upper end of the pressing box through a fixing plate, and four corners of the lower end of the pressing box are all fixedly connected with supporting legs; a feeding inlet is formed in the upper end of the stir-frying box, a material falling hole is formed in the inner bottom of the stir-frying box, and the lower end of the stir-frying box is fixedly connected with a tapered funnel corresponding to the material falling hole position; a gate segment is arranged at the material falling hole position, a first feeding passage corresponding to the tapered funnel position is arranged on the upper end of the pressing box, the lower end of the tapered funnel penetrates through the first feeding passage, and two installing grooves are formed in the inner bottom of the stir-frying box. The pressing refining device is compact in structure, through the integrated arrangement of the stir-frying box and pressing box, it can be avoided that tea seeds under low temperature and moist circumstances cause low pressing efficiency, centrifugal force is utilized to throw away oil liquid, the oil extraction rate of the tea seeds is improved, and the pressing effect is good.

Owner:韦德智

Sugarcane crushing and squeezing device used for agriculture

InactiveCN111660597AFacilitate pressing and discharge of waste residuePrevent slidingJuice extractionMetal working apparatusAgricultural engineeringAgricultural science

The invention belongs to the technical field of sugarcane production, and particularly relates to a sugarcane crushing and squeezing device used for agriculture. By aiming at the problem that in a squeezing process of an existing squeezing device, leakage holes are likely to be blocked by sugarcane slags so as to be unfavorable for discharging waste slags, the invention now puts forward the following scheme that the sugarcane crushing and squeezing device comprises a base of a flat square tube structure, wherein the middle of the upper surface of the base is provided with a round hole; a squeezing bucket is clamped in the round hole; the bucket bottom of the squeezing bucket is of a taper-shaped structure; and on the upper surface of the base, a C-shaped steel stand column of which the opening faces the middle is fixed near an edge. When the sugarcane crushing and squeezing device is used and sugarcanes need to be squeezed, blocked sugarcanes only need to be added into the squeezing bucket, and then, the rotation of a transmission rod is controlled to squeeze the sugarcanes. During squeezing, extruded juice can be discharged out of the squeezing bucket along a notch on the side surface of an end cap, and in addition, when waste slags need to be cleaned, the end cap only needs to be slightly raised to slowly discharge the waste slags from the bottom.

Owner:烟台增鲜农业科技有限公司

Camellia oil for pregnant women skin care and preparation method thereof

InactiveCN108685806AImprove water storage capacityRestore elasticityCosmetic preparationsToilet preparationsWrinkle skinPolygonum cuspidatum root extract

The invention discloses camellia oil for pregnant women skin care, wherein the camellia oil comprises camellia seed oil, glyceryl caprylate / caprate, tocopherol acetate, limnanthes alba seed oil, jojoba seed oil, hoplostethus atlanticus oil, squalane, butyrospermum parkii kotschy fruit oil, a chamomilla recutita leaf extract, a glycyrrhiza glabra root extract, a herba centellae extract, tocopherol,a scutellaria root extract, a tea leaf extract and a polygonum cuspidatum root extract. The camellia oil has the beneficial effects that edible raw materials are adopted, natural wild organic safflower camellia seed oil is extracted, and the camellia oil nourishes skin, improves the smoothness of pregnant skin, is affinity and easy to absorb, strengthens the water storage capacity of the skin, solves the problems of dry itching and redness of the pregnant skin, restores skin elasticity, effectively improves the relaxation of the pregnant skin and prevents the production of fine wrinkles.

Owner:她芙医美(厦门)科技有限公司

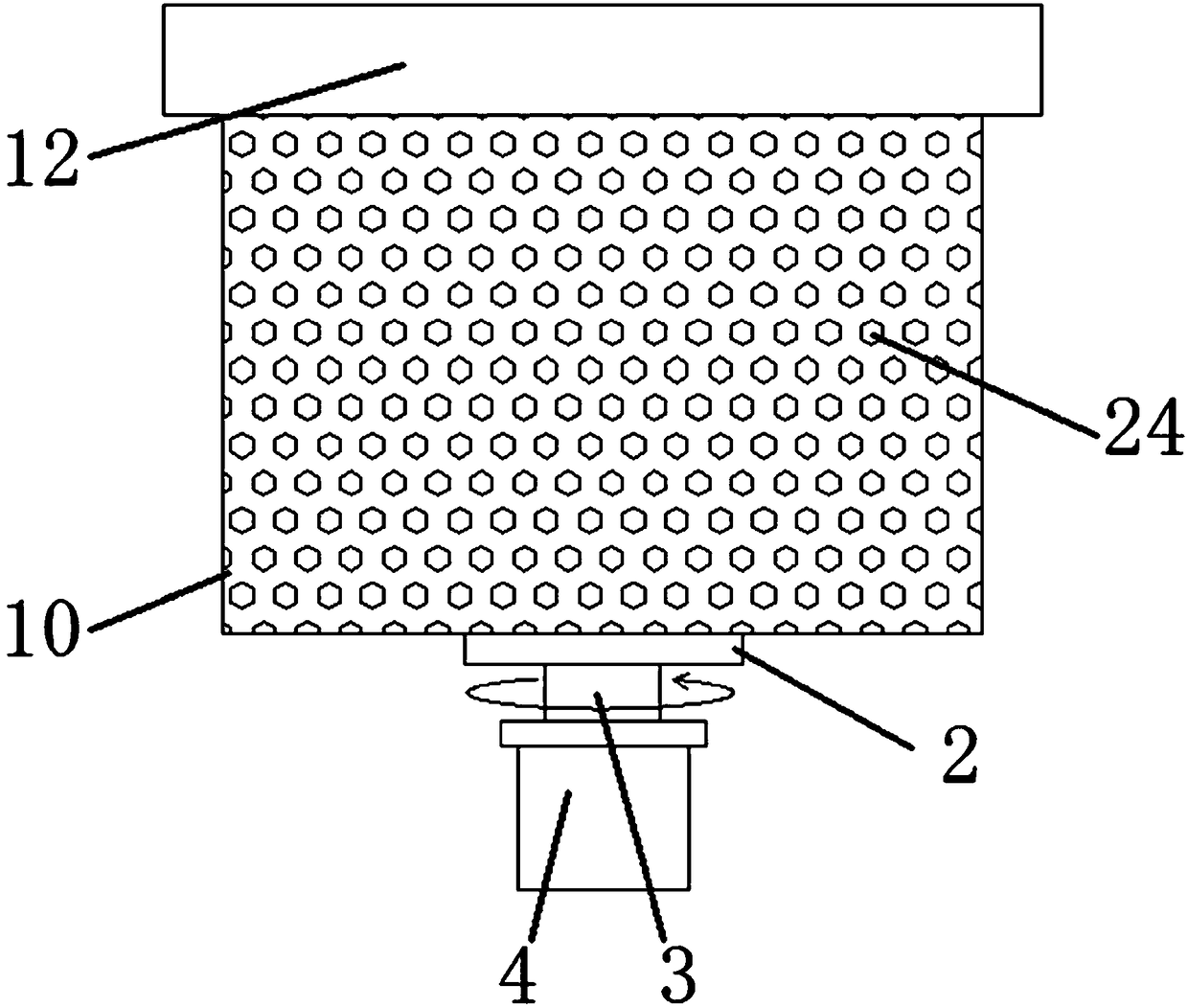

Domestic rotary squeezer

The invention discloses a domestic rotary squeezer. The domestic rotary squeezer comprises a rotating disk, a liquid collecting barrel, a squeezing barrel, a squeezing head and a cross beam plate, wherein a supporting frame is welded at the bottom part of the liquid collecting barrel; the supporting frame is fixedly arranged on the base; the squeezing barrel is arranged in the liquid collecting barrel; the middle part of the lower end of the squeezing barrel is connected with the rotating disk; a squeezing cavity is formed in the squeezing barrel; a plurality of liquid outlets are formed in the side wall of the squeezing barrel; a pressing plate is arranged in the squeezing barrel; the squeezing head is arranged above the pressing plate; the squeezing head is arranged on the bottom end ofan ejector rod; the top part of the ejector rod is connected with a spring baffle plate; springs sleeve the ejector rod above the spring baffle plate; the upper ends of the springs lean against the cross beam plate. According to the domestic rotary squeezer disclosed by the invention, centrifugal throwing of squeezed juice is convenient, and the efficiency and an effect of centrifugally spin-driedjuice are higher; continuous pressurized squeezing of the squeezing head and the pressing plate on materials in the squeezing cavity can be realized, manually operated pressing is not required, troubles are reduced, and the labor is saved; high-speed rotating, centrifuging, drying and squeezing operation of the squeezing barrel and pressurizing operation of the squeezing head and the pressing head are intermittently carried out, and the squeezing effect is good.

Owner:韩志杰

Improved press rolls of paper machine

The present invention relates to an improved pressing roller for paper-making machine. It is characterized by that it includes a metal roller self-body, the external peripheral surface of said metal roller self-body is covered with a layer of stainless steel material, and the external surface of said stainless steel material layer is covered with a layer of ceramic material. Said improved pressing roller not only can obtain good pressing effect, but also can raise the product quality of paper-making machine.

Owner:冯亚强

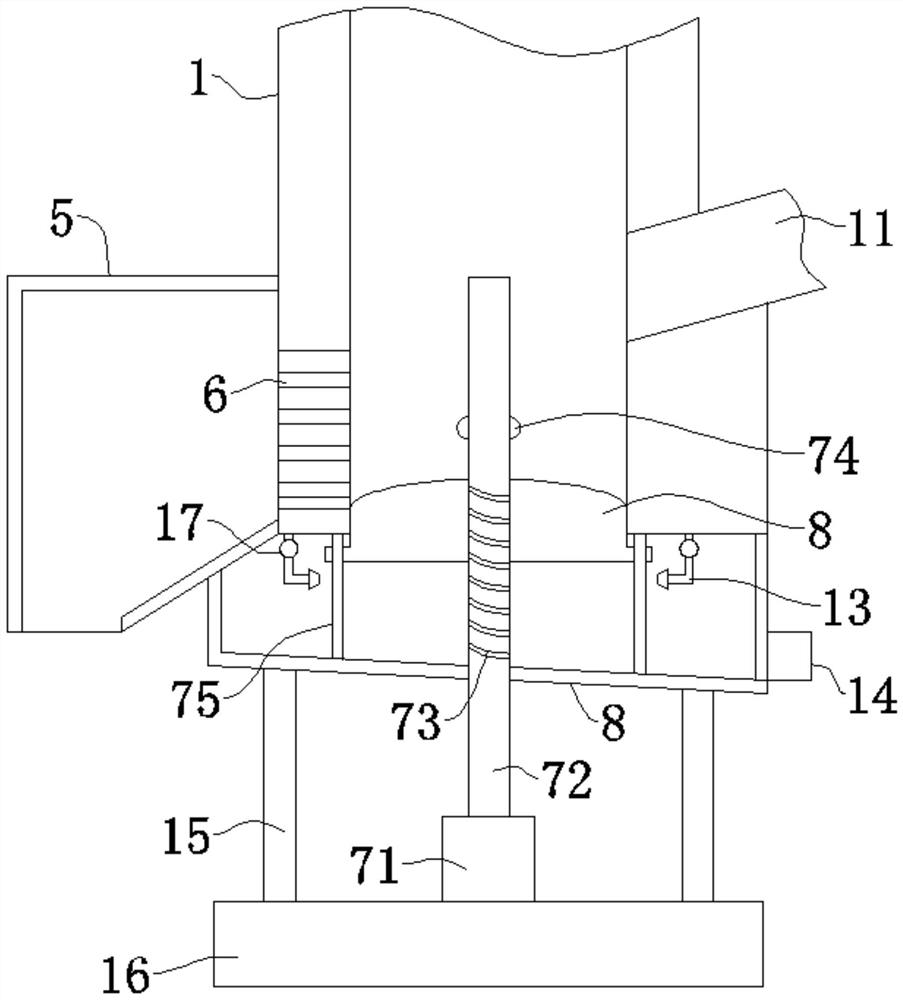

Sesame oil squeezing, filtering and storing integrated device

ActiveCN112721274ASesame is evenly stressedGood squeezing effectCleaning using gasesFatty-oils/fats productionSeeds sesameEnvironmental geology

The invention discloses a sesame oil squeezing, filtering and storing integrated device, and belongs to the technical field of sesame oil processing. The integrated device comprises a supporting frame, a squeezing barrel, a hydraulic cylinder, a storage tank, a sesame oil discharging channel, a driving mechanism, a residue storage box, a squeezing block, a chassis, supporting rods and a base; the residue storage box is located below the squeezing barrel, the supporting rods are arranged between the base and the residue storage box in a supporting manner, filtering holes are formed in the side wall of the lower portion of the squeezing barrel, and the sesame oil discharging channel is connected between the squeezing barrel and the storage tank; the squeezing block is installed on the hydraulic cylinder, the hydraulic cylinder is used for driving the squeezing block to move up and down in the squeezing barrel, and the chassis is located at the bottom in the squeezing barrel and used for cooperating with the squeezing block for squeezing; and the squeezing block comprises a pressing column and an extruding block, the extruding block wraps the bottom and the periphery of the lower portion of the pressing column, and the driving mechanism is used for driving the extruding block to rotate on the pressing column and driving the chassis to move vertically. According to the sesame oil squeezing, filtering and storing integrated device provided by the invention, sesame seeds are uniformly stressed, the squeezing effect is good, and the oil yield is high.

Owner:HUNAN CHANGKANG IND

Household oil press

The invention relates to a household oil press. The household oil press is characterized by comprising a machine body provided with a driving mechanism, a pressing assembly, a material distributing assembly, a pan and a stirring mechanism; a pressing rod of the pressing assembly is a variable-diameter variable-pitch double-output inclined-plane screw rod, and the variable-diameter variable-pitch double-output inclined-plane screw rod is composed of two sections of screws with different diameters and different pitches; the thread diameter, the thread pitch and the thread thickness of the rear-section screw close to the root part of the pressing rod is larger than the thread diameter, the thread pitch and the thread thickness of the front-section screw respectively; a pressing chamber is provided with a variable-inner-diameter chamber cavity matched with the pressing rod; a control circuit board is arranged in the machine body; a power switch, a key panel and a display screen are arranged on the outer side of the machine body; and the power switch, the key panel, the display screen, a material distribution stepping motor, a stirring motor, a pan heating tape, a pressing rod heating block and a pressing motor are all electrically connected to the control circuit board. The invention aims to provide the household oil press. The household oil press is simple in structure, small in size, high in automation degree and capable of improving the oil yield.

Owner:韦啟武

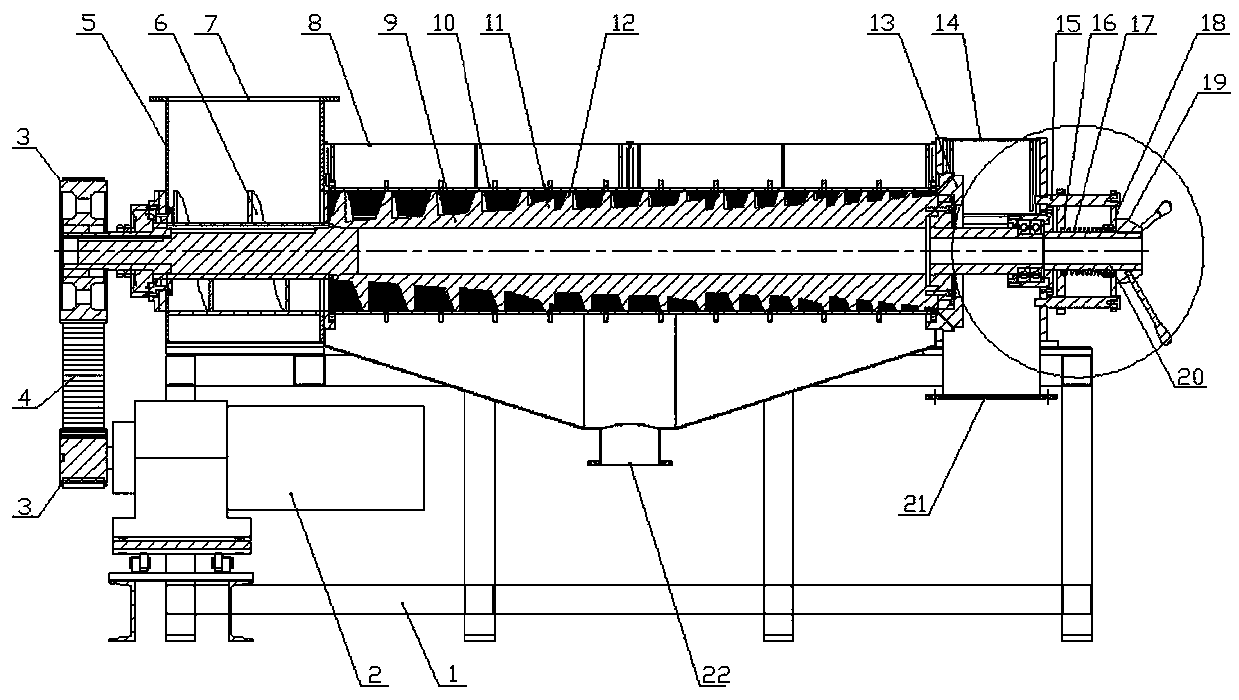

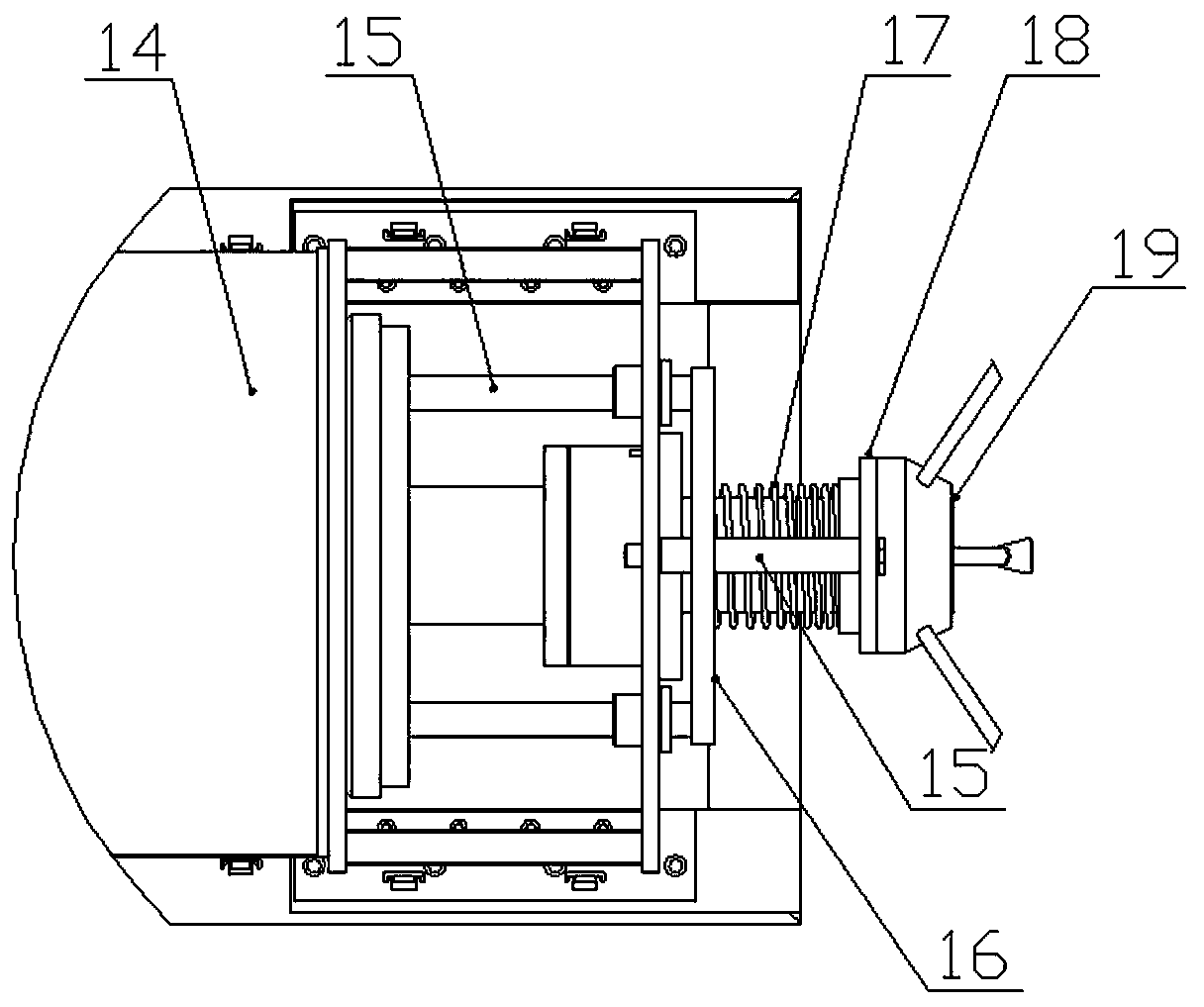

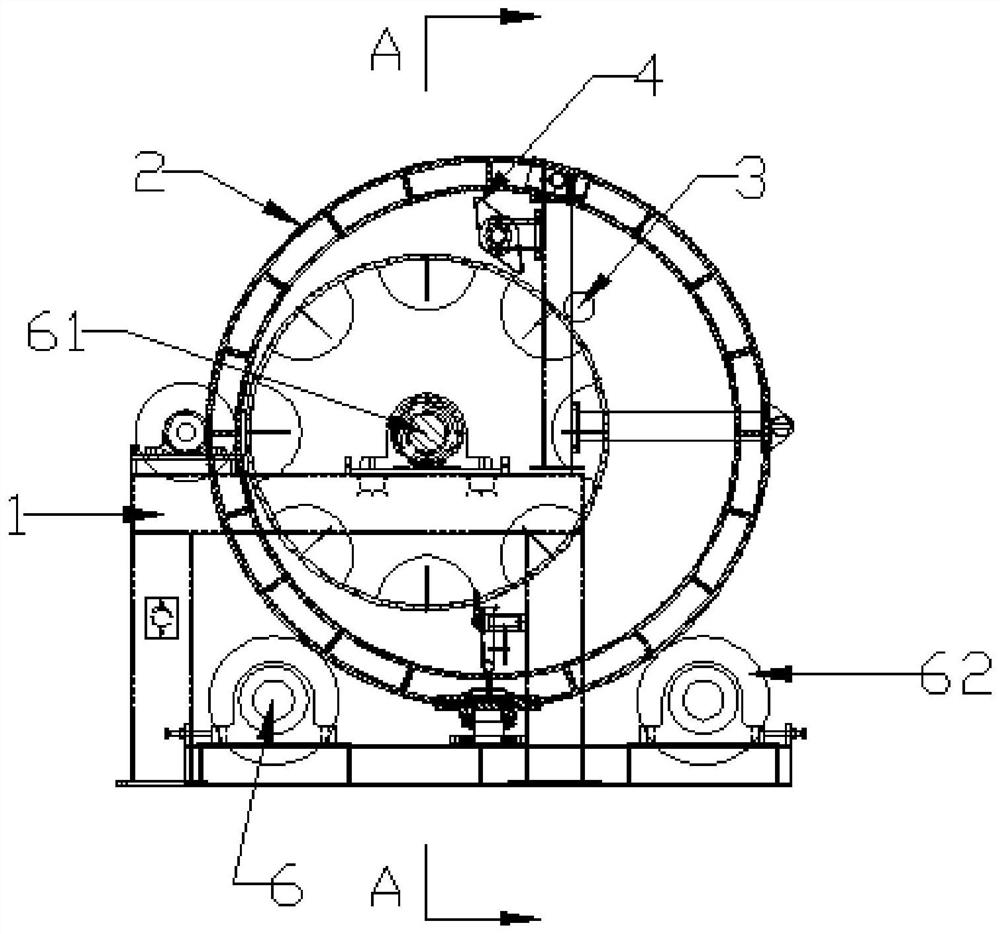

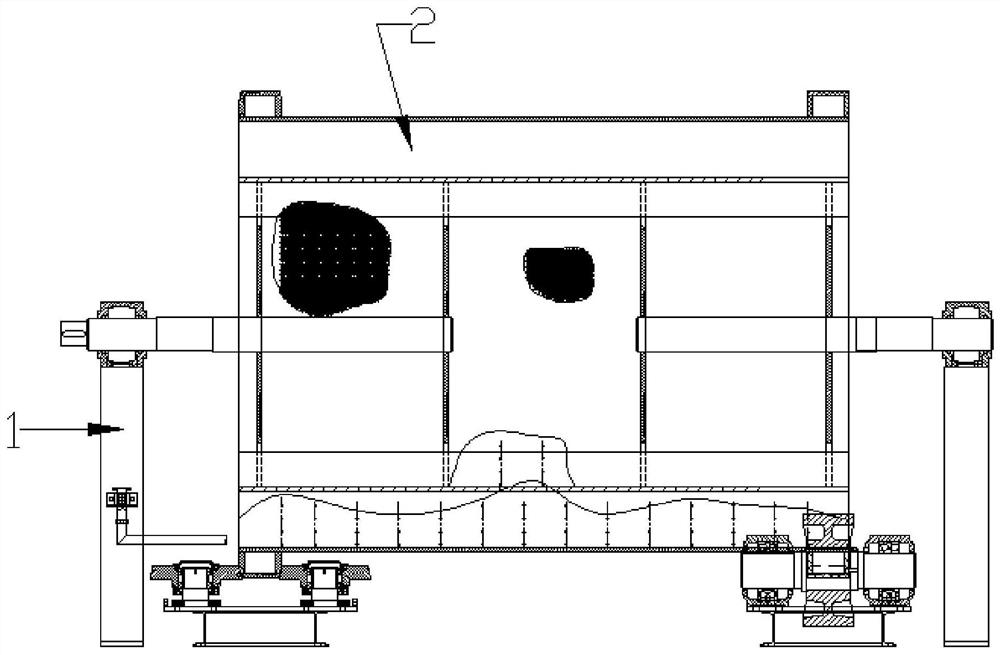

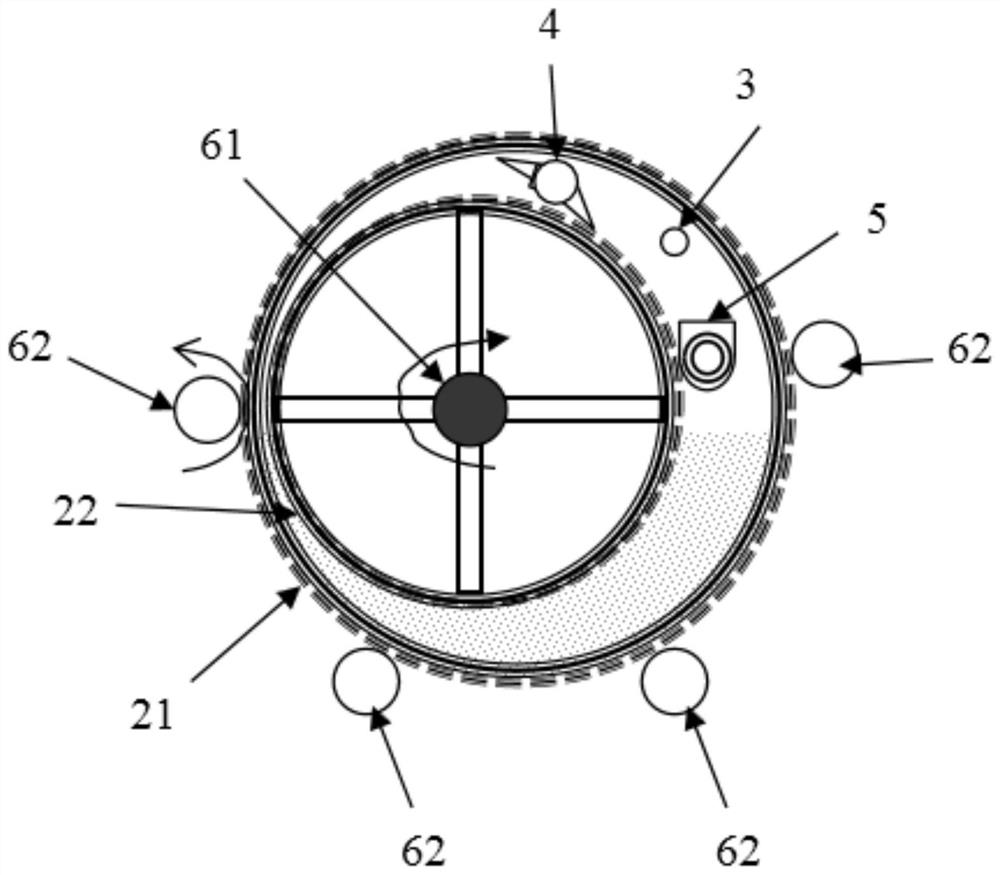

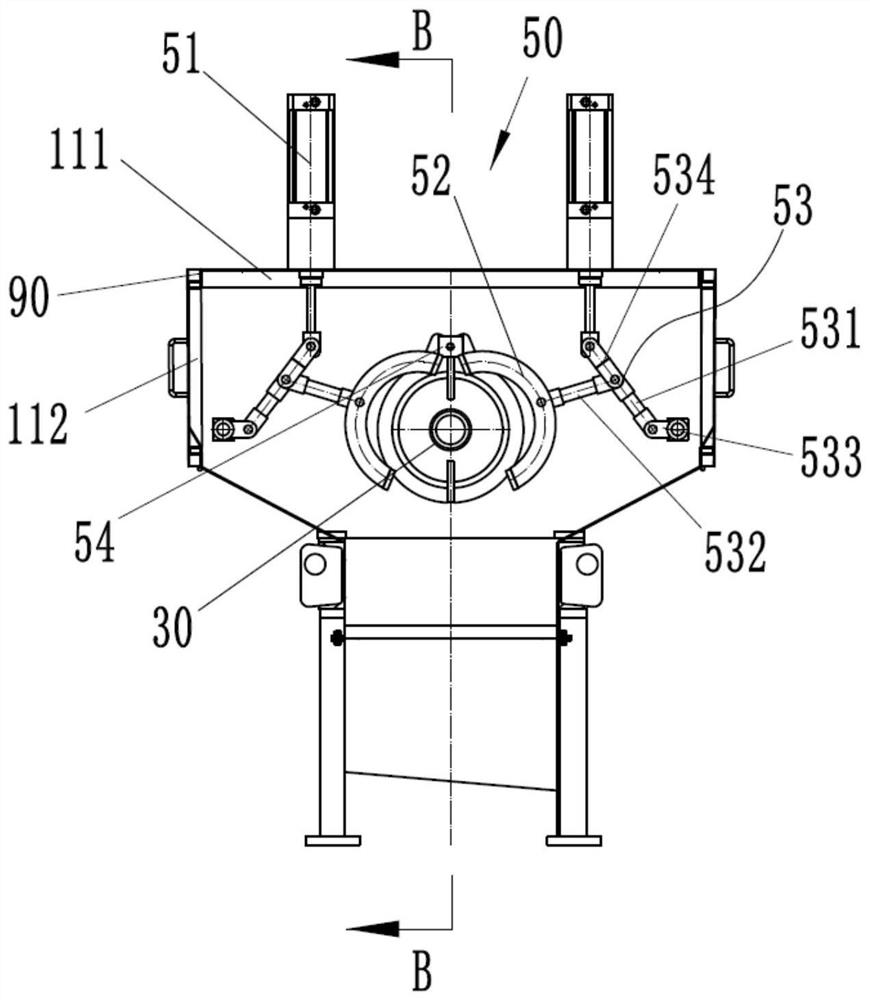

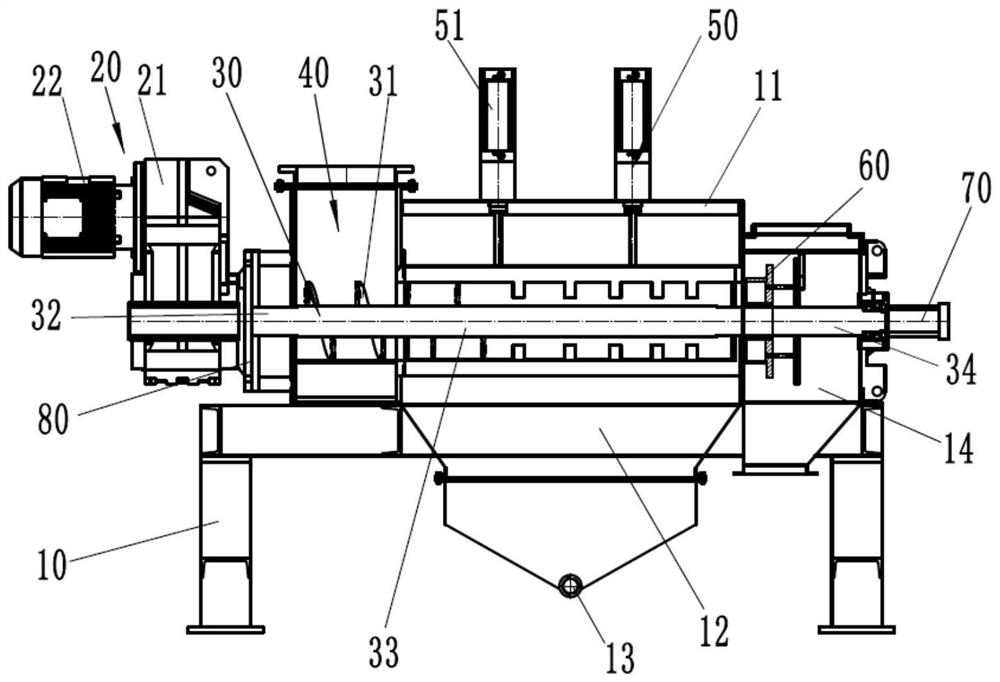

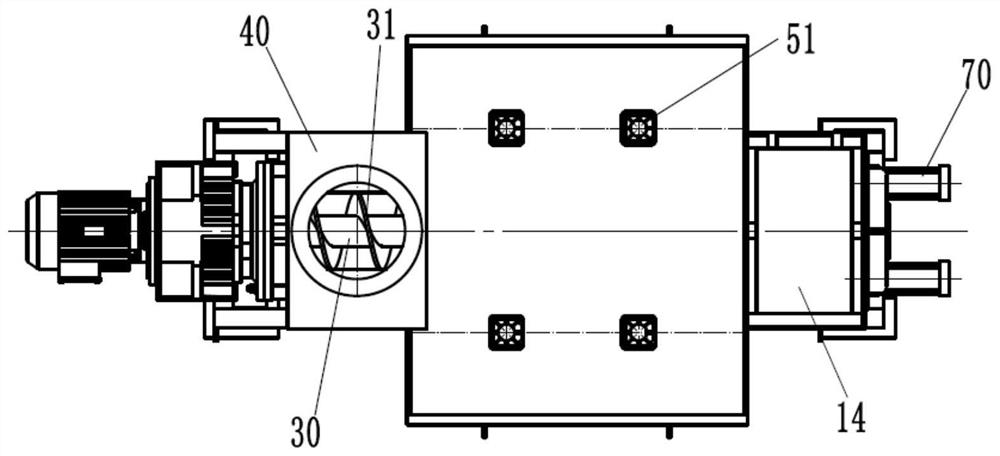

Rotary drum type solid-liquid separator

ActiveCN111617526ALow movement resistanceTo achieve the purpose of drying materialsFiltration separationStructural engineeringSolid content

The invention discloses a rotary drum type solid-liquid separator which comprises a rack, a rotary drum set, a feeding mechanism, an unloading mechanism, a discharging mechanism and a driving mechanism. The rotary drum set comprises at least two rotary drums which are different in diameter and sequentially arranged in a sleeving mode from inside to outside. At least one of the two adjacent rotarydrums is used for filtering liquid, the plurality of rotary drums can rotate respectively, every two adjacent rotary drums rotate around different circle centers to form a gradually-contracted ox horn-shaped channel, and therefore a liquid removal interval with the pressure intensity gradually increased is formed. At least one of the rotary drums is fixed on the rack. At least one feeding mechanism and at least one unloading mechanism are arranged in each ox horn-shaped channel. The number of the discharging mechanism and the number of the driving mechanism in the whole rotary drum type solid-liquid separator are respectively at least one. The rotating directions of the rotary drums are consistent. Forced pressure filtration and variable-volume filtration can be conducted at the same time,and the solid content of filter cakes can be conveniently adjusted.

Owner:嘉兴绿方舟环保技术有限公司

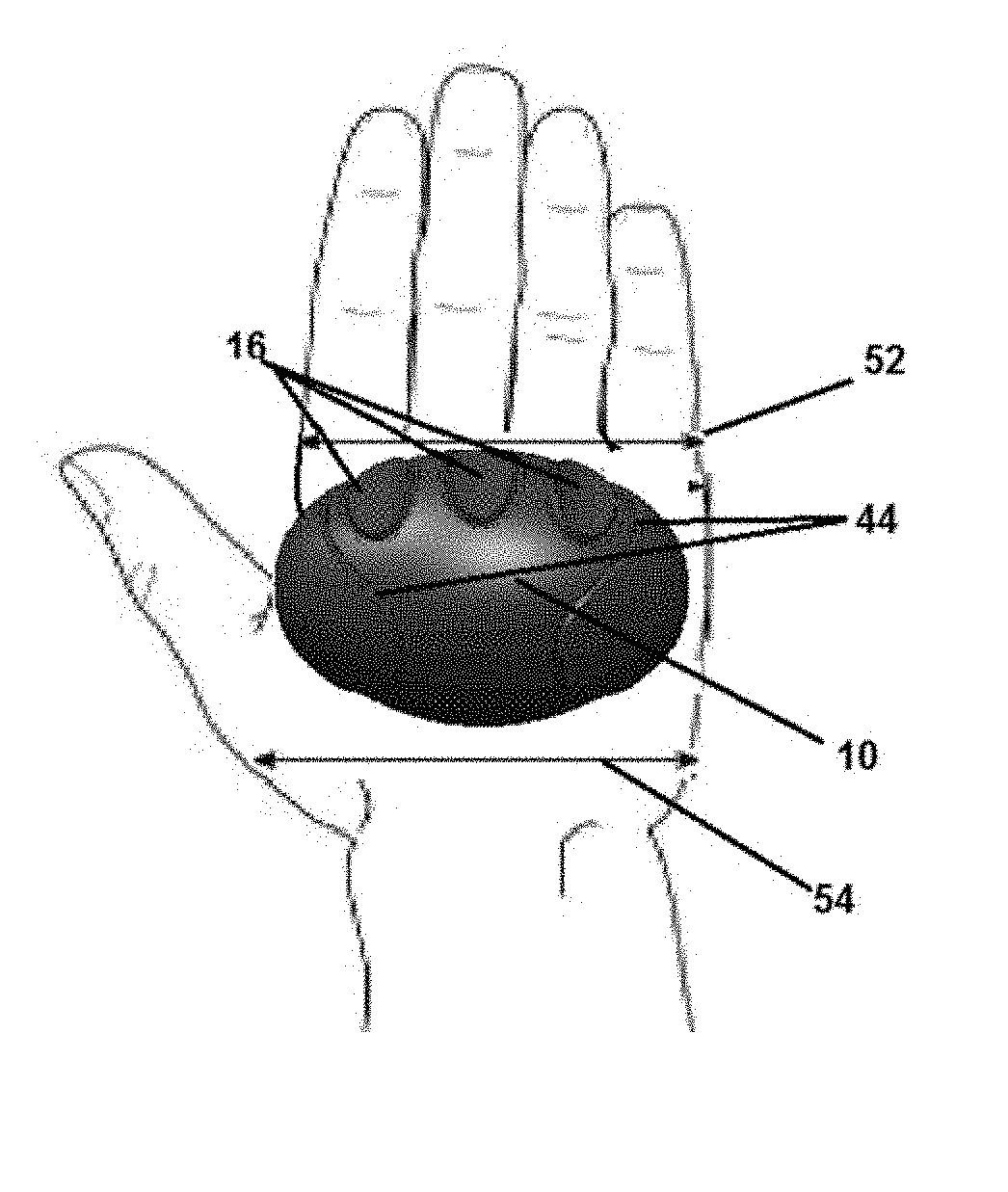

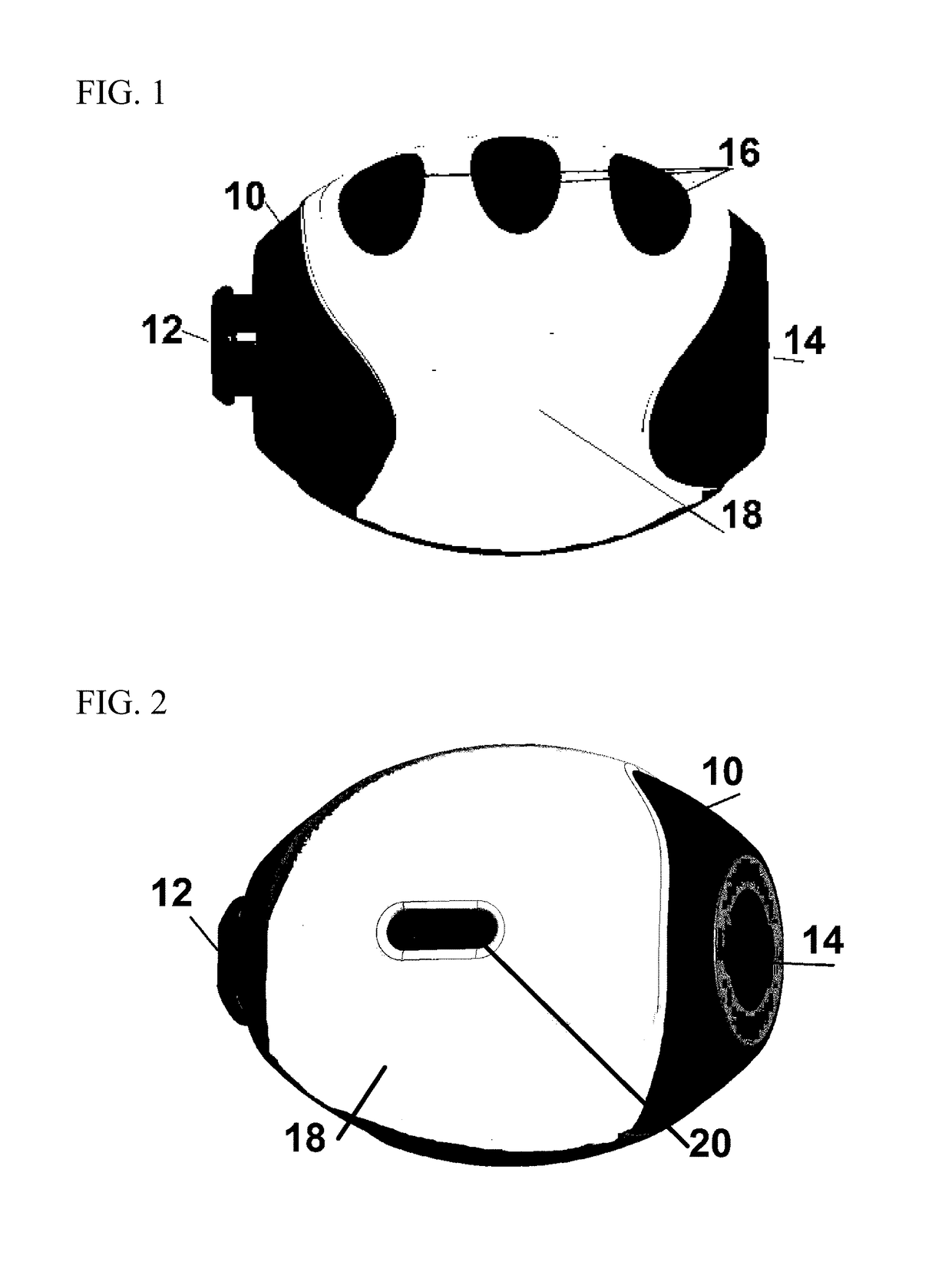

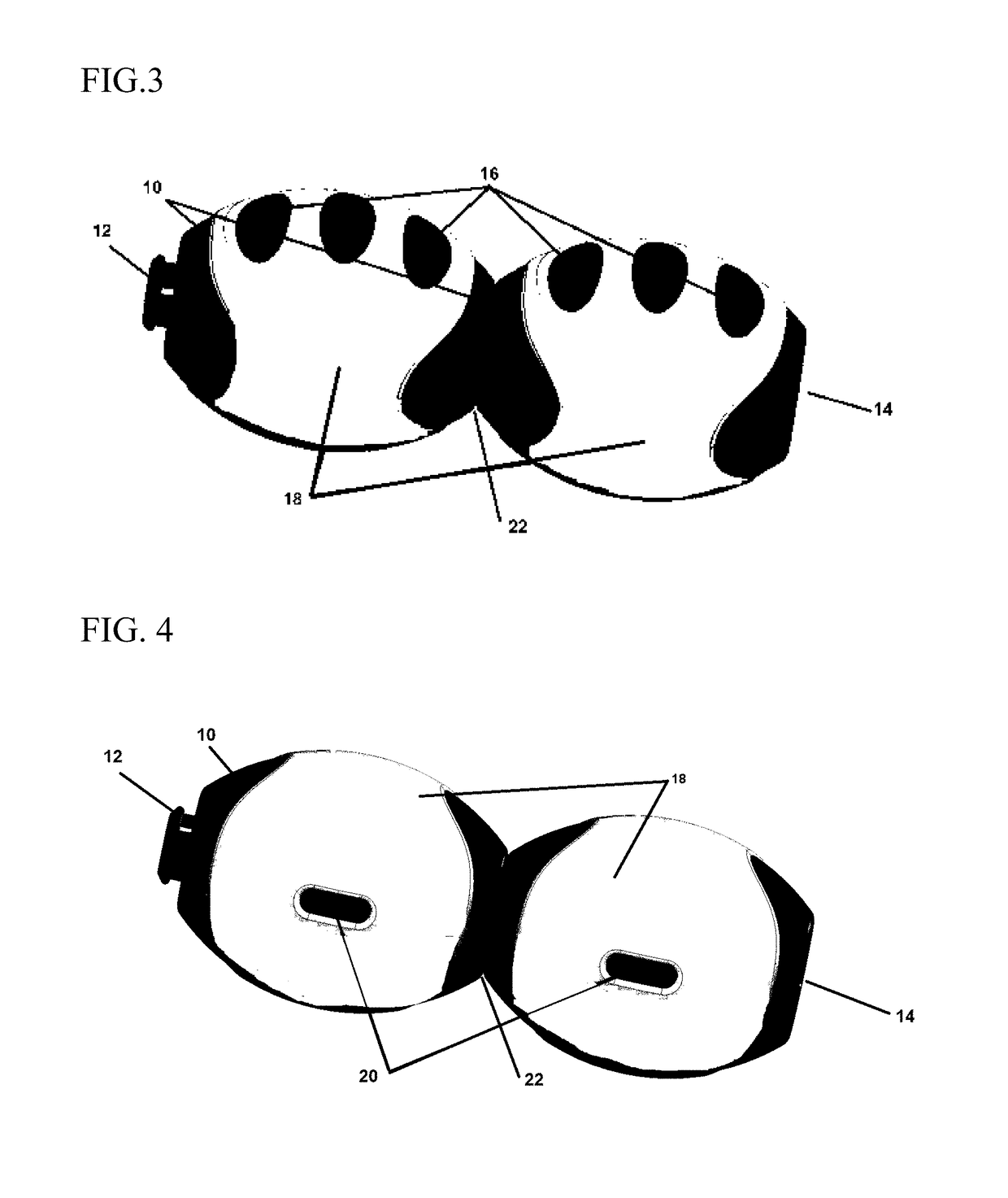

Ergonomic held weight unit and method of use

ActiveUS20170361146A1Increase or decrease weightAccurate measurementWeighing apparatus detailsSensorsModular unitComputer module

Hand held weight units of light weight manufactured as a solid unit, a shell unit with core insert combinations or modular units with interlocking ends. Shell units with core inserts and modular interlocking units allow for the changing of held weight by inserting or removing inserts or by locking or unlocking of modular weight unit sets creating varying held weight. The weight units are primarily used with upper body exercises during aerobic exercises in the home, outdoors, or in a gym setting such as walking or running to vary the intensity of workout during use.

Owner:MALCOLM CHRISTIAN

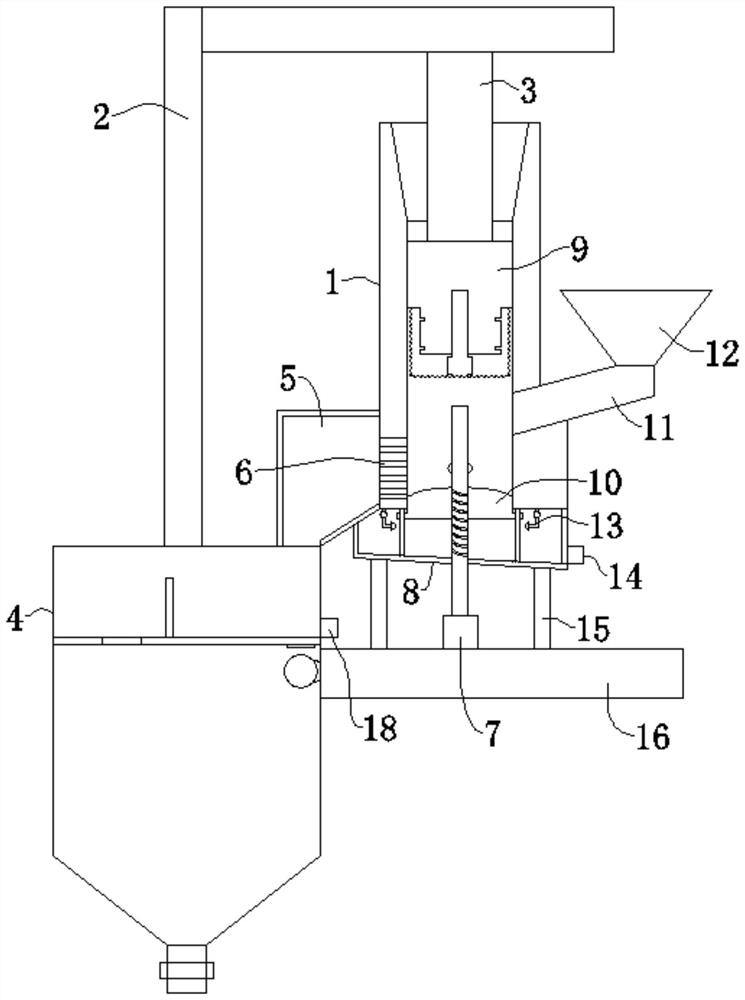

Squeezer

PendingCN112265308AGood squeezing effectIncrease productivityPressesLinear driveStructural engineering

The invention discloses a squeezer. The squeezer comprises a support, a main machine body, a residue discharging hopper, a driving device, an auger, a feeding hopper, a filter pressing mechanism, a tail plug and a first linear driving device, the main machine body is arranged on the support, the feeding hopper is arranged on the left side of the main machine body, the residue discharging hopper isarranged on the right side of the main machine body, the discharging opening is formed in the bottom of the main machine body; the auger is arranged in the main machine body, the feeding hopper and the residue discharging hopper in a penetrating mode, spiral blades are arranged on the periphery of the auger, the driving device drives the auger to rotate, the filter pressing mechanism comprises apair of movable auger covers and an adjusting assembly, the pair of movable auger covers are pivoted in the main machine body, the adjusting assembly is used for adjusting opening and closing of the pair of movable auger covers, the pair of movable auger covers is arranged on the outer side of the auger in a covering mode after being closed, the tail plug is movably arranged on the auger in a sleeving mode, a gap is formed between the tail plug and a feeding port of the residue discharging hopper, the first linear driving device is fixedly arranged on the residue discharging hopper, and the output end of the first linear driving device is connected with the tail plug. The squeezer is good in squeezing effect, high in production efficiency and convenient to clean.

Owner:ZHEJIANG BAIZHENTANG FOOD

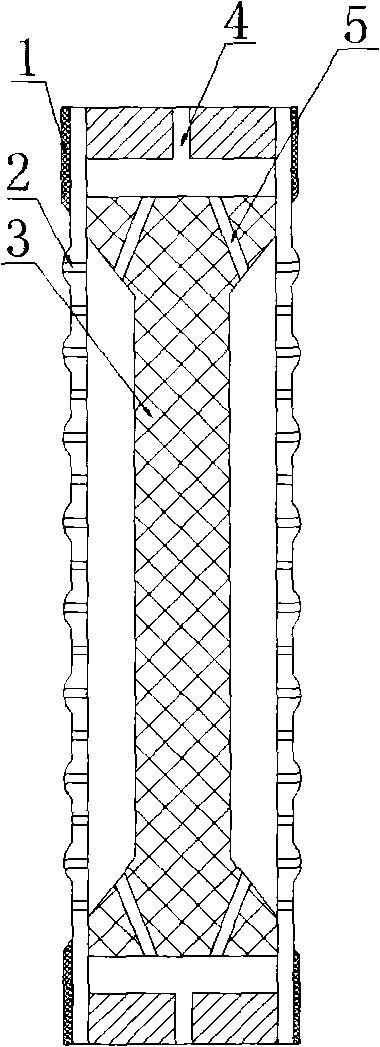

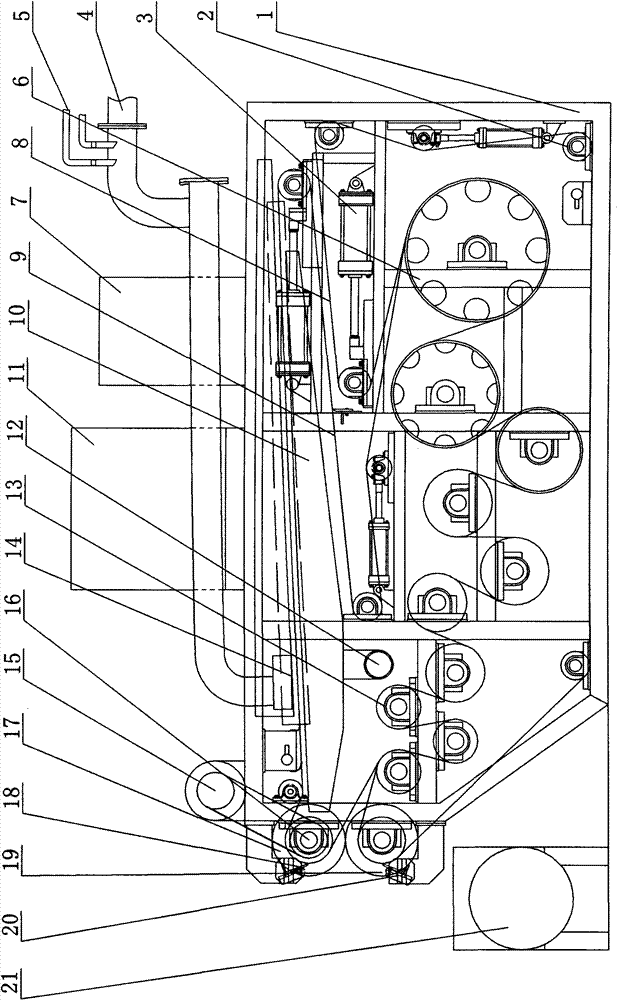

Belt sludge treatment press filter

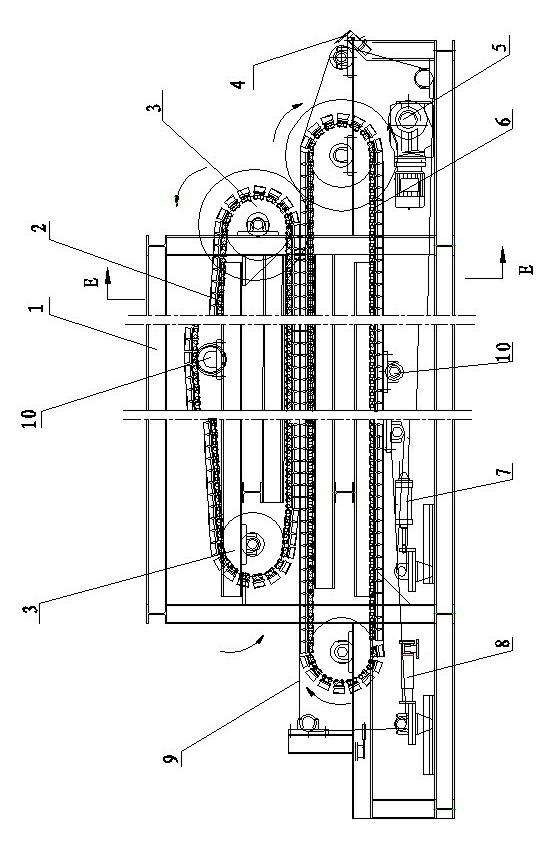

InactiveCN102206029BReduce volumeCompact structureSludge treatment by de-watering/drying/thickeningSludgeBelt filter

The invention discloses a belt sludge treatment press filter, and relates to an improvement of a structure of a belt filter. The belt sludge treatment press filter has small volume and compact structure, and provides a pressed sludge with low water content. The belt sludge treatment press filter comprises a frame. An electric cabinet and a pneumatic control cabinet are arranged on the frame. The key points of the structure are as follows: the top of the frame is provided with a sludge transport pipe with a medicine inlet; the side of the frame is provided with a pair same gears arranged aboveand below, wherein the gears are driven through a motor, and shafts of the pair gears are respectively provided with an upper press roller and a lower press roller; an upper filter belt of the upper press roller passes through an outlet of the sludge transport pipe in the frame, bypasses a pre-press roller and a press roller, and is returned to the upper press roller; an lower filter belt of the lower press roller bypasses an intermediate roller, and is superposed with the upper filter belt on the pre-press roller, then bypasses the press roller, and is returned to the lower press roller; a water collecting tank is arranged below the upper filter belt arranged below the outlet, and the bottom of the water collecting tank is provided with a drain pipe; the upper press roller and the lower press roller are respectively provided with an upper scraper and a lower scraper.

Owner:沈阳禹华环保有限公司

Plant beverage preparation device

ActiveCN113455603AEasy to cleanBest extraction effectRotary stirring mixersTransportation and packagingMechanical engineeringRaw material

The invention relates to the technical field of plant beverage production, in particular to a plant beverage preparation device. The plant beverage preparation device comprises a main device body, wherein a discharging structure is arranged on the side face of the main device body; a squeezing structure is arranged in the discharging structure; a stirring structure is arranged on the side surface of the squeezing structure; a conveying structure is arranged on the bottom side of the discharging structure. a compression structure is installed on the side face of the discharging structure; and a cooking and concentrating structure is arranged on the bottom side of the compression structure. According to the invention, raw materials are added and contained through the discharging structure; raw pulp is sufficiently squeezed while the materials are soaked through the squeezing structure; the materials are prevented from being accumulated at corners in the squeezing process through the stirring structure; the roughly filtered raw pulp is further filtered and discharged through the conveying structure; the height of a liquid level in a squeezing lever is adjusted at will through the compression structure; and meanwhile, filtered juice is stored, and an extracted liquid medicine is further filtered and cooked through the cooking and concentrating structure.

Owner:梧州市华夏医药科技有限公司

Pollution-free and environmentally friendly vinasse treatment device

PendingCN109228482AAutomatic forward conveying smoothlyEfficient separationBy-product recoveryPressesAlcoholEngineering

The invention discloses a pollution-free and environmentally friendly vinasse treatment device. The device comprises a sealing extruding structure composed of a cylinder and a threaded rod, the end portion of the threaded rod extends out of the end portion of the cylinder and is connected with a threaded rod driving mechanism, and a feeding inlet is formed in one end of the cylinder; a dischargingoutlet is formed in the other end of the cylinder, heating devices capable of heating the cylinder are distributed on the portion, between the feeding inlet and the discharging outlet, of the outer wall of the cylinder, gas exhausting holes used for gas in an inner cavity of the cylinder to be exhausted are distributed in the top of the cylinder, and the gas exhausting holes are communicated witha gas sucking device through a pipeline. The device has the advantages that moisture in vinasse can be efficiently extruded out, in the moisture extruding process, vinasse residues are conveyed awayfrom the cylinder, and the extruding efficiency is improved; moisture and ethyl alcohol which are extruded from the vinasse entering the cylinder only can be exhausted from openings in the two ends ofthe cylinder or the discharging outlet, or the moisture and the ethyl alcohol are heated to become steam and volatile ethyl alcohol so as to be exhausted from the gas exhausting holes, therefore it is only required that collecting device are placed at corresponding positions, the moisture and ethyl alcohol can be prevented from spilling, or waste gas can be prevented from being exhausted directly, and the device is green, environmentally friendly and pollution-free.

Owner:浙江华业塑料机械股份有限公司

Pressing device used for fragrance processing

InactiveCN107813526AEasy to install and disassembleGood squeezing effectPressesHydraulic pumpEngineering

The invention discloses a pressing device used for fragrance processing. The pressing device comprises a device shell, a sealing cover, fixing bolts, a feeding pipe, supporting legs, a hydraulic pump,a control panel, a power connecting wire, a pull rod, a bottom plate, a connecting plate, side plates, a filtering plate, a hydraulic rod, a pressing plate, a filtering net, filtering holes, a sealing plate, a liquid outlet pipe, an installation plate, a collecting hopper and an inner groove. The pressing device has the beneficial effects that the filtering plate and the connecting plate are installed between the two side plates, the sealing cover is installed through the fixing bolts, so that the device is overall mounted and demounted more conveniently; after the device is used for a long time, impurities are likely to adhere to the interior of the device, the pressing effect is affected, a user cleans the interior of the device by demounting the device, and therefore the pressing effect of the device is improved; the movable bottom plate is arranged on one side of the filtering plate, the detachable sealing plate is arranged at the bottom of the device shell, and therefore the restof waste materials obtained after pressing of materials is completed above the bottom plate can be taken out by pulling the bottom plate open and the demounting the sealing plate.

Owner:防城港市润禾农林科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com