Method for preparing Chinese flowering crabapple fruit juice by using pectinase

A technology of crabapple fruit and pectinase, applied in food science and other fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Selection and cleaning: select fully mature and plump high-quality crabapple fruit, rinse with running water, and wash away the soil, microorganisms and pesticides attached to the crabapple fruit;

[0028] b. Slicing and beating: Cut the washed crabapple into small pieces, beat the pulp with a masher, and mix well;

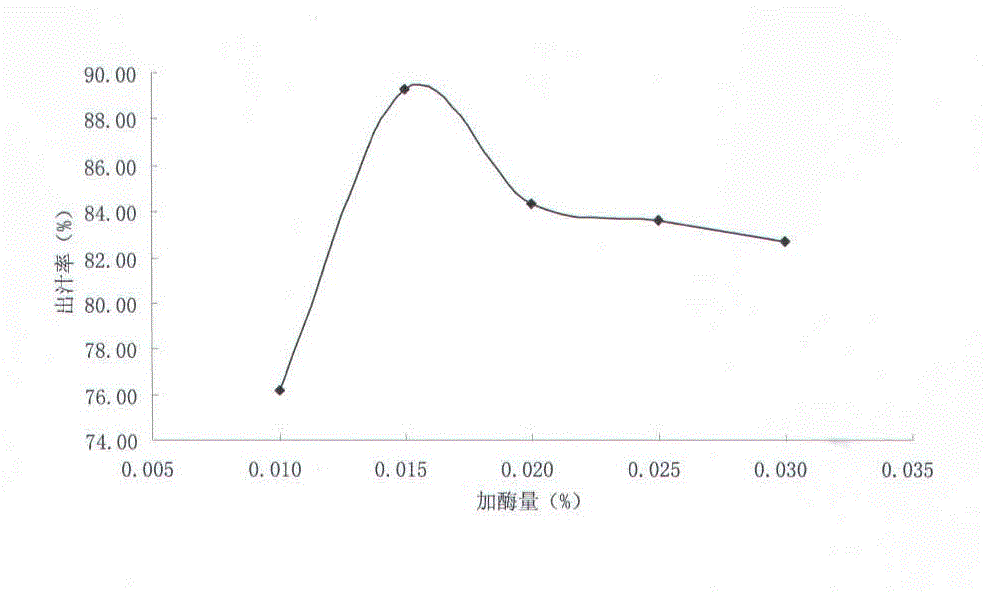

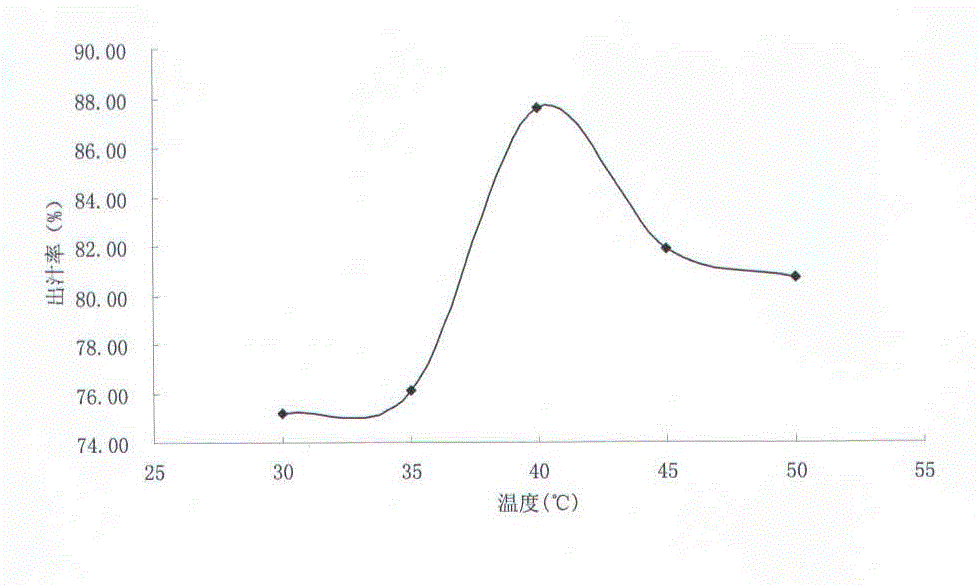

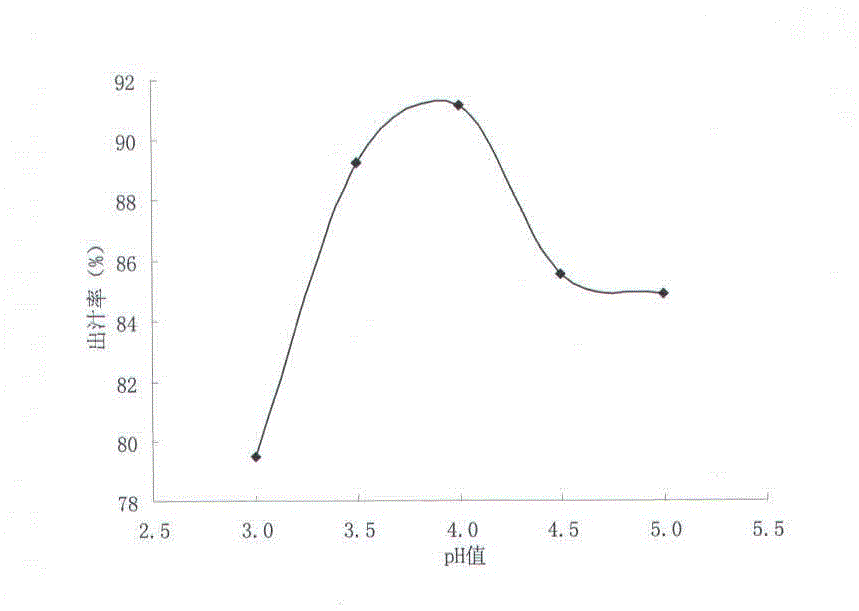

[0029] c. Pectin enzymatic hydrolysis: add 0.015% by weight pectinase to the beaten crabapple pulp for enzymatic hydrolysis, the enzymatic hydrolysis temperature is 35°C, the enzymatic hydrolysis time is 90min, and the pH is 3.5;

[0030] d. Separation of fruit juice: filter the enzymatically hydrolyzed juice with four layers of gauze, and separate the pomace to obtain the original crabapple juice, with a juice yield of 79.12%.

Embodiment 2

[0032] a. Selection and cleaning: select fully mature and plump high-quality crabapple fruit, rinse with running water, and wash away the soil, microorganisms and pesticides attached to the crabapple fruit;

[0033] b. Slicing and beating: Cut the washed crabapple into small pieces, beat the pulp with a masher, and mix well;

[0034] c. Pectin enzymatic hydrolysis: add 0.020% by weight pectinase to the beaten crabapple pulp for enzymolysis. The enzymolysis temperature is 40°C, the enzymolysis time is 150min, and the pH is 4.0;

[0035] d. Separation of fruit juice: filter the enzymatically hydrolyzed fruit with four layers of gauze and separate the pomace to obtain light yellow crabapple fruit juice, with a juice yield of 92.18%.

Embodiment 3

[0037] a. Selection and cleaning: select fully mature and plump high-quality crabapple fruit, rinse with running water, and wash away the soil, microorganisms and pesticides attached to the crabapple fruit;

[0038] b. Slicing and beating: Cut the washed crabapple into small pieces, beat the pulp with a masher, and mix well;

[0039] c. Pectin enzymatic hydrolysis: add 0.020% pectinase to the beaten crabapple pulp for enzymatic hydrolysis, the enzymatic hydrolysis temperature is 45°C, the enzymatic hydrolysis time is 120min, and the pH is 4.5;

[0040] d. Separation of fruit juice: filter the enzymatically hydrolyzed fruit juice with four layers of gauze, separate the pomace, and subpackage to obtain the light yellow crabapple fruit juice, with a juice yield of 91.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com