Digital printing thermal transfer printing body paper making machine and paper making method

A digital inkjet and thermal transfer technology, applied in the field of papermaking, can solve the problems of small horizontal expansion rate, large transverse expansion rate of digital inkjet thermal transfer base paper, pattern distortion and deformation, etc., to improve smoothness, eliminate embossing, The effect of increasing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Headbox 35

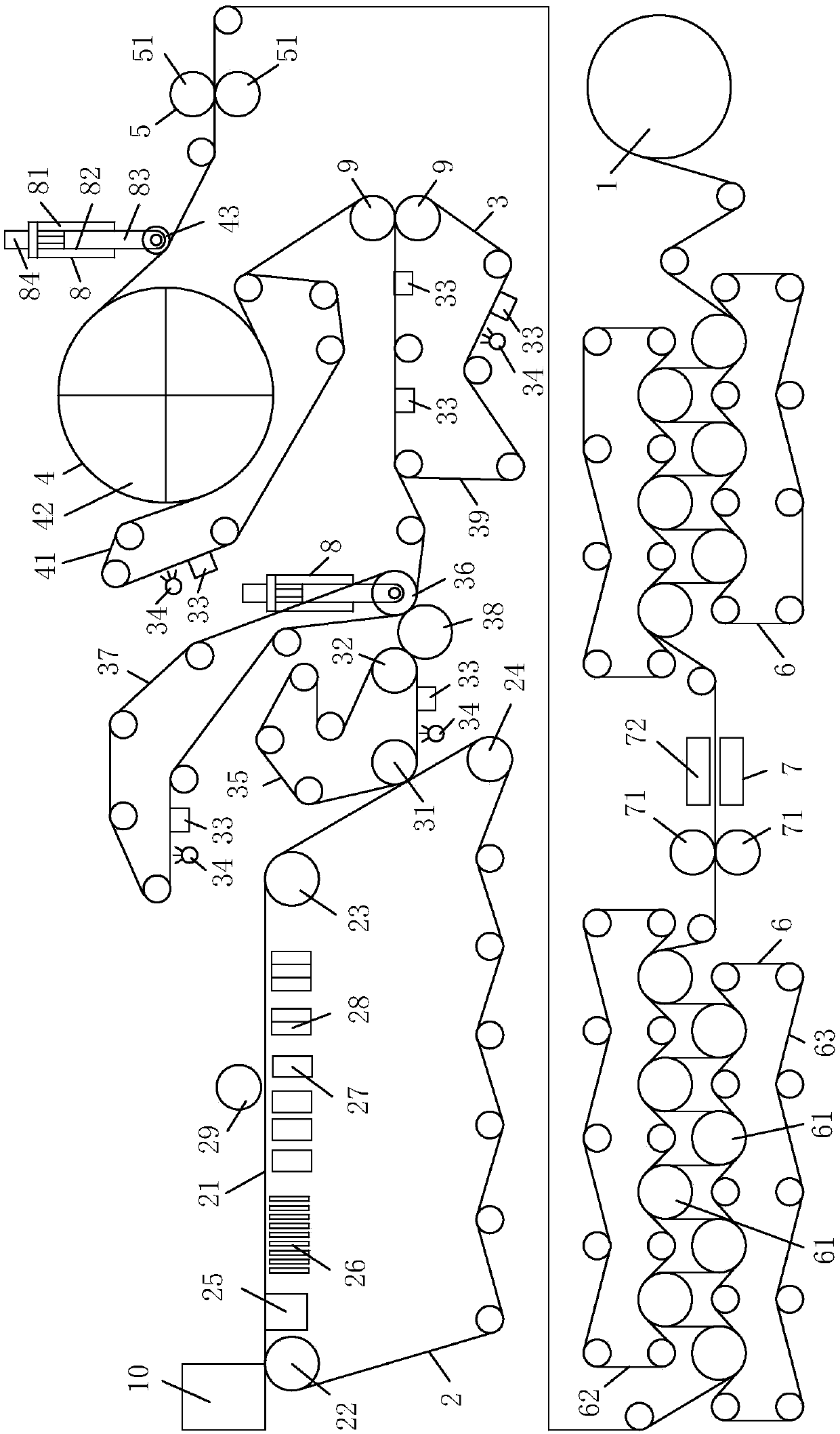

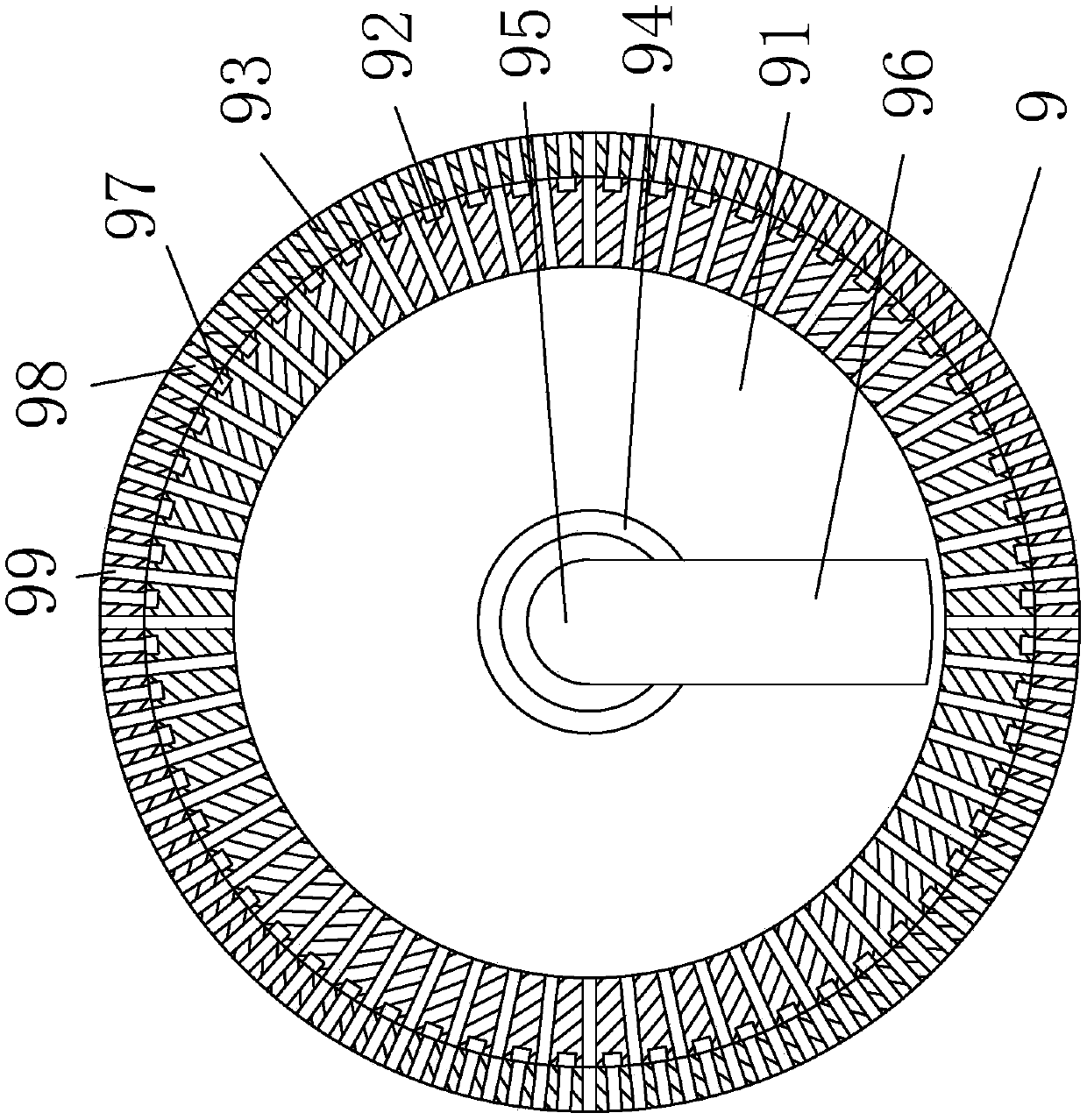

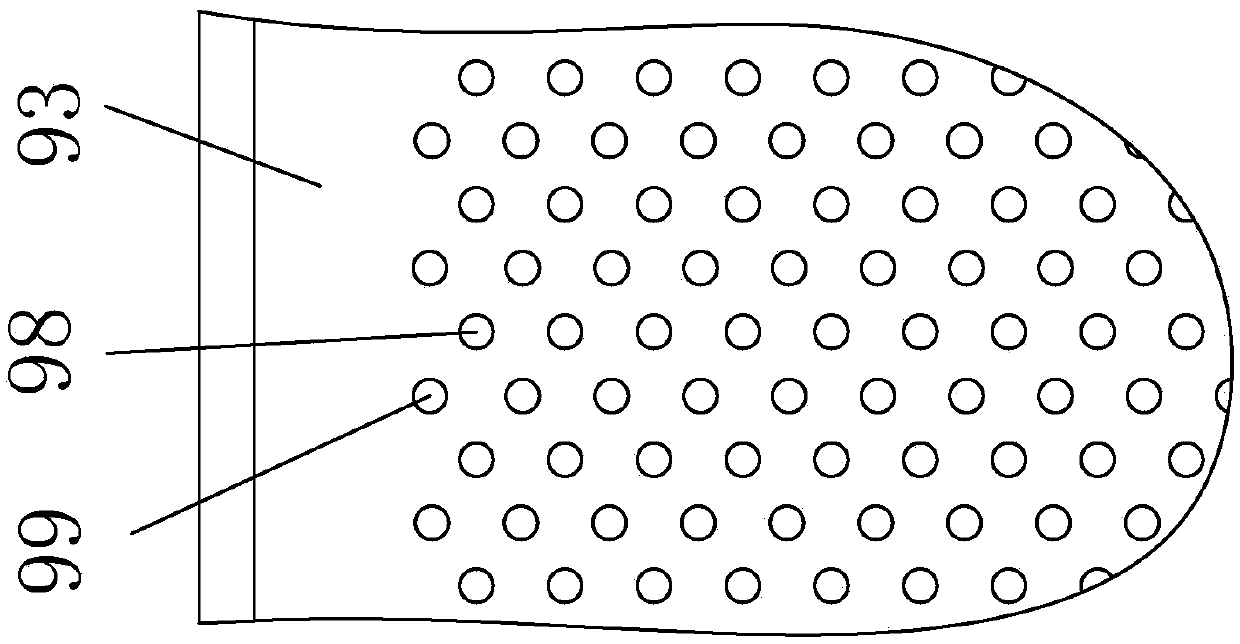

[0021] as attached figure 1 , attached figure 2 , attached image 3 Shown: a digital inkjet thermal transfer printing base paper machine, including: a fourdrinier wire 21, a breast roll 22, a couch roll 23 and a paper-making device 2 located at the lower side of the couch roll 23, and a roll paper cylinder 1 , the press device 3, the front drying device 4 of the large drying cylinder, the surface sizing device 5, the drying device 6 after the two small drying cylinders, which are arranged in turn between the papermaking device 2 and the paper cylinder 1, are located in the two small drying cylinders Coating device 7 between post-drying devices 6 .

[0022] The press device 3 includes: a first paper suction roll 31 positioned at the rear side of the fourdrinier wire 21 and between the couch roll 23 and the wire drive roll 24, a second paper suction roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com