Process for making sugar by using sorgo

A technology for sweet sorghum and sweet sorghum straw, which is applied in the field of sugar production, can solve the problems of high cost, not generally realized production use, strong technicality, etc., and achieves the effects of less filtering mud, good pressing effect and simple clarification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

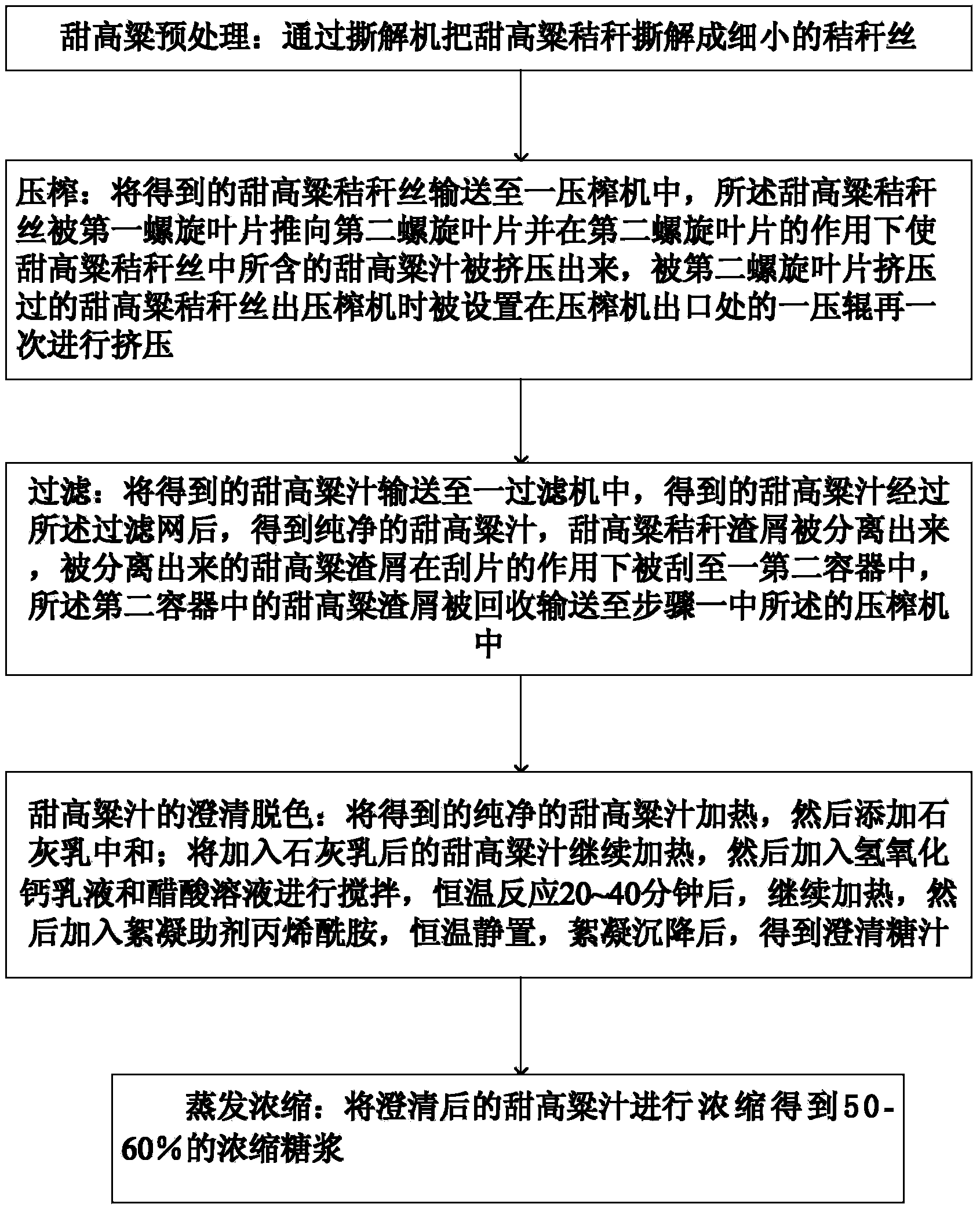

[0020] Such as figure 1 Shown, the present invention provides a kind of sweet sorghum sugar making process, comprises the following steps:

[0021] Step 1. Sweet sorghum pretreatment: the sweet sorghum stalks are torn into fine straw silks by a tearing machine;

[0022] Step 2. Squeezing: The sweet sorghum stalks obtained in step 1 are transported to a press machine, the press machine includes a press chamber, a first screw blade for conveying in the press chamber, and a screw blade rotating with the first screw blade. The second helical blade used for squeezing in the opposite direction, the second helical blade is a variable-diameter equidistant helical blade, the diameter of the helical blade gradually increases, and the space decreases, which will play a role in squeezing. The sorghum stalk is pushed to the second helical blade by the first helical blade, and the sweet sorghum juice contained in the sweet sorghum stalk is squeezed out under the action of the second helica...

Embodiment 2

[0027] Step 1. Sweet sorghum pretreatment: the sweet sorghum stalks are torn into fine straw silks by a tearing machine;

[0028] Step 2. Squeezing: The sweet sorghum stalks obtained in step 1 are transported to a press machine, the press machine includes a press chamber, a first screw blade for conveying in the press chamber, and a screw blade rotating with the first screw blade. The second helical blade used for squeezing in the opposite direction, the second helical blade is a variable-diameter equidistant helical blade, the diameter of the helical blade gradually increases, and the space decreases, which will play a role in squeezing. The sorghum stalk is pushed to the second helical blade by the first helical blade, and the sweet sorghum juice contained in the sweet sorghum stalk is squeezed out under the action of the second helical blade, and the extruded sweet sorghum juice is extracted from the squeezer The outflow from the sieve holes set on the wall of the cavity is...

Embodiment 3

[0033] Step 1. Sweet sorghum pretreatment: the sweet sorghum stalks are torn into fine straw silks by a tearing machine;

[0034] Step 2. Squeezing: The sweet sorghum stalks obtained in step 1 are transported to a press machine, the press machine includes a press chamber, a first screw blade for conveying in the press chamber, and a screw blade rotating with the first screw blade. The second helical blade used for squeezing in the opposite direction, the second helical blade is a variable-diameter equidistant helical blade, the diameter of the helical blade gradually increases, and the space decreases, which will play a role in squeezing. The sorghum stalk is pushed to the second helical blade by the first helical blade, and the sweet sorghum juice contained in the sweet sorghum stalk is squeezed out under the action of the second helical blade, and the extruded sweet sorghum juice is extracted from the squeezer The outflow from the sieve holes set on the wall of the cavity is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com