Filtering material filter sheet with micropore and strainer plate and blotter press

A filter press and filter disc technology, applied in the field of filter press manufacturing, can solve the problems of high equipment manufacturing cost, high extrusion energy consumption, and high equipment pressure requirements, and achieve good pressing effect, cost reduction, The effect of accelerating the pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

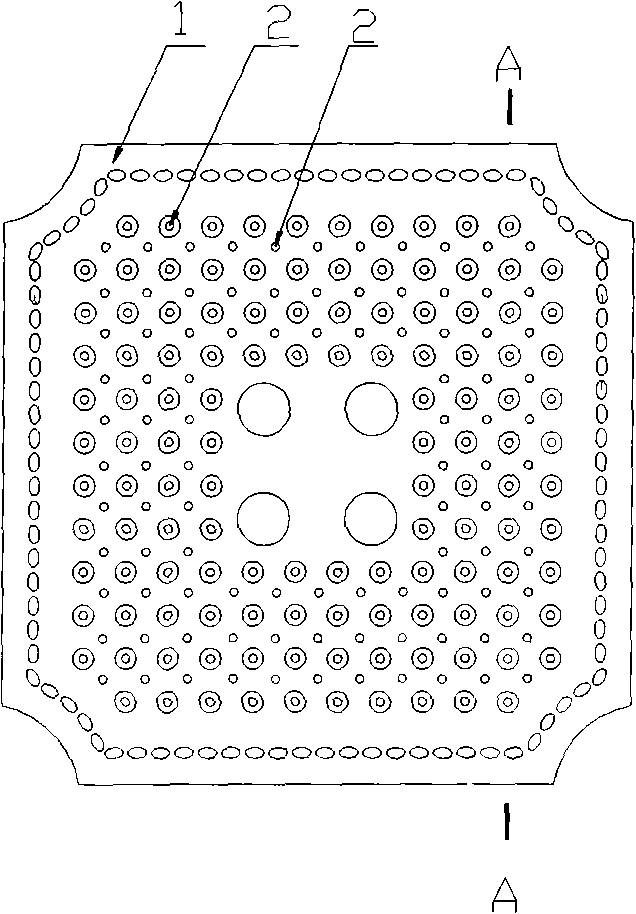

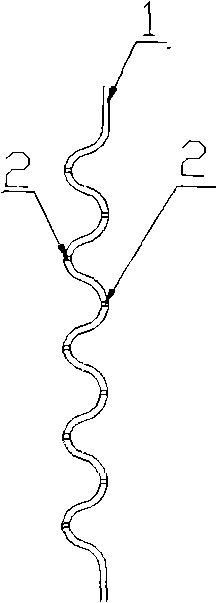

[0013] Embodiment 1: with reference to attached figure 1 and 2 . A filter sheet with micropores, the surface of the filter sheet 1 has a convex-concave structure, and there are diversion holes 2 on the convex points or concave points or convex-concave points, and the filter sheet 1 is stamped and formed by metal and metal molds, or Non-metallic materials and mold molding production.

Embodiment 2

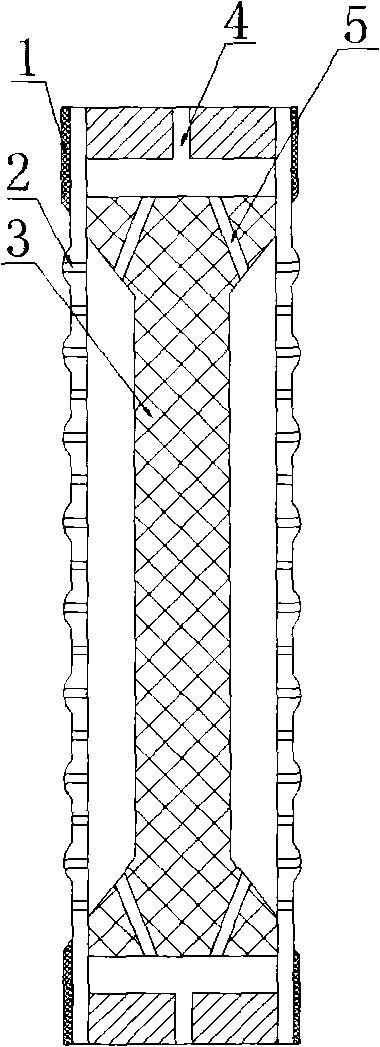

[0014] Embodiment 2: with reference to attached image 3 . On the basis of Example 1, the filter plate made of filter material with micropores includes the filter plate 1 and the plate core 3, and the plate core 3 adopts the prior art compression molding or casting molding. The surface of filter sheet 1 has a structure of convex and concave points, and there are diversion holes 2 on the convex points or concave points or convex and concave points; the end of the plate core 3 is provided with diversion channels 4, and the side of the core plate of the plate core is provided with fluid The channel 5 is connected with the diversion channel 4 and molded by mold. The filter sheet 1 is compounded (located) on the plate core 3 using the existing technology. The filter sheet 1 is made of metal or non-metallic material, and the plate core 3 is made of metal or non-metallic material. Made of metal material.

Embodiment 3

[0015] Embodiment 3: with reference to attached Figure 4 . On the basis of embodiment 2, the filter press constituted by the filter plate with micropores, it comprises frame 12, and frame 12 adopts prior art to make and filter plate extruding frame 7 is placed on the frame, extruding The pressing plate 10 is located in the filter plate extruding frame 7 and is connected with the extruding device 11, the extruding device 11 is a single-sided extruding device or a double-sided extruding device, and the extruding device 11 is located on the guide rail on the frame 12 and along the The guide rail is moved and locked (the frame 12 is provided with a pin hole and matched with the pin device on the oil cylinder to lock or open), the bottom of the filter plate extrusion frame 7 is provided with a liquid receiving tank 9, and the upper part is provided with a cover 6. The filter plate 8 with micropores is located on one side of the extruding surface of the extruding plate 10 in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com