Household oil press

A technology for oil presses and home use, which is applied in the direction of presses, manufacturing tools, etc., which can solve the problems of not being able to meet customer needs, low degree of automation, and low oil yield, and achieve convenience for home use, good pressing effect, and good oil output rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached with the manual figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 , to describe the embodiment of the present invention.

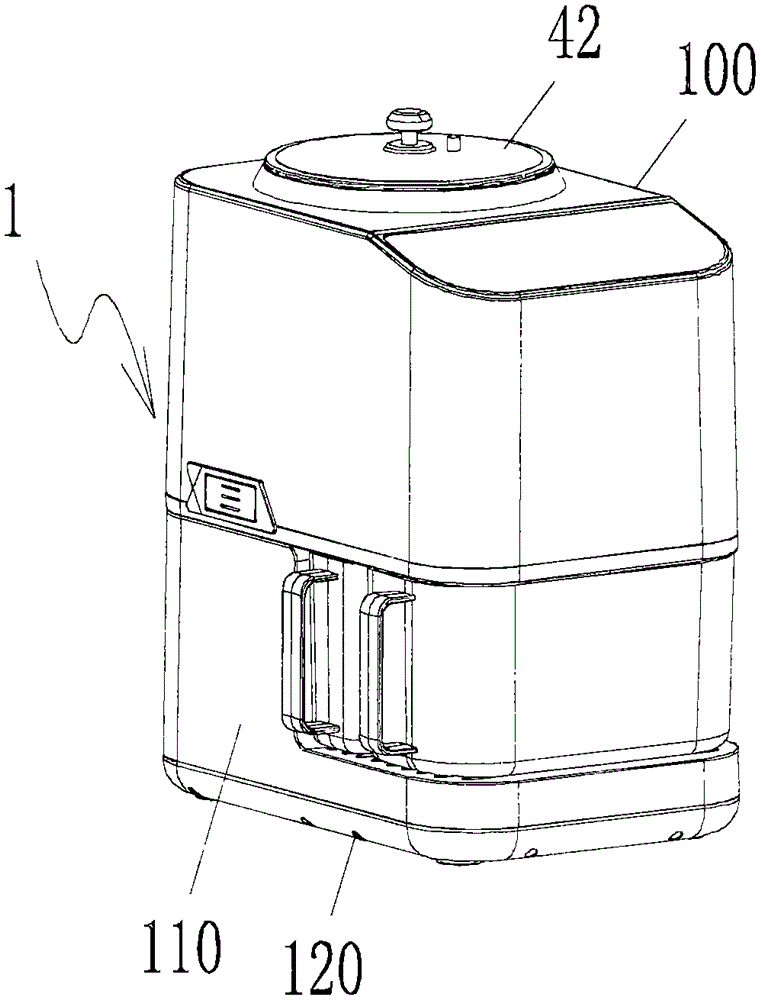

[0035] Such as Figure 1 to Figure 13 As shown, the household oil press includes a body 1 provided with a driving mechanism, a pressing assembly, a distribution assembly, a wok 41, a pot cover 42, a wok heating belt and a stirring mechanism.

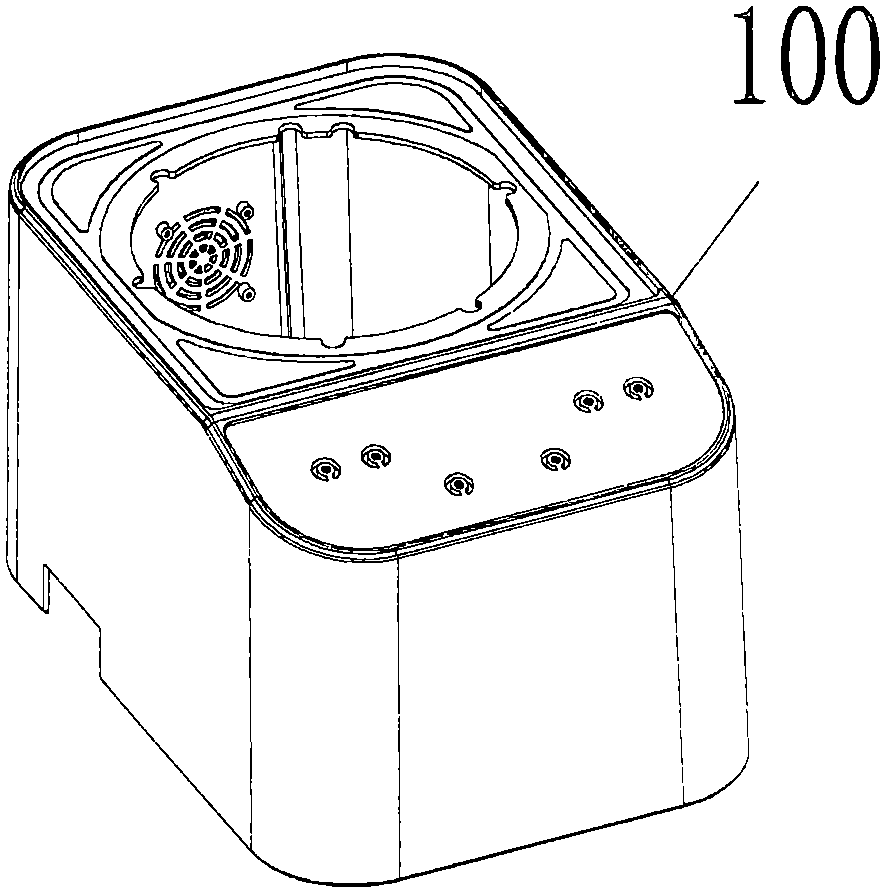

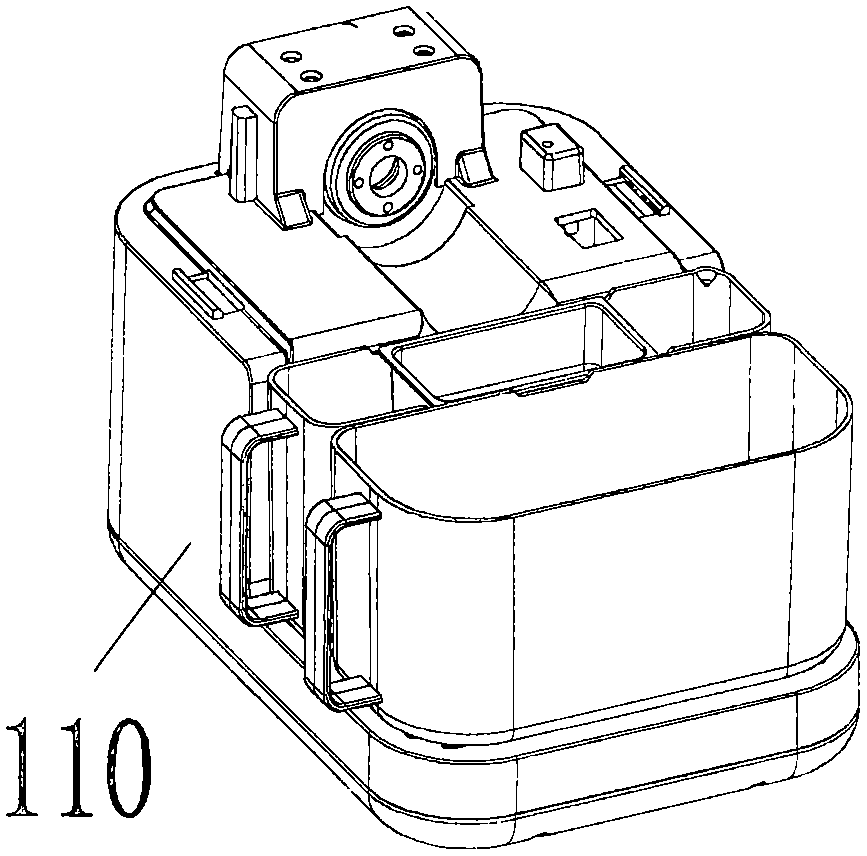

[0036] The casing of the body 1 is formed by buckling an upper casing 100 , a lower casing 110 and a bottom casing 120 sequentially.

[0037] The squeezing assembly includes a squeezing chamber 21, a squeezing rod 22, a squeezing chamber connector 23, a connecting locking pin, and a squeezing rod heating block 26; the squeezing rod 22 is driven by a squeezing motor 24 on the drive mechanism, and there is a Reduction gear gearbox 25 transmissions. The squeeze chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com