Double-kettle turning type supercritical fluid extraction device

A technology of supercritical fluid and extraction device, which is applied in the field of extraction kettles to achieve the effects of large extraction capacity, improved extraction efficiency, and prevention of ultra-thick filter cake layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the drawings and examples, but the present invention is not limited to the following embodiments.

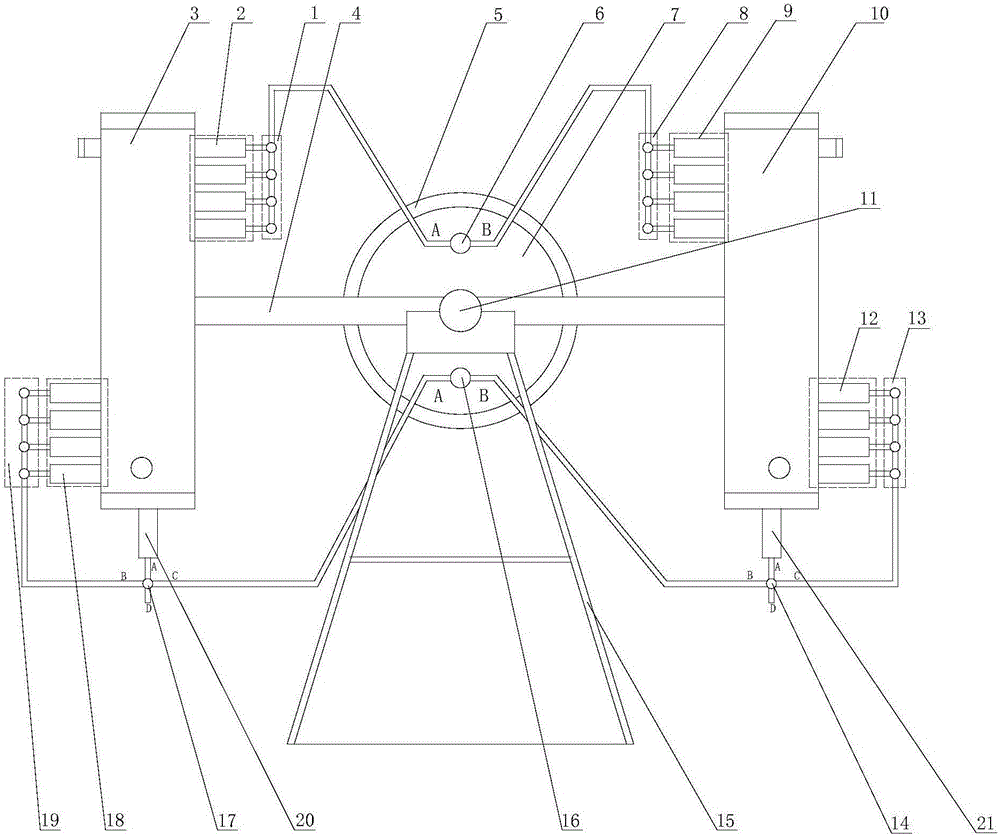

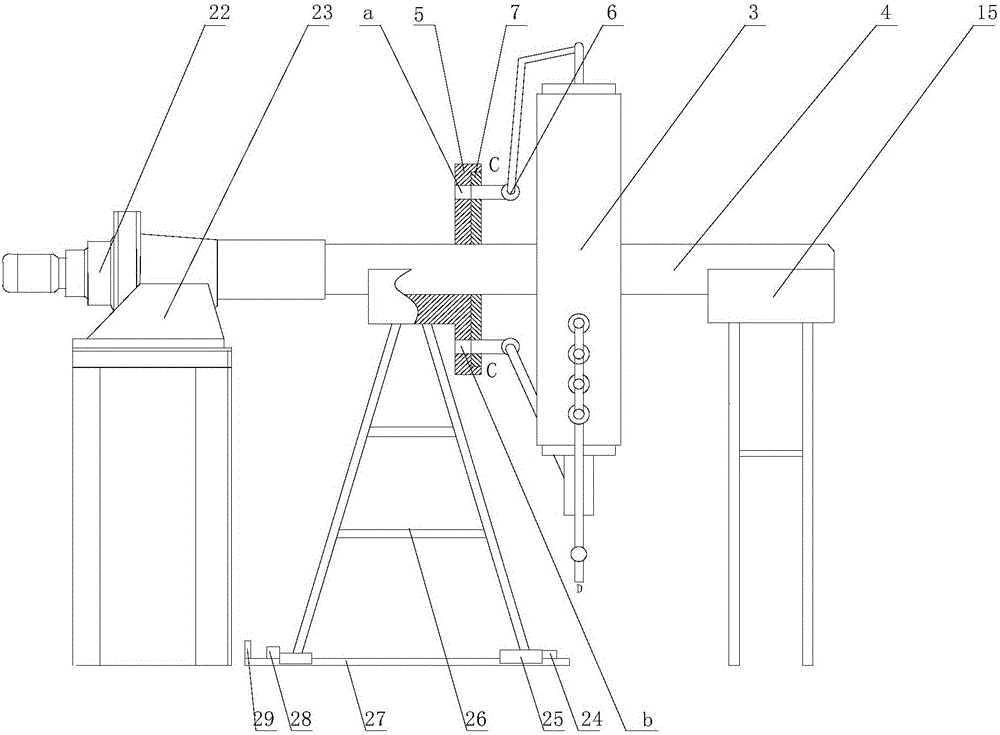

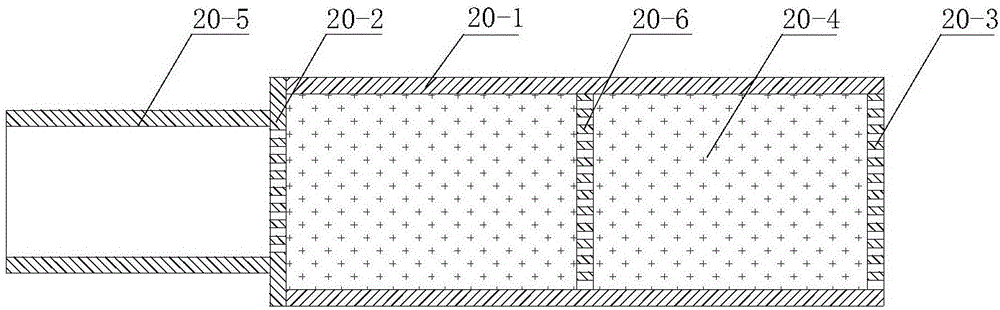

[0024] exist figure 1 , 2 Among them, the double-pot overturning supercritical fluid extraction device in this embodiment consists of the first three-way valve group 1, the first filter tube assembly 2, the left extraction kettle 3, the extraction kettle pole 4, the fixed plate 5, the fifth and third Through valve 6, rotating disc 7, third three-way valve group 8, fourth filter tube assembly 9, right extraction kettle 10, transmission shaft 11, fifth filter tube assembly 12, fourth three-way valve group 13, The second four-way valve 14, the third support 15, the sixth three-way valve 16, the first four-way valve 17, the second filter tube assembly 18, the second three-way valve group 19, the third filter tube 20, the first Six resistance tubes 21, motor 22, first support 23, front baffle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com