Processing method of Piteguo juice

A processing method and technology of beet fruit, applied in the field of processing of beet fruit juice, can solve the problems of finished product flavor, poor taste, long after-ripening time, low juice extraction rate, etc., achieve pure taste and smell, enhance The effect of clarifying and improving the juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

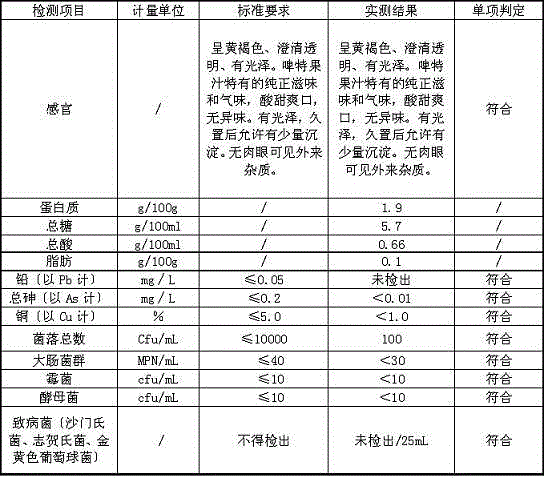

Image

Examples

Embodiment 1

[0019] Example 1 The processing method of beer special fruit juice, comprises the following steps:

[0020] ⑴Raw material selection: Picked fresh beer fruit is matured for 15 days under natural conditions, and the beer fruit with no decay, dark brown color and soft tissue structure is selected as raw material.

[0021] ⑵Wash the Beiteguo fruit twice with clean water, and crush it with a cyclone fruit crusher to obtain particles smaller than 0.3×0.3×0.3cm.

[0022] (3) Put the crushed granules into an enzymatic hydrolysis tank, add 0.35 g / L compound enzyme, and enzymolyze at 45°C for 75 minutes, and adjust the pH value to 40.~4.5 with food-grade acid and alkali, and then Squeeze under a pressure of 20MPa to obtain pomace and juice.

[0023] Wherein: the composite enzyme refers to the mixture of pectinase and cellulase in a weight ratio of 2g:1g.

[0024] ⑷Add pectinase to the juice according to 0.2% of its mass, and the enzymolysis time is 90min under the condition of enz...

Embodiment 2

[0025] Example 2 The processing method of beer special fruit juice, comprises the following steps:

[0026] ⑴Raw material selection: Picked fresh beer fruit is matured for 15 days under natural conditions, and the beer fruit with no decay, dark brown color and soft tissue structure is selected as raw material.

[0027] ⑵Wash the Beiteguo fruit twice with clean water, and crush it with a cyclone fruit crusher to obtain particles smaller than 0.3×0.3×0.3cm.

[0028] (3) Put the crushed granules into an enzymatic hydrolysis tank, add 0.50 g / L compound enzyme, and enzymolyze it for 45 minutes at a temperature of 55°C, and adjust its pH value to 40.~4.5 with food-grade acid and alkali, and then Squeeze under the pressure of 40MPa to obtain pomace and juice.

[0029] Wherein: the composite enzyme refers to the mixture of pectinase and cellulase in a weight ratio of 4g:1g.

[0030] ⑷Add pectinase to the juice according to 0.4% of its mass, and the enzymolysis time is 60min und...

Embodiment 3

[0031] Example 3 The processing method of beer special fruit juice, comprises the following steps:

[0032] ⑴Raw material selection: Picked fresh beer fruit is matured for 15 days under natural conditions, and the beer fruit with no decay, dark brown color and soft tissue structure is selected as raw material.

[0033] ⑵Wash the Beiteguo fruit twice with clean water, and crush it with a cyclone fruit crusher to obtain particles smaller than 0.3×0.3×0.3cm.

[0034] (3) Put the crushed granules into an enzymatic hydrolysis tank, add 0.40 g / L compound enzyme, and enzymolyze them for 60 minutes at a temperature of 50°C, and adjust the pH value to 40.~4.5 with food-grade acid and alkali, and then Squeeze under the pressure of 30MPa to obtain pomace and juice.

[0035] Wherein: the composite enzyme refers to the mixture of pectinase and cellulase in a weight ratio of 3g:1g.

[0036] ⑷Add pectinase to the juice according to 0.3% of its mass, and the enzymolysis time is 75min u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com