Rotary drum type solid-liquid separator

A solid-liquid separator and drum-type technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of inability to form variable volume, cannot satisfy high-pressure deep dehydration, etc., and achieve improved pressing effect and movement resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one, be used for the sludge dewatering of piling construction site:

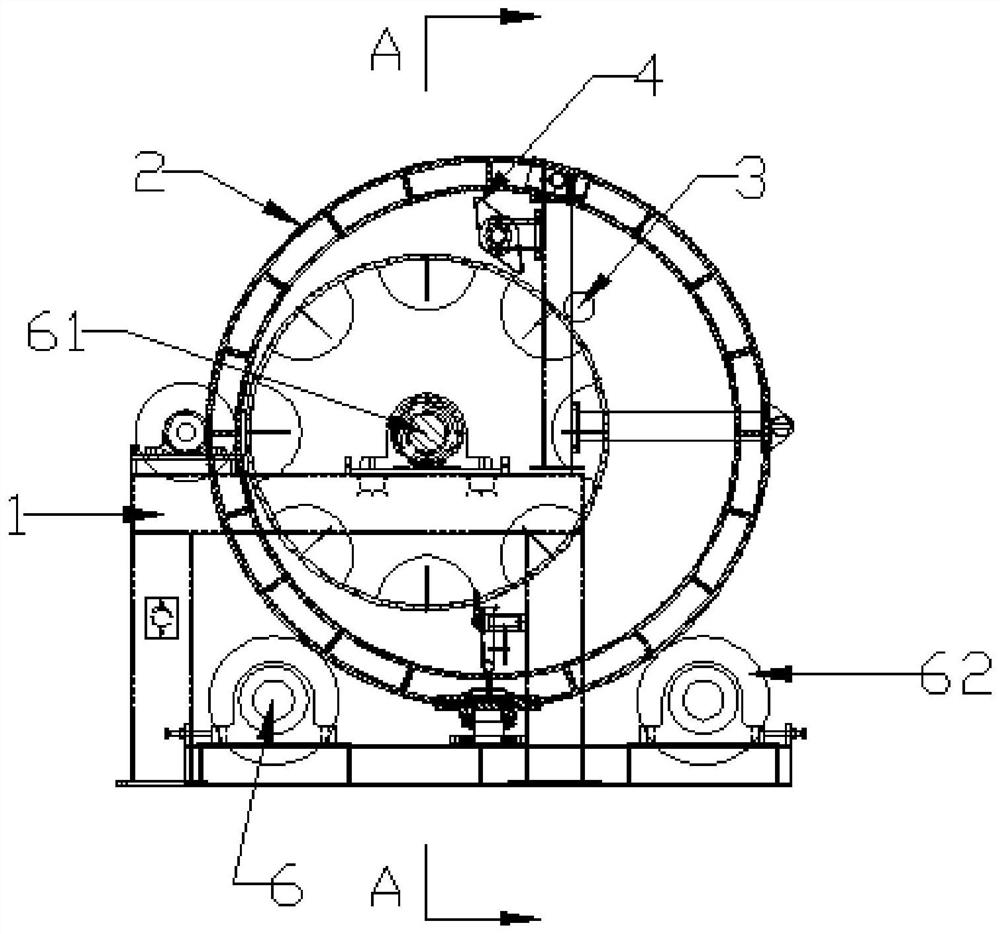

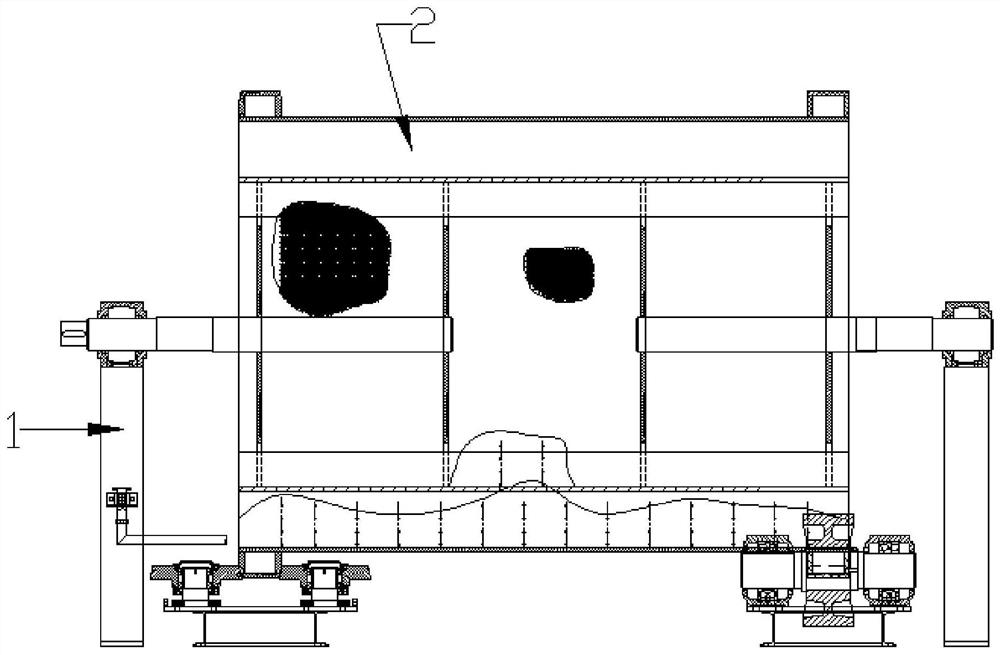

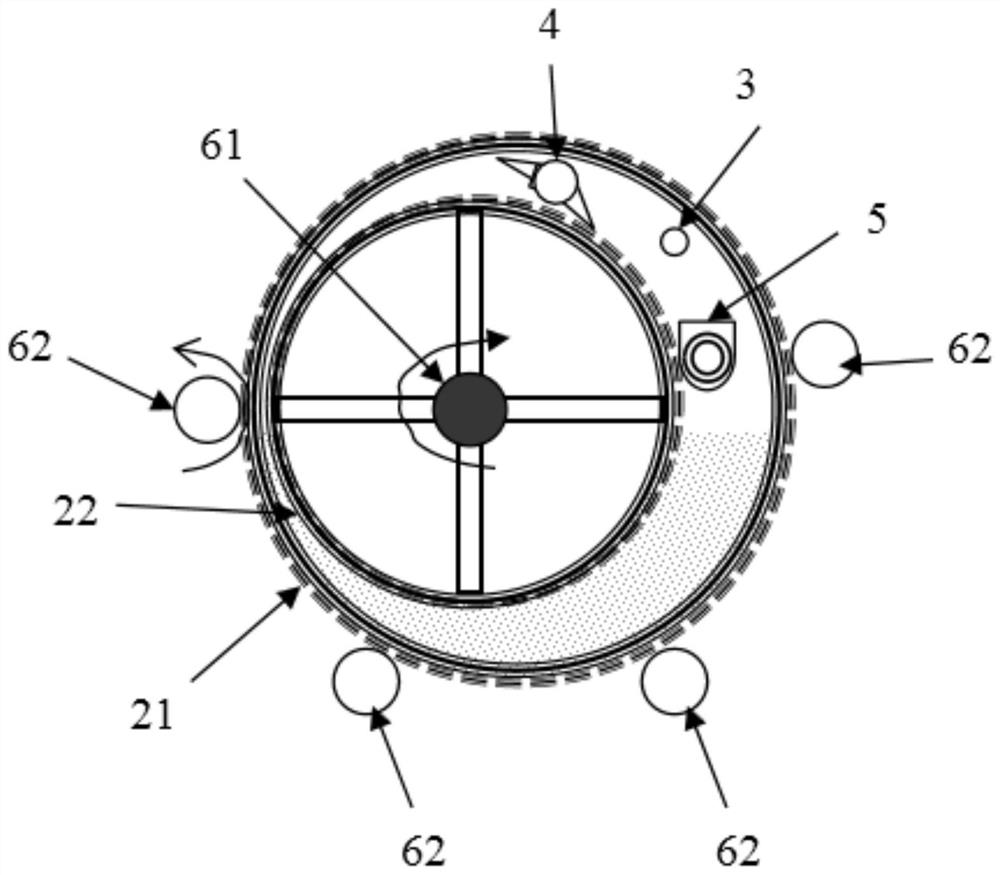

[0026] refer to image 3 , Figure 4 , a drum type solid-liquid separator of the present invention includes a frame 1, a drum group 2, a feeding mechanism 3, a discharging mechanism 4, a discharging mechanism 5 and a driving mechanism 6, and the drum group 2 includes a diameter The inner drum 22 and the outer drum 21 are different and set in order from the inside to the outside. Both the inner drum 22 and the outer drum 21 can permeate the liquid. The inner drum 22 and the outer drum 21 can be rotatably fixed on the machine respectively. On the frame 1 and rotate around different centers of circles to form a gradually shrinking horn-shaped channel to form a dehydration zone with gradually increasing pressure. A feeding mechanism 3, a discharging mechanism 4 and a discharging mechanism 5 are arranged in the horn-shaped channel.

[0027] Outer drum 21 adopts 25MM thick A3 steel plate of D25...

Embodiment 2

[0033] Embodiment two, be used for river sludge dewatering:

[0034] refer to Figure 5 , Figure 6 , a drum type solid-liquid separator of the present invention includes a frame 1, a drum group 2, a feeding mechanism 3, a discharging mechanism 4, a discharging mechanism 5 and a driving mechanism 6, and the drum group 2 includes a diameter The inner drum 22, the middle drum 23 and the outer drum 21 are set differently from the inside to the outside in order. The inner drum 22 and the outer drum 21 are both for liquid diafiltration, and the middle drum 23 is not for liquid diafiltration. The inner drum 22. The intermediate drum 23 and the outer drum 21 are respectively rotatably fixed on the frame 1 and rotate around different centers of circles. A gradually shrinking horn-shaped channel is formed between adjacent drums to form a dehydration zone with a gradually increasing pressure. A number of feeding mechanisms 3 , discharging mechanisms 4 and discharging mechanisms 5 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com