Sugarcane crushing and squeezing device used for agriculture

A sugarcane and agricultural technology, applied in the field of agricultural sugarcane crushing and juicing devices, can solve the problems that the leaks are easily blocked by bagasse, unfavorable waste residue, and excretion, and achieve the effect of convenient pressing and discharge of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

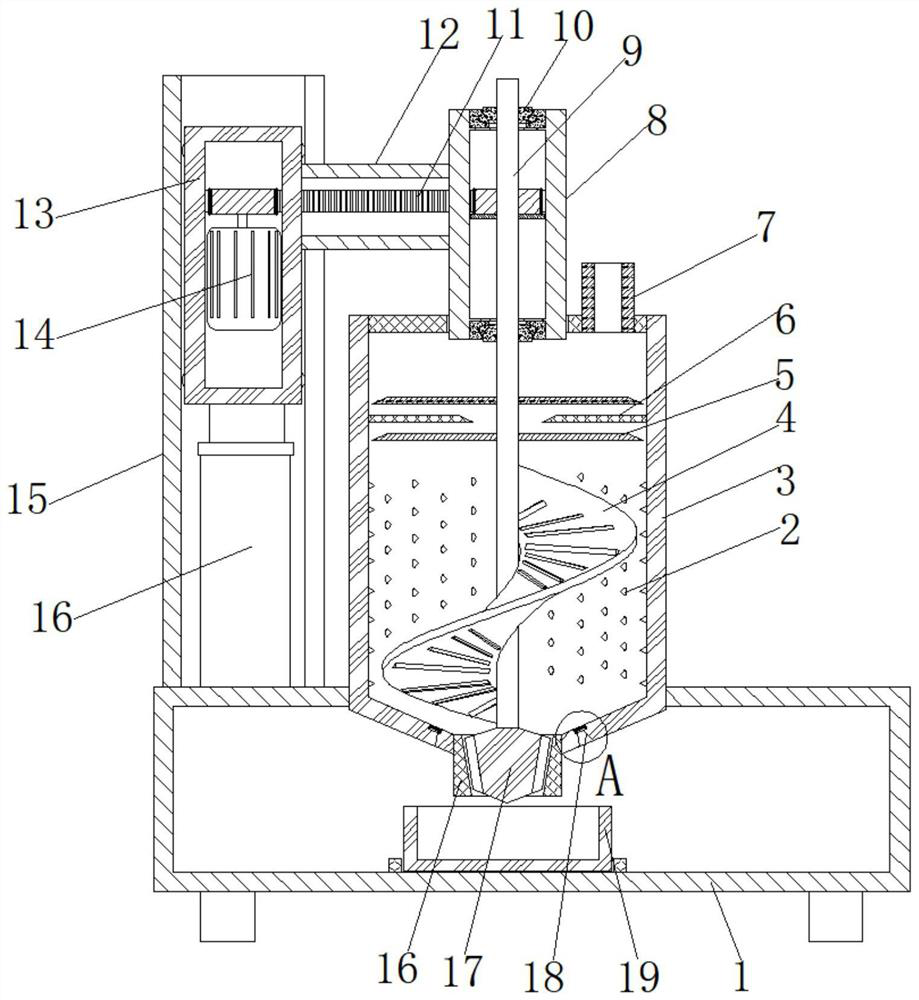

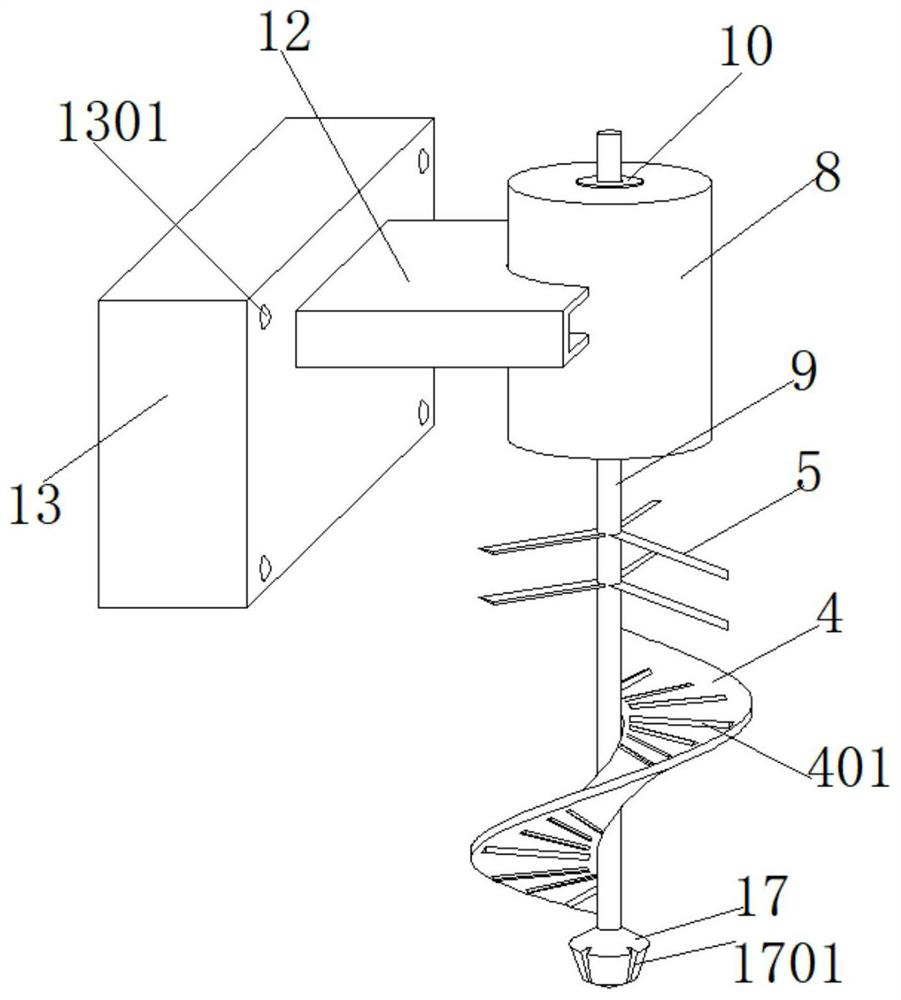

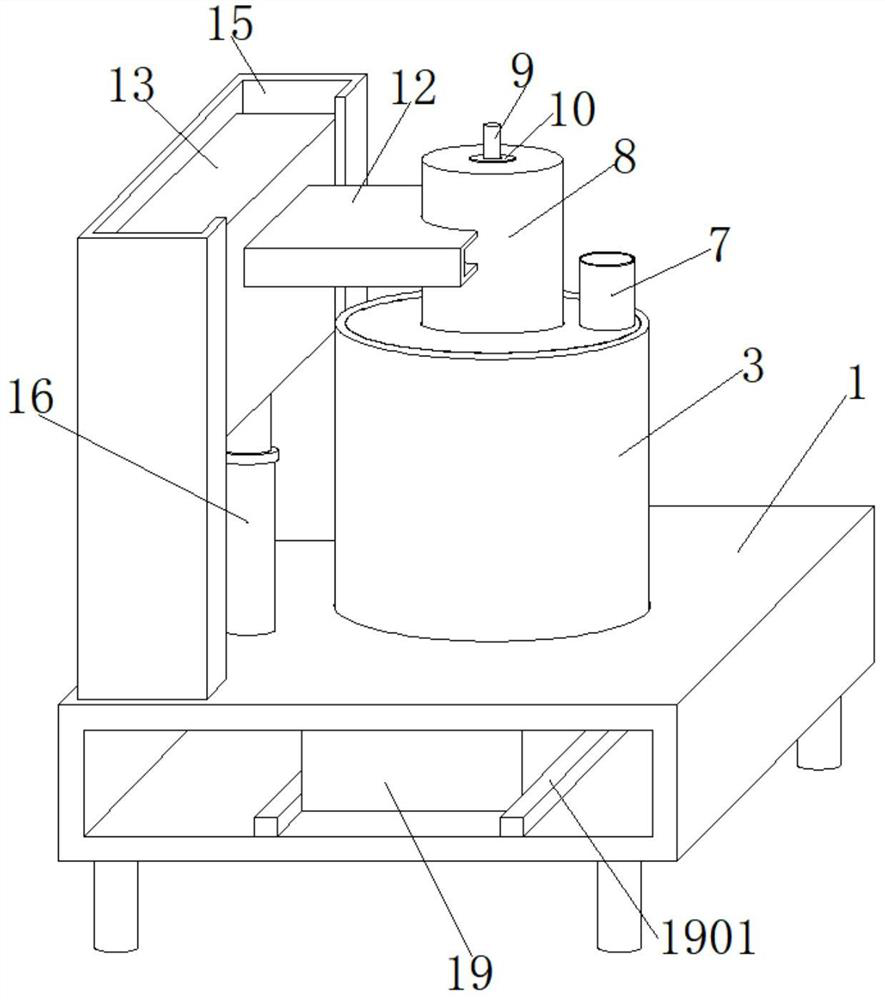

[0029] refer to Figure 1-5 , an agricultural sugarcane crushing and juicing device, comprising a forehead base 1 in a flat square tube structure, a round hole is opened in the middle of the upper surface of the base 1, and a juicer barrel 3 is clamped in the round hole, and the juicer barrel The barrel bottom of 3 has a tapered structure, and the upper surface of the base 1 near the edge is fixed with a C-shaped steel column 15 with an opening facing the middle, and a sliding box 13 is slidably connected in the chute of the C-shaped steel column 15, and the sliding box 13 is far away from the bottom of the groove One side of the support tube 12 is fixed with bolts, and the end of the support tube 12 away from the sliding box 13 is clamped with a bearing fixing barrel 8, and the upper and lower ends of the bearing fixing barrel 8 are respectively clamped with mutually symmetrical tapered roller bearings 10 , and a transmission rod 9 is rotatably connected between the two taper...

Embodiment 2

[0039] refer to figure 1 and Figure 5 , an agricultural sugarcane crushing and juicing device. Compared with Embodiment 1, this embodiment also includes that the bottom of the juice barrel 3 is provided with sinking tanks that are equidistantly distributed near the conical bottom, and the bottom of the sinking tank is Metal mesh rings 1801 are snapped together, and there is a leakage hole 18 at the bottom of the sinker, and the diameter of the leakage hole 18 near the top is smaller than that near the bottom.

[0040] If the squeezed liquid is discharged too slowly during use, it can be discharged from the leakage hole 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com