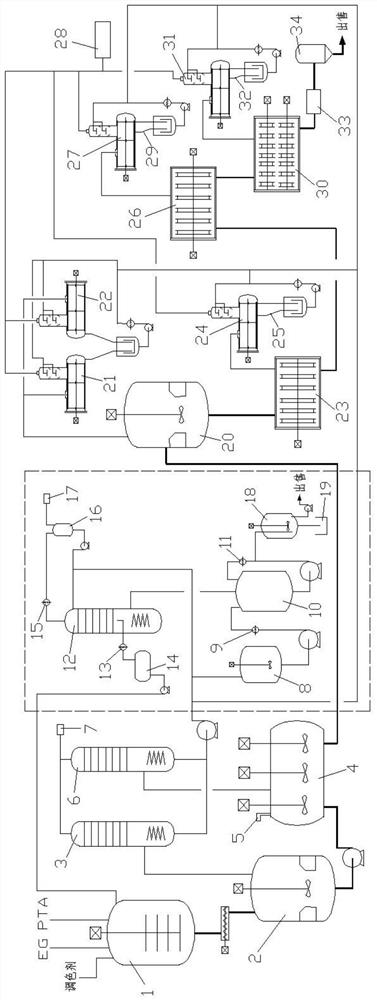

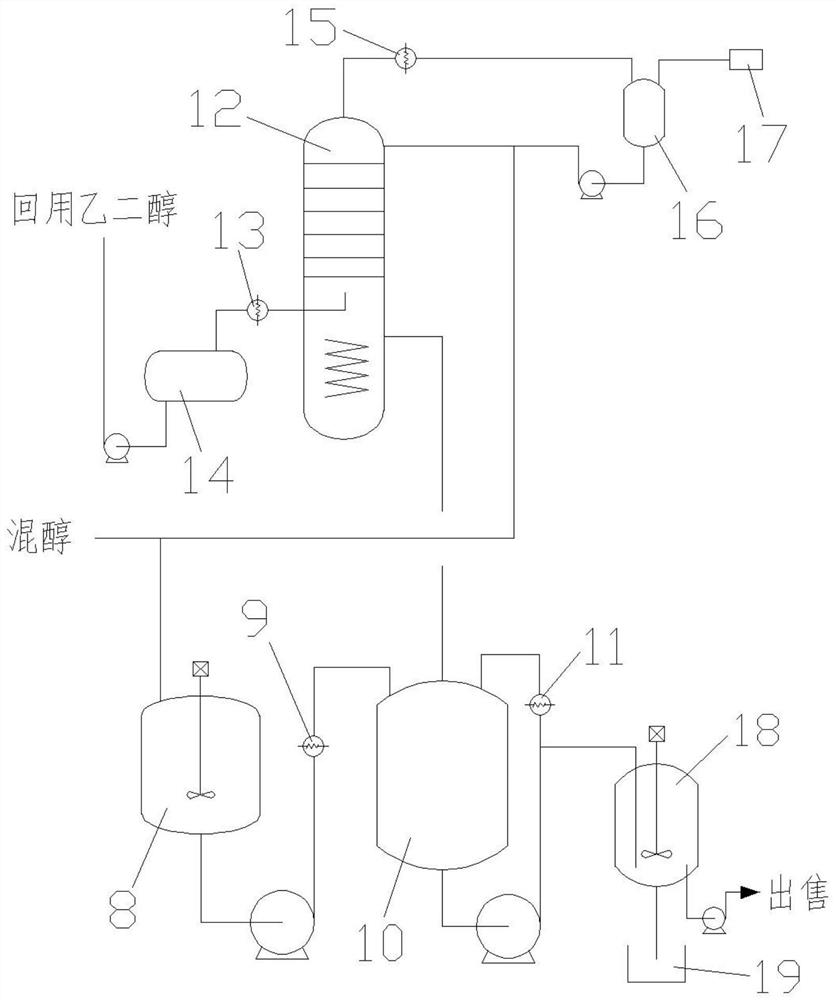

High-viscosity copolyester production system and method with mixed alcohol separation and recovery functions

A separation recovery and production system technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high reaction temperature, achieve high removal efficiency, flexible adjustment, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]On the high-viscosity copolyester continuous production line, put PTA / EG in a molar ratio of 1:1.1 and a certain proportion of toner into the slurry preparation tank 1. After the slurry is mixed, the material is sent to the first esterification In kettle 2, under the conditions of reaction temperature 249°C and pressure 60Kpa (A), the esterification rate is controlled to be higher than 90%. The esterified product is sent to the second esterification kettle 4, and the third monomer isophthalic acid (IPA) enters the second monomer through the material addition system 5 at 23.6% mol (amount relative to PTA) and a certain proportion of catalyst and heat stabilizer. In the esterification kettle 4, the esterification reaction is further carried out under slight positive pressure, a slightly higher temperature than the first esterification kettle, and stirring. After the esterification rate reaches 97%, it enters the first precondensation kettle 20. At a reaction temperature of ...

Embodiment 2

[0065] On the high-viscosity copolyester continuous production line, put PTA / EG in a molar ratio of 1:1.1 and a certain proportion of toner into the slurry preparation tank 1. After the slurry is mixed, the material is sent to the first esterification In kettle 2, under the conditions of reaction temperature 255°C and pressure 68Kpa (A), the esterification rate reaches 90%. The esterified product is sent to the second esterification kettle 4, and the third monomer 1,4-cyclohexanedimethanol (CHDM) is added at 3.31% mol (amount relative to PTA) and a certain proportion of catalyst and heat stabilizer through the material System 5 enters the second esterification tank 4, and undergoes further esterification reaction under slightly positive pressure, a slightly higher temperature than the first esterification tank and stirring, and the esterification rate reaches 98%. The esterified product enters the first pre-condensation tank 20, and the polycondensation reaction occurs at a re...

Embodiment 3

[0067] On the high-viscosity copolyester continuous production line, put PTA / EG in a molar ratio of 1:1.1 and a certain proportion of toner into the slurry preparation tank 1. After the slurry is mixed, the material is sent to the first esterification In kettle 2, under the conditions of reaction temperature 254°C and pressure 85Kpa (A), the esterification rate reaches 90%. The esterified product is sent to the second esterification tank 4, and the third monomer 2,2,4,4-tetramethyl-1,3-cyclobutanediol (CBDO) is 5.87% mol (amount relative to PTA) and A certain proportion of catalysts and heat stabilizers enter the second esterification kettle 4 through the material addition system 5, and undergo further esterification reaction under slightly positive pressure, a slightly higher temperature than the first esterification kettle and stirring, and the esterification rate reaches 97%. . The esterified product enters the first pre-condensation tank 20, and polycondensation reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com