Method for delaying quality deterioration in raw sugar storage process

A technology for sugar storage and raw sugar, which is applied in the field of delaying the quality deterioration in the process of raw sugar storage, can solve problems such as the decline of raw sugar quality, the increase of color value, the decrease of sugar content, etc., so as to delay the rise and delay of the conversion rate of raw sugar. The increase of color value, the effect of improving the quality of raw sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 2Kg of raw sugar with a pH of 6.0 and place it in a stirring tank, add 0.4g of calcium oxide solid in the stirring tank, stir evenly, take part of the raw sugar to measure its raw sugar pH value, the result is 8.0, its water content 0.3% by weight.

[0042] The raw sugar and the raw sugar added with calcium oxide were stored in a constant temperature and humidity box (40°C, 70% RH), and the raw sugar quality (raw sugar color value, raw sugar conversion rate), the measurement results of raw sugar and the quality change of raw sugar mixed with calcium oxide storage are shown in Table 1.

[0043] Table 1

[0044] storage time / week

[0045] From the results shown in Table 1, it can be seen that the quality of raw sugar and calcium oxide-raw sugar has changed during the storage period. After 6 weeks, the color value of raw sugar increased by 29%, and the color value of calcium oxide-raw sugar only increased by 6%. , the color value increased by 23% after addi...

Embodiment 2

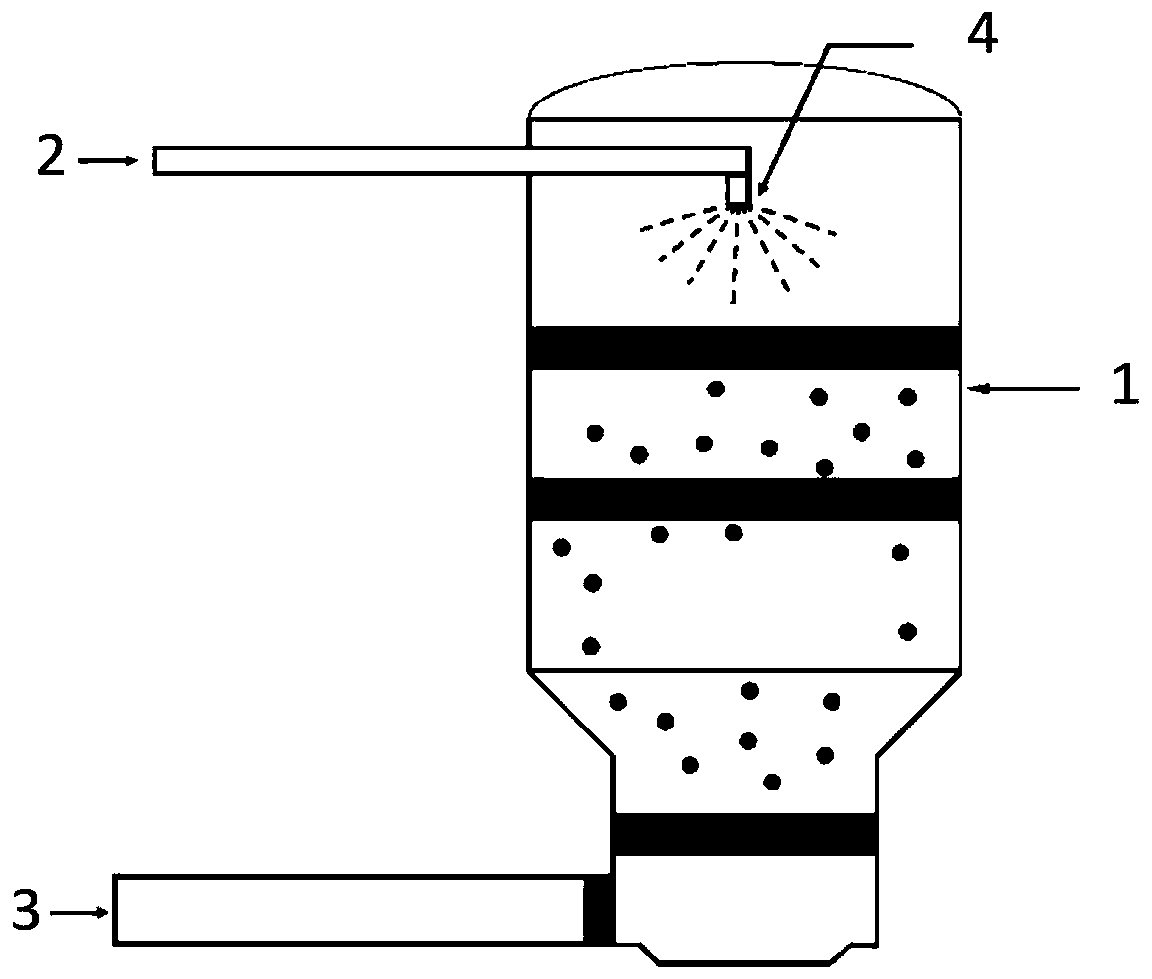

[0047] Such as figure 1 As shown, the raw sugar that takes the pH of 2Kg to be 6.0 is placed in the drying cavity of fluidized bed 1, and calcium hydroxide aqueous solution is passed in the fluidized bed cavity by liquid feed pipe 2, and its concentration is 0.14% by weight, usually The input volume is 400mL, the flow rate is 2.0mL / min, the air pressure in the feed pipe 1 is 2bar, the peristaltic pump sprays the calcium hydroxide aqueous solution on the raw sugar through the nozzle 4, and the fluidized bed cavity system is in a closed state during spraying state. The working parameters of the fluidized bed are as follows: the air flotation air pressure of the air feed pipe 3 passed through the gas feed pipe 3 is 4bar, and the flow rate of the air fed into it is 80m 3 / h, the temperature in the fluidized bed cavity is 45°C, and the raw sugar material is kept tumbling continuously in the fluidized bed glass drying cavity. After the calcium hydroxide aqueous solution is fed, cl...

Embodiment 3

[0052] The raw sugar on the line is transported to the drum drying stage through a conveyor belt at a flow rate of 30t / h, and a peristaltic pump is used to spray an aqueous solution of calcium hydroxide (0.16% by weight) on the raw sugar through a feed nozzle. The working parameters of the drum drying are as follows: the drum drying temperature is 40°C, the drum drying time is 10 min, the flow rate of the calcium hydroxide aqueous solution is 1.8 mL / min, the feed air pressure is 3 bar, and the raw sugar material is continuously tumbling in the drying chamber. The mass ratio of the volume of calcium hydroxide aqueous solution pumped into the drum dryer to the raw sugar is 5:1. After the calcium hydroxide aqueous solution was fed, the feed pump and the feed air valve were closed, and the pH value of the dried raw sugar was measured to be 7.5, and the water content thereof was 0.4% by weight.

[0053] The raw sugar and the raw sugar sprayed with calcium hydroxide aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com