Gasoline deposited carbon remover, and preparation method and use method thereof

A cleaning agent and carbon deposition technology, applied in the direction of chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of cleaning parts damage, human hazards, etc., and achieve low cost, good effect, and low toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

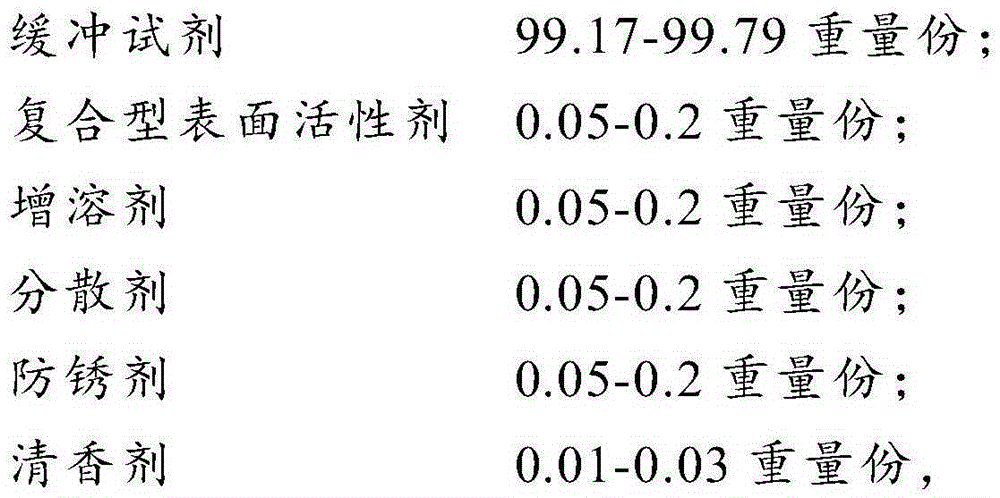

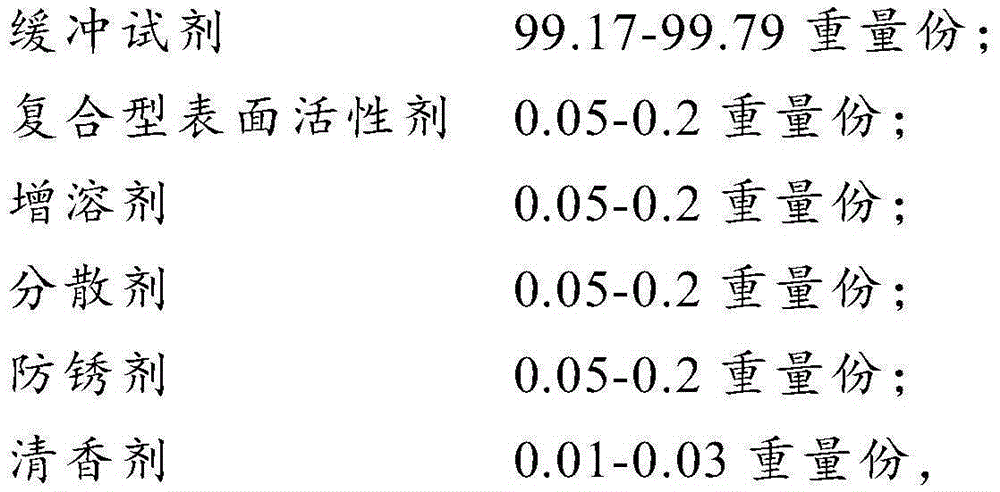

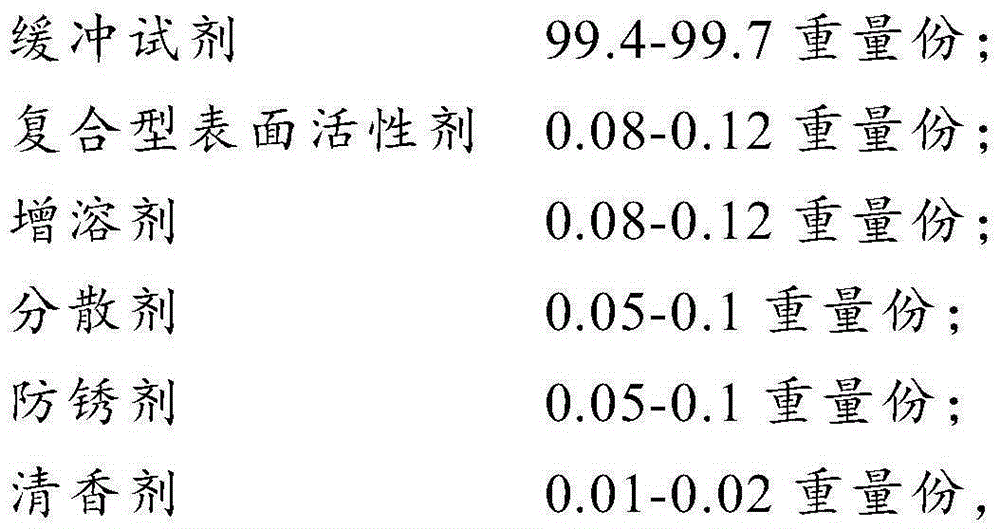

[0033] Correspondingly, the present invention also provides a preparation method of the gasoline carbon deposit cleaning agent described in the above technical scheme, comprising the following steps: mixing buffer reagent, complex surfactant, solubilizer, part dispersant, rust inhibitor and fragrance The agent is mixed, and after stirring, the gasoline carbon deposit cleaning agent is obtained, and the buffer agent is sodium carbonate and sodium bicarbonate.

[0034] Because the nonionic surfactant fatty alcohol polyoxyethylene ether (AEO) that the present invention preferably adopts, dispersant triethanolamine and fresh fragrance agent linalool are organic reagents, are liquid, therefore, the present invention preferably adopts following preparation method: Sodium carbonate, sodium bicarbonate, anionic surfactant sodium alkylbenzene sulfonate, solubilizer sodium tripolyphosphate and antirust agent potassium permanganate are fully stirred and mixed in a solid particle mixer to ...

Embodiment 1

[0055] The preparation of gasoline carbon deposit cleaning agent of the present invention: calculate with mass ratio, sodium carbonate 23.94kg, sodium bicarbonate 75.74kg, anionic surfactant sodium alkylbenzene sulfonate 0.071kg, solubilizer sodium tripolyphosphate 0.1kg, The antirust agent potassium permanganate is 0.05 kg, fully stirred and mixed in a solid particle mixer to obtain mixed particles;

[0056] In the process of full stirring, mix 0.029kg of non-ionic surfactant fatty alcohol polyoxyethylene ether (AEO), 0.05kg of dispersant triethanolamine and 0.02kg of fragrance agent linalool, and use a sprayer to evenly spray on the solid particles , making it adhere to the surface of the mixed particles to obtain a gasoline carbon deposit cleaner.

[0057] Preparation of gasoline carbon deposit cleaner solution: dissolve the above gasoline carbon deposit cleaner in ultrapure water according to the concentration ratio of 88.72g / L, and use a solid-liquid stirrer to fully stir...

Embodiment 2-3

[0062] Adopt the preparation method and use method of Example 1, change the temperature and detergent concentration in the cleaning process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com