Preparation method for high-density nickel hydroxide doped precursor

A technology of nickel-cobalt hydroxide and nickel hydroxide, which is applied in the fields of chemical instruments and methods, nickel compounds, inorganic chemistry, etc. It can solve the problems of uniform mixing of Ni-Co-Al, unsuitable feeding speed, low production efficiency, etc. problems, to achieve the effect of inhibiting individual crystallization, easy control, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

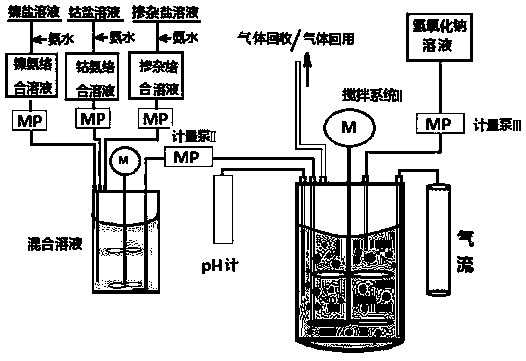

[0032] A method for preparing a high-density doped nickel cobalt hydroxide precursor, specifically comprising the following steps:

[0033] (1) Prepare nickel nitrate, cobalt sulfate, aluminum chloride solutions, Ni in nickel nitrate solution 2+ The concentration is 1mol / L, Co in cobalt sulfate solution 2+ The concentration is 1mol / L, Al in the aluminum chloride solution 3+ The concentration of the ammonia water is 0.1mol / L, and the ammonia water with a concentration of 2mol / L is added under the condition of stirring, and the ammonia water is in accordance with the molar ratio of ammonia to metal ions NH 3 : Metal ion=8:1 ratio is added, respectively form stable and homogeneous complex solution, i.e. nickel-ammonia complex solution, cobalt-ammonia complex solution, aluminum ammonia complex solution;

[0034] (2) According to Ni 0.98 co 0.01 al 0.01 (OH) 2 stoichiometric ratio, the step (1) obtained three kinds of complex solution according to the ratio of Ni:Co:Al=0.98:0...

Embodiment 2

[0039] A method for preparing a high-density doped nickel cobalt hydroxide precursor, specifically comprising the following steps:

[0040] (1) Prepare nickel sulfate, cobalt chloride, aluminum nitrate salt solution, Ni in nickel sulfate solution 2+ Concentration of 2mol / L, Co in cobalt chloride solution 2+ The concentration is 2mol / L, Al in aluminum nitrate solution 3+ The concentration of the ammonia water is 1mol / L, and the ammonia water with a concentration of 5mol / L is added under the condition of stirring, and the ammonia water is in accordance with the molar ratio of ammonia to metal ions NH 3 : metal ions=12:1 ratio is added to form a stable and uniform complex solution respectively, i.e. nickel ammonia complex solution, cobalt ammonium complex solution, aluminum ammonia complex solution;

[0041] (2) According to Ni 0.815 co 0.15 al 0.035 (OH) 2 The stoichiometric ratio of the three complex solutions obtained in step (1) is stirred and mixed according to the r...

Embodiment 3

[0046] A method for preparing a high-density doped nickel cobalt hydroxide precursor, specifically comprising the following steps:

[0047] (1) Prepare nickel chloride, cobalt nitrate, and manganese sulfate solutions respectively, and Ni in nickel chloride solution 2+ The concentration is 1.5mol / L, Co in cobalt nitrate solution 2+ The concentration is 1.5mol / L, Mn in manganese sulfate solution 3+ The concentration of ammonia water is 0.5mol / L, under the condition of stirring, add ammonia water with a concentration of 14mol / L to the above solution respectively, and the ammonia water is according to the molar ratio of ammonia to metal ions NH 3 : Metal ion=10:1 ratio is added, and what form stable and homogeneous complex solution respectively obtains is respectively nickel ammonia complex solution, cobalt ammonia complex solution, manganese ammonia complex solution;

[0048] (2) According to Ni 0.7 co 0.2 mn 0.1 (OH) 2 Stir and mix the three complex solutions obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com