Beet sugar decalcification system

A technology of beet sugar and ion exchange resin, which is applied in the fields of sucrose production, sugar production, sugar juice purification, etc., to achieve the effects of continuous production, prolonging service life and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

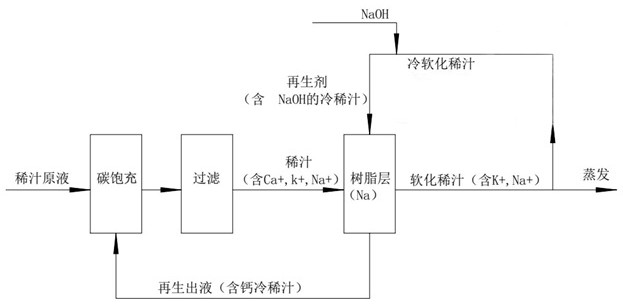

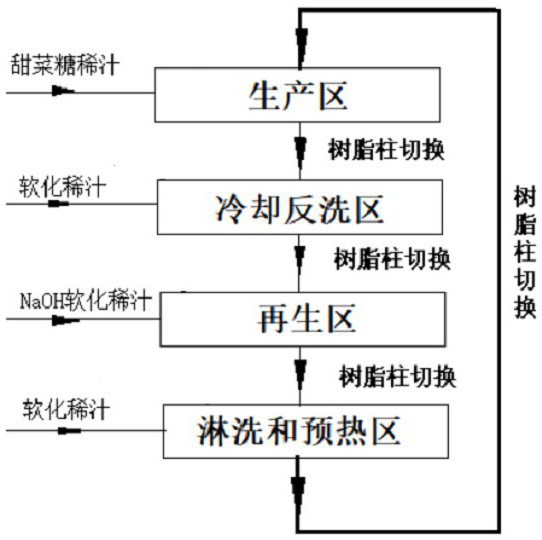

Method used

Image

Examples

Embodiment 1

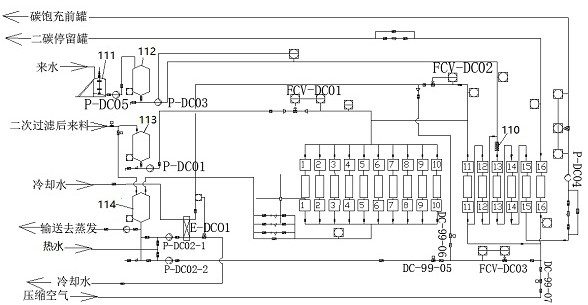

[0045] If the location of the pre-carbon filling tank is relatively high and / or far away, a regeneration discharge transfer pump P-DC04 can be installed on the regeneration discharge pipeline, and this pump can be used for relay transportation, which can reduce the pipeline pressure of regeneration discharge damage.

[0046] Rinsing and preheating zone (11--12 process positions): including the resin column switched from the regeneration zone, the number of resin columns is set according to the production situation, and is not limited to 2 in this embodiment. Specifically, cold rinsing is performed at the initial stage of cycle switching, and the softened thin juice cooled to 40°C by the cooling heat exchanger E-DC01 enters from the upper part of 11, is forwardly serially washed to the lower part of 12, and then serially flows to the regeneration area. Rinsing and regeneration are carried out simultaneously, which takes about 0.6 hours. Preheating is performed in the latter st...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com