Method and system for purifying monomers

A monomer and equipment technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

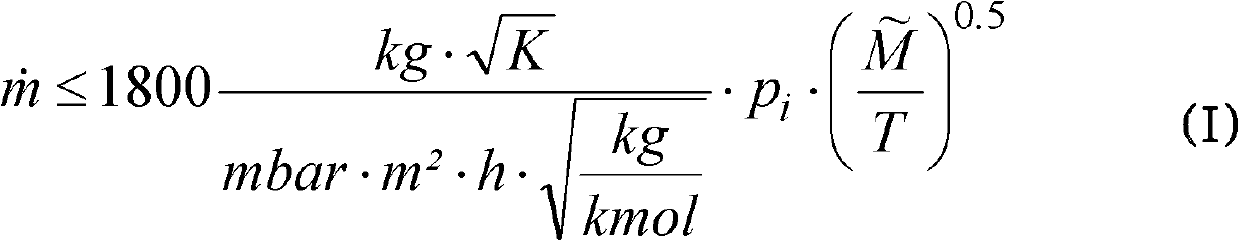

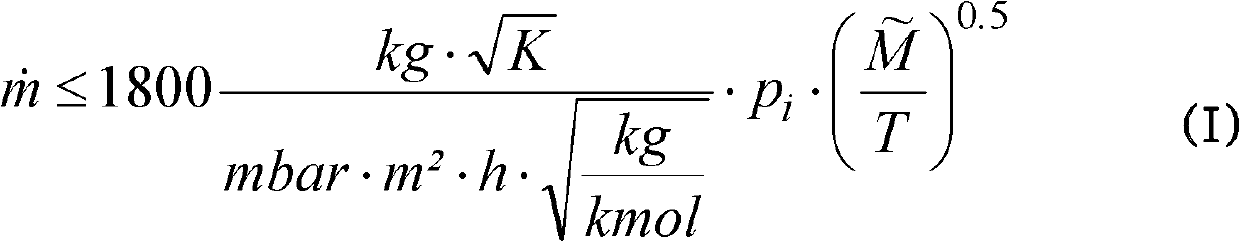

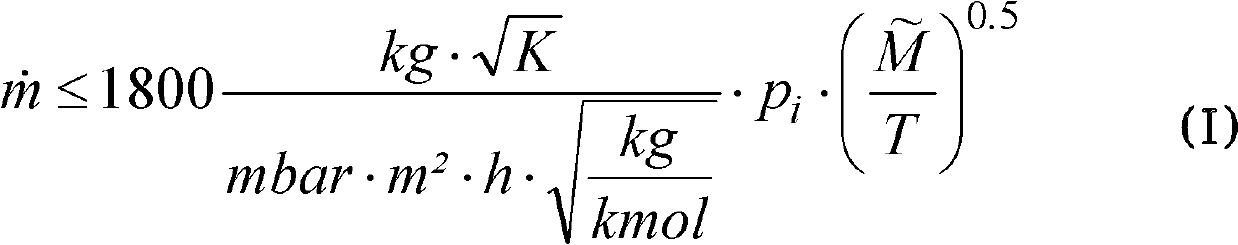

[0100] A composition comprising approximately 98% by weight 2-hydroxyethyl methacrylate (HEMA) and approximately 50 ppm hydroquinone monomethyl ether was introduced into a short path evaporator. Adjust the pressure in the short path evaporator and the temperature of the vapor so that 440kg / h / m is obtained according to the relation (1) 2 value. The mass flow density of vapor established by evaporating temperature and condensing temperature is 27kg / h / m 2 . Under these conditions, impurities with low boiling points are removed by evaporation, leaving 2-hydroxyethyl methacrylate to be purified in the residue. No significant polymerization of the supplied composition was found in the short path evaporator.

[0101] The residue obtained from said first evaporation process is conducted a second time into a short path evaporator. In this case, adjust the pressure in the short-path evaporator and the temperature of the vapor to meet the requirement of obtaining 112kg / h / m according ...

Embodiment 2

[0103] A composition comprising about 98% by weight 2-hydroxyethyl methacrylate (HEMA) and about 50 ppm hydroquinone monomethyl ether was introduced into a short path evaporator. Adjust the pressure in the short-path evaporator and the temperature of the vapor so that 369 kg / h / m is obtained according to relation (1) 2 value. The mass flow density of vapor established by evaporating temperature and condensing temperature is 32kg / h / m 2 . Under these conditions, impurities with low boiling points are removed by evaporation, leaving 2-hydroxyethyl methacrylate to be purified in the residue. No significant polymerization of the fed composition was found in the short path evaporator.

[0104] The residue obtained from said first evaporation process is conducted a second time into a short path evaporator. In this case, adjust the pressure in the short-path evaporator and the temperature of the steam to meet the requirement of obtaining 296kg / h / m according to relational formula (I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com